Silicon Wafer Fabrication u1r1z

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 2z6p3t

Overview 5o1f4z

& View Silicon Wafer Fabrication as PDF for free.

More details 6z3438

- Words: 575

- Pages: 24

Silicon and Wafer Preparation Lyndon Mark P. Olaguera PS147: Physical Electronics

OBJECTIVES At the end of this lesson, the student should be able to: 1. describe how the raw silicon is refined into semiconductorgrade silicon. 2. explain the crystal structure and growth method for producing mono-crystalline silicon. 3. outline and describe the basic process steps for wafer preparation, starting from a silicon ingot and finishing with a wafer. 4. explain what epitaxy is and why it is important for wafers.

Semiconductor Grade Si Pure silicon—used to minimize micro-defects at the atomic level of the silicon that are detrimental to semiconductor performance. Semiconductor grade Si(SGS)—highly refined silicon >>also known as electronic grade silicon

Semiconductor Grade Si

Source: Semiconductor Manufacturing Technology by Michael Quirk, Julian Seda, 2001

Siemens Process Silicon produced by this process does not have atoms arranged in a desirable crystal order.

Source: Semiconductor Manufacturing Technology by Michael Quirk, Julian Seda, 2001

CRYSTAL STRUCTURE CRYSTAL>>a solid material that has an ordered, repeatable three dimensional pattern over a long range of many atoms.

Source: Semiconductor Manufacturing Technology by Michael Quirk, Julian Seda, 2001

CRYSTAL STRUCTURE Amorphous Materials >>non crystalline solids that lack a repetitive structure and demonstrate structural disorder at the atomic level. E.g. Plastic Source: Semiconductor Manufacturing Technology by Michael Quirk, Julian Seda, 2001

CRYSTAL STRUCTURE Unit Cell >>the simplest arrangement of atoms that, when repeated in a three dimensional framework gives the crystal structure.

Source: Semiconductor Manufacturing Technology by Michael Quirk, Julian Seda, 2001

CRYSTAL STRUCTURE

http://2.bp.blogspot.com/-B-6gSM0wsXw/UC_bwvm7ooI/AAAAAAAABAw/1y1TIhYkc/s1600/seven.pnghttp://2.bp.blogspot.com/-B6gSM0wsXw/UC_bwvm7ooI/AAAAAAAABAw/1y1TIhYkc/s1600/seven.pnghttp://2.bp.blogspot.com/-B6gSM0wsXw/UC_bwvm7ooI/AAAAAAAABAw/1y1TIhYkc/s1600/seven.pngv

CRYSTAL STRUCTURE

Source: Semiconductor Manufacturing Technology by Michael Quirk, Julian Seda, 2001

CRYSTAL STRUCTURE Within a crystal structure, unit cells are tightly packed, therefore, share atoms. Sharing of atoms– this is how unit cells build up into a cohesive crystal lattice structure. FCC unit cell—four shared atoms. Silicon crystal—Four shared and Four unshared (four atoms inside the cubic structure) Source: Semiconductor Manufacturing Technology by Michael Quirk, Julian Seda, 2001

POLY-CRYSTAL and MONOCRYSTAL Poly crystal—the unit cells are not in a regular arrangement. Silicon produced from the semiconductor grade purification process— poly-silicon. Mono-crystals—if unit cells are neatly arranged in a three dimensional, repeatable manner.

Source: Semiconductor Manufacturing Technology by Michael Quirk, Julian Seda, 2001.

REQUIREMENTS for Si Wafer Processing

Pure Mono-crystalline WHY?? 1. Repeatable units provide the desirable electrical and mechanical properties

CRYSTAL ORIENTATION

(100)– common for MOS devices, GaAs devices. (111)—bipolar devices (tighter packing density)

Source: Semiconductor Manufacturing Technology by Michael Quirk, Julian Seda, 2001.

MONOCRYSTAL SILICON GROWTH Crystal Growth—process of converting the polysilicon chunks of SGS into a large monocrystal of Si. INGOT—grown silicon monocrystal. Czochralsky Method (CZ)--Most commonly used technique for growing monocrystal ingots.

Source: Semiconductor Manufacturing Technology by Michael Quirk, Julian Seda, 2001.

MONOCRYSTAL SILICON GROWTH Objectives of the pull process: Replicate the seed structure while obtaining dopant uniformity Achieving the correct ingot diameter Limiting the introduction of impurities

Parameters affecting the growth process: 1. Pull rate 2. Crystal rotation 3. //Temperature

DOPING

Adding impurities to obtain the desired resistivity Resistivity of pure silicon =2.5x10^5 ohm-cm

FLOAT ZONE METHOD Produces a silicon monoscrystal ingot which significantly lower oxygen content. Produces ingots with smaller diameters.

WAFER DIAMETERS

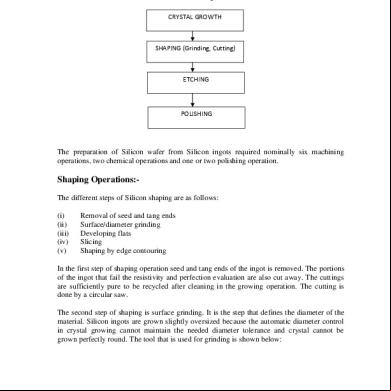

WAFER PREPARATION

SHAPING OPERATIONS End Removal Diameter Grinding Wafer Flat or Notch

Source: Semiconductor Manufacturing Technology by Michael Quirk, Julian Seda, 2001.

WAFER IDENTIFYING FLATS

Source: Semiconductor Manufacturing Technology by Michael Quirk, Julian Seda, 2001.

WAFER SLICING

http://www.pveducation.org/node/496

WAFER LAPPING

http://www.microchemicals.com/s/pics/wafer_lapping_polishing.jpg

OBJECTIVES At the end of this lesson, the student should be able to: 1. describe how the raw silicon is refined into semiconductorgrade silicon. 2. explain the crystal structure and growth method for producing mono-crystalline silicon. 3. outline and describe the basic process steps for wafer preparation, starting from a silicon ingot and finishing with a wafer. 4. explain what epitaxy is and why it is important for wafers.

Semiconductor Grade Si Pure silicon—used to minimize micro-defects at the atomic level of the silicon that are detrimental to semiconductor performance. Semiconductor grade Si(SGS)—highly refined silicon >>also known as electronic grade silicon

Semiconductor Grade Si

Source: Semiconductor Manufacturing Technology by Michael Quirk, Julian Seda, 2001

Siemens Process Silicon produced by this process does not have atoms arranged in a desirable crystal order.

Source: Semiconductor Manufacturing Technology by Michael Quirk, Julian Seda, 2001

CRYSTAL STRUCTURE CRYSTAL>>a solid material that has an ordered, repeatable three dimensional pattern over a long range of many atoms.

Source: Semiconductor Manufacturing Technology by Michael Quirk, Julian Seda, 2001

CRYSTAL STRUCTURE Amorphous Materials >>non crystalline solids that lack a repetitive structure and demonstrate structural disorder at the atomic level. E.g. Plastic Source: Semiconductor Manufacturing Technology by Michael Quirk, Julian Seda, 2001

CRYSTAL STRUCTURE Unit Cell >>the simplest arrangement of atoms that, when repeated in a three dimensional framework gives the crystal structure.

Source: Semiconductor Manufacturing Technology by Michael Quirk, Julian Seda, 2001

CRYSTAL STRUCTURE

http://2.bp.blogspot.com/-B-6gSM0wsXw/UC_bwvm7ooI/AAAAAAAABAw/1y1TIhYkc/s1600/seven.pnghttp://2.bp.blogspot.com/-B6gSM0wsXw/UC_bwvm7ooI/AAAAAAAABAw/1y1TIhYkc/s1600/seven.pnghttp://2.bp.blogspot.com/-B6gSM0wsXw/UC_bwvm7ooI/AAAAAAAABAw/1y1TIhYkc/s1600/seven.pngv

CRYSTAL STRUCTURE

Source: Semiconductor Manufacturing Technology by Michael Quirk, Julian Seda, 2001

CRYSTAL STRUCTURE Within a crystal structure, unit cells are tightly packed, therefore, share atoms. Sharing of atoms– this is how unit cells build up into a cohesive crystal lattice structure. FCC unit cell—four shared atoms. Silicon crystal—Four shared and Four unshared (four atoms inside the cubic structure) Source: Semiconductor Manufacturing Technology by Michael Quirk, Julian Seda, 2001

POLY-CRYSTAL and MONOCRYSTAL Poly crystal—the unit cells are not in a regular arrangement. Silicon produced from the semiconductor grade purification process— poly-silicon. Mono-crystals—if unit cells are neatly arranged in a three dimensional, repeatable manner.

Source: Semiconductor Manufacturing Technology by Michael Quirk, Julian Seda, 2001.

REQUIREMENTS for Si Wafer Processing

Pure Mono-crystalline WHY?? 1. Repeatable units provide the desirable electrical and mechanical properties

CRYSTAL ORIENTATION

(100)– common for MOS devices, GaAs devices. (111)—bipolar devices (tighter packing density)

Source: Semiconductor Manufacturing Technology by Michael Quirk, Julian Seda, 2001.

MONOCRYSTAL SILICON GROWTH Crystal Growth—process of converting the polysilicon chunks of SGS into a large monocrystal of Si. INGOT—grown silicon monocrystal. Czochralsky Method (CZ)--Most commonly used technique for growing monocrystal ingots.

Source: Semiconductor Manufacturing Technology by Michael Quirk, Julian Seda, 2001.

MONOCRYSTAL SILICON GROWTH Objectives of the pull process: Replicate the seed structure while obtaining dopant uniformity Achieving the correct ingot diameter Limiting the introduction of impurities

Parameters affecting the growth process: 1. Pull rate 2. Crystal rotation 3. //Temperature

DOPING

Adding impurities to obtain the desired resistivity Resistivity of pure silicon =2.5x10^5 ohm-cm

FLOAT ZONE METHOD Produces a silicon monoscrystal ingot which significantly lower oxygen content. Produces ingots with smaller diameters.

WAFER DIAMETERS

WAFER PREPARATION

SHAPING OPERATIONS End Removal Diameter Grinding Wafer Flat or Notch

Source: Semiconductor Manufacturing Technology by Michael Quirk, Julian Seda, 2001.

WAFER IDENTIFYING FLATS

Source: Semiconductor Manufacturing Technology by Michael Quirk, Julian Seda, 2001.

WAFER SLICING

http://www.pveducation.org/node/496

WAFER LAPPING

http://www.microchemicals.com/s/pics/wafer_lapping_polishing.jpg