An Introduction To Directional Drilling 2x5a58

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 2z6p3t

Overview 5o1f4z

& View An Introduction To Directional Drilling as PDF for free.

More details 6z3438

- Words: 4,246

- Pages: 86

Directional Drilling presentation

١

In the name of Allah An Introduction to Directional Drilling (Advanced Drilling Engineering course)

Instructor: Dr. Tabatabaei nejad Lecturer: Mojtaba Owrangi - 87333102 Master of Petroleum Drilling & Production engineering Sahand University of Technology

Introduction 1. 2. 3. 4. 5. 6. 7.

Definition & Reasons for D.D Reference Systems and Coordinates Types of Directional well trajectories Calculation of a well trajectory Directional Drilling Measurements Deflection Tools Principles of BHA Directional Drilling presentation

٣

Definition & Reasons for D.D z Definition : z

The science of directing a well bore along a predetermined trajectory to intersect a designated subsurface target.

z Kick off point (KOP): z

The kick off point is defined as the point below surface location where the well is deflected from the vertical.

z Target: Target z

A predetermined point in the reservoir that D.D should reaches to it. Directional Drilling presentation

٤

Well classification Vertical Well

Wells with less than 10º deviation

High Inclination Well Horizontal Well

Wells between 60 and 85º deviation

Extended Reach Well Designer Well

Horizontal/TVD displacement greater than 2.5

Wells with more than 85º deviation

Wells with significant turn in the horizontal plane of 30 to 180 degrees, and turn not restricted by inclination

Directional Drilling presentation

٥

Directional wells Radius Classification

Build Rate ( degrees/30 meter )

Radius (meter)

Long Radius

1- 6

1719 – 286

Medium Radius

7 – 30

285 – 57

Intermediate Radius

30 - 70

56 – 24

Short Radius

71 - 150

23 - 11.5

Directional Drilling presentation

٦

Reasons for D.D

1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12.

Side-tracking existing well (because of hole problems or fish or reaching new targets) Restricted surface locations (inaccessible locations) To reach multiple targets To reduce number of offshore platforms Horizontal Drilling To reach thin reservoirs (using horizontal wells) Salt dome drilling (directing the well from the salt dome to avoid casing collapse problems) To avoid gas or water coning For intersecting fractures Relief wells For controlling vertical wells Shoreline drilling

Directional Drilling presentation

٧

D.D applications

Directional Drilling presentation

٨

D.D applications (multiple targets)

Directional Drilling presentation

٩

D.D applications (relief well)

Directional Drilling presentation

١٠

D.D applications (side-tracking)

Directional Drilling presentation

١١

D.D applications (inaccessible locations)

Directional Drilling presentation

١٢

D.D applications (shoreline drilling)

Directional Drilling presentation

١٣

D.D applications (salt dome drilling)

Directional Drilling presentation

١٤

D.D applications (fault drilling)

Directional Drilling presentation

١٥

D.D applications (horizontal well)

Directional Drilling presentation

١٦

Horizontal well z

z

Horizontal wells z

The Incl. reaches to 90° through reservoir section : ﺑﻴﺸﺘﺮﻳﻦ ﻛﺎرﺑﺮد در اﻓﺰاﻳﺶ ﺑﻬﺮه ﺑﺮداري و در ﻣﺨﺎزن ﺧﺎص ﻣﺜﻞz

z

Fracture Limestone & Low permeability zone

Horizontal drain holes: ﻓﻮﺗﻲ30 ﺧﺎص ﺑﺮاي اﻳﺠﺎد زاوﻳﻪ ﺧﻴﻠﻲ ﺳﺮﻳﻊ و در ﻳﻚ ﺷﻌﺎعBHA

z

2° per ft Deep Kickoff and Build :ﺷﺒﻴﻪ ﻧﻮع

z

Directional Drilling presentation

z

١٧

Drilling Fluid Selection z

Virtually all of the considerations for choosing a fluid for drilling a vertical hole apply to choosing a fluid for a directional hole: z z z z z z z

Formation protection Hole cleaning Lubricity Inhibition Fluid weight required Economics Environmental impact

Directional Drilling presentation

١٨

Reference Systems and Coordinates z

Depth references z

Measured Depth (MD) Pipe tally, wire line depth counter, or mud loggers depth counter True Vertical Depth (TVD) calculated from the deviation survey data z

z

z

z

Inclination references z

is the angle (in degrees) between the vertical and the well bore axis at a particular point.

Directional Drilling presentation

١٩

TVD & MD

Directional Drilling presentation

٢٠

Reference Systems and Coordinates

Directional Drilling presentation

٢١

Reference Systems and Coordinates z

Azimuth references z z z

z

Magnetic North (measured by MWD) True (Geographic) North Grid North

Horizontal departure or displacement •

Horizontal distance between rig location & the target.

Note:

True north = magnetic north ± (declination) Directional Drilling presentation

٢٢

Reference Systems and Coordinates

Directional Drilling presentation

٢٣

Reference Systems and Coordinates

Directional Drilling presentation

٢٤

Types of Directional well trajectories

1. 2. 3. 4. 5.

Build and hold Build-hole-drop (S type) Build-hold-drop-hold (modified S type) Continuous build Deep Kickoff and Build

Directional Drilling presentation

٢٥

Types of Directional well trajectories

Directional Drilling presentation

٢٦

Build and hold z

Features: z z z z z z

z

Shallow kick-off point (KOP) Build-up section Tangent section Penetrate target at an angle equal to the Max buildup angle No major changes in incl. & azimuth After build up section Incl: 15 – 55 deg or may be more

Applications: z z

Deep wells with large horizontal displacements Moderately deep wells with moderate horizontal displacement, where intermediate casing is not required

Directional Drilling presentation

٢٧

Build-hole-drop (S type) & Build-hold-drop-hold (modified S type)

Modified S type

S type

Directional Drilling presentation

٢٨

Build-hole-drop (S type) & Build-hold-drop-hold (modified S type)

z

z

Features: z z z z

Shallow KOP Build-up section Tangent section Drop-off section

Applications: z z z z

z

There are several variations: z z z

Build, hold &drop back to vertical (illustrated above) Build, hold, drop & hold (illustrated above) Build, hold & continuous drop through reservoir

z

z

Multiple pay zones Reduces final angle in reservoir Lease or target limitations Well spacing requirements Deep wells with small horizontal displacements

Disadvantages: z z z

Increased torque & drag Risk of key seating Logging problems due to inclination

Directional Drilling presentation

٢٩

Continuous build z

Features: z z z

Decrease in torque & drag Lowest risk of key seating Continuous build rate

KOP

Build Section

z

Applications: z

This type occurs when using down-hole motors with bent sub.

Directional Drilling presentation

Target

٣٠

Deep Kickoff and Build z

Features: z z z

z

Applications: z z z

z

Deep KOP Build-up section Short tangent section (optional)

Salt dome drilling Sidetracking Appraisal wells to assess the extent of a newly discovered reservoir

Disadvantages: z

z

z z

Formations are harder so the initial deflection may be more difficult to achieve Harder to achieve desired tool face orientation with down hole motor deflection assemblies (more reactive torque) Longer trip time for any BHA changes required Build up rate is more difficult to control

Directional Drilling presentation

٣١

Calculation of a well trajectory (build-hold where X3 < r1) z

Radius of curvature: 180 r1 =

π

×

1 q

q= build rate (deg/100 ft) z

Maximum inclination angle, ɵ, when X3

⎤ ⎛ r − X3 ⎞ ⎟⎟ ⎥ − arc tan ⎜⎜ 1 ⎢⎣ ( r1 − X 3 ) 2 + ( D 3 − D1 ) 2 ⎥⎦ ⎝ D 3 − D1 ⎠

θ = arc sin ⎢

z

z

r1

The length of arc, section DC: π θ L DC = × r1 × θ Or LDC = q 180 Horizontal departure at the end of build section:

X 2 = r1 (1 − cos θ ) Directional Drilling presentation

٣٢

Calculation of a well trajectory (build-hold where X3 < r1) z

The total measured depth:

D M = D1 + z

θ q

+

r1 tan Ω

TVD at the end of build section:

D 2 = D 1 + r1 ⋅ sin θ z

Measured depth at section: =

z

′ cos θ

′ = ( D′ − D1 − r1 ⋅ sinθ )

Another way of expressing maximum inclination angle, in term of r1, D1, D3 and X3 for X3

(

r1 D 3 − D1

)× sin ⎡⎢arc ⎣

⎛ D − D1 ⎞ ⎤ ⎫⎪ ⎟⎟ ⎥ ⎬ tan ⎜⎜ 3 r X − 3 ⎠⎦ ⎪ ⎝ 1 ⎭ Directional Drilling presentation

٣٣

Calculation of a well trajectory (build-hold where X3 > r1) z

The maximum inclination angle, ɵ can be calculated by: ⎛ D 3 − D1 ⎞ ⎟⎟ − θ = 180 − arc tan ⎜⎜ ⎝ X 3 − r1 ⎠

⎧⎪ ⎛ ⎡ ⎞ ⎛ D 3 − D1 r1 ⎟⎟ × sin ⎢ arc tan ⎜⎜ arc cos ⎨ ⎜⎜ ⎪⎩ ⎝ D 3 − D1 ⎠ ⎝ X 3 − r1 ⎣

Directional Drilling presentation

⎞ ⎤ ⎫⎪ ⎟⎟ ⎥ ⎬ ⎠ ⎦ ⎪⎭

٣٤

Calculation of a well trajectory (S type) r1<X3 & r1+r2<X4

θ = arc tan( ⎧⎪ arc cos⎨ ⎪⎩

(

D4 − D1 )− r1 + r2 − X 4

r1 + r2 D 4 − D1

⎛

D −D

⎞

4 1 ⎟⎟ − θ = 180 − arc tan⎜⎜ X r r − ( − ) 1 2 ⎠ ⎝ 4

⎡ ⎛ D4 − D1 ⎞⎤ ⎫⎪ ⎟⎟⎥ ⎬ × sin ⎢arc tan⎜⎜ r r X + − 4 ⎠⎦ ⎪ ⎝ 1 2 ⎣ ⎭

)

r1<X3 & r1+r2>X4

⎧⎪⎛ r + r ⎞ ⎡ ⎛ D4 − D1 ⎞⎤ ⎫⎪ ⎟⎟⎥ ⎬ arc cos⎨⎜⎜ 1 2 ⎟⎟ × sin ⎢arc tan⎜⎜ X r r − ( + ) ⎪⎩⎝ D4 − D1 ⎠ 4 1 2 ⎝ ⎠⎦ ⎪⎭ ⎣

Directional Drilling presentation

٣٥

Example 1- Design of D.D Design a directional well with the following restrictions: ¾ ¾ ¾ ¾

¾

A. B.

Total horizontal departure= 4500 ft True vertical depth (TVD)= 12500 ft Depth of KOP= 2500 ft Rate of build of inclination angle= 1.5 deg/100ft Type 1 well (build-hold)

Determine the maximum hole angle? What is the total measured depth?

Directional Drilling presentation

٣٦

Example 1- Design of D.D

Ans. r1=(180/Л)*(1/q)=(180/Л)*(100/1.5)= 3820 ft Because r1<X3:

z

⎛D −D ⎞

1 ⎟⎟ − θ = 180 − arc tan ⎜⎜ 4 ⎝ X 4 − r1 ⎠

z

⎧⎪⎛ ⎡ ⎞ ⎛ D − D1 ⎞ ⎤ ⎫⎪ r1 ⎟⎟ × sin ⎢ arc tan ⎜⎜ 4 ⎟⎟ ⎥ ⎬ arc cos ⎨⎜⎜ X r − ⎪⎩⎝ D 4 − D1 ⎠ 4 1 ⎝ ⎠ ⎦ ⎪⎭ ⎣

⇒

ɵ=26.29 deg

D1=2500 ft , D3=12500 ft , X3=4500 ft, r1=3820 ft z Total measured depth:

D M = D1 +

θ q

+

r1 tan Ω

DM=2500+1753+9264=13517 ft

Directional Drilling presentation

٣٧

Survey Calculation Methods •

Various procedures have been developed to estimate the well bore trajectory as it is being drilled. Eighteen methods are known for computing surveys, but the 3 most widely used methods are the tangential, angel-averaging and minimum curvature methods.

•

The normal method for determining the well path is to ascertain the coordinates by using some type of surveying instrument to measure the inclination and direction at various depths (stations) and then to calculate the trajectory.

Directional Drilling presentation

٣٨

Survey Calculation Methods Below is a list of the most used methods: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16.

Acceleration method Average angle method Angle-averaging method Backward station method Balanced tangential method Circular arc method Compensated acceleration method Mercury method Minimum curvature method Quadrant method Radius of curvature method Secant method Tangential method Terminal angle method Trapezoidal method Vector averaging method

Directional Drilling presentation

٣٩

Survey Calculation Methods

Directional Drilling presentation

٤٠

Survey Calculation Methods z

Tangential method: method z

z

(Backward station method) or (Terminal angle method)

the tangential method uses only the inclination and direction angles at lower end of the course length. n ⎧ It is inaccurate among other methods: L = L

⎪ n ∑ i i =1 Li = DMi . sin(α i ). cos(ε i ) ⎫ ⎪ n ⎪ ⎪ M i = DMi . sin(α i ). sin(ε i )⎬ ⇒ ⎨M n = ∑ M i i =1 ⎪ ⎪ Di = DMi . cos(α i ) ⎭ ⎪ n Li= latitude north/south ⎪ Dn = ∑ Di Mi= latitude east/west i =1 ⎩ Di= TVD segment αi= inclination angle z

DMi= course length

εi= direction angle

Directional Drilling presentation

٤١

Example 2- tangential method Use the following survey data to determine the trajectory coordinates for tangential method? Measured depth, ft 3000 3300 3600 3900 5000 6000 7000 8000 9000 10000

Hole angle, deg 2 4 8 12 15 16 17 17 17 17

Directional Drilling presentation

Azimuth N 28 E N 10 E N 35 E N 25 E N 30 E N 28 E N 50 E N 20 E N 30 E N 25 E

٤٢

Survey Calculation Methods Average angle Or Angle Averaging Method: •

the angle averaging method is the simple average of the angles at the top and bottom of course length. n ⎧ α i + α i −1 ε i + ε i −1 ⎫ ). cos( ) ⎪ ⎪ Ln = ∑ Li Li = DMi . sin( i =1 2 2 ⎪ ⎪ n α i + α i −1 ε i + ε i −1 ⎪ ⎪ ). sin( ) ⎬ ⇒ ⎨M n = ∑ M i M i = DMi . sin( 2 2 i =1 ⎪ ⎪ n α i + α i −1 ⎪ ⎪ ) Di = DMi . cos( Dn = ∑ Di ⎪ ⎪ 2 ⎭ ⎩ i =1

Directional Drilling presentation

٤٣

Example 3- Average angle method Determine the trajectory coordinates for the corrected survey points given below: Measured depth (ft) 7100 7200 7300 7400 7500

inclination angle (deg) 0 10.1 13.4 16.3 19.6

direction angle 0 S68W S65W S57W S61W

Note: For the first point the direction should not be averaged, it means that at MD= 7200 we use dir. = 248 instead of 124. For the first point the inclination should be averaged, so for MD=7200 the incl. = 5.05. Directional Drilling presentation

٤٤

Survey Calculation Methods Minimum curvature method and Radius of curvature method: The minimum curvature method uses the angles at A1 and A2 and assumes a curved well bore over the course length not a straight line.

Directional Drilling presentation

٤٥

Survey Calculation Methods z

β is in [radian] and if it is less than 0.25

radian, it is reasonable to set F=1.0

⎫ cos β i = cos (α i − α i −1 ) − {sin α i −1 . sin α i (1 − cos (ε i − ε i −1 ))}⎪ ⎪ β ⎪ F = ⎛⎜ 2 ⎞⎟. tan ⎛⎜ i ⎞⎟ ⎪ ⎝ βi ⎠ ⎝ 2⎠ ⎪ ⎪ D Mi ⎞ ⎛ Mi = ⎜ .(sin( α i −1 ). sin (ε i −1 ) + sin α i . sin ε i ).Fi ⎟ ⎬⇒ 2 ⎝ ⎠ ⎪ ⎪ D Li = ⎛⎜ Mi ⎞⎟.(sin( α i −1 ). cos (ε i −1 ) + sin α i . cos ε i ).Fi ⎪ 2⎠ ⎝ ⎪ D ⎪ Di = ⎛⎜ Mi ⎞⎟.(cos( α i −1 ) + cos α i ).Fi ⎪⎭ 2⎠ ⎝

Directional Drilling presentation

n ⎧ ⎪ Ln = ∑ Li i =1 ⎪ n ⎪ ⎨M n = ∑ M i i =1 ⎪ n ⎪ ⎪ D n = ∑ Di i =1 ⎩

٤٦

Comparison of accuracy of various calculation methods Calculation method

Total vertical depth & North displacement & differences from actual (ft) differences from actual (ft)

Tangential

1628.61

-25.38

998.02

+43.09

Balanced tan

1653.61

-0.38

954.72

-0.21

Angle-ave.

1654.18

+0.19

955.04

+0.11

Radius of curvature

1653.99

0.0

954.93

0.0

Minimum curvature

1653.99

0.0

954.93

0.0

Mercury

1653.63

-0.37

954.89

0.04

Directional Drilling presentation

٤٧

Directional Drilling presentation

٤٨

Dogleg Severity z

Large angle changes occurring over a short course length can place high bending stresses on the pipe. In addition, these doglegs can cause key seating problems. Most operators place a limit on the amount of angle change allowable over a 100-ft segment. The limit is 4-6 deg per 100 ft.

100 DL = L[(sin I1 sin I 2 )(sin A1 sin A2 + cos A1 cos A2 ) + cosI1 cosI 2 ] † † † †

DL: dogleg, deg/100ft L: course length I1, I2 : Inclination at upper & lower survey, deg A1, A2 : direction at upper & lower survey, deg

Directional Drilling presentation

٤٩

Directional Drilling Measurements z Magnetic single shot instruments z Magnetic multi shot instruments z Measurement while drilling (MWD) z z z z z

Electromagnetic Acoustic Pressure pulse Pressure pulse modulation Cable & DP

Directional Drilling presentation

٥٠

Directional Drilling Measurements

Directional Sensor Hardware The figure above shows the basic configuration of the Directional Sensor probe. The directional probe is mounted to the MWD assembly and keyed into a Non-Magnetic Drill Collar. The nominal length of the sub is 30 feet. The nonmagnetic collar is usually referred to as Monel.

Directional Drilling presentation

٥١

Directional Drilling Measurements z Records

–inclination –direction –tool face position z on

sensitized paper or photographic film Inclination may be determined by –a float on a liquid –a pendulum Directional Drilling presentation

٥٢

Directional Drilling Measurements (Single shot) z

Procedure: –load film into instrument –activate timer (activate stopwatch) –make up the tool –drop the tool –retrieve tool (wire line or drill pipe)

Directional Drilling presentation

٥٣

Magnetic Multi shot Instruments z

Are capable of taking numerous survey records in one run.

z

May be dropped down the drill pipe or run on wire line in open hole. The unit contains a watch that is spring wound and uses the power of the spring to operate a timer cam.

z

z

z

The multishot tool is usually dropped down the drill pipe and landed in the nonmagnetic drill collar. During the trip out, a survey is taken every 90 ft, i.e. every stand.

More closely spaced stations could be obtained by stopping the pipe more often, and waiting for a picture. z A stopwatch at the surface is synchronized with the instrument watch. z

Directional Drilling presentation

٥٤

Magnetic Multi shot Instruments

Directional Drilling presentation

٥٥

MWD (Measurement While Drilling) z

While drilling it is possible to transmit to the surface down hole information on: Inclination Direction tool-face gamma ray Resistivity

temperature weight on bit angle torque on bit sonic velocity

z

Inclination, direction, and tool-face angle are of particular interest in directional drilling. A lower cost MWD tool can be used if only directional drilling information is required.

z

Information is typically transmitted through the mud column by: +ve or - ve pressure pulses, or pressure pulse modulation Directional Drilling presentation

٥٦

Deflection Tools z

Hole angles are usually kicked off by jetting, whip stocks or some type of bent sub, down hole motor tools.

z

Geology affects the decision as well as the desire to use a steering tool.

Jetting: It was a widely used technique several years ago. It involved the use of a large bit jet and two smaller jets. After washing 6-8 ft rotary was used to drill the rest of the t

1.

Whip stock is a very simple device used to kick off the well.

2.

Separated into 2 categories: i. ii.

Open hole whip stocks Casing whip stocks

Bent subs: are used with down hole motors. The sub has 1/2 -5/2 degree of bend in it that will deflect the motor in the desired direction.

3.

Directional Drilling presentation

٥٧

Deflection tools (Jetting) z

Jetting z

A standard soft formation tricone bit, with one very large nozzle and two smaller ones.

z

Important parameter: z

Geology: z z

z

z

S.S & oolitic limestone (best) Unconsolidated S.S & very soft rock (good) Very soft rocks erode too much (bad) z As a rough rule of thumb, ROP>24m/hr using normal drilling parameters

Hydraulic energy z

A rule of thumb: mud velocity through the large jet should be at least 500 ft/sec.

Directional Drilling presentation

٥٨

Deflection tools (Jetting)

Directional Drilling presentation

٥٩

Advantages & Disadvantages Of Jetting z

Advantages z Same BHA to change trajectory & drilling ahead z Simple and cheap method in soft formations. z Dogleg severity can be partly controlled from surface by varying the number of feet “jetted” each time. z The survey tool is not far behind the bit. z Orientation of tool face is fairly easy

z

Disadvantages z Only works in soft formation and therefore at shallow depths. z high dogleg severities are often produced. Deviation is produced in a series of sudden changes, rather than a smooth continuous change. For this reason, it is normal practice to jet an under gauge hole and then open it out to full gauge, which smoothes off the worst of the doglegs.

Directional Drilling presentation

٦٠

Deflection tools (Whip stock) z 1. 2. 3. 4. 5. 6.

Some movies about D.D: Movie 1 (bottom trip W.S) Movie 2 (section milling) Movie 3 (section milling) Movie 4 (retrieving a W.S) Movie 5 (cement type W.S) Movie 6 (Casing W.S) Directional Drilling presentation

٦١

Deflection tools (Whip stock)

Directional Drilling presentation

٦٢

Deflection tools (Whip stock) z

Whip stocks z

Standard removable Whip stock used to kick off wells Sidetracking Disadvantage If the whip stock is set on the fill, then whip stock rotate when drilling starts Fill tend to wash away, causing the bit to slide down the side of the well bore and entire whip stock assembly to rotate Critical: when bit leaves the end of W. wedge, if the rock too soft & circulation too high, bit can lose curvature and continue straight number of “trips” involved. whip stock produced a sudden, sharp deflection Advantages It is a fairly simple piece of equipment which requires relatively little maintenance and has no temperature limitations. z z

z

z

z

z

z z

z

z

Directional Drilling presentation

٦٣

Deflection tools (Whip stock) • Circulating Whip stock – the drilling mud initially flows through a age to the bottom of the whip stock which permits more efficient cleaning of the bottom of the hole and ensures a clean seat for the tool.

– It is most efficient for washing out bottom hole fills. z

Permanent Casing Whip stock z used where a “window” is to be cut in casing for a sidetrack z advantage z

z

operation usually takes less time.

disadvantage z z

gives a sharp dogleg Casing window is too short. Numerous trips & long hours of rotation can wear or damage the casing, difficult to trip out the BHA through the casing window

Directional Drilling presentation

٦٤

Deflection tools (Whip stock)

Directional Drilling presentation

٦٥

Down hole motors z z

Was developed in 1966, and 2 years later the PDM began to be used in the US PDM & turbine + Bent Sub + Bent Housing or eccentric stabilizers

turbine motor (left) and positive displacement motor (right) designs.

Directional Drilling presentation

٦٦

PDM s vs. Turbines z

PDM: z

z

The directional driller can use pump pressure as a weight indicator longer bit life z

z

because of the slower rotary speed.

Use a small bend at the U-t housing instead of bent sub

z

Turbine: z z

operate at higher temperatures DO NOT have a dump valve.

Directional Drilling presentation

٦٧

Factors Affecting directional behavior of rotary assemblies

z z z z z z z z z

Gauge and placement of stabilizers Diameter and length of drill collars Weight -on-bit Rotary speed Bit type Formation anisotropy and dip angle of the bedding planes Formation hardness Flow rate Rate of penetration Directional Drilling presentation

٦٨

PDM accessories

Directional Drilling presentation

٦٩

PDM accessories

Directional Drilling presentation

٧٠

PDM accessories

Directional Drilling presentation

٧١

PDM accessories

Directional Drilling presentation

٧٢

Turbine accessories

Directional Drilling presentation

٧٣

Principles of BHA (Fulcrum) z

The Fulcrum principle is used to build angle (increase borehole inclination)

z

Full gauge near bit stabilizer, followed by 40 to 120ft DC, before the first string stabilizer, or no string stabilizer

Directional Drilling presentation

٧٤

Principles of BHA (Fulcrum) The rate of build will be INCREASED by the following: • Increasing the distance from the near-bit stabilizer to the first string stabilizer • Increase in hole inclination • Reduction of drill collar diameter • Increase in weight on bit • Reduction in rotary speed • Reduction in flow rate (in soft formations)

Directional Drilling presentation

٧٥

Principles of BHA (Stabilization) z

The Stabilization (Packed Hole) Principle:

hold angle and direction three stabilizers in quick succession behind the bit separated by short, stiff drill collar sections, then the three stabilizers will resist going around a curve and force the bit to drill a reasonably straight path

Directional Drilling presentation

٧٦

Principles of BHA (Stabilization)

Directional Drilling presentation

٧٧

Principles of BHA (Pendulum) Drop angle

Directional Drilling presentation

٧٨

References z z z z z z z z z

“Applied drilling engineering” Adam T.bourgoyne, spe text book,vol 2. “Oil well drilling engineering” H. Rabia, univ. of newcastle,1985. “Advanced directional drilling” drilling services, computalog, Texas. “Drilling engineering” N.J Adams, pennwell books, Tulsa, Oklahoma. “Drilling engineering workbook” baker huges INTEQ,80270H rev. B, Dec 1995. “IADC Drilling manual”, e-book version(11),2000. “Well engineering & construction” Hussein Rabia, e-book version. “Introduction to directional drilling” schlumberger hand out, 1998 “Directional drilling training manual”, schlumberger handbook, 1996

Directional Drilling presentation

٧٩

Attachment- review of 6 calculation methods

Directional Drilling presentation

٨٠

Attachment- review of 6 calculation methods

Directional Drilling presentation

٨١

Attachment- review of 6 calculation methods

Directional Drilling presentation

٨٢

Attachment- review of 6 calculation methods

Directional Drilling presentation

٨٣

Attachment- review of 6 calculation methods

Directional Drilling presentation

٨٤

Attachment- review of 6 calculation methods

Directional Drilling presentation

٨٥

That was all I knew about D.D Thanks for your attention

Directional Drilling presentation

٨٦

١

In the name of Allah An Introduction to Directional Drilling (Advanced Drilling Engineering course)

Instructor: Dr. Tabatabaei nejad Lecturer: Mojtaba Owrangi - 87333102 Master of Petroleum Drilling & Production engineering Sahand University of Technology

Introduction 1. 2. 3. 4. 5. 6. 7.

Definition & Reasons for D.D Reference Systems and Coordinates Types of Directional well trajectories Calculation of a well trajectory Directional Drilling Measurements Deflection Tools Principles of BHA Directional Drilling presentation

٣

Definition & Reasons for D.D z Definition : z

The science of directing a well bore along a predetermined trajectory to intersect a designated subsurface target.

z Kick off point (KOP): z

The kick off point is defined as the point below surface location where the well is deflected from the vertical.

z Target: Target z

A predetermined point in the reservoir that D.D should reaches to it. Directional Drilling presentation

٤

Well classification Vertical Well

Wells with less than 10º deviation

High Inclination Well Horizontal Well

Wells between 60 and 85º deviation

Extended Reach Well Designer Well

Horizontal/TVD displacement greater than 2.5

Wells with more than 85º deviation

Wells with significant turn in the horizontal plane of 30 to 180 degrees, and turn not restricted by inclination

Directional Drilling presentation

٥

Directional wells Radius Classification

Build Rate ( degrees/30 meter )

Radius (meter)

Long Radius

1- 6

1719 – 286

Medium Radius

7 – 30

285 – 57

Intermediate Radius

30 - 70

56 – 24

Short Radius

71 - 150

23 - 11.5

Directional Drilling presentation

٦

Reasons for D.D

1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12.

Side-tracking existing well (because of hole problems or fish or reaching new targets) Restricted surface locations (inaccessible locations) To reach multiple targets To reduce number of offshore platforms Horizontal Drilling To reach thin reservoirs (using horizontal wells) Salt dome drilling (directing the well from the salt dome to avoid casing collapse problems) To avoid gas or water coning For intersecting fractures Relief wells For controlling vertical wells Shoreline drilling

Directional Drilling presentation

٧

D.D applications

Directional Drilling presentation

٨

D.D applications (multiple targets)

Directional Drilling presentation

٩

D.D applications (relief well)

Directional Drilling presentation

١٠

D.D applications (side-tracking)

Directional Drilling presentation

١١

D.D applications (inaccessible locations)

Directional Drilling presentation

١٢

D.D applications (shoreline drilling)

Directional Drilling presentation

١٣

D.D applications (salt dome drilling)

Directional Drilling presentation

١٤

D.D applications (fault drilling)

Directional Drilling presentation

١٥

D.D applications (horizontal well)

Directional Drilling presentation

١٦

Horizontal well z

z

Horizontal wells z

The Incl. reaches to 90° through reservoir section : ﺑﻴﺸﺘﺮﻳﻦ ﻛﺎرﺑﺮد در اﻓﺰاﻳﺶ ﺑﻬﺮه ﺑﺮداري و در ﻣﺨﺎزن ﺧﺎص ﻣﺜﻞz

z

Fracture Limestone & Low permeability zone

Horizontal drain holes: ﻓﻮﺗﻲ30 ﺧﺎص ﺑﺮاي اﻳﺠﺎد زاوﻳﻪ ﺧﻴﻠﻲ ﺳﺮﻳﻊ و در ﻳﻚ ﺷﻌﺎعBHA

z

2° per ft Deep Kickoff and Build :ﺷﺒﻴﻪ ﻧﻮع

z

Directional Drilling presentation

z

١٧

Drilling Fluid Selection z

Virtually all of the considerations for choosing a fluid for drilling a vertical hole apply to choosing a fluid for a directional hole: z z z z z z z

Formation protection Hole cleaning Lubricity Inhibition Fluid weight required Economics Environmental impact

Directional Drilling presentation

١٨

Reference Systems and Coordinates z

Depth references z

Measured Depth (MD) Pipe tally, wire line depth counter, or mud loggers depth counter True Vertical Depth (TVD) calculated from the deviation survey data z

z

z

z

Inclination references z

is the angle (in degrees) between the vertical and the well bore axis at a particular point.

Directional Drilling presentation

١٩

TVD & MD

Directional Drilling presentation

٢٠

Reference Systems and Coordinates

Directional Drilling presentation

٢١

Reference Systems and Coordinates z

Azimuth references z z z

z

Magnetic North (measured by MWD) True (Geographic) North Grid North

Horizontal departure or displacement •

Horizontal distance between rig location & the target.

Note:

True north = magnetic north ± (declination) Directional Drilling presentation

٢٢

Reference Systems and Coordinates

Directional Drilling presentation

٢٣

Reference Systems and Coordinates

Directional Drilling presentation

٢٤

Types of Directional well trajectories

1. 2. 3. 4. 5.

Build and hold Build-hole-drop (S type) Build-hold-drop-hold (modified S type) Continuous build Deep Kickoff and Build

Directional Drilling presentation

٢٥

Types of Directional well trajectories

Directional Drilling presentation

٢٦

Build and hold z

Features: z z z z z z

z

Shallow kick-off point (KOP) Build-up section Tangent section Penetrate target at an angle equal to the Max buildup angle No major changes in incl. & azimuth After build up section Incl: 15 – 55 deg or may be more

Applications: z z

Deep wells with large horizontal displacements Moderately deep wells with moderate horizontal displacement, where intermediate casing is not required

Directional Drilling presentation

٢٧

Build-hole-drop (S type) & Build-hold-drop-hold (modified S type)

Modified S type

S type

Directional Drilling presentation

٢٨

Build-hole-drop (S type) & Build-hold-drop-hold (modified S type)

z

z

Features: z z z z

Shallow KOP Build-up section Tangent section Drop-off section

Applications: z z z z

z

There are several variations: z z z

Build, hold &drop back to vertical (illustrated above) Build, hold, drop & hold (illustrated above) Build, hold & continuous drop through reservoir

z

z

Multiple pay zones Reduces final angle in reservoir Lease or target limitations Well spacing requirements Deep wells with small horizontal displacements

Disadvantages: z z z

Increased torque & drag Risk of key seating Logging problems due to inclination

Directional Drilling presentation

٢٩

Continuous build z

Features: z z z

Decrease in torque & drag Lowest risk of key seating Continuous build rate

KOP

Build Section

z

Applications: z

This type occurs when using down-hole motors with bent sub.

Directional Drilling presentation

Target

٣٠

Deep Kickoff and Build z

Features: z z z

z

Applications: z z z

z

Deep KOP Build-up section Short tangent section (optional)

Salt dome drilling Sidetracking Appraisal wells to assess the extent of a newly discovered reservoir

Disadvantages: z

z

z z

Formations are harder so the initial deflection may be more difficult to achieve Harder to achieve desired tool face orientation with down hole motor deflection assemblies (more reactive torque) Longer trip time for any BHA changes required Build up rate is more difficult to control

Directional Drilling presentation

٣١

Calculation of a well trajectory (build-hold where X3 < r1) z

Radius of curvature: 180 r1 =

π

×

1 q

q= build rate (deg/100 ft) z

Maximum inclination angle, ɵ, when X3

⎤ ⎛ r − X3 ⎞ ⎟⎟ ⎥ − arc tan ⎜⎜ 1 ⎢⎣ ( r1 − X 3 ) 2 + ( D 3 − D1 ) 2 ⎥⎦ ⎝ D 3 − D1 ⎠

θ = arc sin ⎢

z

z

r1

The length of arc, section DC: π θ L DC = × r1 × θ Or LDC = q 180 Horizontal departure at the end of build section:

X 2 = r1 (1 − cos θ ) Directional Drilling presentation

٣٢

Calculation of a well trajectory (build-hold where X3 < r1) z

The total measured depth:

D M = D1 + z

θ q

+

r1 tan Ω

TVD at the end of build section:

D 2 = D 1 + r1 ⋅ sin θ z

Measured depth at section: =

z

′ cos θ

′ = ( D′ − D1 − r1 ⋅ sinθ )

Another way of expressing maximum inclination angle, in term of r1, D1, D3 and X3 for X3

(

r1 D 3 − D1

)× sin ⎡⎢arc ⎣

⎛ D − D1 ⎞ ⎤ ⎫⎪ ⎟⎟ ⎥ ⎬ tan ⎜⎜ 3 r X − 3 ⎠⎦ ⎪ ⎝ 1 ⎭ Directional Drilling presentation

٣٣

Calculation of a well trajectory (build-hold where X3 > r1) z

The maximum inclination angle, ɵ can be calculated by: ⎛ D 3 − D1 ⎞ ⎟⎟ − θ = 180 − arc tan ⎜⎜ ⎝ X 3 − r1 ⎠

⎧⎪ ⎛ ⎡ ⎞ ⎛ D 3 − D1 r1 ⎟⎟ × sin ⎢ arc tan ⎜⎜ arc cos ⎨ ⎜⎜ ⎪⎩ ⎝ D 3 − D1 ⎠ ⎝ X 3 − r1 ⎣

Directional Drilling presentation

⎞ ⎤ ⎫⎪ ⎟⎟ ⎥ ⎬ ⎠ ⎦ ⎪⎭

٣٤

Calculation of a well trajectory (S type) r1<X3 & r1+r2<X4

θ = arc tan( ⎧⎪ arc cos⎨ ⎪⎩

(

D4 − D1 )− r1 + r2 − X 4

r1 + r2 D 4 − D1

⎛

D −D

⎞

4 1 ⎟⎟ − θ = 180 − arc tan⎜⎜ X r r − ( − ) 1 2 ⎠ ⎝ 4

⎡ ⎛ D4 − D1 ⎞⎤ ⎫⎪ ⎟⎟⎥ ⎬ × sin ⎢arc tan⎜⎜ r r X + − 4 ⎠⎦ ⎪ ⎝ 1 2 ⎣ ⎭

)

r1<X3 & r1+r2>X4

⎧⎪⎛ r + r ⎞ ⎡ ⎛ D4 − D1 ⎞⎤ ⎫⎪ ⎟⎟⎥ ⎬ arc cos⎨⎜⎜ 1 2 ⎟⎟ × sin ⎢arc tan⎜⎜ X r r − ( + ) ⎪⎩⎝ D4 − D1 ⎠ 4 1 2 ⎝ ⎠⎦ ⎪⎭ ⎣

Directional Drilling presentation

٣٥

Example 1- Design of D.D Design a directional well with the following restrictions: ¾ ¾ ¾ ¾

¾

A. B.

Total horizontal departure= 4500 ft True vertical depth (TVD)= 12500 ft Depth of KOP= 2500 ft Rate of build of inclination angle= 1.5 deg/100ft Type 1 well (build-hold)

Determine the maximum hole angle? What is the total measured depth?

Directional Drilling presentation

٣٦

Example 1- Design of D.D

Ans. r1=(180/Л)*(1/q)=(180/Л)*(100/1.5)= 3820 ft Because r1<X3:

z

⎛D −D ⎞

1 ⎟⎟ − θ = 180 − arc tan ⎜⎜ 4 ⎝ X 4 − r1 ⎠

z

⎧⎪⎛ ⎡ ⎞ ⎛ D − D1 ⎞ ⎤ ⎫⎪ r1 ⎟⎟ × sin ⎢ arc tan ⎜⎜ 4 ⎟⎟ ⎥ ⎬ arc cos ⎨⎜⎜ X r − ⎪⎩⎝ D 4 − D1 ⎠ 4 1 ⎝ ⎠ ⎦ ⎪⎭ ⎣

⇒

ɵ=26.29 deg

D1=2500 ft , D3=12500 ft , X3=4500 ft, r1=3820 ft z Total measured depth:

D M = D1 +

θ q

+

r1 tan Ω

DM=2500+1753+9264=13517 ft

Directional Drilling presentation

٣٧

Survey Calculation Methods •

Various procedures have been developed to estimate the well bore trajectory as it is being drilled. Eighteen methods are known for computing surveys, but the 3 most widely used methods are the tangential, angel-averaging and minimum curvature methods.

•

The normal method for determining the well path is to ascertain the coordinates by using some type of surveying instrument to measure the inclination and direction at various depths (stations) and then to calculate the trajectory.

Directional Drilling presentation

٣٨

Survey Calculation Methods Below is a list of the most used methods: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16.

Acceleration method Average angle method Angle-averaging method Backward station method Balanced tangential method Circular arc method Compensated acceleration method Mercury method Minimum curvature method Quadrant method Radius of curvature method Secant method Tangential method Terminal angle method Trapezoidal method Vector averaging method

Directional Drilling presentation

٣٩

Survey Calculation Methods

Directional Drilling presentation

٤٠

Survey Calculation Methods z

Tangential method: method z

z

(Backward station method) or (Terminal angle method)

the tangential method uses only the inclination and direction angles at lower end of the course length. n ⎧ It is inaccurate among other methods: L = L

⎪ n ∑ i i =1 Li = DMi . sin(α i ). cos(ε i ) ⎫ ⎪ n ⎪ ⎪ M i = DMi . sin(α i ). sin(ε i )⎬ ⇒ ⎨M n = ∑ M i i =1 ⎪ ⎪ Di = DMi . cos(α i ) ⎭ ⎪ n Li= latitude north/south ⎪ Dn = ∑ Di Mi= latitude east/west i =1 ⎩ Di= TVD segment αi= inclination angle z

DMi= course length

εi= direction angle

Directional Drilling presentation

٤١

Example 2- tangential method Use the following survey data to determine the trajectory coordinates for tangential method? Measured depth, ft 3000 3300 3600 3900 5000 6000 7000 8000 9000 10000

Hole angle, deg 2 4 8 12 15 16 17 17 17 17

Directional Drilling presentation

Azimuth N 28 E N 10 E N 35 E N 25 E N 30 E N 28 E N 50 E N 20 E N 30 E N 25 E

٤٢

Survey Calculation Methods Average angle Or Angle Averaging Method: •

the angle averaging method is the simple average of the angles at the top and bottom of course length. n ⎧ α i + α i −1 ε i + ε i −1 ⎫ ). cos( ) ⎪ ⎪ Ln = ∑ Li Li = DMi . sin( i =1 2 2 ⎪ ⎪ n α i + α i −1 ε i + ε i −1 ⎪ ⎪ ). sin( ) ⎬ ⇒ ⎨M n = ∑ M i M i = DMi . sin( 2 2 i =1 ⎪ ⎪ n α i + α i −1 ⎪ ⎪ ) Di = DMi . cos( Dn = ∑ Di ⎪ ⎪ 2 ⎭ ⎩ i =1

Directional Drilling presentation

٤٣

Example 3- Average angle method Determine the trajectory coordinates for the corrected survey points given below: Measured depth (ft) 7100 7200 7300 7400 7500

inclination angle (deg) 0 10.1 13.4 16.3 19.6

direction angle 0 S68W S65W S57W S61W

Note: For the first point the direction should not be averaged, it means that at MD= 7200 we use dir. = 248 instead of 124. For the first point the inclination should be averaged, so for MD=7200 the incl. = 5.05. Directional Drilling presentation

٤٤

Survey Calculation Methods Minimum curvature method and Radius of curvature method: The minimum curvature method uses the angles at A1 and A2 and assumes a curved well bore over the course length not a straight line.

Directional Drilling presentation

٤٥

Survey Calculation Methods z

β is in [radian] and if it is less than 0.25

radian, it is reasonable to set F=1.0

⎫ cos β i = cos (α i − α i −1 ) − {sin α i −1 . sin α i (1 − cos (ε i − ε i −1 ))}⎪ ⎪ β ⎪ F = ⎛⎜ 2 ⎞⎟. tan ⎛⎜ i ⎞⎟ ⎪ ⎝ βi ⎠ ⎝ 2⎠ ⎪ ⎪ D Mi ⎞ ⎛ Mi = ⎜ .(sin( α i −1 ). sin (ε i −1 ) + sin α i . sin ε i ).Fi ⎟ ⎬⇒ 2 ⎝ ⎠ ⎪ ⎪ D Li = ⎛⎜ Mi ⎞⎟.(sin( α i −1 ). cos (ε i −1 ) + sin α i . cos ε i ).Fi ⎪ 2⎠ ⎝ ⎪ D ⎪ Di = ⎛⎜ Mi ⎞⎟.(cos( α i −1 ) + cos α i ).Fi ⎪⎭ 2⎠ ⎝

Directional Drilling presentation

n ⎧ ⎪ Ln = ∑ Li i =1 ⎪ n ⎪ ⎨M n = ∑ M i i =1 ⎪ n ⎪ ⎪ D n = ∑ Di i =1 ⎩

٤٦

Comparison of accuracy of various calculation methods Calculation method

Total vertical depth & North displacement & differences from actual (ft) differences from actual (ft)

Tangential

1628.61

-25.38

998.02

+43.09

Balanced tan

1653.61

-0.38

954.72

-0.21

Angle-ave.

1654.18

+0.19

955.04

+0.11

Radius of curvature

1653.99

0.0

954.93

0.0

Minimum curvature

1653.99

0.0

954.93

0.0

Mercury

1653.63

-0.37

954.89

0.04

Directional Drilling presentation

٤٧

Directional Drilling presentation

٤٨

Dogleg Severity z

Large angle changes occurring over a short course length can place high bending stresses on the pipe. In addition, these doglegs can cause key seating problems. Most operators place a limit on the amount of angle change allowable over a 100-ft segment. The limit is 4-6 deg per 100 ft.

100 DL = L[(sin I1 sin I 2 )(sin A1 sin A2 + cos A1 cos A2 ) + cosI1 cosI 2 ] † † † †

DL: dogleg, deg/100ft L: course length I1, I2 : Inclination at upper & lower survey, deg A1, A2 : direction at upper & lower survey, deg

Directional Drilling presentation

٤٩

Directional Drilling Measurements z Magnetic single shot instruments z Magnetic multi shot instruments z Measurement while drilling (MWD) z z z z z

Electromagnetic Acoustic Pressure pulse Pressure pulse modulation Cable & DP

Directional Drilling presentation

٥٠

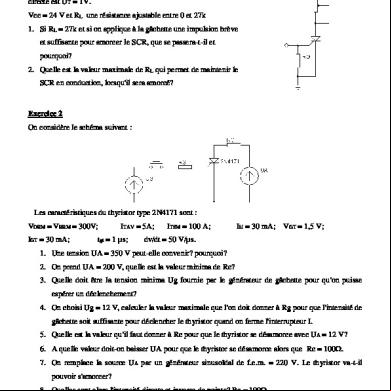

Directional Drilling Measurements

Directional Sensor Hardware The figure above shows the basic configuration of the Directional Sensor probe. The directional probe is mounted to the MWD assembly and keyed into a Non-Magnetic Drill Collar. The nominal length of the sub is 30 feet. The nonmagnetic collar is usually referred to as Monel.

Directional Drilling presentation

٥١

Directional Drilling Measurements z Records

–inclination –direction –tool face position z on

sensitized paper or photographic film Inclination may be determined by –a float on a liquid –a pendulum Directional Drilling presentation

٥٢

Directional Drilling Measurements (Single shot) z

Procedure: –load film into instrument –activate timer (activate stopwatch) –make up the tool –drop the tool –retrieve tool (wire line or drill pipe)

Directional Drilling presentation

٥٣

Magnetic Multi shot Instruments z

Are capable of taking numerous survey records in one run.

z

May be dropped down the drill pipe or run on wire line in open hole. The unit contains a watch that is spring wound and uses the power of the spring to operate a timer cam.

z

z

z

The multishot tool is usually dropped down the drill pipe and landed in the nonmagnetic drill collar. During the trip out, a survey is taken every 90 ft, i.e. every stand.

More closely spaced stations could be obtained by stopping the pipe more often, and waiting for a picture. z A stopwatch at the surface is synchronized with the instrument watch. z

Directional Drilling presentation

٥٤

Magnetic Multi shot Instruments

Directional Drilling presentation

٥٥

MWD (Measurement While Drilling) z

While drilling it is possible to transmit to the surface down hole information on: Inclination Direction tool-face gamma ray Resistivity

temperature weight on bit angle torque on bit sonic velocity

z

Inclination, direction, and tool-face angle are of particular interest in directional drilling. A lower cost MWD tool can be used if only directional drilling information is required.

z

Information is typically transmitted through the mud column by: +ve or - ve pressure pulses, or pressure pulse modulation Directional Drilling presentation

٥٦

Deflection Tools z

Hole angles are usually kicked off by jetting, whip stocks or some type of bent sub, down hole motor tools.

z

Geology affects the decision as well as the desire to use a steering tool.

Jetting: It was a widely used technique several years ago. It involved the use of a large bit jet and two smaller jets. After washing 6-8 ft rotary was used to drill the rest of the t

1.

Whip stock is a very simple device used to kick off the well.

2.

Separated into 2 categories: i. ii.

Open hole whip stocks Casing whip stocks

Bent subs: are used with down hole motors. The sub has 1/2 -5/2 degree of bend in it that will deflect the motor in the desired direction.

3.

Directional Drilling presentation

٥٧

Deflection tools (Jetting) z

Jetting z

A standard soft formation tricone bit, with one very large nozzle and two smaller ones.

z

Important parameter: z

Geology: z z

z

z

S.S & oolitic limestone (best) Unconsolidated S.S & very soft rock (good) Very soft rocks erode too much (bad) z As a rough rule of thumb, ROP>24m/hr using normal drilling parameters

Hydraulic energy z

A rule of thumb: mud velocity through the large jet should be at least 500 ft/sec.

Directional Drilling presentation

٥٨

Deflection tools (Jetting)

Directional Drilling presentation

٥٩

Advantages & Disadvantages Of Jetting z

Advantages z Same BHA to change trajectory & drilling ahead z Simple and cheap method in soft formations. z Dogleg severity can be partly controlled from surface by varying the number of feet “jetted” each time. z The survey tool is not far behind the bit. z Orientation of tool face is fairly easy

z

Disadvantages z Only works in soft formation and therefore at shallow depths. z high dogleg severities are often produced. Deviation is produced in a series of sudden changes, rather than a smooth continuous change. For this reason, it is normal practice to jet an under gauge hole and then open it out to full gauge, which smoothes off the worst of the doglegs.

Directional Drilling presentation

٦٠

Deflection tools (Whip stock) z 1. 2. 3. 4. 5. 6.

Some movies about D.D: Movie 1 (bottom trip W.S) Movie 2 (section milling) Movie 3 (section milling) Movie 4 (retrieving a W.S) Movie 5 (cement type W.S) Movie 6 (Casing W.S) Directional Drilling presentation

٦١

Deflection tools (Whip stock)

Directional Drilling presentation

٦٢

Deflection tools (Whip stock) z

Whip stocks z

Standard removable Whip stock used to kick off wells Sidetracking Disadvantage If the whip stock is set on the fill, then whip stock rotate when drilling starts Fill tend to wash away, causing the bit to slide down the side of the well bore and entire whip stock assembly to rotate Critical: when bit leaves the end of W. wedge, if the rock too soft & circulation too high, bit can lose curvature and continue straight number of “trips” involved. whip stock produced a sudden, sharp deflection Advantages It is a fairly simple piece of equipment which requires relatively little maintenance and has no temperature limitations. z z

z

z

z

z

z z

z

z

Directional Drilling presentation

٦٣

Deflection tools (Whip stock) • Circulating Whip stock – the drilling mud initially flows through a age to the bottom of the whip stock which permits more efficient cleaning of the bottom of the hole and ensures a clean seat for the tool.

– It is most efficient for washing out bottom hole fills. z

Permanent Casing Whip stock z used where a “window” is to be cut in casing for a sidetrack z advantage z

z

operation usually takes less time.

disadvantage z z

gives a sharp dogleg Casing window is too short. Numerous trips & long hours of rotation can wear or damage the casing, difficult to trip out the BHA through the casing window

Directional Drilling presentation

٦٤

Deflection tools (Whip stock)

Directional Drilling presentation

٦٥

Down hole motors z z

Was developed in 1966, and 2 years later the PDM began to be used in the US PDM & turbine + Bent Sub + Bent Housing or eccentric stabilizers

turbine motor (left) and positive displacement motor (right) designs.

Directional Drilling presentation

٦٦

PDM s vs. Turbines z

PDM: z

z

The directional driller can use pump pressure as a weight indicator longer bit life z

z

because of the slower rotary speed.

Use a small bend at the U-t housing instead of bent sub

z

Turbine: z z

operate at higher temperatures DO NOT have a dump valve.

Directional Drilling presentation

٦٧

Factors Affecting directional behavior of rotary assemblies

z z z z z z z z z

Gauge and placement of stabilizers Diameter and length of drill collars Weight -on-bit Rotary speed Bit type Formation anisotropy and dip angle of the bedding planes Formation hardness Flow rate Rate of penetration Directional Drilling presentation

٦٨

PDM accessories

Directional Drilling presentation

٦٩

PDM accessories

Directional Drilling presentation

٧٠

PDM accessories

Directional Drilling presentation

٧١

PDM accessories

Directional Drilling presentation

٧٢

Turbine accessories

Directional Drilling presentation

٧٣

Principles of BHA (Fulcrum) z

The Fulcrum principle is used to build angle (increase borehole inclination)

z

Full gauge near bit stabilizer, followed by 40 to 120ft DC, before the first string stabilizer, or no string stabilizer

Directional Drilling presentation

٧٤

Principles of BHA (Fulcrum) The rate of build will be INCREASED by the following: • Increasing the distance from the near-bit stabilizer to the first string stabilizer • Increase in hole inclination • Reduction of drill collar diameter • Increase in weight on bit • Reduction in rotary speed • Reduction in flow rate (in soft formations)

Directional Drilling presentation

٧٥

Principles of BHA (Stabilization) z

The Stabilization (Packed Hole) Principle:

hold angle and direction three stabilizers in quick succession behind the bit separated by short, stiff drill collar sections, then the three stabilizers will resist going around a curve and force the bit to drill a reasonably straight path

Directional Drilling presentation

٧٦

Principles of BHA (Stabilization)

Directional Drilling presentation

٧٧

Principles of BHA (Pendulum) Drop angle

Directional Drilling presentation

٧٨

References z z z z z z z z z

“Applied drilling engineering” Adam T.bourgoyne, spe text book,vol 2. “Oil well drilling engineering” H. Rabia, univ. of newcastle,1985. “Advanced directional drilling” drilling services, computalog, Texas. “Drilling engineering” N.J Adams, pennwell books, Tulsa, Oklahoma. “Drilling engineering workbook” baker huges INTEQ,80270H rev. B, Dec 1995. “IADC Drilling manual”, e-book version(11),2000. “Well engineering & construction” Hussein Rabia, e-book version. “Introduction to directional drilling” schlumberger hand out, 1998 “Directional drilling training manual”, schlumberger handbook, 1996

Directional Drilling presentation

٧٩

Attachment- review of 6 calculation methods

Directional Drilling presentation

٨٠

Attachment- review of 6 calculation methods

Directional Drilling presentation

٨١

Attachment- review of 6 calculation methods

Directional Drilling presentation

٨٢

Attachment- review of 6 calculation methods

Directional Drilling presentation

٨٣

Attachment- review of 6 calculation methods

Directional Drilling presentation

٨٤

Attachment- review of 6 calculation methods

Directional Drilling presentation

٨٥

That was all I knew about D.D Thanks for your attention

Directional Drilling presentation

٨٦