Api 610 10th Edition (iso 13709) Pump Datasheet 1ph5f

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 2z6p3t

Overview 5o1f4z

& View Api 610 10th Edition (iso 13709) Pump Datasheet as PDF for free.

More details 6z3438

- Words: 1,220

- Pages: 3

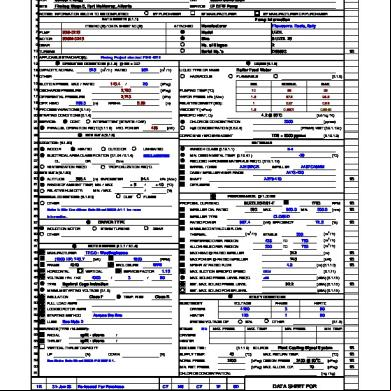

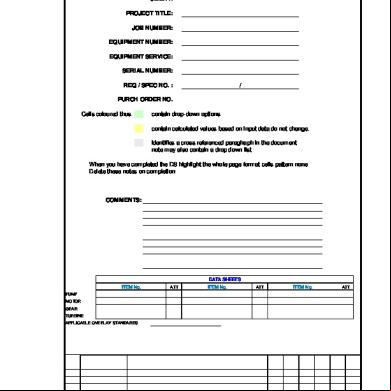

API 610 10TH EDITION (ISO 13709) CENTRIFUGAL PUMP PROCESS DATA SHEET (SI UNITS) 1 APPLICABLE TO:

PROPOSAL

PURCHASE

MR No.

MR95-G-8-1

Inquiry No.

MR95-G-8-1

By:

C.Yu

2 FOR

Suncor Energy

UNIT

Firebag Stage 5, Fort McMurray, Alberta

SERVICE

4 NOTES: INFORMATION BELOW TO BE COMPLETED:

Date:

31-Jan-08

BY PURCHASER

LP BFW Pump

BY MANUFACTURER

BY MANUFACTURER OR PURCHASER

Pump Information Manufacturer

Flowserve. Desio, Italy

7 PUMP

95G-3215

Model

UZDL

8 MOTOR

95GM-3215

Size

6 UZDL 25

No. of Stages

2

Serial No.'s

D66893

ITEM NO.(S) / DATA SHEET NO.(S)

ATTACHED

9 GEAR 10 TURBINE 11 APPLICABLE STANDARD(S): 12

(m3 / h) RATED

545

LIQUID (5.1.3) 3

654

(m / h)

20

(kPag)

HAZARDOUS

15 SUCTION PRESS. MAX. / RATED

143.4

/

16 DISCHARGE PRESSURE

2,763

(kPag)

17 DIFFERENTIAL PRESSURE

2,743

(kPa)

288.3

(m)

5.96

NPSHA

(m)

19 PROCESS VARIATIONS (5.1.4)

21 SERVICE:

PUMPING TEMP (°C)

10

85

98

1.2

57.8

94.3

RELATIVE DENSITY (SG):

1

0.97

0.96

1.3

0.3301

0.2849

4.2 @ 85°C

498

(kW)

SITE DATA (5.1.3)

(PPMW) WET (5.2.1.12c)

TDS < 8000 ppmw

CORROSIVE / EROSIVE AGENT

INDOOR

26

ELECTRICAL AREA CLASSIFICATION (5.1.24 / 6.1.4)

HEATED

CL.

OUTDOOR

GR.

UNHEATED

ANNEX H CLASS (5.12.1.1)

UNCLASSIFIED

MIN. DESIGN METAL TEMP. (5.12.4.1)

Zone

WINTERIZATION REQ'D

TROPICALIZATION REQ'D.

593.4

30

ALTITUDE

RANGE OF AMBIENT TEMP, MIN. / MAX.

32

A216WCB

BARREL / CASE

RELATIVE HUMIDITY:

94.4

(m) BAROMETER

+5

MIN. / MAX.

33 UNUSUAL CONDITIONS: (5.1.30)

DUST

kPa (Abs.)

/

+ 40 (°C)

/

(%)

Refer to Site Conditions Data Sheet DS93-A-1-1 for more

IMPELLER DIA. RATED

36

information.

IMPELLER TYPE

6UZDL25-BS1-F

PROPOSAL CURVE NO.

DRIVER TYPE INDUCTION MOTOR

593

GEAR

OTHER

687.4 (m / h)

MOTOR DRIVER (6.1.1 / 6.1.4)

ALLOWABLE OPER. REGION

TECO - Westinghouse 1800

(kW)

44

FRAME

45

HORIZONTAL

46

VOLTAGE / PH. / HZ.

47

TYPE

48

MINIMUM STARTING VOLTAGE (6.1.5)

4010

(RPM)

WPII

ENCLOSURE VERTICAL

4000

3

/

60

/

Squirrel Cage Induction

INSULATION FULL LOAD AMPS

51

LOCKED ROTOR AMPS

52

STARTING METHOD

53

LUBE

1B

MAX POWER @ RATED IMPELLER

745

(kW)

1B

4.0

MAX. SUCTION SPECIFIC SPEED

9204

MAX. SOUND PRESS. LEVEL REQ'D.

<85

54 BEARINGS (TYPE / NUMBER):

57

VERTICAL THRUST CAPACITY

58

UP

59

See Motor Data Sheet DS95-P-GM3215-1.

split - sleeve split - sleeve

(dBA) (5.1.16) (dBA) (5.1.16)

HERTZ

60

HEATER

120

1

60

N/A

DRIVERS HEATER

80%

MAX. PRESS.

COOLING TEG:

45

NORM. PRESS.

2100

MIN. RET. PRESS.

61

CHLORIDE CONCENTRATION:

31-Jan-08

Re-issued For Purchase

CY

NS

CY

TP

SD

1-Jun-07

Issued For Purchase

GO

ES

CY

TP

SD

No.

DATE

BY

CHK

ENG.

APPR.

OTHER

LOCATION:

Firebag Stage 5, Fort McMurray, Alberta

SERVICE:

LP BFW Pump

EQUIPMENT NO.

95G-3215

MIN. TEMP.

Plant Cooling Glycol System

MAX. RETURN TEMP.

(kPag) DESIGN PRESS.

2400 @ 80oC 70

1B

(°C)

1B

(kPag)

1B

(kPag)

1B

(mg / kg)

1A

Suncor Energy

SOURCE

(°C)

(6.1.5) MIN. PRESS.

(kPag) MAX. ALLOW. D.P.

1B

FOR:

OTHER

MAX. TEMP.

(5.1.19)

SUPPLY TEMP.

60

REVISION

PHASE

3

/

(N)

1B

(dBA) (5.1.16)

4160

/

DOWN

1B

(5.1.11)

DRIVERS

STEAM

THRUST

(m) (5.1.10)

92.2

VOLTAGE

SYSTEM VOLTAGE DIP

RADIAL

3 (m / h)

UTILITY CONDITIONS

See Note 2

(N)

TO

(m)

Class B

Across the line

56

1B

342

ELECTRICITY

55

(%) (m / h)

EST. MAX. SOUND POWER LEVEL TEMP. RISE

1B

MAX HEAD @ RATED IMPELLER

EST. MAX. SOUND PRESS. LEVEL

Class F

49 50

1B

(m3 / h)

750 750

TO

NPSHR AT RATED FLOW

1.15

SERVICE FACTOR

RPM (mm)

3

300

STABLE

438 300

PREFERRED OPER. REGION

(1000 HP) 745.7

72.5

(kW) EFFICIENCY

3

THERMAL

MANUFACTURER

500.0

MIN.

MINIMUM CONTINUOUS FLOW:

40 41

1783 650.0

MAX.

CLOSED

RATED POWER

STEAM TURBINE

1B

PERFORMANCE: @ 1.00 SG

FUMES

35

43

A487CA6NM A473-420

IMPELLER

DIFFS

OTHER

37

(°C)

A276-410

SHAFT

34

42

-29

CASE / IMPELLER WEAR RINGS

31

39

S-6

REDUCED HARDNESS MATERIALS REQ'D. (5.12.1.12)

29 SITE DATA (5.1.30)

38

(5.12.1.9)

MATERIALS

25

28

(ppmw)

H2S CONCENTRATION (6.5.2.4)

24 LOCATION: (5.1.30)

27

(kJ / kg °K)

3000

CHLORIDE CONCENTRATION

HYD. POWER

MAX.

VAPOR PRESS. kPa (Abs.)

INTERMITTENT (STARTS / DAY)

PARALLEL OPERATION REQ'D (5.1.13)

(5.1.5) NORMAL

MIN.

SPECIFIC HEAT,

CONT.

23

FLAMMABLE

VISCOSITY (mPa.s)

20 STARTING CONDITIONS (5.1.4)

22

Boiler Feed Water

LIQUID TYPE OR NAME

14 OTHER

18 DIFF. HEAD

1B

Firebag Project standard FB-G-5616

OPERATING CONDITIONS (5.1.3) @ SG = 0.97

13 CAPACITY, NORMAL

Rev.

Steam Generation

DATA SHEETS (6.1.1)

6

95G-3215

AS BUILT

3 SITE

5

Item No.

DATA SHEET FOR 95G-3215 Project No. DOCUMENT NO.

03-00061A

DS95-A-G3215-1

1B

REV. 1B

SM 23/01/2006

DS-Pump-API 610 10th Ed. Centrifugal Template

REV 0

PROCESS DATA SHEET

SHT 1 OF 5

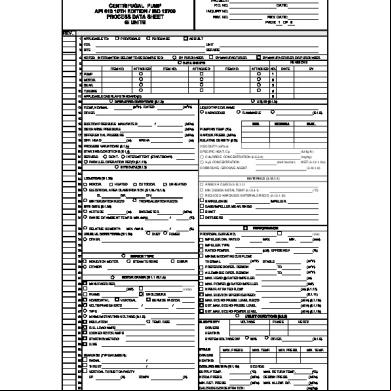

API 610 10TH EDITION (ISO 13709) CENTRIFUGAL PUMP PROCESS DATA SHEET (SI UNITS)

MR No. Inquiry No. By:

MR95-G-8-1 MR95-G-8-1 C.Yu

Item No.

95G-3215

Date:

31-Jan-08

NOTES

1 2 1.

Pump lube oil shall be Mobil SCH 626 (ISO VG68)

3 4 2.

Motor lubrication shall be Mobil SCH 626 (ISO VG68)

5 6 3.

Seller shall provide casing drains and vents in accordance to the detail below and Suncor Piping Material Class ES on the low point of the pump casing. Seller shall provide a Gate Valve, i.e., Class 300 RF to ASME B16.5, Forged Body w/integral flanges, Bolted Bonned, OS & Y, Solid Wedge, API Trim 8, Integral or Renewable seats, Regular Port, Design to API 602. Seller shall attach a Suncor valve tag number of VGA0315#8.

1B

10

All casing drains shall be terminated at one common skid edge flanged connection. All casing vents shall be terminated at one

1B

11

common skid edge flanged connection. Each casing drain and vent line shall have provision for individual isolation valve.

1B

7 8 9

12

CASING DRAIN AND VENT DETAILS

13 14 15 16 17

Pump Casing

18

Nipple shall be combined with other casing drain and vent lines (as applicable), and extended to the edge of baseplate, terminated in a common skid connection

Gussets in 2 planes shall be of the same metallurgy as pump casing, 90° apart.

19 20

1B

21 22 23 24 25

1B

26

VGA-0315#8

27 28 29 30

S.W.

31

Gaskets shall be spiral wound 316SS graphite filled, c/w CS outer ring per ASME 16.20

32

S.W.

33 34

Valves shall be tagged with metal tags stamped with Suncor valve number. The metal tags shall be stainless steel, minimum size 18mm x 50mm and shall be attached to valves with minimum 20 gauge strand SS wire.

35 36 37 38 4.

NPSHR at normal flow of 545 m3/h is 2.0 m. The NPSHA shown is based on the normal temperature of 85°C.

1B

39 40 5.

Baseplate for pump and motor shall be engineered and designed for non-grout construction. However, grout holes shall be

41

provided.

42 43 6.

Content for this Data Sheet is based on Suncor Firebag Stage 3 Data Sheet DS93-A-G3215-1 Rev 1D

1B

This pump 95G-3215 is identical to Stage 3 Pump 93G-3215.

1B

44 45 7. 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64

SM 23/01/2006

FOR:

Suncor Energy

LOCATION:

Firebag Stage 5, Fort McMurray, Alberta

SERVICE:

LP BFW Pump

EQUIPMENT NO.

95G-3215

DS-Pump-API 610 10th Ed. Centrifugal Template

Project No. DOCUMENT NO.

03-00061A

DS95-A-G3215-1 REV 0

PROCESS DATA SHEET

1B

REV. 1B SHT 2 OF 5

PROPOSAL

PURCHASE

MR No.

MR95-G-8-1

Inquiry No.

MR95-G-8-1

By:

C.Yu

2 FOR

Suncor Energy

UNIT

Firebag Stage 5, Fort McMurray, Alberta

SERVICE

4 NOTES: INFORMATION BELOW TO BE COMPLETED:

Date:

31-Jan-08

BY PURCHASER

LP BFW Pump

BY MANUFACTURER

BY MANUFACTURER OR PURCHASER

Pump Information Manufacturer

Flowserve. Desio, Italy

7 PUMP

95G-3215

Model

UZDL

8 MOTOR

95GM-3215

Size

6 UZDL 25

No. of Stages

2

Serial No.'s

D66893

ITEM NO.(S) / DATA SHEET NO.(S)

ATTACHED

9 GEAR 10 TURBINE 11 APPLICABLE STANDARD(S): 12

(m3 / h) RATED

545

LIQUID (5.1.3) 3

654

(m / h)

20

(kPag)

HAZARDOUS

15 SUCTION PRESS. MAX. / RATED

143.4

/

16 DISCHARGE PRESSURE

2,763

(kPag)

17 DIFFERENTIAL PRESSURE

2,743

(kPa)

288.3

(m)

5.96

NPSHA

(m)

19 PROCESS VARIATIONS (5.1.4)

21 SERVICE:

PUMPING TEMP (°C)

10

85

98

1.2

57.8

94.3

RELATIVE DENSITY (SG):

1

0.97

0.96

1.3

0.3301

0.2849

4.2 @ 85°C

498

(kW)

SITE DATA (5.1.3)

(PPMW) WET (5.2.1.12c)

TDS < 8000 ppmw

CORROSIVE / EROSIVE AGENT

INDOOR

26

ELECTRICAL AREA CLASSIFICATION (5.1.24 / 6.1.4)

HEATED

CL.

OUTDOOR

GR.

UNHEATED

ANNEX H CLASS (5.12.1.1)

UNCLASSIFIED

MIN. DESIGN METAL TEMP. (5.12.4.1)

Zone

WINTERIZATION REQ'D

TROPICALIZATION REQ'D.

593.4

30

ALTITUDE

RANGE OF AMBIENT TEMP, MIN. / MAX.

32

A216WCB

BARREL / CASE

RELATIVE HUMIDITY:

94.4

(m) BAROMETER

+5

MIN. / MAX.

33 UNUSUAL CONDITIONS: (5.1.30)

DUST

kPa (Abs.)

/

+ 40 (°C)

/

(%)

Refer to Site Conditions Data Sheet DS93-A-1-1 for more

IMPELLER DIA. RATED

36

information.

IMPELLER TYPE

6UZDL25-BS1-F

PROPOSAL CURVE NO.

DRIVER TYPE INDUCTION MOTOR

593

GEAR

OTHER

687.4 (m / h)

MOTOR DRIVER (6.1.1 / 6.1.4)

ALLOWABLE OPER. REGION

TECO - Westinghouse 1800

(kW)

44

FRAME

45

HORIZONTAL

46

VOLTAGE / PH. / HZ.

47

TYPE

48

MINIMUM STARTING VOLTAGE (6.1.5)

4010

(RPM)

WPII

ENCLOSURE VERTICAL

4000

3

/

60

/

Squirrel Cage Induction

INSULATION FULL LOAD AMPS

51

LOCKED ROTOR AMPS

52

STARTING METHOD

53

LUBE

1B

MAX POWER @ RATED IMPELLER

745

(kW)

1B

4.0

MAX. SUCTION SPECIFIC SPEED

9204

MAX. SOUND PRESS. LEVEL REQ'D.

<85

54 BEARINGS (TYPE / NUMBER):

57

VERTICAL THRUST CAPACITY

58

UP

59

See Motor Data Sheet DS95-P-GM3215-1.

split - sleeve split - sleeve

(dBA) (5.1.16) (dBA) (5.1.16)

HERTZ

60

HEATER

120

1

60

N/A

DRIVERS HEATER

80%

MAX. PRESS.

COOLING TEG:

45

NORM. PRESS.

2100

MIN. RET. PRESS.

61

CHLORIDE CONCENTRATION:

31-Jan-08

Re-issued For Purchase

CY

NS

CY

TP

SD

1-Jun-07

Issued For Purchase

GO

ES

CY

TP

SD

No.

DATE

BY

CHK

ENG.

APPR.

OTHER

LOCATION:

Firebag Stage 5, Fort McMurray, Alberta

SERVICE:

LP BFW Pump

EQUIPMENT NO.

95G-3215

MIN. TEMP.

Plant Cooling Glycol System

MAX. RETURN TEMP.

(kPag) DESIGN PRESS.

2400 @ 80oC 70

1B

(°C)

1B

(kPag)

1B

(kPag)

1B

(mg / kg)

1A

Suncor Energy

SOURCE

(°C)

(6.1.5) MIN. PRESS.

(kPag) MAX. ALLOW. D.P.

1B

FOR:

OTHER

MAX. TEMP.

(5.1.19)

SUPPLY TEMP.

60

REVISION

PHASE

3

/

(N)

1B

(dBA) (5.1.16)

4160

/

DOWN

1B

(5.1.11)

DRIVERS

STEAM

THRUST

(m) (5.1.10)

92.2

VOLTAGE

SYSTEM VOLTAGE DIP

RADIAL

3 (m / h)

UTILITY CONDITIONS

See Note 2

(N)

TO

(m)

Class B

Across the line

56

1B

342

ELECTRICITY

55

(%) (m / h)

EST. MAX. SOUND POWER LEVEL TEMP. RISE

1B

MAX HEAD @ RATED IMPELLER

EST. MAX. SOUND PRESS. LEVEL

Class F

49 50

1B

(m3 / h)

750 750

TO

NPSHR AT RATED FLOW

1.15

SERVICE FACTOR

RPM (mm)

3

300

STABLE

438 300

PREFERRED OPER. REGION

(1000 HP) 745.7

72.5

(kW) EFFICIENCY

3

THERMAL

MANUFACTURER

500.0

MIN.

MINIMUM CONTINUOUS FLOW:

40 41

1783 650.0

MAX.

CLOSED

RATED POWER

STEAM TURBINE

1B

PERFORMANCE: @ 1.00 SG

FUMES

35

43

A487CA6NM A473-420

IMPELLER

DIFFS

OTHER

37

(°C)

A276-410

SHAFT

34

42

-29

CASE / IMPELLER WEAR RINGS

31

39

S-6

REDUCED HARDNESS MATERIALS REQ'D. (5.12.1.12)

29 SITE DATA (5.1.30)

38

(5.12.1.9)

MATERIALS

25

28

(ppmw)

H2S CONCENTRATION (6.5.2.4)

24 LOCATION: (5.1.30)

27

(kJ / kg °K)

3000

CHLORIDE CONCENTRATION

HYD. POWER

MAX.

VAPOR PRESS. kPa (Abs.)

INTERMITTENT (STARTS / DAY)

PARALLEL OPERATION REQ'D (5.1.13)

(5.1.5) NORMAL

MIN.

SPECIFIC HEAT,

CONT.

23

FLAMMABLE

VISCOSITY (mPa.s)

20 STARTING CONDITIONS (5.1.4)

22

Boiler Feed Water

LIQUID TYPE OR NAME

14 OTHER

18 DIFF. HEAD

1B

Firebag Project standard FB-G-5616

OPERATING CONDITIONS (5.1.3) @ SG = 0.97

13 CAPACITY, NORMAL

Rev.

Steam Generation

DATA SHEETS (6.1.1)

6

95G-3215

AS BUILT

3 SITE

5

Item No.

DATA SHEET FOR 95G-3215 Project No. DOCUMENT NO.

03-00061A

DS95-A-G3215-1

1B

REV. 1B

SM 23/01/2006

DS-Pump-API 610 10th Ed. Centrifugal Template

REV 0

PROCESS DATA SHEET

SHT 1 OF 5

API 610 10TH EDITION (ISO 13709) CENTRIFUGAL PUMP PROCESS DATA SHEET (SI UNITS)

MR No. Inquiry No. By:

MR95-G-8-1 MR95-G-8-1 C.Yu

Item No.

95G-3215

Date:

31-Jan-08

NOTES

1 2 1.

Pump lube oil shall be Mobil SCH 626 (ISO VG68)

3 4 2.

Motor lubrication shall be Mobil SCH 626 (ISO VG68)

5 6 3.

Seller shall provide casing drains and vents in accordance to the detail below and Suncor Piping Material Class ES on the low point of the pump casing. Seller shall provide a Gate Valve, i.e., Class 300 RF to ASME B16.5, Forged Body w/integral flanges, Bolted Bonned, OS & Y, Solid Wedge, API Trim 8, Integral or Renewable seats, Regular Port, Design to API 602. Seller shall attach a Suncor valve tag number of VGA0315#8.

1B

10

All casing drains shall be terminated at one common skid edge flanged connection. All casing vents shall be terminated at one

1B

11

common skid edge flanged connection. Each casing drain and vent line shall have provision for individual isolation valve.

1B

7 8 9

12

CASING DRAIN AND VENT DETAILS

13 14 15 16 17

Pump Casing

18

Nipple shall be combined with other casing drain and vent lines (as applicable), and extended to the edge of baseplate, terminated in a common skid connection

Gussets in 2 planes shall be of the same metallurgy as pump casing, 90° apart.

19 20

1B

21 22 23 24 25

1B

26

VGA-0315#8

27 28 29 30

S.W.

31

Gaskets shall be spiral wound 316SS graphite filled, c/w CS outer ring per ASME 16.20

32

S.W.

33 34

Valves shall be tagged with metal tags stamped with Suncor valve number. The metal tags shall be stainless steel, minimum size 18mm x 50mm and shall be attached to valves with minimum 20 gauge strand SS wire.

35 36 37 38 4.

NPSHR at normal flow of 545 m3/h is 2.0 m. The NPSHA shown is based on the normal temperature of 85°C.

1B

39 40 5.

Baseplate for pump and motor shall be engineered and designed for non-grout construction. However, grout holes shall be

41

provided.

42 43 6.

Content for this Data Sheet is based on Suncor Firebag Stage 3 Data Sheet DS93-A-G3215-1 Rev 1D

1B

This pump 95G-3215 is identical to Stage 3 Pump 93G-3215.

1B

44 45 7. 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64

SM 23/01/2006

FOR:

Suncor Energy

LOCATION:

Firebag Stage 5, Fort McMurray, Alberta

SERVICE:

LP BFW Pump

EQUIPMENT NO.

95G-3215

DS-Pump-API 610 10th Ed. Centrifugal Template

Project No. DOCUMENT NO.

03-00061A

DS95-A-G3215-1 REV 0

PROCESS DATA SHEET

1B

REV. 1B SHT 2 OF 5