Motor Komatsu 4lu34

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 2z6p3t

Overview 5o1f4z

& View Motor Komatsu as PDF for free.

More details 6z3438

- Words: 11,836

- Pages:

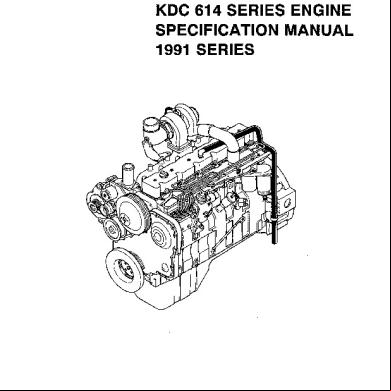

CEBM614SPO

KDC 614 SERIES ENGINE SPECIFICATION MANUAL 1991 SERIES

IbmatsuDresser [Rev. A]

Specification Manual 614 Series Engine 1991 Model

KDC 614 Series Engine

This manual contains complete assembly and rebuild specifications for the 614 Series engine and related components. This manual is intended as a quick reference guide for an experienced technician who is familiar with our product. A series of specific service manuals (Troubleshooting and Repair, Shop, Alternative Repair, and so forth) are available and can be ordered through your distributor using the form at the end of this manual. This specification in this manual are based on the most current information at the time of publications. to initiate any changes at any time without obligation.

[Rev. A]

KDC reserves the right

Table of Contents Page Additional

Service Literature

Air Compressor

- Inspection

............................................................................................................................. Specifications..

....................................................................................................

Air Compressor - Torque Values ....................................................................................................................... Blowby Measurement..

.......................................................................................................................................

Capscrew Markings and Torque Values ............................................................................................................ Capscrew Markings and Torque Values - Metric .............................................................................................. Capscrew Markings and Torque Values . U.S. Customary ............................................................................... Component Manufacturers’ Addresses ............................................................................................................. Air Compressors ............................................................................................................................................. Air Cylinders ................................................................................................................................................... Heaters Air .... ..................................................................................................................................................... 1.m.. Arr siranrng Motors .......................................................................................................................................... Alternators ....................................................................................................................................................... Auxiliary Brakes.. ............................................................................................................................................. Belts ............................................................................................................................................................... Clutches ......................................................................................................................................................... Coolant Heaters .............................................................................................................................................. Drive Plates .................................................................................................................................................... Electric Starting Motors ................................................................................................................................... Engine Protection Controls ............................................................................................................................. Fan Clutches .................................................................................................................................................. Fans ............................................................................................................................................................... Filters ............................................................................................................................................................. Flexplates ....................................................................................................................................................... Fuel Warmers ................................................................................................................................................. Gauges ........................................................................................................................................................... Governors ....................................................................................................................................................... Hydraulic and Power Steering Pumps ............................................................................................................. Oil Heaters ..................................................................................................................................................... Torque Converters ..........................................................................................................................................

58 58 58 58 58 58 58 58 59 59 59 59 59 59 59 59 59 60 60

Component Specifications and Torque Values.. ............................................................................................... Cylinder Block - Rebuild Specifications ............................................................................................................ Cylinder Block - Torque Values.. ...................................................................................................................... Cylinder Head - Rebuild Specifications ............................................................................................................ Engine Assembly - Specifications.. ................................................................................................................... Engine Assembly - Torque Values.. ..................................................................................................................

10 22 28 29 10 12

Cooling System Specifications .......................................................................................................................... Air Intake System - Specifications.. .................................................................................................................. Air Intake System - Torque Values.. ................................................................................................................. Cooling System Torque Values ........................................................................................................................

40 42 42 41

Drive Belt Tension.. ............................................................................................................................................

XI

Electrical System - Specifications

.....................................................................................................................

45

Electrical System - Torque Values.. ...................................................................................................................

45

Engine Diagrams ..................................................................................................................................................

3

Engine Identification ............................................................................................................................................ Engine Dataplate ............................................................................................................................................... Fuel Injection Pump Dataplate ...........................................................................................................................

1 1 2

Engine Specifications - General .......................................................................................................................... Batteries (Specific Gravity). ................................................................................................................................ Cooling System.. ................................................................................................................................................ Electrical System ............................................................................................................................................... Fuel System.. ..................................................................................................................................................... General Engine Data ......................................................................................................................................... Intake Air and Exhaust System.. ........................................................................................................................ Lubrication System ............................................................................................................................................

7 9 8 9 8 7 8 7

...........................................................................................................

48

Engine Testing - General Specifications

Page . . .. . . .. . .. .. . . . . . .. .. .. .. . .. . .. .. . . .. . . . . .. .. . . . . .. . . . . . .. . .. . . .. . . . . . . . . . . . . . . . . .. . . . . . . . . . .. . .. .. . .. .. . . . .. . . . 46

Engine Testing - Test Specifications Exhaust System - Specifications

.. . . . . . . . . . . . . . . . . . . . . . . .. ... . .. . .. .. .. . . .. . . . . . . . .. . . . . .. . . . .. . .. . .. . . .. . . .. . . . . . .. . . . . . . . . . . . . . . . . . . . .. ... . .. . .. .. ... 44

Exhaust System - Torque Values .. .. . . . . . . . . . . . .. .. . . . .. .. . .. . .. .. .. .. .. .. . . . .. . . . . . .. . . . . . . . . .. . . .. .. .. . . . . . . . . . . . . . .. .. . .. . . . . . . . . . . . .. . ... . .. .. .. . .. 44 Fuel Systems - Rebuild Specifications . . .. . . . .. .. . . . . .. . .. . .. . ... . .. . . .. . . .. . . . . . . .. . . . . . .. . . . . .. .. . . . . . . . . . . . . .. . .. . . . . . . . . . . . . . . . .. . ... .. .. . . . . . .. Fuel Injection Pump Sealing Washer . .. . . . . . . .. . .. . . . .. .. . ... .. .. . .. . . . .. . . . .. . . . . . . .. . . . . .. .. . .. . . .. . .. . . . . .. . . .. . . . . . . . . . . . . . . . . . . .. ... .. .. .. . . . . . Zf Fuel Shutoff Solenoid Adjustment . .. . . . . . . . . . .. . . . . . . . . . . .. . .. ... . .. .. .. . . .. . . . . . . . .. . . . . .. . . . . . ... . .. . .. . . . . . . . . . . . . .. . .. . . . . . .. . . . . .. . .. ... . . . . . .. . Fuel System - Torque Values .. .. .. . . . . . . . . . . . .. .. . . .. . . . . .. . . ... . .. .. .. . .. . . . .. . . . . . . . . .. . .. . . . . . . .. . . .. . .. .. . . . . .. . . . . .. . . . . . . . . . . . . . . . . .. ... . .. . . .... :: Fuel System Specifications . .. .. . .. . . . . . . . . . . . . . . . . . . . . . . . . . .. . ... . .. . . ... . .. .. . . . . . . .. . . . .. . . . . . .. . ... .. .. . . . . . . . . . .. . . . . . . . . . . .. . . . . . . .. ... .. .. . . ...... 32 Literature

Survey Form . . . . . . . .. . .. .. .. . . . . . . . . . . .. . .. . . .. . . .. . . . . .. .. .. . .... . . . . .. . . .. . . . . .. . . . . . . .. . . . .. . .. . . . . . . . . . . . . . .. . . . . . . . . . . . . .. . . .. . .. ... .. . . . .. . . . . 2 . . .. . . . .. . .. . .. . . .. .. .. .. . .. . .. . . . . .. . . . . . . .. . . .. . .. . . . .. . .. . . .. .. . . . . . . . . . . . . . . . . . . . . . . . . . . . ... . .. .. . . . . .. . 37

Lubricating

Oil System - Specifications

Lubricating

Oil System Torque Values . . . . ..._......................................................................................................

38

Mounting Adaptations - Torque Values . . . .. .. . .. . . .. . . . . .. .. .. . .. .. . .. . . . . .. . . . . . .. . . . . .. .. .. . .. .. . . . .. . . . . . . . . . .. . . . . .. . . . . .. . . . .. . . . .. ... . .. . .. . . t; REPTO .. . . . . . . . . . . . . . .. . . .. . . . . . . . . . .. . . ... . .. . . . . . . .. . . . . . . . . . . . . . . . . ... . .. . . ... .. . . . .. ... . .. .. . . . . .. . . . . . . .. . .. . . .. . . . . . . .. . .................................-.. Mounting Adaptations Specifications . . . . . . . . . . . . . . . . . .. . . . .. . ... . .. . .. . . .. . . . .. . . . .. . . . .. . . . .. ... . . .. . . . . . . .. . . . . . .. . . . .. . . . . . . . . .. . . .. . .. .. .. . . . .. . Flywheel Housing (Wet Application) . . . . . . .. .. .. . . .. . . . . . . .. . . ... . .. .. . . .. . . .. .. . . . . .. . . .. . .. . . . .. . .. . . .. . . . . . . . . . . . . . .. . . .. . . . . . . .. . .. . .. .. .. .. . . .. . :: Flywheel Ring Gear Installation . .. . . . . .. .. . . . . .. . . .. . . . . . . .. . .. . ... .. .. . . .. .. . .. . .. .. .. . . .. . . .. . .. . . .. . . . . . . . . . . .. . .. . . .. . . . . . . . . . . . . . . .. .. ... .. . . . .. .. 47 Newton-Meter

to Foot-Pound

Conversion

Chart .,.............................................................................................

53

Pipe Plug Torque Values . . . . . . .. . .. .. .. . . . . . . . . . . . . . .. . . . . . . . . . .. .. . .. . .. .. .. .. . . . .. . .. . . . .. . . .. .. . . . . .. .. . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . .. . .... . .. .. . . . . 56 Rocker Lever Assembly - Rebuild Specifications Service Literature Specifications

Ordering Location

. . ... . .. . .. . .. . .. . . . .. . .. .. . . .. . . . . .. . . . .. . . . .. .. . . . . . . . . . . . . .. . . . . . . . . . . . . . . .. . .. .. .. . .. .. . . 32

. . . . . . . . . . . . .. . . . .. . .. .. . . ... . .. . . .. . . . . . .. . . . .. .. . . . .. . . .. .. . .. . . . . . . . . . . . .. . . . . . . . . . . .. . . . .. . .. . . ... .. . . . .. . . 62

- General Information . . . . . . . . . . . . . .. . . . . .. . .. . .. .. .. . .. . . .. . . .. .. . . . . . . .. . . . .. . .. . .. . .. . . . . . . . .. . . .. .. . .. . .. . . . . . . . . . . .. . .. . ... . . .. . .. . . 6

Tap-Drill Chart - U.S. Customary & Metric . . . .. . . . . . . . . .. . .. . .. .. .. .. .. . . . .. . . . . . .. . . . .. .. . . . . .. . .. .. . . . . . . . .. . .. . . . . . . .. . . .. . .. .. . .. . .. .. .. . . . .. . . 57 Valve Tappet - Rebuild Specifications Weight and Measures

- Conversion

. . . . . .. . .. . . . . . . . . . . .. . .. ... . . .. . . .. . .. . . . . . . . .. .. . . .. . .. . . .. . .. . . . . . . . . .. . .. . .. .. . .. . . . . . . . . . . .. . .. . .. .. .. . . .. 32

Factors . . . . . . . . . . .. . .. .. . .. .. . . .. .. . .. .. . . . .. .. . . .. . . . .. . .. . . . . . . . . . .. .. .. . . . . . . . .. . . . . . .. .. . .. . .. . .. . . .. . . . . 52

Engine Identification Page 1

614 Series

Engine Identification ’ Engine Dataplate The engine dataplate shows specific information about your engine. The engine serial number provides information for ordering parts and service needs. NOTE: The engine dataplate must not be changed unless approved by KDC.

. ..,I TVVILLE.

ILLINOIS.

SO048 U.S.*

I

-TIMING

0 Warning

ENGINE

KDC

TDC

Injury Hay Raault And Warranty I* Voldad If Fuel RPM Or Altltuder Exceed PIubll;ked Ynxlmum Valuea For This Model And Appllcatlon. MADE IN U.S.A.

VALVE

LASH

FIRING

ORDER

COLD

INT.

EXH.

SERIAL

NO.

P/N

RATED

NP

AT

RCY

Rata

E.C.S.

FUEL

RATE

KDC

MODEL

AT

RATED

HP

MH=lSTROK

The KDC model designation represent the basic design and configuration of your engine. Example Engine Model Names:

(1)

Number of cylinders

(2)

Displacement per cylinder/l00

(3)

Type of aspiration T = Turbocharged

(4)

A = Aftercooled

in cc

Engine Identification Page 2

614 Series

Fuel Injection Pump Dataplate The fuel injection pump dataplate is located on the side of the fuel injection pump. It provides information for fuel pump calibration.

The Bosch fuel injection pump dataplate contains: 1. Pump Serial Number 2. Bosch Ten Digit Number

0 1 o

3. Bosch Designation Code

I

I

9 400

230

097-+-@

PES6AlOOD320/3RS2691 Made in USA

la901 d

The Cummins part number for the fuel pump-governor combination is located on the governor dataplate.

fD901 q rn

The Bosch governor dataplate contains: 1. Bosch Governor Designation Code 2. Cummins Pump Part Number WRSV425

llOOAOC2190-8R

/i

,,

Engine Diagrams Page 3

614 Series

Engine Diagrams The following illustrations contain information about engine components, filter locations, drain points and access locations for instrumentation and engine controls. The information and configuration of components shown in these drawings component locations will vary depending on applications and installations.

High Pressure Fuel Lines Front Liing &e&et

X(inch]NPTF

are of a general

nature.

Some

(Air)

M22 x 1 SO (Air)

I

Fuel Injection Pump

Fuel/Water Separator Fud Trensfer Pump

,_ __

__,._____‘_.--

Tep for Magnetic Pick-up

Front En&e Mounting Bracket

Fuel Pump Side View

Engine Diagrams Page 4

614 Series

TUtbOdl8~?

Wastegate Actuator,

Turbocharger Air Outlet

Exhaust Outlet

Provision for Coolant Heater Provldon for Cab Heater Lubricating Oil Cooler

R

H(inch]NPlF (coolant)

Turbocharger Oil Drain

Coolant Inlet

1

Turbocharger Side View

Engine Diagrams Page 5

614 Series

/

Rear View

Front View

614 Series

Engine Identification Page 6

Specifications - General Information The specifications in this manual are organized in the same sequence as the 614 Series Engine Shop Manual. The minimum and maximum tolerance limit specifications are listed in both metric and U.S. Customary dimensions. The metric dimension is given first, followed by the U.S. Customary dimension in brackets; for example: 0.50mm [0.020 inch]. The assemMy and rebuild specifications and torque values are provided to be sure the parts are assembled correctly, fit properly, and are secured with the correct torque value. Most of capscrews used to assemble the 614 Series engine are metric. Some components, such as the air compressor and fuel injection pump are installed with U.S. Customary capscrews. Capscrew torque values are listed in newton meters and foot pounds, unless otherwise specified, If a torque value is not listed, use the standard value for the capscrew. Referto the Table of Contents for Capscrew Markings and Torque Values in this manual.

Engine Specifications - General Page 7

614 Series

Engine Specifications

- General

General Engine Data Bore ........................................................................

114mm [4.49in]

Stroke .......................................................................

135mm[5.32in]

Displacement ...............................................................

8.27 liters [504.5 in31

Compression ratio 614 ..............................................................................

18.411

614T .............................................................................

17.3:1

814TA ............................................................................

16.5:1

Firingorder

..1~~~-2

......................................................................

.

Valve clearance Intake. ..................................................................

.0.30 mm [0.012 in]

Exhaust .................................................................

.0.61 mm [0.024 in]

Engine rotation (viewed from front of engine) ................................................

Clockwise

Aspiration ..Natu~ly~pi~

614 ...................................................................

..Tu~oc~rg

614T .....................................................................

. .

Turbocharged and Aftercooled

614TA .......................................................... Engine weight (with standard accessories) Dryweight..

....................................................

570to606kg[1256to1335Ib]

Wetweight..

....................................................

599to836kg

[1320to1402Ib]

Lubrication System Oil pressure At idle (minimum allowable)

69 kPa [lo psi]

.....................................................

207 kPa [30 psi]

At rated speed (minimum allowable) ..............................................

138 kPa [20 psi]

Diierent’al pressure to open oil filter by valve .......................................

106.8 Ipm [28.2 gpm]

Oil flow at rated speed (less flow though pressure regulator ............................. Oil temperature at rated speed .........................................

98.9” to 126.6”C [210” to 26O”F]

Oil temperature thermostat Fuilyopen

..116”C[241”

.................................................................

Closed ............................................ Oil pan capacity (all engines) (high - low) ..............................

..~.......................l~“c[2190

F] q

18.9 to 15.1 liters [20 to 16 U.S. Qts.]

Total system capacity 614 ...............................................................

23.6 liters 125.0 U.S. Qts.]

614T ...............................................................

23.8 liters 125.2 U.S. ots]

614 Series

Englne Speciflcetione - General Page 0

Cooling System Begins to open . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81” to 83°C (178” to 182”fl Fullyopen

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..~oC[2O3o~

Top tank temperature Maximum allowable

109°C [212”F]

............................................................

Minimum recommended .........................................................

.70X

[158’F]

50 kPa [7 psi]

Pressure cap for 99°C [21O”Fj system .................................................

103 kPa [15 psi]

Pressure cap for 104’C [220°F] system ...............................................

103 to 276 kPa [15 to 40 psi]

Water Pressure (Upper manifold) at 2000 RPM engine speed ......................

258 Ipm [68 gpm]

Coolant flow (thermostats fully opened, engine speed 2000 RPM) ........................... Coolant capacity (engine only) 614,614T ............................................................

9.9 liters [lo.5 U.S. Qts.] 10.9 liters [11.5 U.S. Cts.]

614TA ..............................................................

Intake Air and Exhaust System Maximum allowable intake restriction at rated speed and load (with dirty air filter element) 614 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..50.8cmH.O[20inH20] 614T,614TA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63.5cmH,0[25inH20] Maximum turbocharger outlet restriction at rated speed and load 614T,614TA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76.2mmHg[3inHg] 614T,614TA.........................................................

101.6cmHs0[40inH20]

Fuel System Fuel transfer pump maximum inlet restriction ......................................

95 mm Hg [3.75 in Hg]

Fuel transfer pump maximum output pressure 614,614T, 614TA ............................................................ Minimum pressure to fuel pump inlet ............................................... Minimum flow to fuel injection pump ............................... Fuel filter restriction (maximum pressure drop across filters) ..................................

172 kPa [25 psi] 1.2 Bar 118psi] 250 percent of rated fuel requirement 35 kPa [5 psi]

Fuel pump gallery pressure ........................................................

140 kPa [20 psi]

.............................................

518 mm Hg [20.4 in Hg]

Fuel return restriction (maximum)

Engine Specifications - General Page 9

614 Series

Electrical System Minimum Recommended Battery Capacity 12 Volt System -18OC [OOF] Cold cranking amperes .. . .. .... .. . ... .. ... ...... .. . .. .. .... . .. . . .. . . ... . ...... ... . .. .. ... .. .. . . . .. . . .. . .... .... . .. .. ... .. . . 1800 (Reserve capacity amperes)* . . . . . .. . .. .... .. . .. .. .... .... .... . .. .. .. ... ... . .. . . .. .. ..... ... .. .. .. .. .. ... . . .. .. . .. . . .... .... ... .. .. .. . .. (640) O°C [32OF] Cold cranking amperes . .. .. ... ... . . ... .. .. .... ... .. . .. ... .. .. ... . .. .. ... . .. .. .. .. . .... .... .. .. . . . .. . . .. . .... . .. .i . . . . . . . . . . . 1280 (Reserve capacity amperes)* . . . .. . .. .. .. ... .. ... . .......... .. . ... . .... .. .. . . . .. . .. .. ..... ... .. .. .. ... ... .. .. .. . . . . ... ... ... .... . ... . .. . (480) 24 Volt System * * -18OC [OOF] Cold cranking amperes .. . ... ... . ... .. .......... .. .. .. . ... .. ... . . .. . . .. .. ..... ... ... . ... .. .. .. . .. . . . . . .. .. ... .... ... . ... .. . .. . 900 (Reserve capacity amperes)* . . . . . .. . . ... ... . ... .. ... ..... ... . .. .. .. ... ... . . . .. . . .. ... ..... ... .. . ... .. .. .. . .. . . . .. . . .. ..... .. ... .. .. . .. . (320) 640 O°C [32OF] Cold cranking amperes . . . .. ... . .. ... . ..... ... .... .. . .. ... . .... . .. . . . . ..-...................................................... (Reserve capacity amperes)* . . . . .. . . .. ... .. .. . ... .... ... ..... . . .. ... . .... . .. . . . .. .. .. .. ... ... .. .. .. .. ... . . .. . . . .. .. ... .. .. .. .. .. ... .. .. (240)

* The number of plates within a given battery size determine reserve capacity. Reserve capacity determines the length of time sustained cranking can occur. *

l

Per battery (two 12 volt batteries in series) CCA Ratings are based on -18OC [OOF].

Batteries (Specific Gravity)

1.260 1.230 1.200 1.170 1.110

- 1.280 - 1.250 - 1.220 - 1.190 - 1.130

State of Charge 100% 75% 50% 25% Discharged

Component Specifications and Torque Values Page 10 Componentor Assembly (Procedure) Ref.No./Steps

614 Series Metric

U.S.

Component Specifications and Torque Values Engine Assembly - Specifications Cylinder Liner Protrusion

0.025 mm 0.122 mm

MIN MAX

0.229 mm

MIN

0.009 in

0.04 mm

MAX

0.0016 in

Cylinder Block Upper Liner Bore I.D.

132.900 mm 132.990 mm

MIN MAX

5.2323 in 5.2356 in

Cylinder Liner Top Press Fit O.D.

132.938 mm 132.958 mm

MIN MAX

5.2339 in 5.2346 in

0.157 mm 0.334 mm

MIN MAX

i-fj;tf .

0.535 mm

MAX

0.0210 in

MIN MAX MIN MAX MAX MIN

0.0157 0.0275 0.0157 0.0275 ;zrxli& .

. zE.8

i::

Note: Use Part No. 3922503, Cylinder Liner Clamp Set to seat the liner into the bore. Check the liner protrusion with the clamps removed. Cylinder Liner-to-Block Clearance

Cylinder Liner Out-of-Round

Crankshaft End Clearance New

Piston Ring Gap (New) Top Ring Gap Intermediate Ring Gap Oil Control Ring Gap

0.49 0.70 0.49 0.70 0.80 0.30

mm mm mm mm mm

;;

in in in in ;;

Component Specifications and Torquepz;;;; 614 Series Component or Assembly (Procedure)

Ref.No./Steps

Connecting Rod Bearing Side Clearance

Metric

U.S.

0.100 mm 0.330 mm

MIN MAX

0.0039

0.0130

Oil Pump Drive Gear Backlash

A

0.08 mm 0.45 mm

MIN MAX

cy;

Oil Pump Idler Gear Backlash

B

0.08 mm 0.45 mm

MIN MAX

0.003 in 0.018 in

Camshaft Gear Backlash

0.152 mm 0.380 mm

MIN MAX

0.006 in 0.015 in

Camshaft End Clearance

0.12 mm 0.46 mm

MIN MAX

0.127 mm

MAX

Flywheel Bore Runout T.I.R.

Flywheel Face Runout T.I.R.

Valve Adjustment Clearance Intake Valve Exhaust Valve

Radius (A) mm in 203 8 264 10 305 12 356 14 406 16

0.203 mm 0.254 mm E$ :: 01406 mm

0.30 mm 0.61 mm

I;

0.0050 in

0.008 0.010 0.012 yOI;;

in in in I;

Corepoont Specifications and Torque Values 614 Series Component or Assembly (Procedure)

Ref.No./Steps

Metric

U.S.

Vibration Damper Face Alignment (Wobble) T.I.R.

0.28 mm

MAX

0.011 in

Vibration Damper Eccentricity T.I.R.

0.28 mm

MAX

0.011 in

Engine Assembly - Torque Values Cylinder Liner Clamps

Main Bearing Cap Capscrews

68 Nom

Step 1 32

-Fmnl

50 ft-lb

50 Nom 119 Nom 176 Nom

I Connecting Rod Nuts

Step 1 :

40 N*m 80 N*m 120 Nom

r8ar Housing Mounting Capscrews Ml2

24 Nom 60 Nom

18 ft-lb 44 ft-lb

Oil Pump Mounting Capscrews

24 Nom

18 ft-lb

Component Specifications and Torqu;:;:;; 614 Series Component or Assembly (Procedure)

Ref.No./Steps

Metric

U.S.

24 N*m

18 ft-lb

9 Nom 9 Nom 9 N*m

80 in-lb 80 in-lb 80 in-lb

24 N*m

18 ft-lb

80 Nom

59 ft-lb

8 Nom

71 in-lb

Flywheel Housing Mounting Capscrews

60 Nom

44 ft-lb

Flywheel Housing Access Plate Capscrews

24 Nom

18 ft-lb

Water Pump Mounting Capscrews

Oil Pump Suction Tube to Block

A

Brace to Block Brace to Suction Tube

:

Oil Pan Mounting Capscrews Note: Tighten the capscrews in the sequence shown. Start at the center of the oil pan and alternate toward both ends.

Oil Pan Drain Plug

Timing Pin Torx’” Capscrews

Component Specifications and Torque Values Page 14

614 Series Component or Assembly (Procedure)

Ref.No./Steps

Flywheel Mounting Capscrews

Metric

U.S.

140 Nom

101 ft-lb

Starting Motor Mounting Capscrews

77 Nom

57 ft-lb

Coolant Heater

12 Nom

106 in-lb

Oil Cooler Mounting Capscrews Oil Filter Head Mounting Capscrews

24 Nom 24 Nom

18 ft-lb 18 ft-lb

Cylinder Head Mounting Capscrews

Step 1 3

70 Nom (All Capscrews) 52 ft-lb 145 Nom (Long Only) 105 ft-lb Rotate 90 Degrees (All Capscrews)

Note: Tighten the capscrews in the sequence shown. Start at the center of the cylinder head and alternate toward both ends. I-Fro,%

I

Rocker Lever Retaining Clamp Capscrews

55 Nom

41 ft-lb

Rocker Lever Adjusting Screw Locknut

24 Nom

18 ft-lb

Component Specifications and Torquepz;Fz

614 Series Component or Assembly (Procedure)

Ref.No./Steps

Valve Cover Capscrews Note: Tighten the capscrews in the sequence

Metric

U.S.

24 Nom

18 ft-lb

24 Nom 43 Nom

18 ft-lb 32 ft-lb

24 Nom

18 ft-lb

shown. Start at the center of the valve cover and alternate toward both ends.

Crankcase Breather Tube Bracket Capscrews

Injection Nozzle Clamp Capscrew

A B

Fuel Drain Manifold Banjo Connector l Injector l Filter Head

9 Nom 15 Nom

Engine Lifting Bracket Capscrews

77 N*m

57 ft-lb

Intake Manifold Cover Capscrews

24 Nom

18 ft-lb

Aftercooler Assembly Capscrews

24 Nom

18 ft-lb

Component Specifications and Torque Values Page 16

614 Series Metric

U.S.

6 Nom

53 in-lb

Exhaust Manifoki Mounting Capscrews

43 Nom

32 ft-lb

Turbocharger Mounting Studs

10 Nom

89 in-lb

Turbocharger Mounting Nut

45 Nom

33 ft-lb

Turbocharger Oil Drain Mounting Capscrew

24 Nom

18 ft-lb

Turbocharger Oil Drain Line Hose Clamps

5 Nom

44 in-lb

Turbocharger Turbine Housing Capscrews

20 Nom

15 ft-lb

Component or Assembly (Procedure) After-cooler Coolant Supply Tube Capscrews

Ref.No./Steps

*

Component Specifications and Torque Values 614 Series Component or Assembly (Procedure)

Page 17 Ref.No./Steps

Metric

U.S.

Turbocharger Compressor Housing Clamp V-Band Clamp Nut Actuator Bracket Brace Capscrews

8 Nom 13 Nom

71 in-lb 115 in-lb

Turbocharger Oil Supply Hose Fittings Hose Connection

24 Nom 35 Nom

18 ft-lb 26 ft-lb

Turbocharger Exhaust Outlet: Band Clamp Capscrews

8 Nom 43 N*m

71 in-lb 32 ft-lb

5 Nom

44 in-lb

24 Nom

18 ft-lb

Coolant Vent Line Fitting

8 Nom

71 in-lb

Coolant Vent Petcock

5 Nom

44 in-lb

Turbocharger Air Crossover Hose Clamps

Water Outlet Connection Capecrews

Component Page 18

Specifications

and Torque Values 614 Series Component or Assembly (Procedure)

Ref.No./Steps

Metric

U.S.

Coolant Vent Line Tube

8 Nom

71 in-lb

Coolant Inlet Connection Hose Clamps

5 N*m

44 in-lb

24 Nom

1a ft-lb

24 Nom

18 ft-lb

43 Nom 24 Nom 80 Nom

32 ft-lb 18 ft-lb 59 ft-lb

Belt Tensioner Mounting Bracket

24 Nom

18 ft-lb

Belt Tensioner Mounting Capscrews

43 N*m

32 ft-lb

Alternator

Mounting Bracket Capscrews

Water Pump Mounting Capscrew

Alternator

Mounting Capscrew

A :

Component

Specifications

614 Series Component or Assembly (Procedure)

Ref.No./Steps

Fan Hub Mounting Capscrews

Fuel Ir$ection Pump Ft;d;tlng Nuts

Metric

U.S.

24 N*m

18 ft-lb

44 Nom Hand Tight

Fuel Injection Pump Timing Pin Access Plug

32 R-lb

40 Nom

30 ft-lb

92 Nom 104 Nom 165 Nom

68 ft-lb 77 ft-lb 122 ft-lb

Fuel Injection Pump Supply Banjo Fitting

24 N*m

18 ft-lb

Fuel Filter Head Adapter Fuel Filter Adapter Nut

4 Nom 32 Nom

35 in-lb 24 ft-lb

Fuel Injection Pump Drive Gear Nut A Pump k%upmupmp

Fuel Filter Install the filter as specified

by the filter manufacturer.

and Torqwi;$;;

Component Page 20

Specifications

and Torque Values 614 Series Component or Assembly (Procedure)

Ref.No./Steps

High Pressure Fuel Line Fittings

High Pressure Fuel Line Bracket

Gear Cover Capscrews

Vibration Damper Pulley to Vibration Damper

Fan Hub Pulley Mounting Capscrews

Front Engine Bracket Mounting Capscrews l

Without

Fuel Transfer Pump Mounting Capscrews

2

Metric

U.S.

30 Nom

22 ft-lb

24 Nom

18 ft-lb

24 N*m

16 ft-lb

200 Nom 77 Nom

148 ft-lb 57 ft-lb

45 Nom

32 ft-lb

112 Nom 60 Nom

83 ft-lb 44 R-lb

24 Nom

18 f&lb

Component Specifications and Toquepz;$

614 Series Componentor Assembly (Procedure)

Metric

U.S.

Fuel Transfer Pump Fuel Line Fittings

24 Nom

18 ft-lb

Fuel Injection Pump Solenoid

10 Nom

89 in-lb

Air Compressor Mounting Nuts

77 Nom

57 ft-lb

Air Compressor Brace Capscrews

43 Nom

32 ft-lb

8 Nom

71 in-lb

35 N*m

28 in-lb

AK Compreesor Oil Supply Line Fitting

Air Compressor Coolant Supply Line Fitting

A$kmpressor Outlet

Ref.No./Stepe

Connections 5 Nom 24 N*m

Component Page 22

Specifications

and Torque Values 614 Series

Component or Assembly (Procedure)

Ref.No./Steps

Metric

U.S.

Cylinder Block - Rebuild Specifications Cylinder Block Head Deck Flatness

x::;z Fi

K

0.0030 in 0.0030 in

132.900 mm 132.990 mm

MIN MAX

5.2323 in 5.2358 in

122.930 mm 123.000 mm

MIN MAX

4.8397 in 4.8425 in

309.40 mm 309.60 mm

MIN MAX

;g.;m; 1; . .

361 .QO mm 362.10 mm

MIN MAX

14.248 in 14.256 in

98.079 mm 98.125 mm

MIN MAX

yEm; .

104.982 mm 105.018 mm

MIN MAX

4.1331 in 4.1346 in

Without Bushing

64.01 mm

MAX

2.520 in

With Bushing Installed

60.12 mm

MAX

2.367 in

End-to-End Side-to-Side

Cylinder Block Upper Liner Bore I.D.

Cylinder Block Counterbore Depth from Cylinder Block Head Deck

Cylinder Block Height from Head Deck to Top of Main Bearing Bore

Cylinder Block Height from Head Deck. pozce to Centerlme of the Mam Beanng

Main Bearing Bore Diameter With New Bearings Without Bearings

’ ;;

Camshaft Bore Diameter

Component Specifications and Torque Values 614 Series Component or Assembly (Procedure)

Page 23 Ref.No./Steps

Metric

U.S.

Vahre Tappet Bore Diameter

16.00 mm 16.05 mm

MIN MAX

Cylinder Liner Inside Diameter

114.000 mm 114.117 mm

MIN MAX

4.4662 in 4.4926 in

Cylinder Liner Out-of-Round

0.04 mm

MAX

0.0016 in

Cylinder Liner Taper

0.04 mm

MAX

0.0016 in

Cylinder Liner Seat Area Depth

123.013 mm 123.039 mm

MIN MAX

4.6430 4.6440

Cylinder Liner O.D. (Top Press Pii)

132.936 mm 132.956 mm

MIN MAX

5.2336 in 5.2346 in

Piston Pin Bore Inside Diameter

45.006 mm 45.025 mm

MIN MAX

1.7719 in 1.7726 in

Piston Pin Outside Diameter

44.993 mm 45.003 mm

MIN MAX

1.7714 in 1.7718 in

Note:Discardthe piston pin if it is more than 0.03 mm [O.OOl inch] out of round.

in in

-. ED

.

Q-

-77E

J

Component Page 24

Specifications

and Torque Values 614 Series Component or Assembly (Procedure) Piston Skirt Outside Diameter

Ref.No./Steps

Metric

U.S.

113.814 mm 113.886 mm

MIN MAX

4.4810 in 4.4840 in

113.938 mm

MIN

4.4857 in

114.323 mm

MIN

4.5009 in

0.070 mm 0.150 mm

MIN MAX

I,” ’ ;.Ix&gg .

0.020 mm 0.130 mm

MIN MAX

0.0008 in 0.0051 in

0.025 mm

MAX

0.010 in

Top Ring Groove Keystone Angie Wear Use micrometer and Part No. 3823966.

Intermediate Ring Groove Keystone Angie Wear Use micrometer

and Part No. 3823965.

Rectangular Ring Side

Intermediate

Clearance Oil Control Ring Side Clearance

E,,kshaft

Seal Wear Groove, Front and

Crankshaft Connecting Rod Journal l

Outside Diameter

75.962 mm 76.013 mm

MIN MAX

2.9906 in 2.9926 in

l

Out-of-Round Taper

0.050 mm 0.013 mm

K

0.0020 in 0.0005 in

l

Crankshaft Main Searing Journal l

Outside Diameter

97.982 mm 98.031 mm

MIN MAX

3.8568 in 3.8595 in

l

Out-of-Round Taper

0.050 mm 0.013 mm

MME

0.0020 in 0.0005 in

42.975 mm 43.076 mm

MIN MAX

1.6919 in 1.6959 in

l

Crankshaft Thrust Face Width (Standard)

Component

Specifications

614 Series Component or Assembly (Procedure) Crankshaft Rear Seal Flange O.D.

Ref.No./Steps

U.S.

Metric 199.975 mm 130.025 mm

MIN MAX

5.1171 in 5.1191 in

Crankshaft Damper Pilot O.D.

23.924 mm 24.000 mm

MIN MAX

0.9419 in 0.9449 in

Crankshaft Gear Journal O.D.

75.987 in 76.008 mm

MIN MAX

0.157 mm 0.334 mm

MIN MAX

0.0062 in 0.0131 in

Used

0.535 mm

MAX

0.0210 in

Crankshaft Gear Bore I.D.

75.898 mm 75.923 mm

MIN MAX

2.9881 in 2.9891 in

149% 45 Min. 6 Hrs.

MAX MIN MAX

300°F 45 Min. 6 Hrs.

177% 45 Min. 6Hrs.

MAX MIN MAX

350°F 45 Min. 6 Hrs.

3.446 mm

3.454 mm

MIN MAX

0.1357 in 0.1360 in

0.066 mm 0.134 mm

MIN MAX

0.0026 in 0.0053 in

Crankshaft End Clearance New

Crankshaft Gear Installation - Austempered Gear: l l

Temperature Time

- Steel Gear: l l

Temperature Time

Standard Main Bearing Thickness (Used) Main Bearing Clearance With Plastigauge

and TorqueP~;~~

Component Page 26

Specifications

and Torque Values

614 Series Component or Assembly (Procedure) Thrust Bearing Flange Thickness

Ref.No./Steps

Metric

U.S.

3.417 mm 3.530 mm

MIN MAX

0.1345 in 0.1389 in

With Bushing

45.023 mm 45.060 mm

MIN MAX

1.7726 in 1.7740 in

Without Bushing

48.988 mm 49.012 mm

MIN MAX

1.9286 in 1.9296 in

76.046 mm 76.104 mm

MIN MAX

2.9939 in 2.9962 in

0.033 mm 0.117 mm

MIN MAX

0.0013 in 0.0046 in

0.100 mm 0.330 mm

MIN MAX

0.0039 0.0130

(Standard)

2.428 mm 2.471 mm

MIN MAX

0.0956 in 0.0973 in

Connecting Rod Length

215.975 mm 216.025 mm

MIN MAX

8.5029 in 8.5049 in

Connecting Rod Piston Pin I.D.

Connecting Rod Crankshaft Bore I.D. (With Bearings)

Connecting Rod Bearing Clearance (With Plastigauge)

Connecting Rod Bearing Side Clearance

Connecting Rod Bearing Thickness

Connecting Rod Bend (Alignment) l

Without Bushing

0.20 mm

MAX

0.008 in

l

With Bushing

0.15 mm

MAX

0.006 in

Component Specifications 614 Series Component or Assembly (Procedure)

Ref.No./Steps

Metric

U.S.

Connecting Rod Twist l

Without Bushing

0.50 mm

0.020 in

l

With Bushing

0.30 mm

0.012 in

60.12 mm

2.367 in

Without Bushing Note: If one of the bushings exceed the specifications, all of the bushings must be replaced.

64.01 mm

2.520 in

Camshaft Journal Outside Diameter

59.962 mm 60.013 mm

MIN MAX

2.3607 in 2.3627 in

E:Eiti

MIN MAX

2.0383 in 2.0571 in

Exhaust Lobe

51.596 mm 52.073 mm

MIN MAX

2.0313 in 2.0501 in

Fuel Transfer Pump Lobe

41.310 mm 41.829 mm

MIN MAX

1.6264 in 1.6468 in

41.562 mm 41.580 mm

MIN MAX

1.6363 in 1.6370 in

9.340 mm 9.580 mm

MIN MAX

Camshaft Bore Diameter l

With Bushing

l

Camshaft Lobe Diameter Intake Lobe

Camshaft Nose (Gear Mounting Surface) Outside Diameter

Camshaft Thrust Plate Thickness

and Torque Values Page 27

El 0

0

-rlG

Camshaft Gear Bore Inside Diameter

41.480 mm 41.505 mm

MIN MAX

1.6331 in 1.6341 in

Component Specifications and Torque Values Page 28 Component or Assembly (Procedure)

614 Series Ref.No./Steps

U.S.

MetriC

Camshaft Gear Installation - Austempered Gear: l Temperature l Heating Time

149% 4.5 Min. 6 Hrs.

E MAX

300°F 45 Min. 6 Hrs.

- Steel Gear: l Temperature l Heating Time

177% 45 Min. 6 Hrs.

MAX MIN MAX

35O=‘F 45 Min. 6 Hrs.

Vibration Damper Face Alignment (Wobble ) T.I.R.

0.28 mm

MAX

0.011 in

Vibration Damper Eccentricity T.I.R.

0.28 mm

MAX

0.011 in

Vibration Damper Thickness Measure the thickness at four locations 90 degrees apart approximately 3.18 mm IO.125 in] from the outside diameter. The difference between any two of the four measurements must not exceed 0.25 mm [O.OlO in].

149.96 mm 150.04 mm

Rear Cover Crankshaft Seal Bore I.D.

MIN MAX

z*g .

;;

Cylinder Block - Torque Values Cylinder Block Pipe Plugs (Into Cast Iron) Refer to chart on page V-56.

10 15 25 35

Nom Nom Nom N*m

;z !E 95 N:m Cylinder Block - Main Bearing Cap ChpSCRiW

1 :

50 Nom 119 Nom 176 Nom

Size 1116 inch 118 inch l/4 inch ;;; !$I ;l;Ii;h

7 ft-lb 11 ft-lb

Component Specifications and Torque Values 614 Series Component or Assembly (Procedure)

Page 29 Ref.No./Steps

Connecting Rod Capacrew Nuts : 3

Metric

U.S.

40 Nom 80 N*m 120 Nom

30 ft-lb 60 ft-lb 88 ft-lb

Cylinder Head - Rebuild Specifications FzM&r Head Capscrew Free Length l

Long

Cylinder Head Flatness End-t*End Side-to-Side Local Flatness (Within a 51 mm [2.0 inch] area)

Fili

l

81.5 mm

MAX

3.21 in

182.6 mm

MAX

6.40 in

0.200 mm 0.076 mm

1%

0.0254 mm

MAX

0.001 in

115.75 mm 118.25 mm

MIN MAX

4.557 in 4.577 in

114.75 mm

MIN

4.518 in

3.0 mm 4.0 mm

MIN MAX

0.118 in 0.157 in

9.539 mm 9.559 mm

MIN MAX

0.3756 in 0.3763 in

9.591 mm

MAX

0.3776 in

20.65 mm 21.16 mm

MIN MAX

0.813 in 0.833 in

22.50 mm 23.01 mm

MIN MAX

0.886 in 0.906 in

0.0079 in 0.0030 in

Head Thickness

Machined

Injector Nozzle lip Protrusion

~&vewGuide I.D. (Installed)

l

used

;Vck; Guide Height (Installed)

Component Page 30

Specifications

and Torque Values 614 Series Component or Assembly (Procedure)

Ref.No./Stepe

Metric

U.S.

Valve Guide Bore I.D.

15.931 mm 15.971 mm

MIN MAX

0.6272 in 0.6288 in

Valve Guide (New) O.D.

15.988 mm 16.000 mm

MIN MAX

0.6294 in 0.6299 in

0.05 mm

MAX

0.002 in

1.09 mm 1.62 mm

MIN MAX

0.043 in 0.064 in

53.930 mm

MAX

2.1231 in

47.027 mm

MAX

1.8515 in

12.20 mm

MAX

0.480 in

9.83 mm

MAX

0.387 in

Valve Seat-to-Valve Guide Concentricity (360 Degree9

Valve Recess in Cylinder Head

E’akt Insert Bore I.D. (Standard Insert)

EzUv: Insert Bore Depth (Standard Insert) Exhaust

EEkt Sealing Surface Angle Exhaust

A

B

Component Specifications 614

Series

Component or Assembly (Procedure)

Ref.No./Steps

Valve Seat Width Limit

MIN MAX

0.060 in 0.080 in

508 mm Hg 635 mm Hg

MIN MAX

20 in Hg 25 in Hg

457 mm Hg 254 mm Hg

MIN MAX

18 in Hg 10 in Hg

Nominal

2.585 in

1.5 mm

Valve Seat Vacuum New Used Acceptable

leakage rate in 10 seconds.

Valve Spring Free Height

A

U.S.

Metric 2.0 mm

65.66 mm

and Torque Values Page 31

(7-l/2 coils)

I B

50.80 mm

C

464.5 N 513.5 N

MIN MAX

104.4 Ibf 115.4 Ibf

C

450.0 N

MIN

101.2 Ibf

B

37.90 mm

Nominal

1.492 in

C

959.5 N 1060.5 N

MIN MAX

215.7 Ibf 238.4 Ibf

C

940.0 N

MIN

211.3 Ibf

Valve Stem O.D.

9.46 mm 9.50 mm

MIN MAX

0.372 in 0.374 in

Valve Head Thickness at O.D.

1.50 mm

MIN

0.059 in

Valve Spring Working Height ;r;g Force at Assembled Height

Valve Spring at Opening Height ;rr$g Force at Opening Height

Used

Nominal

2.00 in

I

Rocker Lever Assembly - Rebuild Specifications Page 32 Component or Assembly (Procedure)

614 Series Metric

Ref.No./Steps

U.S.

Rocker Lever Assembly - Rebuild Specifications Rocker Lever gore I.D.

22.256 mm 22.301 mm

MIN MAX

0.8782 in 0.8780 in

Rocker Lever Shaft O.D.

22.199 mm 22.231 mm

MIN MAX

0.8740 in 0.8752 in

MIN MAX

0.6270 in 0.6291 in

Valve Tappet - Rebuild Specifications Valve Tappet Stem O.D.

15.925 mm 15.980 mm

Valve Tappet Visual Limits Inspect the socket stem and face for excessive wear, cracks or damage Concavity

Normal Wear Abnormal (Do not use) Abnormal (Do not use) (A)

0.025 mm

Valve Tappet Face 1. A single pit cannot bs greater than 2 mm [0.078 in] in diameter. 2. Interconnection of pits is not allowed and is treated as one pit. 3. Total pits when added together should not exceed 8 mm [0.238 in] diameter or a total of 4 percent of the tappet face. 4. No pitting is allowed on the edges of the wear face of the valve tappet.

Fuel Systems - Rebuild Specifications Note: This manualdoes not cover fuel injection pump rebuild or calibration. Rebuild and calibration should be performedin a facilii certified in the rebuild and calibration of the fuel injection pumps.

Fuel System Specifications Engine Low Idle Speed Refer to the engine dataplate.

0.001 in

Fuel Systems - Rebuild Specifications Page 33

614 Series Component or Assembly (Prowdun) Fuel Transfer Pump Inlet Restriction 6C, 6CT 6CTA

Fuel Transfer Pump O&t High Idle 6C, 6CT 6CTA

Ref.No./Steps

Metric

95 mm Hg 153 mm Hg

U.S.

MAX MAX

3.75 in Hg 6inHg

Pressure at

Fuel Injection Pump Fuel inlet Pressure

172 kPa 207 kPa

140 kPa

25 psi 30 psi

MIN

20 psi

Fuel Injection Pump Fuel Return Line Restriction

518 mm Hg

MAX

20.4 in Hg

Fuel Filter Restriction Pressure Drop Across Filter

35 kPa

MAX

5 psi

Fuel Drain Line Restriction

70 kPa

MAX

10 psi

E;Fo\eion

Pump Throttle Lever 3.18 mm 6.35 mm

I

-

Fuel Systems - Rebuild Specifications Page 34 Component or Aeeembty (Procedure)

614 Series Ref.No./Steps

Metric

U.S.

Fuel Shutoff Solenoid Adjustment - Synchro-Start l Plunger Stroke Gap l Plunger Stroke Length

0.04 mm 25.4 mm

k!%

0.118 in 1.0 in

- Trombette l Plunger Stroke Gap l Plunger Stroke Length

k?

K

0.118 in 1.3 in

1:

Fuel Shutoff Soknoid Adjustment RQVK Governor

A

66.9 mm

2.64 in

24 Nom

18 f&lb

A D

24 Nom 15 Nom

18 ft-lb 11 ft-lb

A

24 Nom 14 Nom 27 Nom 70 Nom 5 Nom

18 Rib 10 ft-lb 20 ft-lb 50 f-t-lb 36 in-lb

4 Nom 32 Nom

35 in-lb 24 ft-lb

Fuel System - Torque Values Air Fuel Control (AFC) Pitting

Fuel Filter Note: install the filter as specified by the filter manufacturer.

Fuel Injection Pump Sealing Washer - Bosch Pump l Sealing Washer l Sealing Washer

Fuel Injection Pump Sealing Washer - Nip ndenso Pump l &%ing Washer l Sealing Washer l Sealing Washer l Sealing Washer l Sealing Washer (Bleed Screw)

Fuel Filter Heed Adapter Fuel Filter Adapter Nut

: D E

Fuel Systems - Rebuild Specifications Page 35

614 Series Component or Assembly (Procedure)

Metric

U.S.

Fuel Filter Head Banjo Fittings

24 Nom

18 f-t-lb

Fuel Injection Pump Solenoid Mounting Cspscrews

43 Nom

32 ft-lb

Fuel Injection Pump Supply Banjo Fiing

24 N*m

18 ft-lb

Fuel Injection Pump Mounting Nuts Studs

Fuel Injection Pump Lower Bracket Ml0 Pump to Bracket Capscrew Ml0 Bracket to Block Cap-screw

Fuel Injection Pump Drive Gear Nut A Pump MW Pump P Pump

Fuel Injection Pump liming Pin Access Plug

Ref.No./Steps

44 N*m Hand Tight

32 ft-lb

24 Nom 77 Nom

18 ft-lb 57 ft-lb

92 Nom 104 Nom 188 Nom

88 ft-lb 77 it-lb 122 ft-lb

15 N*m

11 ft-lb

Fuel Systems - Rebuild Specifications Page 36 Component or Assembly (Procedure)

614 Series Ref.No./Steps

Fuel Shutoff Solenoid Mounting Bracket Capscrews

Metric

U.S.

10 Nom

89 in-lb

Fuel Transfer Pump Fittings : pnt;p - Hand Primer

30 Nom 30 N*m 30 N*m

Fuel Transfer Pump Fuel Line Fittings

24 Nom

18 ft-lb

Fuel Transfer Pump Mounting Capscrews

24 Nom

18 ft-lb

High Pressure Fuel Line Fiiings

30 N*m

22 ft-lb

24 Nmrn

18 ft-lb

High Pressure Fuel Line Bracket

2

Injector Opening Pressure a. Open valve b. Operate spray tester lever at one stroke per second c. Read pressure indicated when spray began

Lubricating 614 Series Component or Assembly (Procedure)

Ref.No./Steps

U.S.

Metric

Leakage Test: a. Open valve b. Operate spray tester lever to hold pressure 20 bar [290 psi] below opening pressure c. No drops should fall from the tip within 20 seconds

Injector Nozzle Clamp Capscrew

injector Nozzle Banjo Fitting

24 N*m

18 ft-lb

9 Nom

80 in-lb

Lubricating Oil System - Specifications Lubricating Oil Thermostat l Fully Open Temperature l Maximum Opening Distance

Oil Capacii of Pan (All Engines): - Low Level - High Level Tog6S

15.1 liters 18.9 liters

16.0 U.S. Qts. 20.0 U.S. Qts.

em Capacity

Jst 6CTk.3

23.6 liters 23.8 liters

Oil Cookr Element Distortion

;;kFr

240°F 1.80 in

116°C 45.9 mm

0.8 mm

MAX

0.031 in

Element Pressure Test

Temperature

70 psi 18OOF

Oil System - Specificd$

Lubricating Page 38

Oil System Torque Values 614 Series Component or Assembly (Procedure)

Ref.No./Steps

Metric

U.S.

Oil pressure Regulator Spring ?w&Frss

Length 86.63 mm

Nominal

3.411 in

190 N

MIN

42.8 Ibf

153 N

MIN

34.4 Ibf

Oil Pump Gerotor Tip Clearance

0.025 mm 0.178 mm

MIN MAX

0.001 in 0.007 in

Oil Pump Port Plate Clearance

0.025 mm 0.127 mm

MIN MAX

. KE

.I::

0.127 mm 0.381 mm

MIN MAX

Z-E .

.I::

Oil Pump Drive Gear Backlash

0.08 mm 0.45 mm

MIN MAX

0.003 in 0.018 in

Oil Pump Idler Gear Backlash

0.08 mm 0.45 mm

MIN MAX

0.003 in 0.018 in

Spring Load at 53.98 mm t2.125 in] Valve Open

Spring Load at 69.33 mm t2.375 in] Assembled

Oil Pump Body Bore Clearance

,-_

Lubricating Oil System Torque Values Crankcase Breather Tube Bracket M8 (Valve Cover) Ml2 (Cylinder Head)

24 Nom 80 N*m

18 ft-lb 59 ft-lb

Lubricating Oil System Torque Values Page 39

614 Series Component or Assembly (Procedure)

Ref.No./Steps

Oil Cooler Cover Mounting Capscrews Oil Filter Head Mounting Capscrews

Metric

U.S.

24 Nom 24 Nom

18 ft-lb 18 ft-lb

Oil Cooler Cover Pipe Plugs Nom Nom Nom Nom

74 in-lb 74 in-lb 27 f&lb 35 ft-lb

Oil Pressure Regulator Plug

80 N*m

59 ft-lb

Oil Drain Plug

80 Nom

59 R-lb

Oil Pan Mounting Capscrews Note: Tighten the capscrews in the sequence

24 Nom

18 ft-lb

9 Nom 9 Nom 9 Nom

80 in-lb 80 in-lb 80 in-lb

24 Nom

18 ft-lb

10 10 36 46

shown. Start at the center of the oil pan and alternate toward both ends.

Oil Pump Suction Tube Bracket Suction Tube to Block Brace to Block Brace to Suction Tube

Oil Pump Mounting Capscrews

Coo;;% System Specifications 614 Series Component

or Assembly (Procedure)

Ref.No./Steps

Oil Temperature Thermostat

Metric

U.S.

50 Nom

37 ft-lb

Cooling System Specifications Fan Hub Assembled Height

Fan Hub Searing Installation Force

Fan Hub Shaft End Clearance

Radiator Cap Pressure Test 104% [220°F] 99% [21 ooq

Thermostat Operating Temperature Initial Opening Temperature Fully Open Temperature Maximum Open Distance

Viscous Fan Drive Operating Temperature Start Modulation Maximum Speed

124.85 mm 125.65 mm

MIN MAX

4.915 in 4.946 in

N

MIN

2023 Ibf

0.15 mm

MAX

0.006 in

103 kPa 48 kPa

MIN MIN

15 psi 7 psi

81% 83°C

MIN MAX

178°F 182°F

95%

MAX

203“F

MAX

1.63 in

9000

41.5 mm

Cooling System Specifsa;f;~ 614 Series Metric

U.S.

Belt Tensioner Mounting Capscrew

43 Nom

32 ft-lb

Fan Hub Mounting Capscrew

24 Nom

18 ft-lb

Fan Hub Pulley Mounting Capscrews

45 Nom

33 ft-lb

5 N*m

44 in-lb

Thermostat Housing Mounting Capscrews

24 Nom

18 ff-lb

Water Pump Mounting Capscrews

24 Nom

18 ft-lb

Water Outlet Connection

24 Nom

18 ft-lb

Component or Assembly (Procedure)

Ref.No./Steps

Cooling System Torque Values

Coolant Inlet Hose Clamps

E;;in.s

System Specifications 614 Series Component or Assembly (Procedure)

U.S.

MetriC

Flef.No./Steps

Air Intake System - Specifications Intake Air Restrictii Naturally Aspirated Turbocharged

Turbochzwger Shafl Radial Clearance (Side to Sii)

;;;

:;

# 2

MAX MAX

20.0 in H,O 25.0 in H,O

0.21 mm 0.46 mm

MIN MAX

0.008 in 0.018 in

0.03 mm 0.08 mm

MIN MAX

0.001 in 0.003 in

21 kPa

MAX

3 psi

165 kPa 179 kPa

MIN MAX

24 psi 26 psi

Note: Specifications and instructions for rebuilding the turbocharger are provided in the Hl Turbocharger Shop Manual, Bulletin No. 3810321.

Turbocharger Cleerance)

Shaft Axial Clearance (End

Charge Air Cooler Differential Pressure Across Cooler

Wastegate Actuator Calibration l

Air Pressure

l

Actuator Rod Movement Oi?

Fl:

MIN MAX

ij?&j

.

i;

Air Intake System - Torque Values Turbocharger Mounting Nut

Tuuerger

45 Nom

33 ft-lb

24 Nom

18 ft-lb

Oil Drain Mounting

Cooling System Specifications Page 43

614 Series Component or Assembly (Procedure)

Ref.No./Steps

Metric

U.S.

Turbocharger Air Crossover Hose Clamps

5 N*m

44 in-lb

Turbocharger Oil Drain Tube Hose Clamps

5 N*m

44 in-lb

Turbocharger Turbine Housing Capscrews

11 N*m

97 in-lb

8 Nom

71 in-lb

Turbocharger Oil Supply Hose Connection

id Nom

11 ft-lb

Turbocharger Discharge Elbow Clamp Nut

8 Nom

71 in-lb

10 Nom

89 in-lb

T$xxharger

Compressor Housing Clamp

Turbocharger Mounting Studs Use two mounting nuts locked together

Exhaust System - Specifications Page 44

614 Series

Component or Assembly (Procedure)

Exhaust System

-

Ref.No./Steps

Metric

U.S.

Specifications

Exhaust Restriction

Exhaust Manifold Flatness

7.5 cm Hg

MAX

3.0 in Hg

0.20 mm

MAX

0.008 in

Exhaust System - Torque Values Exhaust Manifold Mounting Capscrews: l Flan ed Head l Hex a ead

43 Nom 43 N*m

32 ft-lb 32 ft-lb

Air Compressor - Inspection Specifications Crankshaft End Clearance l Single Cylinder Air Compressor l

0.05 mm 0.15 mm

Two Cylinder Air Compressor ::z

1:

MIN MAX MIN MAX

0.002 in :-zz i:: 01008 in

Note:Specificationsand instructionsfor rebuilding the air compressors are provided in the Air Equipment Rebuild Manuals, Bulletin Nos. 3810242 and 3810257.

Air Compressor

-

Torque Values

Air Compressor Brace to Air Compressor lMM;ing Capscrews Bendix Midland

43 Nom 43 N*m 32 Nom

32 ft-lb 32 ft-lb 24 ft-lb

Air Compressor Brace to Cylinder Block Mounting Capscrew

43 Nom

32 ft-lb

77 Nom Hand Tight

57 ft-lb

ii&Compressor Flange Mounting Nuts Stud to Gear Housing

Electrical System - Specifications

Page 45

614 Series Component or Assembly (Procedure) A&Co~~~ssor

Ref.No./Steps

Metric

U.S.

15 N*m

12 ft-lb

35 Nom

26 lt-lb

Oil Supply Hose

Air Compressor Coolant Line Connection

Electrical System - Specifications 360N 490 N

Drive Belt

MIN MAX

1g

Engine has an automatic belt tensioner, no adjustment necessary.

Specific Gravity State of at 27% [WOOF] f;hj 1.260 to 1.280 1.230 to 1.250 75% 1.200 to 1.220 50% 1.170 to 1.190 25% 1.110 to 1.130 Discharged

Batteries

Electrical System - Torque Values BeltTensioner Capscrew

Alternator Mounting Ml 0 Capscrew Lower Suppoti Bracket M8 Capscrew Ml 0 Capscrew Mounting Capscrews

Starting Motor Mounting Capscrew

44 Nom

32 ft-lb

A

44 Nom

32 ft-lb

B

24 Nom 44 Nom

18 ft-lb 32 ft-lb

C

77 Nom

57 ft-lb

77 Nom

57 ft-lb

7EiL:

%zzgq

Eiiiz 100% 75%

1.26s1.280 1230.1250 1200.1220

25%

1.170-1.190

Discharged

1.110-1.130

Engine Testing - Test Specifications Page 46 Component or Assembly (Procedure)

614Series Ref.No./Steps

Metric

U.S.

Coolant Heater

12 Nom

106 in-lb

Temperature Sensor Installation - Cast Iron Installation - Aluminum

50 N*m 30 Nom

37 ft-lb 22 ft-lb

120 Nom

69 ft-lb

16 N*m 10 Nom

12 ft-lb 69 in-lb

Oil Heater Element

Oil Pressure Switch Installation - Cast Iron Installation - Aluminum

Engine Testing - Test Specifications Notex The specifications and instructions for testing the engineare provided in the C Series Shop Manual, Bulletin No. 3666008.

Crankcase Gases (Blowby) Limits Refer to Engine Testing - General Specifications, page 46.

Mounting Adaptations Specifications Flywheel Housing (wet Application) Set Screw Installation Depth

0.00 mm 3.00 mm

MN MAX

0.000 in 0.118 in

Mounting Adaptations - Torque Values Page 47

614 Series Component or Assembly (Procedure)

Ref.No./Steps

U.S.

Metric

Flywheel Ring Gear Installation Temperature . Time Interval l

177% 30 Min. 6 Hours

MIN MAX

360°F 30 Min. 6 Hours

Mounting Adaptations - Torque Values Flywheel Housing Access Plate Capscrews

24 Nom

16 ft-lb

Flywheel Housing Mounting Capscrews

60 Nom

44 ft-lb

140 Nom

101 ft-lb

Flywheel Mounting Capecrews

h;FTesting

- General Specifications 614 Series

Engine Testing - General Specifications Note: Due to variations in ratings of different engine models, refer to the specific engine data sheet for the particular engine model being tested. Maintain the following limits during an engine run-in on a dynamometer: Intake Restriction: (Maximum) .

Clean Filter ........................................................................................................

380 mm H.# [15 in. H,O]

l

Dirty Filter .........................................................................................................

635 mm Ha0 [25 in. H,O] 38OC [lOOoF]

Air inlet Temperature (Maximum) ...............................................................................................

7OOOC[l 290°F]

Exhaust Temperature ............................................................................................................. Exhaust Back Pressure: (Maximum) l

industrial ...............................................................................................................

l

EPA Certified ......................................................................................................

76 mm Hg 13.0 in. Hg] 114 mm Hg 14.5 in. Hg]

Smoke: (Steady State - Rated Power and RPM) l

Bosch Smoke Meter (Maximum) ................................................................................................

l

Celesco Smoke Meter (Maximum) .........................................................................................

2.5 Units 4% Opacity 1OOOC[212OF]

Coolant Temperature (Maximum) .............................................................................................

126.6OC [260°F]

Lubricating Oil Temperature (Maximum) ................................................................................ Lubricating Oil Pressure: l

Low Idle (Minimum Allowable) ..........................................................................................

69 kPa [lo psi]

l

Rated Speed (Minimum Allowable) .................................................................................

207 kPa [30 psi]

Fuel Filter Restriction (Maximum) .

Dirty Filter .............................................................................................................

89 mm Hg [3.5 in. Hg] 35 kPa [5 psi]

Fuel Return Restriction (Maximum) ............................................................................................ Blowby: l 6C8.3 (Maximum) (Rectangular intermediate ring) (Rectangular intermediate ring) l 6CT8.3 (Maximum) (Rectangular intermediate ring) l 6CTA8.3 (Maximum) l All Engines With Reverse Twist Intermediate Ring l

*New (UMin) 44 113 113 145

l

Worn (L/Min) 88 228 226 290

Blowby checking tool, Part No. 3822566, has a special 7.67 mm [0.302 in.] orifice that must be used to obtain an accurate reading.

Refer to the blowby conversion chart on the following page to convert liters/minute into inches/water.

Blowby Measurement Page 49

614 Series

Blowby Measurement Blowby is generally recorded in liters/minute. Install the Part No. 3822566, Engine Blowby Tool, to the crankcase breather tube in the valve cover. Install a water manometer to the engine blowby tool. Use the Blowby Conversion Chart to convert the manometer reading to liters/minute. Note: A pressuregauge can be used to record the engine blowby. Minimum Gauge Capacity: 1270mm Hz0 [SO inches

WI.

Blowby Conversion git1;~(7.67 Inches of Water 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

mm rO.302 in])

Liters/Minute 50 84 103 119 133 145 155 164 172 180 187 193 200 206 211 217 226 229 235 239 242 246 248

Drive Belt Tension Page 50

614 Series

Drive Belt Tension SAE Belt Size

Belt Tension New Click-type

N

Ibf

Belt Te;;zdt Range N

Ibf

0.380 in.

3822524

620

140

270 to 490

60 to 110

0.440 in.

3822524

620

140

270 to 490

60 to 110

112 in.

3822524

ST-1138

620

140

270 to 490

60 to 110

11/16 in.

3822524

ST-1138

620

140

270 to 490

60 to 110

314 in.

3822524

ST-1138

620

140

270 to 490

60 to 110

718 in.

3822524

ST-1138

620

140

270 to 490

60 to 110 60 to 110

4 rib

3822524

ST-1138

620

140

270 to 490

5 rib

3822524

ST-1138

670

150

270 to 530

60 to 120

6 rib

3822525

ST-1293

710

160

290 to 580

65 to 130

8 rib

3822525

ST-1293

890

200

360 to 710

80 to 160

10 rib

3822525

3823138

1110

250

440 to 890

1OOto200

12 rib

3822525

3823138

1330

300

530 to 1070

120 to 240

* A belt is considered used if it has been in service for ten minutes or longer. l

If used belt tension is less than the minimum value, tighten the belt to the maximum used belt value.

FRACTION,

614 Series

FRACTION,

THBS.

TZ.

N%.

TZ. 1

1 3 1 5 3 7

I

9 5

I

I

I

I

11

3 13 7 15 114

MM 0.397

0.0313

0.794

0.0469

1.191

0.0625

1.588

0.0781

1.984

0.0938

2.381

0.1094

2.778

7 29 15 31 l/2 CONVERSION

FACTOR:1

T&.

0.1406

3.572

0.1563

3.969

I 0.1719

4.763

0.2031

5.159

0.2188

5.556

0.2344

5.953

0.2500

6.350

10.716

0.4375

11.113

0.4531

11.509

0.4688

11.906

0.4844

12.303

0.5000

12.700

INCHES

35 9 37 19 39

21 I

I

I

43 45

23 47 314

,

I

0.5313

13.494

0.5469

13.691

0.5625

14.288

0.5781

14.684

0.5938

15.081

0.6094

15.478 1 15.875 I

0.6406

16.272

0.6563

16.669 I 17.066 I

0.6875

17.463

0.7031

17.859

0.7188

18.256

0.7344

18.653

0.7500

19.050

0.9219

23.416

0.9375

23.813

0.9531

24.209

0.9688

24.606

0.9844

25.003

1.0000

25.400

I

59 15 61 31 63 1 IN.

13.097

I 0.6719

11

MM

0.5156

t 0.6250

1 41

I

0.4219

Tit.

N&

17

5

CONVE;fFW&

CONVERSIONS

T&i.

I 4.366 I

0.1675

MILLIMETER

33

1 3.175 1

,

27

I

MILLIMETER

0.0156

I

I

I

INCHES

t 0.1250

I

1

DECIMAL,

DECIMAL,

,

I

INCH = 25.4Mtvl I

Weight and Measures Page 52

- Conversion

Factors

614 Series

Weight and Measures QUANTITY

U.S. CUSTOMARY

Area

Fuel Consumption Fuel

Performance

I

Unit Name

1 Abbe.

sq. inch

in*

sq. foot

ft2

pounds per horsepower hour miles per gallon

mhr

1

pounds force

lbf

Length

inch

in

foot horsepower

ft

Power

Torque

Velocity Volume: liquid displacement

pounds force per sa. in inches of mercury inches of water inches of mercury

FROM METRIC TO U.S. CUSTOMARY MULTIPLY BY

645.16

0.001550

6.452 0.0929 808.277

0.155 10.764 0.001645

4.4482

0.224809

25.40

0.039370

Abbr.

liters per kiter

I/km

Newton millimeters

N mm

millimeters kilowatt

I mm

kw

hp psi

kilopascal

kPa

in Hg

kilopascal

kPa

in H20

kilopascal

in Hg

millimeters 1 of mercury

I

inches of water bars

in H2C

bars

bars

bars

kPa

0.2488

mm Hg

25.40

I

millimeters of water kilopascals

I

3.3769

0.29613 I

1

4.019299 0.039370 I

I

mm H20 kPa mm Hg

OF

millimeters of mercury centigrade

1 per foot

1 ft lb !

1 Newton-meter !

1 Nom !

I Po;y;”

I

Newton-meter

Nom

0.113

8.850756

kilometers/hour liter liter

kph I

1.6093 I 3.7853

0.8214 0.264179

I

4.548

0.219978

liter

I

cubic centimeter kilograms

cm3

0.01639 18.387

61.02545 0.08102

fahrenheit 1 pound force

miles/hour gallon (U.S.)

in lb I

mph gal.

gallon (Imp*) cubic inch cubic inch

Weight (mass) Work

1

FROM U.S. CUSTOMARY TO METRIC MULTIPLY BY

km/l

Force

Temperature

Unit Name

sq. millimeters 1 m* sea.centimeters I c* m* sq. meter glkw-hr gramsper ki+owatthour

9,“,lps per

Pressure

Conversion Factors

METRIC

I

1

-

gal. .

in3 in3

OC

0.737562

I

I

I

lb BTU

joules

j

Eriiph Thermal

BTU

kilowatt-hour

kw-hr

hphr

(1.8 x “C) +32

1.35582

I

pounds (avoir.) British Thermal Unit

horsepower hours

(OF-32) i 1.8

kilowatt-hour

1

I

kg

kw-hr

o.ooo293

0.746

I

3414 I

1.341

614

Newton-Meter to Foot-Pound Conversion Chart Page 53

Series

Newton-Meter to Foot-Pound Conversion Chart Nom

ft-lb

Nom

B-lb

Nom

ft-lb

1

8.850756 in-lb

55

41

155

114

5

44 in-lb

80

44

160

118

8

53 in-lb

65

48

185

122

7

62 in-lb

70

52

170

125

8

71 in-lb

75

55

175

129

9

80 in-lb

80

59

180

133

10

89 in-lb

85

63

185

136

0.737562 R-lb

90

66

190

140

1 12

9

95

70

195

144

14

10

100

74

200

148

15

11

105

77

205

151

16

12

110

81

210

155

18.

13

115

85

215

159

20

15

120

89

220

162

25

18

125

92

225

165

30

22

130

96

230

170

35

28

135

100

235

173

40

30

140

103

240

177

45

33

145

107

245

180

50

37

150

111

250

184

NOTE: To convert from Newton-Meters to Kilogram-Meters divide Newton-Meters by 9.803.

Ca;r;w

Markings and Torque Values 614 Series

A

Capscrew Markings and Torque Values Caution: When replacing capscrews, always use a capscrew of the same measurement and strength as the capscrew being replaced. Using the wrong capscrews can result in engine damage.

Metric capscrews and nuts are identified by the grade number stamped on the head of the capscrew or on the surface of the nuts. U.S. Customary capscrews are identified by radial lines stamped on the head of the capscrew. The following examples indicate how capscrews are identified:

M8 Major Thread Diameter in Millimeters

Metric - MS1.25 X 25 1.25 25 Distance Length in Between Threads in Millimeters Millimeters

U.S. Customary [5/16 X 18 X l-1121 l-112 5/l 6 18 Length Major Number in Threads Thread per Inch Inches Diameter in Inches

NOTES: 1. Always use the torque values listed in the following tables when specific torque values are not available. 2. Do not use the torque values in place of those specified in other sections of this manual. 3. The torque values in the table are based on the use of lubricated threads. 4. When the ft-lb value is less than 10, give consideration to converting the ft-lb value to in-lb to obtain a better torque with an in-lb torque wrench. Example: 6 ft-lb equals 72 in-lb.

Capscrew

Markings and Torquepi;:;;

614SefieS

Capscrew Markings and Torque Values - Metric Commercial

Steel Class 8.8

Capscrew Head Markings

SF Diam. mm 6 7 8 10 12 14 16 18

Torque Cast iron Aluminum Nom ft-lb Nom ft-lb 9 5 7 4 14 9 11 7 25 18 18 14 45 33 30 25 80 60 55 40 125 90 90 65 180 130 140 100 230 170 180 135

Torque Cast Iron Aluminum ft-lb Nom ft-lb Nom 7~ 4 12 9 7 14 11 18 14 25 18 33 25 60 45 30 75 55 40 105 122 90 65 165 140 loo 175 240 180 135 320 240

Torque Aluminum Cast Iron ft-lb Nom ft-lb Nom 4 7 14 9 7 18 11 23 14 40 29 18 25 70 50 30 40 95 55 125 65 195 145 90 100 290 210 140 400

290

180

135

Capscrew Markings and Torque Values - U.S. Customary SAE Grade Number Capscrew Head Markings These are allSAE Grade 5 (3)line

8

5

Torque - Grade 5 Capscrew

Capscrew Body Sue 114 - 20 -26 5116 - 18 - 24 316 - 16 - 24 7116 - 14 - 20 112 - 13 -20 9116 - 12 - 18 516 - 11 - 18 314 - 10 - 16 718 - 9 - 14 l-8 - 14

Nom 9 12 E z 60 E

100 135 150 :: 325 365 490 530 720 800

Iroil ft-lb 9’ 15 17 ii 2 70 75 100 110 135 155 240 270 360 390 530 590

Aluminum Nom ft-lb : 16 :: 35 zz :z 110 115 150 160 255 iis 420 570 650

6 7 12

: 25 35 40 55 60 80 65 110 120 190 210 260 310 420 480

Cepscrew Torque - Grede 8 Cspscrew

Cast Iron ft-lb Nom 11 15 16 E 55 60 :: 130 150 190 210 z 460 515 iz 1100 1200

:: 24 40 45 65 70 95 110 140 155 190 215 340 380 550 610 820 890

Aluminum N*m ft-lb 8 6 9 7 16 19 25 35 : 75 80 110 115 150 160 255 265 380 420 570 650

12 ii 25 35 zi ii 85 110 120 190 210 280 310 420 480

Pipe Plug Torque Values Page 56

614 Series

Pipe Plug Torque Values Sire Thread in

l/l6 l/8 l/4 318 l/2 314 1 l-114 l-112

Torque