Wafer Bumping 101l6e

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 2z6p3t

Overview 5o1f4z

& View Wafer Bumping as PDF for free.

More details 6z3438

- Words: 212

- Pages: 2

Wafer Bumping Wafer bumping services are offered as a preparatory step for flip-chip bonding or as bumping service alone. The types of solder bumping available include high lead solder, eutectic solder and lead free solder. Lead free bump, which is composed of tin-silver alloy, can meet the WEEE directives. Additionally, it can eliminate alpha particle sources. Fujitsu's solder bumping service is currently offered for 6”and 8”wafers, and soon 12" wafers. Using advanced technology fabrication, Fujitsu manufactures 11,000 bumps on a die with 120µm bump pitch with lead free solder, and a 100µm bump pitch. Cross section of solder bump

Solder Ball

Barrier Metal Ni (plated) Cu (sputtered) Ti (sputtered)

Silicon

AI Pad

ivation

Cross section of electroless Ni UBM and AP- bump Solder Bump

AI Pad ivation

[UBM] Nickel

• • • • • 5

Fujitsu Microelectronics America, Inc.

Industry's most extensive experience Lead-free and other innovative bumping solutions Copper wiring redistribution services Tightest bump pitch Single die bumping capability

Wafer Bumping Fine-pitch bump

Bump pitch:100um Bump height: 50um

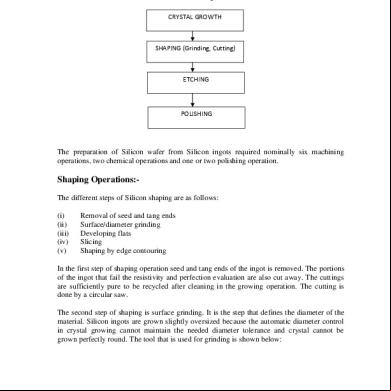

Solder Bumping Process Flow 1. UBM sputtering

Ni (sputter)

ivation

2. Resist patterning for plating

Resist Ti (sputter)

3. Ni plating

4. PbSn Plating

PbSn (plating) Ni (plating)

Pad metal

5. Resist removing

6. Cu/Ti etching

7. Bump shaping

Advanced Packaging Services

6

Solder Ball

Barrier Metal Ni (plated) Cu (sputtered) Ti (sputtered)

Silicon

AI Pad

ivation

Cross section of electroless Ni UBM and AP- bump Solder Bump

AI Pad ivation

[UBM] Nickel

• • • • • 5

Fujitsu Microelectronics America, Inc.

Industry's most extensive experience Lead-free and other innovative bumping solutions Copper wiring redistribution services Tightest bump pitch Single die bumping capability

Wafer Bumping Fine-pitch bump

Bump pitch:100um Bump height: 50um

Solder Bumping Process Flow 1. UBM sputtering

Ni (sputter)

ivation

2. Resist patterning for plating

Resist Ti (sputter)

3. Ni plating

4. PbSn Plating

PbSn (plating) Ni (plating)

Pad metal

5. Resist removing

6. Cu/Ti etching

7. Bump shaping

Advanced Packaging Services

6