What Are The Key En Steel Standards 6t6w5i

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 2z6p3t

Overview 5o1f4z

& View What Are The Key En Steel Standards as PDF for free.

More details 6z3438

- Words: 2,506

- Pages: 7

WHAT ARE THE KEY EN STEEL STANDARDS? JUNE 17, 2014 BY DENIS OAKLEY 1 COMMENT

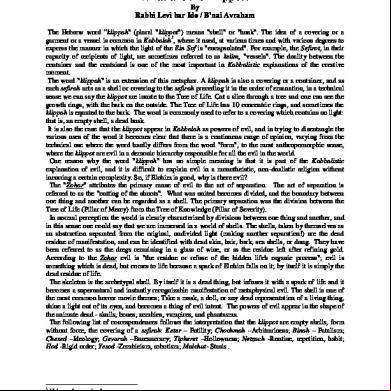

Checking that we are complying with EN Steel Standards

There are a lot of steel standards, there are tens of thousands of steel grades. As a stockist of heavy carbon steel plates these are the 40 key EN steel standards that we tend to use most often. An EN Steel standard is a European standard or euro norm that specifies the requirements for a product or process. Generally EN Steel standards apply when working in the EU, when working for an EU company (directly or indirectly) or when the country doesn’t specify its own standards but instead uses one of the competing suites of standards ASTM, EN, JIS, GOST – or previously BS and DIN. We’ve linked the EN Steel standards back to the BSI website where you can buy these standards. We’ve divided the page into sections about steel grades, general requirements, dimensions and tolerances; and, testing. For each steel standard the first two letters EN denote that it is a European Steel standard, the number after that is the standard number. The next number is the part of the standard. Some standards like EN10025 have multiple parts. Then the next four digits are the date that the latest standard was issued; if a supplementary annex has been issued this will appear next and include the date that the annex was issued.. Finally the standard title – and if relevant the part sub title. If the standard has ISO in its title it is an international standard and may have wide applicability than just the EU. for example EN ISO 9001 is applicable in the US as and ISO standard not as an EN standard. But it is identical. In each section we have ordered the standards by number to make them easy to find. For simplicity if we have never, or very rarely used a EN Steel standard we haven’t included it. Likewise if parts of standards are not of day to day relevance to steel stock-holding or using steel plates then we haven’t included it. Finally we have added OWN for the standards that you should keep in your desk drawer. Each standard costs about $250 to buy so all 40 are a big budget item. We’ve cut that down to 12 that

complement the key steel standards (EN10025, EN10028 and EN10225) that you are likley to be using most often. The links on the standards take you to the BSI website where you can check out more details or buy them if required EN STEEL STANDARDS COVERING KEY STEEL GRADES

This selection of steel standards covers the major steel grades found at heavy steel plate stockholders STRUCTURAL STEEL STANDARDS

EN 10025-1:2004. Hot rolled products of structural steels. General technical delivery conditions This standard covers the common requirements for all types of structural steel plate. Whilst critical in many ways to the manufacturers of steel plates the really useful information about the different structural steel grades is found in the different parts OWN EN 10025-2:2004. Hot rolled products of structural steels. Technical delivery conditions for non-alloy structural steels Most structural steels for normal use are made to this standard. They are standard carbon steels with no alloying at all. These include S235JR, S235J0, S235J2, S235+N, S275JR, S275J0, S275J2, S355JR, S355J0, S355J2+N and S355K2+N and S450J0. OWN if you use the grade EN 10025-3:2004. Hot rolled products of structural steels. Technical delivery conditions for normalized/normalized rolled weldable fine grain structural steels These steels have much smaller grains than the standard structural steels making them somewhat stronger. These include S275N, S275NL, S355N, S355NL, S420N, S420NL, S460N and S460NL OWN if you use the grade EN 10025-4:2004. Hot rolled products of structural steels. Technical delivery conditions for thermomechanical rolled weldable fine grain structural steels The rolling of Thermomechanical or TM steels is quite specialized and has to be done withing certain temperature ranges in order to achieve specific steel characteristics. These include S275M, S275ML, S355M and S355ML, S420M, S420ML, S460M and S460ML TM steels as well as the Dillinger brand DI-MC 355B and 355T steels OWN if you use the grade EN 10025-5:2004. Hot rolled products of structural steels. Technical delivery conditions for structural steels with improved atmospheric corrosion resistance This covers all the wear resistant steels with their nice brown oxide surfaces that are great for bridge superstructures etc. We don’t stock any of these grades. S235J0W, S235J2W, S355J0WP, S355J2WP, S355J0W, S355J2W and S355K2W. OWN if you use the grade

EN 10025-6:2004+A1:2009. Hot rolled products of structural steels. Technical delivery conditions for flat products of high yield strength structural steels in the quenched and tempered condition These are the steels with a high yield strength and include S460Q, S460QL, S460QL1, S500Q, S500QL, S500QL1, S550Q, S550QL, S550QL1, S620Q, S620QL, S620QL1, S690Q, S690QL, S690QL1 , S890Q, S890QL1, S960Q, S960QL, S965 and S1100 as well as the Dillimax branded steels from Dillinger: Dillimax 690T, Dillimax 690E, Dillimax 890T, Dillimax 965T and Dillimax 1100. OWN if you use the grade PRESSURE VESSEL STEEL STANDARDS

BS EN 10028-1:2007+A1:2009. Flat products made of steels for pressure purposes. General requirements This standard covers the common requirements for all types of pressure vessel steel plate. Whilst critical in many ways to the manufacturers of steel plates the really useful information about the different boiler quality steel grades is found in the different parts OWN if you use the grade BS EN 10028-2:2009. Flat products made of steels for pressure purposes. Non-alloy and alloy steels with specified elevated temperature properties This covers pressure vessel steels for use in hot places – or elevated temperatures as the standard calls it. They’re divided into two groups. The alloyed has nickel, chromium and molybdenum to improve their corrosion and heat resistant properties. The unalloyed steels don’t. These include P235GH, P265GH, P295GH and P355GH unalloyed PV steels. Im the alloyed section you get 16Mo3, 18MnMo4-5, 20MnMoNi4-5, 15NiCuMoNb5-6-4, 13CrMo 4-5, 13CrMoSi5-5, 10CrMo 9-10, 12CrMo9-10, X12CrMo5, X12CrMo5, 12CrMoV1210, X10CrMoVNb9-1 and 12CrMo 1.5. OWN if you use the grade BS EN 10028-3:2009. Flat products made of steels for pressure purposes. Weldable fine grain steels, normalized These are the boiler quality steels for low temperature and the equivalents of the ASTM and ASME A516 grades 60 and 70. We have P275NH, P275NL1, P275NH, P355N, P355NH, P355NL1, P355NL2, P460NH, P460NL1 and P460NL2. OWN if you use the grade BS EN 10028-4:2009. Flat products made of steels for pressure purposes. Nickel alloy steels with specified low temperature properties We don’t stock these – but they include 11MnNi5-3, 13MnNi63, 15NiMn6, 12Ni14, X12Ni5, X8Ni9 and X7Ni9. BS EN 10028-5:2009. Flat products made of steels for pressure purposes. Weldable fine grain steels, thermomechanically rolled TM plates for pressure vessels. These include P355M, P355ML1, P355ML2, P420M, P420Ml1, P420ML2, P460M, P460Ml1 and P460ML2. We don;t stock these BS EN 10028-6:2009. Flat products made of steels for pressure purposes. Weldable fine grain steels, quenched and tempered

These are the quenched and tempered pressure vessel steels with a range of Q, QH, QL1 and QL2 after the normal P designation and the yield strength. So P355Q, P355QH, P355QL1 and P355QL2. Etc. We don’t stock any of these. BS EN 10028-7:2007. Flat products made of steels for pressure purposes. Stainless steels A total mystery to me as we only deal with carbon steels. These are all stainless and are included for completeness. X2CrNi12, X6CrNiTi12, X2CrTi17, X3CrTi17, X2CrMoTi17-1, X2CrMoTi18-2, X6CrMoNb171, X2CrTiNb18 OFFSHORE STEEL STANDARDS

EN 10225:2009. Weldable structural steels for fixed offshore structures. Technical delivery conditions This covers plates for fixed and mobile offshore structures and includes both normalised and thermomechanical offshore steels. S355G2+N, S355G3+N, S355G5+M, S355G6+M, S355G7+N, S355G7+M, S355G8+N, S355G 8+M, S355G9+N, S355G10+N, S355G9+M, S355G10+M, S420G1+QT, S420G1+M, S420G2+ QT, S420G2+M, S460G1+QT, S460G1+M, S460G2+QT and S460G2+M OWN if you use the grade GENERAL EN STEEL STANDARDS

BS EN 10020:2000. Definition and classification of grades of steel This is the basis for defining the difference between alloyed and non-alloyed steels, and then the difference between alloyed steels and stainless steels. BS EN 10021:2006. General technical delivery requirements for steel products This is a key standard as it pulls lots of different standards together to integrate how manufacturers of steel plates and purchasers agree on what exactly should be delivered OWN BS EN 10027-1:2005. Designation system for steels. Steel names Steels have names and numbers. This covers how the name of the steel is generated – and thus how you can quickly work out what a steels properties are just from the name. BS EN 10027-2:1992. Designation systems for steels. Steel numbers This covers how steel numbers are defined ad allocated. If you’d ever wondered exactly what 1.8988 is you’ll be able to use the standard to figure out that it is S690QL1 BS EN 10052:1994. Vocabulary of heat treatment for ferrous products This defines 200+ involved in heat treatment of steel (which almost all steels are to some extent. Good for bedtime reading – but valuable when you need to check a term BS EN 10079:2007. Definition of steel products This is another standard full of definitions and it covers what a plate and a coil and section is. All useful stuff but most engineers will only need to know a few definitions in here as it covers ALL steel products from hollow mining drill bars to wire to electrical steel and on to our beloved heavy plates (which actually aren’t defined). BS EN 10168:2004. Steel products. Inspection documents. List of information and description

Whilst EN10204 describes the type of material test certificates that have to accompany steel plates, this describes what has to go into the certificates. So everything that appears on an MTC is specified here – but it doesn’t specify how – so every steel mill does it differently. BS EN 10204:2004. Metallic products. Types of inspection documents This defines the different types of MTC that comes with steel plates. So if you want to know what a 3.1 or a 3.2 certificate is this will tell you – or you can read it on our EN10204 certification page OWN BS EN ISO 9001:2008. Quality management systems. Requirements This defines quality systems and if you are in engineering and don’t have a copy of this you probably have problems with customer complaints. The single most important standard in the world OWN

TOLERANCES AND DIMENSIONS IN EN STEEL STANDARDS BS EN 10029:2010. Hot-rolled steel plates 3 mm thick or above. Tolerances on dimensions and shape This basically says that plates have to be flat, have straight edges and have to be the length and width that you’ve asked for. Without this standard the QA department of most plate buyers would have a lot more work to do both pre and post purchase. OWN BS EN 10163-1:2004. Delivery requirements for surface condition of hot-rolled steel plates, wide flats and sections. General requirements This standard talks about the damage and discontinuities (cracks and pitting) that can appear on the surface of plates and how they can be repaired by grinding and welding. BS EN 10163-2:2004. Delivery requirements for surface condition of hot-rolled steel plates, wide flats and sections. Plate and wide flats EN10163-2 goes into a lot more detail about the different types of discontinuities – imperfections and defects and how these can be repaired for the different types of steel. This s where the meat is for all practical purposes. OWN

EN STEEL STANDARDS FOR TESTING BS EN ISO 6892-1:2009 Metallic materials. Tensile testing. Method of test at ambient temperature Replaces EN 10002-1:2001 This describes how to do tensile testing at room temperature. Normally this is the test lab’s issue – but its good to know exactly what is being done so that you are sure BS EN ISO 6892-2:2011. Metallic materials. Tensile testing. Method of test at elevated temperature Replaces EN 10002-5:1992 And this is how to do tests in the heat. There’s also a draft of how to do tensile tests at low temperatures BS EN ISO 148-1:2010 Metallic materials. Charpy pendulum impact test. Test method Replaces EN 10045-1. This is exactly as it sounds. How to do a charpy V-notch test at the right temperature with the right J values. Critical for many of the plates that we stock. BS EN 10160:1999. Ultrasonic testing of steel flat product of thickness equal or greater than 6 mm (reflection method)

This covers the UT testing of plates looking for internal discontinuities and defining the test patterns and the level of testing S0, S1, S2 and S3 OWN BS EN 10164:2004. Steel products with improved deformation properties perpendicular to the surface of the product. Technical delivery conditions If you are dealing with thick plates this is a key standard as despite it’s name it covers Z35 through thickness testing. OWN BS EN 10229:1998. Evaluation of resistance of steel products to hydrogen induced cracking (HIC) The equivalent of NACE TM0284 in the EN standards world. It describes how to test plate for HIC resistance using Solutions A and B. OWN if you deal with HIC material BS EN ISO 12737:2010. Metallic materials. Determination of plane-strain fracture toughness “This International Standard specifies the ISO method for determining the plane-strain fracture toughness of homogeneous metallic materials using a specimen that is notched and precracked by fatigue, and subjected to slowly increasing crack displacement force.” This is one for the mechanical engineers. PD CEN/TR 10261:2013. Iron and steel. European standards for the determination of chemical composition This is more of a standard for the steel mills and test labs. It describes, with lots of further references, how to establish the chemical composition of the steel for each element. Critical information for the MTC, but no immediately useful for the engineer. BS EN ISO 377:2013. Steel and steel products. Location and preparation of samples and test pieces for mechanical testing This describes how you choose the location and size of test pieces for tests. This can be critical as the steel slabs and plates can vary in their characteristics in statistically predictable ways and if proper sampling is not undertaken then results can be distorted BS EN ISO 643:2012. Steels. Micrographic determination of the apparent grain size Lots of pretty pictures of steel microstructure and grains in order to help analysis. Critical for establishing where steels are fine grain or not. BS EN ISO 2566-1:1999. Steel. Conversion of elongation values. Carbon and low alloy steels When you are tensile testing there are different guages used. Converting between them can be difficult and lead to errors and so this standard ;lays out a specific way of doing it that reduces variation between testers. Not critical but an important building block in the overall schema BS EN ISO 14284:2002. Steel and iron. Sampling and preparation of samples for the determination of chemical composition This covers how you take samples for determining the chemical composition of the steel. Not normally necessary when you have am MTC unless you need to retest. In this case a test lab would normally do this

Read more: http://www.oakleysteel.co.uk/key-en-steel-standards#ixzz4ornZdpiY

Checking that we are complying with EN Steel Standards

There are a lot of steel standards, there are tens of thousands of steel grades. As a stockist of heavy carbon steel plates these are the 40 key EN steel standards that we tend to use most often. An EN Steel standard is a European standard or euro norm that specifies the requirements for a product or process. Generally EN Steel standards apply when working in the EU, when working for an EU company (directly or indirectly) or when the country doesn’t specify its own standards but instead uses one of the competing suites of standards ASTM, EN, JIS, GOST – or previously BS and DIN. We’ve linked the EN Steel standards back to the BSI website where you can buy these standards. We’ve divided the page into sections about steel grades, general requirements, dimensions and tolerances; and, testing. For each steel standard the first two letters EN denote that it is a European Steel standard, the number after that is the standard number. The next number is the part of the standard. Some standards like EN10025 have multiple parts. Then the next four digits are the date that the latest standard was issued; if a supplementary annex has been issued this will appear next and include the date that the annex was issued.. Finally the standard title – and if relevant the part sub title. If the standard has ISO in its title it is an international standard and may have wide applicability than just the EU. for example EN ISO 9001 is applicable in the US as and ISO standard not as an EN standard. But it is identical. In each section we have ordered the standards by number to make them easy to find. For simplicity if we have never, or very rarely used a EN Steel standard we haven’t included it. Likewise if parts of standards are not of day to day relevance to steel stock-holding or using steel plates then we haven’t included it. Finally we have added OWN for the standards that you should keep in your desk drawer. Each standard costs about $250 to buy so all 40 are a big budget item. We’ve cut that down to 12 that

complement the key steel standards (EN10025, EN10028 and EN10225) that you are likley to be using most often. The links on the standards take you to the BSI website where you can check out more details or buy them if required EN STEEL STANDARDS COVERING KEY STEEL GRADES

This selection of steel standards covers the major steel grades found at heavy steel plate stockholders STRUCTURAL STEEL STANDARDS

EN 10025-1:2004. Hot rolled products of structural steels. General technical delivery conditions This standard covers the common requirements for all types of structural steel plate. Whilst critical in many ways to the manufacturers of steel plates the really useful information about the different structural steel grades is found in the different parts OWN EN 10025-2:2004. Hot rolled products of structural steels. Technical delivery conditions for non-alloy structural steels Most structural steels for normal use are made to this standard. They are standard carbon steels with no alloying at all. These include S235JR, S235J0, S235J2, S235+N, S275JR, S275J0, S275J2, S355JR, S355J0, S355J2+N and S355K2+N and S450J0. OWN if you use the grade EN 10025-3:2004. Hot rolled products of structural steels. Technical delivery conditions for normalized/normalized rolled weldable fine grain structural steels These steels have much smaller grains than the standard structural steels making them somewhat stronger. These include S275N, S275NL, S355N, S355NL, S420N, S420NL, S460N and S460NL OWN if you use the grade EN 10025-4:2004. Hot rolled products of structural steels. Technical delivery conditions for thermomechanical rolled weldable fine grain structural steels The rolling of Thermomechanical or TM steels is quite specialized and has to be done withing certain temperature ranges in order to achieve specific steel characteristics. These include S275M, S275ML, S355M and S355ML, S420M, S420ML, S460M and S460ML TM steels as well as the Dillinger brand DI-MC 355B and 355T steels OWN if you use the grade EN 10025-5:2004. Hot rolled products of structural steels. Technical delivery conditions for structural steels with improved atmospheric corrosion resistance This covers all the wear resistant steels with their nice brown oxide surfaces that are great for bridge superstructures etc. We don’t stock any of these grades. S235J0W, S235J2W, S355J0WP, S355J2WP, S355J0W, S355J2W and S355K2W. OWN if you use the grade

EN 10025-6:2004+A1:2009. Hot rolled products of structural steels. Technical delivery conditions for flat products of high yield strength structural steels in the quenched and tempered condition These are the steels with a high yield strength and include S460Q, S460QL, S460QL1, S500Q, S500QL, S500QL1, S550Q, S550QL, S550QL1, S620Q, S620QL, S620QL1, S690Q, S690QL, S690QL1 , S890Q, S890QL1, S960Q, S960QL, S965 and S1100 as well as the Dillimax branded steels from Dillinger: Dillimax 690T, Dillimax 690E, Dillimax 890T, Dillimax 965T and Dillimax 1100. OWN if you use the grade PRESSURE VESSEL STEEL STANDARDS

BS EN 10028-1:2007+A1:2009. Flat products made of steels for pressure purposes. General requirements This standard covers the common requirements for all types of pressure vessel steel plate. Whilst critical in many ways to the manufacturers of steel plates the really useful information about the different boiler quality steel grades is found in the different parts OWN if you use the grade BS EN 10028-2:2009. Flat products made of steels for pressure purposes. Non-alloy and alloy steels with specified elevated temperature properties This covers pressure vessel steels for use in hot places – or elevated temperatures as the standard calls it. They’re divided into two groups. The alloyed has nickel, chromium and molybdenum to improve their corrosion and heat resistant properties. The unalloyed steels don’t. These include P235GH, P265GH, P295GH and P355GH unalloyed PV steels. Im the alloyed section you get 16Mo3, 18MnMo4-5, 20MnMoNi4-5, 15NiCuMoNb5-6-4, 13CrMo 4-5, 13CrMoSi5-5, 10CrMo 9-10, 12CrMo9-10, X12CrMo5, X12CrMo5, 12CrMoV1210, X10CrMoVNb9-1 and 12CrMo 1.5. OWN if you use the grade BS EN 10028-3:2009. Flat products made of steels for pressure purposes. Weldable fine grain steels, normalized These are the boiler quality steels for low temperature and the equivalents of the ASTM and ASME A516 grades 60 and 70. We have P275NH, P275NL1, P275NH, P355N, P355NH, P355NL1, P355NL2, P460NH, P460NL1 and P460NL2. OWN if you use the grade BS EN 10028-4:2009. Flat products made of steels for pressure purposes. Nickel alloy steels with specified low temperature properties We don’t stock these – but they include 11MnNi5-3, 13MnNi63, 15NiMn6, 12Ni14, X12Ni5, X8Ni9 and X7Ni9. BS EN 10028-5:2009. Flat products made of steels for pressure purposes. Weldable fine grain steels, thermomechanically rolled TM plates for pressure vessels. These include P355M, P355ML1, P355ML2, P420M, P420Ml1, P420ML2, P460M, P460Ml1 and P460ML2. We don;t stock these BS EN 10028-6:2009. Flat products made of steels for pressure purposes. Weldable fine grain steels, quenched and tempered

These are the quenched and tempered pressure vessel steels with a range of Q, QH, QL1 and QL2 after the normal P designation and the yield strength. So P355Q, P355QH, P355QL1 and P355QL2. Etc. We don’t stock any of these. BS EN 10028-7:2007. Flat products made of steels for pressure purposes. Stainless steels A total mystery to me as we only deal with carbon steels. These are all stainless and are included for completeness. X2CrNi12, X6CrNiTi12, X2CrTi17, X3CrTi17, X2CrMoTi17-1, X2CrMoTi18-2, X6CrMoNb171, X2CrTiNb18 OFFSHORE STEEL STANDARDS

EN 10225:2009. Weldable structural steels for fixed offshore structures. Technical delivery conditions This covers plates for fixed and mobile offshore structures and includes both normalised and thermomechanical offshore steels. S355G2+N, S355G3+N, S355G5+M, S355G6+M, S355G7+N, S355G7+M, S355G8+N, S355G 8+M, S355G9+N, S355G10+N, S355G9+M, S355G10+M, S420G1+QT, S420G1+M, S420G2+ QT, S420G2+M, S460G1+QT, S460G1+M, S460G2+QT and S460G2+M OWN if you use the grade GENERAL EN STEEL STANDARDS

BS EN 10020:2000. Definition and classification of grades of steel This is the basis for defining the difference between alloyed and non-alloyed steels, and then the difference between alloyed steels and stainless steels. BS EN 10021:2006. General technical delivery requirements for steel products This is a key standard as it pulls lots of different standards together to integrate how manufacturers of steel plates and purchasers agree on what exactly should be delivered OWN BS EN 10027-1:2005. Designation system for steels. Steel names Steels have names and numbers. This covers how the name of the steel is generated – and thus how you can quickly work out what a steels properties are just from the name. BS EN 10027-2:1992. Designation systems for steels. Steel numbers This covers how steel numbers are defined ad allocated. If you’d ever wondered exactly what 1.8988 is you’ll be able to use the standard to figure out that it is S690QL1 BS EN 10052:1994. Vocabulary of heat treatment for ferrous products This defines 200+ involved in heat treatment of steel (which almost all steels are to some extent. Good for bedtime reading – but valuable when you need to check a term BS EN 10079:2007. Definition of steel products This is another standard full of definitions and it covers what a plate and a coil and section is. All useful stuff but most engineers will only need to know a few definitions in here as it covers ALL steel products from hollow mining drill bars to wire to electrical steel and on to our beloved heavy plates (which actually aren’t defined). BS EN 10168:2004. Steel products. Inspection documents. List of information and description

Whilst EN10204 describes the type of material test certificates that have to accompany steel plates, this describes what has to go into the certificates. So everything that appears on an MTC is specified here – but it doesn’t specify how – so every steel mill does it differently. BS EN 10204:2004. Metallic products. Types of inspection documents This defines the different types of MTC that comes with steel plates. So if you want to know what a 3.1 or a 3.2 certificate is this will tell you – or you can read it on our EN10204 certification page OWN BS EN ISO 9001:2008. Quality management systems. Requirements This defines quality systems and if you are in engineering and don’t have a copy of this you probably have problems with customer complaints. The single most important standard in the world OWN

TOLERANCES AND DIMENSIONS IN EN STEEL STANDARDS BS EN 10029:2010. Hot-rolled steel plates 3 mm thick or above. Tolerances on dimensions and shape This basically says that plates have to be flat, have straight edges and have to be the length and width that you’ve asked for. Without this standard the QA department of most plate buyers would have a lot more work to do both pre and post purchase. OWN BS EN 10163-1:2004. Delivery requirements for surface condition of hot-rolled steel plates, wide flats and sections. General requirements This standard talks about the damage and discontinuities (cracks and pitting) that can appear on the surface of plates and how they can be repaired by grinding and welding. BS EN 10163-2:2004. Delivery requirements for surface condition of hot-rolled steel plates, wide flats and sections. Plate and wide flats EN10163-2 goes into a lot more detail about the different types of discontinuities – imperfections and defects and how these can be repaired for the different types of steel. This s where the meat is for all practical purposes. OWN

EN STEEL STANDARDS FOR TESTING BS EN ISO 6892-1:2009 Metallic materials. Tensile testing. Method of test at ambient temperature Replaces EN 10002-1:2001 This describes how to do tensile testing at room temperature. Normally this is the test lab’s issue – but its good to know exactly what is being done so that you are sure BS EN ISO 6892-2:2011. Metallic materials. Tensile testing. Method of test at elevated temperature Replaces EN 10002-5:1992 And this is how to do tests in the heat. There’s also a draft of how to do tensile tests at low temperatures BS EN ISO 148-1:2010 Metallic materials. Charpy pendulum impact test. Test method Replaces EN 10045-1. This is exactly as it sounds. How to do a charpy V-notch test at the right temperature with the right J values. Critical for many of the plates that we stock. BS EN 10160:1999. Ultrasonic testing of steel flat product of thickness equal or greater than 6 mm (reflection method)

This covers the UT testing of plates looking for internal discontinuities and defining the test patterns and the level of testing S0, S1, S2 and S3 OWN BS EN 10164:2004. Steel products with improved deformation properties perpendicular to the surface of the product. Technical delivery conditions If you are dealing with thick plates this is a key standard as despite it’s name it covers Z35 through thickness testing. OWN BS EN 10229:1998. Evaluation of resistance of steel products to hydrogen induced cracking (HIC) The equivalent of NACE TM0284 in the EN standards world. It describes how to test plate for HIC resistance using Solutions A and B. OWN if you deal with HIC material BS EN ISO 12737:2010. Metallic materials. Determination of plane-strain fracture toughness “This International Standard specifies the ISO method for determining the plane-strain fracture toughness of homogeneous metallic materials using a specimen that is notched and precracked by fatigue, and subjected to slowly increasing crack displacement force.” This is one for the mechanical engineers. PD CEN/TR 10261:2013. Iron and steel. European standards for the determination of chemical composition This is more of a standard for the steel mills and test labs. It describes, with lots of further references, how to establish the chemical composition of the steel for each element. Critical information for the MTC, but no immediately useful for the engineer. BS EN ISO 377:2013. Steel and steel products. Location and preparation of samples and test pieces for mechanical testing This describes how you choose the location and size of test pieces for tests. This can be critical as the steel slabs and plates can vary in their characteristics in statistically predictable ways and if proper sampling is not undertaken then results can be distorted BS EN ISO 643:2012. Steels. Micrographic determination of the apparent grain size Lots of pretty pictures of steel microstructure and grains in order to help analysis. Critical for establishing where steels are fine grain or not. BS EN ISO 2566-1:1999. Steel. Conversion of elongation values. Carbon and low alloy steels When you are tensile testing there are different guages used. Converting between them can be difficult and lead to errors and so this standard ;lays out a specific way of doing it that reduces variation between testers. Not critical but an important building block in the overall schema BS EN ISO 14284:2002. Steel and iron. Sampling and preparation of samples for the determination of chemical composition This covers how you take samples for determining the chemical composition of the steel. Not normally necessary when you have am MTC unless you need to retest. In this case a test lab would normally do this

Read more: http://www.oakleysteel.co.uk/key-en-steel-standards#ixzz4ornZdpiY