Samsung Scx-6555n Training Manual.pdf 6u10k

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 2z6p3t

Overview 5o1f4z

& View Samsung Scx-6555n Training Manual.pdf as PDF for free.

More details 6z3438

- Words: 16,308

- Pages: 322

SCX-6555N series training

Contents

I.

Application

II. Feature & specification III. Mechanism IV. Hardware V. CRU VI. Firmware

I. SCX-6555N series Application

SCX-6555N series SmarThru Office

Agenda I. II. III. IV. V. VI.

What is SmarThru Office? SmarThru Office Architecture Requirements and Restrictions How to work? FAQ Troubleshooting

I. What is SmarThru Office?

Objectives

I.

To make you aware of SmarThru Office

I. What is SmarThru Office? It is a Bundled Software package supplied with Samsung multifunctional peripherals (MFP with NIC). SmarThru Office software package assists in working with such peripheral devices as scanner, printers, faxes, etc. It provides the tools for scanning images and documents, performing text recognition, copying and printing images and documents, and doing many other things. It creates its own file system, which is called SmarThru Desktop, which simplifies your work with multimedia and other files. The system consists of three basic parts: SmarThru Office SmarThru Viewer SmarThru Office Launcher

II. SmarThru Office Architecture

Objectives

I.

To show you the architecture of SmarThru Office

II. SmarThru Office Architecture Architecture

Modules with UI Modules without UI External software and API

Mai n Smar Thr u Of f i ce f r ame appl i cat i on Navi gat i on UI

Document / I mage / Bi nder vi ew UI

( shell folder/ST desktop navigation, selecting document collections )

I ndex / Sear ch UI

Scan UI Pr ogr am ( l ocal / net wor k) bar UI

Send t o E- mai l UI

Send t o Fol der UI

Send t o OCR UI

Send t o Fax UI

Thumbnai l UI

Send t o Web UI

Pr i nt UI

Scan Engi ne Appl i cat i on ( l ocal / net wor k) r unner

E- mai l s ender

Fol der Saver

OCR wr apper

Fax s ender

Of f i ce/ PDF wr apper

Web upl oader

Pr i nt eng i ne

Image Converter Leadtools (TIFF, JPEG, etc )

PDF

Network scan serviceNetwork scan service Leadtools Raster Imaging Pro Leadtools Raster Imaging Pro Drivers and SystemDrivers API and System API

I ndex / Sear ch Ser vi ce wr apper

Image Editor / Document Viewer

Conf i gur at i on manager

XML Configuration data

Prof-UIS Library (UI enhancement library) Prof-UISclass Library (UI enhancement class library)

Web Capt ur e ( I E ext ens i on )

Fol der moni t or i ng agent

Fax Driver Fax Fax pr pr ii nt nt er er dr dr ii ver ver UI UI

Por Por t Moni tt or or UI UI

Pr Pr ii nt nt er er por por tt Fax Fax pr i nt er dr i ver l ogi ogi c moni t or moni t or

Outside in Technology by Stellent inc. Index/search engine OCR engine (Components for viewing/accessing of inc. Outside in Technologycontents by Stellent ( MS Indexing Server ) (ReadIRIS) Index/search engine OCR engine MS Office and PDF documents) (Components for viewing/accessing contents of ( MS Indexing Server ) (ReadIRIS) MS Office and PDF documents)

III. Requirement and Restriction

Objectives

I.

To show you the requirements and restrictions of SmarThru Office

III. Requirement and Restriction OS Environment Windows NT4(SP6) / 2k / XP / 2003 Windows XP 64bit Edition Windows 98/ME

Software Requirement To include PDF files for searching, Adobe Acrobat program should be installed before or IFilter module needs to be ed and installed from Adobe website.

Restrictions Search functionality of SmarThru Office utilizes MS Indexing Service that is

available starting from Windows 2000. Therefore, Indexing and searching feature will not be available on Window 98/ME/NT4

IV. How to Work?

Objectives

I.

To show you the work flow of SmarThru Office

IV. How to Work? Work Flow Import document files

SmarThru Office

View of Documents and images

1.Initiate Scan from Host 2.Send Scanned Image

Document Binders

Application Email Folder

OCR FTP

MFP 1.Initiate Scan from device

Indexing and Searching

Backup and Restore

Print Fax

2.Send Scanned Image

Document Viewer / Image Editor

MFP

CAPTURE

PROCESS and DISTRIBUTION

IV. How to Work?

Objectives

II.

To show you the sequence of SmarThru Office

IV. How to Work? 1. General View Toolbar

Menu

SmarThru Office Main Windows Working Area Toolbar Send to Bar Status bar Menu

Working Area

Send to Bar Status bar

IV. How to Work? 1. General View

– Working Area

SmarThru Desktop

SmarThru Desktop Right

Independent file system Created within the standard Windows folder My Documents

Sort on Disk

Sort on Disk Simplify file sort ( Date, File Type, Latest Used )

Windows Folder Windows Folder

Allows to navigate through all the 's Desktop files and folders

The Right Reflects the content of a

selected folder

IV. How to Work? 1. General View

– Send To Bar

Send To Bar Run the corresponding

application directly

Drag and drop selected file to the appropriate application button.

1

Send To Bar

Drag & Drop

2

Open Application

… .

IV. How to Work? 2. Sort on Disk Sort on Disk The Sort on Disk section is intended to simplify file sorting. Sort on Disk

1

2 click

Header or Row(▶) Click : Expand corresponding section

Files of the folders which are not included in Index tab list will not be displayer for the Sort on Disk section. Use files of the folders which are included in Index tab list. Index tab : Edit > Preferences

Sort by : • Date : Order by the date of their last modification • File Types : Allows to view file sorted by type • Latest Used : Allows to view the files last used.

2. Sort on Disk – Work flow for Document viewing Date View

File Type View 1

Set indexing folder ( Edit -> Preferences )

Latest Used View 2

Select view from Sort on Disk

IV. How to Work? 3. Search 1 2

Click Search

Search

Search

Switch Left

(Switch Left )

( Normal <-> Search ) Provides advanced options for searches Use indexed files information • can determine the file folders for indexing on the Index tab for Search.

Search in • Or : Contents, Title, • And : Find what, Ignore what

Document Type Advanced Search

• File Type Advanced Search Result

• Categories

Modification Date • Any Time, Date, Period

IV. How to Work? 4. Sending Documents – Send by E-mail Send by E-mail To send a document by E-mail while working within the SmarThru Office The window of e-mail client will then open with the selected document attached. File menu > Send by > Send by E-mail

1

Drag & Drop

Send by E-mail

2

Select file > Right click > Send by > Send by E-mail Open E-mail Client

IV. How to Work? 4. Sending Documents 2

Send by FTP Open Send by FTP

To a document file to server while working within the SmarThru Office File menu > Send by > Send by Fax Select file > Right click > Send by > Send by FTP

1

Drag & Drop

Send by Fax

IV. How to Work? 4. Sending Documents – Send by Fax Send by Fax To send a document by Local or Network Fax machine while working within the SmarThru Office can send a document by fax machine ed on the Network (Network Fax Settings). File menu > Send by > Send by Fax 1

Select file > Right click > Send by > Send by Fax

Drag & Drop

2

Open Send by Fax

Send by Fax

IV. How to Work? 4. Backup Backup Saves the current contents of SmarThru Desktop to a backup file • File > Back • Click Backup Icon on the system tray

Import Backup File Allows to select backup file and to restore SmarThru Desktop from this file • File > Import Back File

Back up Setup Allows to set backup operation properties • Name and location for backup file • Create new file or Overwrite an existing backup file • File > Backup Setup

IV. How to Work? 5. Scan Scan

Scan

1

2

Open Scan UI

Allows to scan images and process the images and texts already scanned

Select Scanner

Local or Network Scan There are facilities not only for scanning with a local scanner, but also for scanning with a network scanner.

OCR The scanning option allows to use the optical character recognition option for scanning documents into a text file.

IV. How to Work? 5. Scan – Local Scan

2

1 Preview Area

Select Scanner

Local Scan select local scanner device • ex) scanner name

Allows to use Preview button File format Image : JPEG, BMP, PNG, TIFF Document : CSV, HTM, DOC, PDF, RTF, TXT

OCR Language : Allows to select the language for the optical character recognition option. Scan multiple Page

IV. How to Work? 5. Scan – Network Scan 1

Select Scanner

Network Scan select a network scanner device • ex) scanner name (IP Number)

Preview area will be changed according to selection of local or network can not use a Preview button Network Scan restricts scanner option than local scan Preview Area – Network Scanner In case of Network Scanner, Preview function not .

Save File Format JPEG, TIFF, PDF

Note : In order to see network scanner from “Select Scanner”, has to add devices from separate Network scanner client program first.

IV. How to Work? 5. Scan – Work Flow for Scanning 4 1

2

Click Scan button

Scan UI Open

3

Select Scanner driver

Preview area will be changed according to selection of local or network

Local Scanner

6

Save

Network Scanner

5 Preview is displayed only for local scanning

Execute Scan

IV. How to Work? 6. Audit Trail Audit Trail Allows to view all the records on operations for sending documents by fax, e-mail, and FTP. File > Audit Trail

Filter Conditions can set criteria which records of the Audit Trail dialog must meet by specifying the Time, Name and Operation data.

IV. How to Work? 7. Web Capture Web Capture Allows to select a rectangular area on a Web page which interests and capture its contents as a picture file, text file, HTML file. Capture Selection : Allows to capture and save a selected rectangular web page area as a picture. Save as Text: Allows to save a selected web page text as a text file. Save HTML : Allows to save a web page as an HTML file.

IV. How to Work? 8. Document Option Group (<-> Ungroup) can group several documents into one multiple document (Binder ).

Document Arrange Group Document

Document Arrange

To view and reorder the constituent documents, click on the arrow button ( ) in the right bottom corner of the above document in the group.

Page Arrange To arrange pages in the document Choose the page want to move with the help of the arrow buttons The Page Arrange operation is available for PDF files and multipage TIFF files.

IV. How to Work? 8. Edit Option Basic Edit Operations Undo, Redo, Copy, Cut, Paste, Delete, Rename, Selection. 2

Rotate

Rotate (180, 90 CW, 90 CCW)

Allows to rotate all the pages of PDF files, multiple page TIFF files, and any image (BMP, GIF, JPEG). 1

Select file ( PDF, TIFF, BMP, GIF, JPEG )

Edit > Rotate

180 Allows to rotate the selected file 180° .

90 CW : Allows to rotate the selected file 90° clockwise. ( Toolbar :

)

90 CCW : Allows to rotate the selected file to 90° counterclockwise. ( Toolbar : )

IV. How to Work? 8. Edit Option Basic Edit Operations Undo, redo, copy, cut, paste, Delete, Rename, Rotate, Selection 2

Page Action

Page Action (Extraction, Division, Duplication)

Allows to perform different actions with the selected document page 1

Select file (Include more than one page)

Edit > Page Page Extraction : Allows extraction of only the current page from the selected multiplepage document and creation of an document in the same folder.

Page Division : Allows to divide a SmarThru Desktop document into two separate documents.

Page Duplication : Allows to make a duplicate of the current page of the document selected to the same SmarThru Desktop folder.

IV. How to Work? 9. SmarThru Office Viewer SmarThru Office Viewer Allow to view almost any document or image, comment on files and perform standard file operations without returning to the main SmarThru Office window. Edit Option • Undo, Redo, Crop, Find, Property

View Option • Toolbars, Status Bar, page Navigator, etc

Comments Option • Note, Text, Stamp, Marker

Tools Option • Level, Color, Effect, OCR

IV. How to Work? 10. SmarThru Office Launcher SmarThru Office Launcher 2

Independent part of SmarThru Office

Check SmarThru

Launcher automatically start up when log on to Windows. 1

Right button click of Mouse on Tray Icon

Allows to perform scan, print and fax operations without starting SmarThru Office. Scan Print Fax

3

Show SmarThru Office Launcher

V. FAQ How to send an image by email from SmarThru Office To send an image by e-mail, you must have a mail client program by default, like Outlook Express, which has been set up with your e-mail .

In order to add a indexing folder from SmarThru Office Go to Edit > Preferences -> Index Tab -> Add a folder by “Browse” button

VI. Troubleshooting Condition : The local scanner does not work. Suggested solutions: Check that the USB or parallel cable is connected properly (Local Scanner). Make sure that the USB or parallel cable is not defective. Switch the cable with a known good cable. If necessary, replace the cable.

Condition : The network scanner does not work. Suggested solutions: Check that the Network connection is connected Properly (Network Scanner) Check that the Network scanner’s state through Network scanner client program.

SCX-6555N series Smart

Agenda I. II.

What is Smart ? Architecture 1) Architecture 2) Smart Program Architecture 3) Smart Block Diagram III. Interface 1) Smart Tray Icon 2) Launching Smart 3) Smart 4) Options 5) Toner Order 6) Printer Setting 7) Driver Setting 8) Job Monitor IV. Troubleshooting

I. What is Smart • The Smart is a program that will periodically monitor and inform the of the status of the printer. • The Smart also provides some links to make set the printer and printer driver setting such as Printer Setting Utility, Printer Driver Setting interface. • The Smart is basically able to communicate through USB and Network, and it depends on the model. •The Smart is automatically launched when the prints a document and it is closed when the printing job is completed, and Smart is showed up on the screen when an error occurs while printing. •Smart s windows 98, Me, 2000, 2003 and XP, Mac OS 10.3 and Higher, Linux

II. Architecture

2.1 Architecture

Application

Printer Driver

JOB ID

Language Monitor

Printing information utatS ryeuqs

Smart

USB Driver

SNMP Manager

II. Architecture

2.3 Smart Program Architecture C:\Program Files\SamSung\model 1\S

Model 1

code.dat Opts.dat Jobmon.dat ssmsrvc.dat lang\*.trs Printing Information

Data Files

Setup files

ssmmgr.dat lang\*.trs

./sm.inf

Smart manager (Tray Icon)

Smart Option

SMOption.exe

Printing Information

C:\Program Files\SamSung\model 2\S

Model 2

code.dat Opts.dat Jobmon.dat ssmsrvc.dat lang\*.trs

Language Monitor

OEMID + LM[?].dll OEMID + LM[?].smt

Spiomgr.dll Usbio.dll Secsnmp.dll

launch

SSMMgr.exe SPaddon.exe

Windows System Folder

I/O Module

s.exe

Folder\Company Name\Mgr

Launch Call

.\help\*.chm

Smart Paenl

ssmsrvc.exe

./setlang\*.trs Windows

Troubleshooting Guide

Data Files

Data Files

.\help\*.chm

Smart Paenl

ssmsrvc.exe

launch

I/O Module

s.exe Smart Option

SMOption.exe Launch

Troubleshooting Guide

Spiomgr.dll Usbio.dll Secsnmp.dll

Job Monitor

Jobmon.exe

II. Architecture

2.3 Smart Block Diagram

Model 1

Data Files

Troubleshooting Guide

Smart Paenl

I/O Module

Smart Option

Balloon Type Interface

Window Type Interface

Smart Controller

XML Parser

MS XML

Polling Manager

Printer Information Manager

Data File Manager

XML USB IO

XML Network IO

USB IO

Network IO

Language File Parser

Control File Parser

Status Code Praser

XML Parser

USB Driver

HTTP

USB Driver

SNMP Library

Language File

Control File

Code File

XML status file

WIN32 Spooler API

III. Smart Interface

3.1 Smart tray icon and its menu Smart manager (Tray Icon)

III. Smart Interface

3.2 Launching smart Printing Information

Smart manager (Tray Icon)

Smart Paenl

III. Smart Interface

3.3 Smart Model 1

Data Files

Smart Paenl

Smart Option

Troubleshooting Guide

I/O Module

III. Smart Interface

3.4 Smart Options Model 1

Data Files

Smart Paenl

Only for Windows Troubleshooting Guide

I/O Module

Smart Option

Only for Windows and hard disk ed models

III. Smart Interface

3.5 Toner order

III. Smart Interface

3.6 Troubleshooting Guide

III. Smart Interface 3.7 Driver Setting (Only for Windows)

III. Smart Interface 3.8 Job Monitor (Only for Windows)

Job monitor is an application which show the list of print job saved in the hard disk of printer. Also this application have some function such as deletion or reprint.

Job monitor only s printers that have hard disk.

IV. Troubleshooting • Smart only s USB and Network port. If file is printer port, smart show below warning message when try to launch smart . Also printer name is not displayed in the menu of tray icon.

• If IP address or USB port name for model A is linked to printer port of model B, Smart for model B works improperly because model B is not connected.

SCX-6555N series TWAIN WIN

Agenda I. II. III. IV. V. VI. VII.

What is TWAIN? TWAIN Architecture How to work? TWAIN Driver Interface Scan Resolution Component Detail Specification Troubleshooting

I. What is a TWAIN? 1. What is Twain? 1-1. Concept TWAIN is Technology Without An Important Name An image capture API and Protocol for Microsoft Windows , Apple Macintosh and Other operating systems. The standard was first released in 1992, and is currently ratified at version 1.9 as of January 2000. TWAIN is typically used as an interface between image processing software and a scanner or digital camera.

I. What is a TWAIN? 1. What is Twain? 1-1. Concept The application software

: An application must be modified to use TWAIN.

The Source Manager software

: This software manages the interactions between the application and the Source.

The Data Source software

: This software controls the image acquisition device and is written by the device developer to comply with TWAIN specifications.

II. TWAIN Architecture 2. TWAIN Architecture 2-1. Architecture Model

III. How to work? 3. How to work? 3-1. The steps for scanning 1.

2. 3. 4. 5. 6. 7. 8.

Place your image face down on the flatbed, or load the document face up in the Auto Document Feeder. Select the Document Source that will be used for scanning. Preview the image or document scanned at lower resolution. Customize Scan Settings, which includes selecting Image Type, Resolution and Document Type. Adjust Image Colors, including Brightness, Contrast, Gamma, Highlight and Shadow. Try to change these values until the image looks best. Apply Filters to sharpen the image contours or retouch the image. You can also descreen the images scanned from newspapers or magazines. Customize image view, which includes flipping and/or rotating the image if needed. Scan the image using the settings you defined Set the Scan Preferences to make the scanning parameters to be available the next time you perform scanning. Save the customized settings as Favorites to use them when you scan documents or images next time.

III. How to work?

Application

Source Manager

Data Source

Scanner

IV. TWAIN Driver Interface 4. TWAIN Driver Interface

Rules

4-1. Main UI

Preview

It shows simple and friendly UI To access the scan options, expand Options .

Options

Click!

Toolbox Information

IV. TWAIN Driver Interface 4. TWAIN Driver Interface 4-2. Scan Settings Image type: Specify the mode that will be used to scan the original image or document. Text documents Text documents or drawings Black and white photos Drawings, figures, schemes Color photos, posters, etc

Lineart B/W Halftone B/W Gray 256 Scales 256 Colors True Color (R,G,B)

Resolution: To set the resolution from 75 to 4800 DPI Document Type : specify for document type define the limits of the area to be scanned and reduce or enlarge the size of the resulting image by using Scale(%). Document Source: display the device list selected to scan from Auto : the document source is detected automatically. Flatbed : Flatbed is selected as the document source. ADF : Auto Document Feeder is selected as the document source. DADF : Auto Document Feeder with Duplex options. Long Edge Binding & Short Edge Binding

4. TWAIN Driver Interface 4-3. Color Management Rendering Intent: Select the rendering intent corresponding to the image type you are scanning. - Perceptual : Photographs and image with colors - Relative : Photographs and images with more subtle tones - Saturation : Business Graphics(Charts)

Color Profile: To specify the color profile that corresponds to the rendering device, choose the proper value in the Color Profile field. - AdobeRGB1998.icc - AppleRGB.icc - CIERGB.icc - CNZ005.icc - ColorMatchRGB.icc - kodak_dc.icm - NTSC1953.icc - PAL_SECAM.icc - SMPTE-C.icc - sRGB Color Space Profile.icm - WideGamutRGB.icc

IV. TWAIN Driver Interface 4. TWAIN Driver Interface 4-4. Adjustment Brightness: To set the level of color brightness for the entire image. Contrast: To set the color contrast for the entire image. Highlight: To set the color highlight level for the entire image. Shadow: To set the shadow level for the entire image. Gamma : To set the gamma level for the entire image. Auto : To make the TWAIN driver automatically adjust Brightness, Contrast, Highlight, Shadow and Gamma levels. Invert : To invert the image colors.

4. TWAIN Driver Interface 4-5. Histogram To set color settings using a histogram click the Histogram bar in the Options . Channel: Use this option to select the color channel. You can plot either the luminance of the composite channel (RGB or Gray) or the intensity values of an individual channel Graph: Statistical information about the intensity values of the pixels appears below the histogram.

IV. TWAIN Driver Interface 4. TWAIN Driver Interface 4-6. Filters Filters allow you to improve image quality by applying some visual effects. Sharpness: To sharpen your image and improve its clarity. With Sharpness you can make the finest details look more clearly. Blur : To soften and retouch your image or mask small defects like dots and spots. Descreen : To minimize the appearance of unsightly interference patterns (moire patterns) which may occur in your image file when scanning original documents created by a halftone process.

IV. TWAIN Driver Interface 4. TWAIN Driver Interface 4-7. Preferences Transparency: To adjust the TWAIN driver windows look Options: To act automatically on the ScanThru start and/ Or after preview. - Preview on program start. - Auto crop image after preview. - Auto adjust image after preview. Port: To switch from local device to network one or vice versa.

4. TWAIN Driver Interface 4-7. Preferences – Change Port… Use Change Port to switch from local device to network one or vice versa. You can also select a particular network device among several available.

IV. TWAIN Driver Interface 4. TWAIN Driver Interface 4-8. About To view the information about this software.

V. Scan Resolution Resolution

Optical Resolution ( 600* 1200 )

△

Software Enhance Resolution

X

Not

Gray

B/W

24bit

8bit

8bi t

Lineart

Halftone

75(Draft)

O

△

O

O

O

100

O

△

O

O

O

150

O

△

O

O

O

200

O

△

O

O

O

300(Normal)

O

△

O

O

O

600

O

△

O

O

O

1200(Best)

△

△

△

△

△

2400

△

△

△

△

△

4800(Maximum)

△

△

△

△

△

5. Scan Resolution

O

Color

VI. Component Detail Specification 6. Component Detail Specification Image Type - True Color (24bit), 256 Color, Gray(8bit), B/W Lineart and Halftone

Resolution - Optical resolution : 75, 100, 150, 200, 300, 600 dpi - Enhance resolution : ~ 4800 dpi

Document Source - Flatbed - ADF Simplex / Duplex

Image Area - English : Letter - Others : A4

Unit - English: inch - Others : mm New Feature - CMS and Histogram (Since Elbruz SEC Model) I/O - USB : (V1.1, V2.0) – USB 2.0 is recommended - Network (T/IP) OS - Win NT / 2K / XP / 2003 / VISTA (32 & 64 bit)

VII. Troubleshooting 1. "An error has occurred while acquiring the image.“ If this should occur, try and reduce the total image size with the resolution setting. For example, if scanning an A4/Letter original in TrueColorRGB mode with an MS Office application, please set the resolution to 800dpi or less.

2. MFP is not searched automatically on the network. Above all, turn off firewall or SSCAN2IO.exe program (WINDIR\Samsung\6x55) to exception list of firewall program.

SCX-6555N series TWAIN MAC

Agenda I. II. III. IV. V. VI. VII.

What is TWAIN? TWAIN Architecture How to work? TWAIN Driver Interface Scan Resolution Component Detail Specification Troubleshooting

I. What is a TWAIN? 1. What is Twain? 1-1. Concept TWAIN is Technology Without An Important Name An image capture API and Protocol for Microsoft Windows , Apple Macintosh and Other operating systems. The standard was first released in 1992, and is currently ratified at version 1.9 as of January 2000. TWAIN is typically used as an interface between image processing software and a scanner or digital camera.

I. What is a TWAIN? 1. What is Twain? 1-1. Concept The application software

: An application must be modified to use TWAIN.

The Source Manager software

: This software manages the interactions between the application and the Source.

The Data Source software

: This software controls the image acquisition device and is written by the device developer to comply with TWAIN specifications.

II. TWAIN Architecture 2. TWAIN Architecture 2-1. Architecture Model

III. How to work? 3. How to work? 3-1. The steps for scanning 1.

2. 3. 4. 5. 6. 7. 8.

Place your image face down on the flatbed, or load the document face up in the Auto Document Feeder. Select the Document Source that will be used for scanning. Preview the image or document scanned at lower resolution. Customize Scan Settings, which includes selecting Image Type, Resolution and Document Type. Adjust Image Colors, including Brightness, Contrast, Gamma, Highlight and Shadow. Try to change these values until the image looks best. Apply Filters to sharpen the image contours or retouch the image. You can also descreen the images scanned from newspapers or magazines. Customize image view, which includes flipping and/or rotating the image if needed. Scan the image using the settings you defined Set the Scan Preferences to make the scanning parameters to be available the next time you perform scanning. Save the customized settings as Favorites to use them when you scan documents or images next time.

III. How to work?

Application

Source Manager

Data Source

Scanner

IV. TWAIN Driver Interface 4. TWAIN Driver Interface Pr evi ew Ar ea

4-1. Main UI

Click!

I nf or mat i on Ar ea

Cont r ol Ar ea

IV. TWAIN Driver Interface 4. TWAIN Driver Interface 4-2. Scan Settings Image type: Specify the mode that will be used to scan the original image or document. Text documents Text documents or drawings Black and white photos Drawings, figures, schemes Color photos, posters, etc

Lineart B/W Halftone B/W Gray 256 Scales 256 Colors True Color (R,G,B)

Resolution: To set the resolution from 75 to 4800 DPI Document Type : specify for document type define the limits of the area to be scanned and reduce or enlarge the size of the resulting image. Document Source: display the device list selected to scan from Auto : the document source is detected automatically. Flatbed : Flatbed is selected as the document source. ADF : Auto Document Feeder is selected as the document source. DADF : Auto Document Feeder with Duplex options. Long Edge Binding & Short Edge Binding

IV. TWAIN Driver Interface 4. TWAIN Driver Interface 4-3. Adjustment Brightness: To set the level of color brightness for the entire image. Contrast: To set the color contrast for the entire image. Highlight: To set the color highlight level for the entire image. Shadow: To set the shadow level for the entire image. Gamma : To set the gamma level for the entire image. Auto : To make the TWAIN driver automatically adjust Brightness, Contrast, Highlight, Shadow and Gamma levels. Invert : To invert the image colors.

IV. TWAIN Driver Interface 4. TWAIN Driver Interface 4-4. Filters Filters allow you to improve image quality by applying some visual effects. Sharpness: To sharpen your image and improve its clarity. With Sharpness you can make the finest details look more clearly. Blur : To soften and retouch your image or mask small defects like dots and spots. Descreen : To minimize the appearance of unsightly interference patterns (moire patterns) which may occur in your image file when scanning original documents created by a halftone process.

IV. TWAIN Driver Interface 4. TWAIN Driver Interface 4-5. Preferences Transparency: To adjust the TWAIN driver windows look Options: To act automatically on the ScanThru start and/ Or after preview. - Preview on program start. - Auto crop image after preview. - Auto adjust image after preview.

IV. TWAIN Driver Interface 4. TWAIN Driver Interface 4-6. About To view the information about this software.

V. Scan Resolution Resolution

5. Scan Resolution

O

Optical Resolution ( 600* 1200 )

△

Software Enhance Resolution

X

Not

Color

Gray

B/W

24bit

8bit

8bi t

Lineart

Halftone

75(Draft)

O

△

O

O

O

100

O

△

O

O

O

150

O

△

O

O

O

200

O

△

O

O

O

300(Normal)

O

△

O

O

O

600

O

△

O

O

O

1200(Best)

△

△

△

△

△

2400

△

△

△

△

△

4800(Maximum)

△

△

△

△

△

VI. Component Detail Specification 6. Component Detail Specification Image Type - True Color (24bit), 256 Color, Gray(8bit), B/W Lineart and Halftone

Resolution - Optical resolution : 75, 100, 150, 200, 300, 600 dpi - Enhance resolution : ~ 4800 dpi

Document Source - Flatbed - ADF Simplex/ Duplex

Image Area - Letter, A4, Statement, ETC - Default Image Area depend on OS System Preference

Unit - Unit (cm, mm, inch, pixel, Point, Pica) - Default Unit depend on OS System Preference I/O - USB : (V1.1, V2.0) – USB 2.0 is recommended OS - OS X (10.3 / 10.4)

VII. Troubleshooting 1. Twain driver does not work in OS Classic Macintosh Twain driver doesn’t not Mac OS 9.

SCX-6555N series WIA driver

Agenda I. II. III. IV.

What is WIA? How to use? Interface Applications

I. What is a WIA? 1. What is WIA? 1-1. Concept WI A i s Wi ndows I mage Acqui s i t i on WI A i s pr opos ed by Mi cr os of t t o s uppor t t he i mage devi ces ( camer as , s canner s , …) . WI A enabl es t he abi l i t y t o obt ai n pi ct ur es f r om camer as and s canner s , and t o eas i l y mani pul at e t hos e pi ct ur es wi t hout us i ng addi t i onal s of t war e. WI A Dr i ver Suppor t s Mi cr os of t ® Wi ndows ® XP, VI STA and USB onl y.

II. How to use? 2. How to use? 2-1. The s t eps f or s canni ng wi t h Sc anner s and Camer as Wi zar d 1. 2. 3. 4. 5. 6.

Load the document(s) face up with top edge in first into the ADF or Place a single document face down on the scanner glass. From the Start menu on your desktop window, select Settings, Control and then Scanner and Cameras. Double click your machine. The Scanner and Camera Wizard launches. Choose your scanning preferences and click Preview to see how your preferences affect the picture. Enter a picture name, and select a file format and destination to save the picture. When the picture is successfully copied to your computer, you can choose to keep working with the picture. Follow the on-screen instructions.

III. Interface 3. WIA Interface 3-1. Characteristics It shows simple and friendly UI It shows the same UI independent of vendors and products.

FlatBed UI

Document Feeder UI

III. Interface 3-2. Default Option Paper Source If you want to scan with flatbed, select “Flatbed” If your want to scan with document feeder, select “Document Feeder”

Picture Type There are three type : Color, Grayscale, Black and white If you want the other option, select “Adjust the quality of the scanned picture” If you select “Adjust the quality of the scanned picture”, you can show “Advanced properties” dialog.

III. Interface 3-3. Advanced Properties Brightness and Contrast You can control the brightness and contrast of scan image. The range is 0 ~ 255(Default : 128).

Resolution(DPI) You can control the resolution of scan image. The range is dependent of the device capabilities(Default : 150 dpi).

III. Interface 3-4. Duplex Scan Option(XP OS Only) ADF Duplex You can scan duplex by select this item.

Long Edge Binding (Default) Select this item if you want to scan documents bound by long edge.

Short Edge Binding

Select this item if you want to scan documents bound by short edge.

IV. Applications

4. Applications 4-1. Applications that don’t scan multi-pages. Microsoft Paint Microsoft Office XP

4-2. Applications that have latent bugs Lotus 1-2-3 : No gain the result when scan with document feeder Microsoft Office 2000 : The scanned image is some different with the size and color of original image.

SCX-6555N series Network scan

Agenda I.

What is Network Scan?

II.

Using Network Scan

III.

a)

Install

b)

Add device

c)

Scanning

d)

Features

Troubleshooting

I.

What i s Net wor k Scan? The Network Scan system provides a function to share high speed scanning device on the network. ‘NMFP kernel’ NMFP kernel is for servicing scan request by displaying interface, accepting inputs and scanning document.

‘Network Interface Card’ Network Interface Card is for sending the scanned document to right Network Scan software.

‘Network Scan software’ Network Scan software shows NMFP status, modifies scan option, saves scanned data and shows scanned image with default application.

I I . Us i ng Net wor k Scan ( I ns t al l 1)

. ( a) - 1 I ns t al l 1

The inserts a CD.

2

Auto-run program will run.

3

Asks for the software language.

4

Copies files to the destination directory.

5

Short cut is created at the ‘Desk Top’ and ‘Programs’.( different by model )

6

The installed network scan software will run and the network scan manager will be opened.

Network Scan Tray Icon

Network scan manager

I I . Us i ng Net wor k Scan ( I ns t al l 2)

a) - 2 Conf i r m of I ns t al l at i on 1. Install Path –

“C:\Program Files\SAMSUNG\NetworkScan”

1. Network Scan Files –

NSCConfig.nsc (configuration file)

–

NSCEntity.dll, NSClientUI.dll, NSCMainCtrl.dll, NSrotocol.dll (COM library files)

–

NSCSysTrayUI.exe (executable file)

–

Uninstall.Ico (icon file for uninstall short- cut)

–

NSClient.dat, NSCEntity.dat, NSClientUI.dat, NSCSystray.dat (Data files for installed language)

–

NSClient.chm (Help file)

–

Network Scan Manual.pdf (’s guide)

–

NetScan.ini (Application list : model optional)

–

SSOle.dll (MS office module : model optional)

I I . Us i ng Net wor k Scan ( Add Devi ce)

( b) - 1 Open Add Devi ce Wi zar d

Click

Double Click

I I . Us i ng Net wor k Scan ( Add Devi ce)

. ( b) - 2 Add Devi ce Wi zar d

Click

I I . Us i ng Net wor k Scan ( Add Devi ce)

. ( b) - 3 Add Devi ce Wi zar d

Click

I I . Us i ng Net wor k Scan ( Add Devi ce)

. ( b) - 4 Add Devi ce Wi zar d

I I . Us i ng Net wor k Scan ( Add Devi ce)

. ( b) - 5 Add Devi ce Wi zar d

Click

I I . Us i ng Net wor k Scan ( Add Devi ce)

. ( b) - 6 Add Devi ce Wi zar d

Click

I I . Us i ng Net wor k Scan ( Add Devi ce)

( b) - 7 Compl et i on of Add Devi ce

I I . Us i ng Net wor k Scan ( Scanni ng)

( c) Net wor k Scanni g bas i c pat h 1.

The checks the status of the device icon from network scan software.

2.

The walks up to the NMFP device.

3.

The selects a network scan function.

4.

The s with the ID and PIN.

5.

The NMFP device queries the logged network scan software about scan preferences.

6.

The network scan software sends asked settings.

7.

The can change settings at NMFP device before starting scan job if he wishes so.

8.

The network scan software gets ready to receive a scan data.

9.

The NMFP device sends scanned data to the network scan software.

10. The network scan software receives and saves data to specified folder in the ’s PC. 11. After scan job, the log out. 12. The network scan software invokes application with received scan image. 13. The returns his desk. 14. The can see the scanned image.

I I . Us i ng Net wor k Scan ( Feat ues )

. ( d) - 1 Devi ce St at us

I I . Us i ng Net wor k Scan ( Feat ues )

. ( d) - 2 Change Devi ce name

1. Input Device name

I I . Us i ng Net wor k Scan ( Feat ues )

( d) - 3 Ser ver I nf or mat i on

I I . Us i ng Net wor k Scan ( Feat ues )

2. ( d) - 4 Save Name Scheme

File name

Eg.) C:\XXX\My scanner_20040626142212_1.tif Eg.) C:\XXX\My scanner\20040626142212_1.tif

The can set to open scanned image with the default application of Windows OS immediately after scanning.

I I . Us i ng Net wor k Scan ( Feat ues )

. ( d) - 5 Scan Pr ef er ence

Add Folder - The can use this function to set the destination to desired folder.

Add Application - The can use this function to set the destination to desired application.

Scan Size - The can use this function to set desired scan area. Edit button allows to set defined size. Default - The can set current Scan Property to initial Scan Property. Initial Scan Property means values of initialized property when the application is added.

I I . Us i ng Net wor k Scan ( Feat ues )

( d) - 6 Opt i on di al og

III. Troubleshooting(1)

My ID is absent in the NMFP.

Is Network Scan software running?

Did you execute Add device wizard?

I cannot scan a document with 600dpi color.

Refer to MFP Network Scan Spec.

I can’t view the Help file.

To view the Help file(Html Help system), you need to have Internet Explorer 4 service pack 2 or above.

III. Troubleshooting(2)

I can’t find scanned image file.

You can check the scanned file’s destination in the ‘Advanced Tab.

I cannot show scanned image in my PC after scanning.

if the image file format is ed in OS.

Check ‘S end I mage i mmedi at el y . . . ’ option in the ‘Advanced Tab’..

I forgot my ID and PIN.

Check your ID in the ‘Server Tab‘.

If you forgot your PIN, Remove the device and readd the one.

SCX-6555N series Set IP

Agenda I.

What is SetIP?

II.

Using SetIP a)

Execute SetIP

b)

Set T/IP

c)

Set Manually

d)

SetIP Information

I.

What i s Set I P? 1/ 2 • Detect printers in the same network and show network information of devices to a • Configure IP address, Subnet mask and Gateway

SetIP

Set T/IP information Detect printers in the network

Network Printer

Network Printer

Network Printer

I.

What i s Set I P? 2/ 2 Ref r es h

Set T/ I P Set Manual l y About

Li s t of det ect ed devi ces

Cl os e t he pr ogr am

Di s pl ay t he Hel p of pr ogr am

II.

Us i ng Set I P

1. Execute SetIP

- Cl i ck St ar t - > Al l Pr ogr ams - > Sams ung Net wor k Pr i nt er Ut i l i t i es - > Set I P - > Set I P

II.

Us i ng Set I P

2. Set T/IP

- A us er can change I P addr es s , Subnet mas k and Gat eway

II.

Us i ng Set I P

3. Set Manually

- A us er mus t i nput Mac addr es s of s peci f i c devi ce t o conf i gur e I P addr es s , Subnet mas k and Gat eway manual l y,

II.

Us i ng Set I P

4. SetIP Information

Li nk t o Sams ung Webs i t e

- Show Set I P i nf or mat i on t o a us er

SCX-6555N series Direct Printing Utility

Agenda I. II. III. IV. V. VI.

Direct Printing Utility? Architecture How to work? Interface Detail Specification Troubleshooting

I. Direct Printing Utility? 1. Direct Printing Utility?

It sends a PDF file directly to printer without having to open the file. It sends data through the Windows spooler using the port of the printer driver. It only s PDF format. Printer needs to Post Script printer language.

II. Architecture 2. Architecture

PDF2PS

Spooler

PDF File

PC

USB Port Parallel Port Network Port

III. How to work? 3. How to work? 3-1. From the Direct Print Utility window 1. 2. 3. 4. 5.

Double-click the Direct Print Utility shortcut icon on your desk top. Select the printer in the Select Printer section and click Browse. Select the PDF file. The PDF file is added in the Select Files section. Customize the printer settings for your needs. Click Print.

3-2. Using the shortcut icon 1. 2. 3.

Select the PDF file and by dragging drop it to the shortcut icon on your desk top. Customize the printer settings for your needs. Click Print.

1.

Right-click on the PDF file

2.

Select Direct Printing.

3.

Customize the printer settings for your needs

4.

Click Print.

3-3. Using the right-click menu

IV. Interface 4. Interface 4-1. Basic

It consists of basic functions and a simple UI Select Printer : It allows you to select the name of installed printer. If the selected printer does not this utility, It will show alert message windows Print Range : It allows you to print the entire document or specific pages. Copies : Number of copies. Enter the number of copies you want to print. You can select from 1 to 99 copies. Orientation : It allows you to select the direction of the printed page.

IV. Interface 4. Interface 4-2. Advanced

It consists of advanced functions. Paper Size : It allows you to choose the size of the paper or envelope you are printing. If printer cannot selected paper size. It will use printer’s default size. Paper Type : It allows you to choose the type of the paper you are printing. Resolution : It defines the quality of the print output. Color : It allows the to print an image colored or B/W. Reduce / Enlarge : It allows you to reduce or enlarge the size of the being printed image.

V. Detail Specification 5. Detail Specification Print Range : All, Pages(1~9999) Copies : 1~99 pages Orientation : Portrait, Landscape Paper Size : Original,LETTER, LEGAL, EXECUTIVE, A4, A5, B5, FOLIO, COM10, DL, C5, C6, MONARCH, A6, A3, B4,JISB5 Paper Type : Default, Plain Paper, Thick, Thin, Bond, Color Paper, Card Stock, Labels, Transparency, Envelope, Preprinted Resolution : Draft, Normal Color : Auto, Black & White Reduce / Enlarge : Fit to page , Custom (50~200 %)

VI. Troubleshooting 1. PDF is not printed properly. PDF file size has to be smaller than printer memory size The printer has to PostScript printer language. The printer has a restriction related to PDF Version. (Ex : SCX-5x30 : up to PDF 1.4 format) PDF file which needs font files is printed without text.

2. the message window alerts you to select the appropriate printer. Check selected printer direct printing utility or not.

II. SCX-6555N series Feature & spec

Agenda

I.

Product Concept

II.

Specifications

III.

Key Features

Product C oncept Concept Target

Copier based Multi-Function Laser printer SMB, Corporate

Print, Copy, FAX, Scan

633x506x641 mm 45.5 Kg

55ppm (Letter) 53ppm (A4) Max. 1200 dpi effective output Ethernet 10/100/1000 Base TX USB 2.0

SCX-6555N

Max. paper capacity : 3140 sheets

Drum Life :80K Toner yield : 23K Option : - Finisher - SCF - HCF - NW Scan Kit

Specification (1/2) I t em Major Function

SCX- 6555N Standard

Option

- Copy - Direct Print & N/W Print - Direct Scan (USB) N/W Scan( to Email, FTP, SMB) FAX HCF(2100 sheet @ 75g/m2)

- DADF - HDD(80GB)

SCF (520 sheet @ 75g/m2) Finisher with Stapler

Max. x3 Tray Stapling: Portrait, Landscape (Left-Top 1 position)

Memory: 256MB Copy Speed

Simplex Copy Duplex Copy

Print Speed

Printing Technology

Stand: Short/Tall 55 m/Ltr, 53 m/A4

Simplex Print

- Simplex-Duplex(1-2) : Up to. 55 ipm/Ltr, 53 ipm/A4 -Duplex-Duplex(2-2) : Up to. 36 ipm/Ltr, 35 ipm/A4 Up to 55 ppm/Ltr, 53 ppm/A4

Duplex Print

Up to 50 ipm/Ltr, 48 ipm/A4

Printing Method 4 Beam LASER Scanning Unit and Electro-Photography Photoconductive OPC Materials Developing System Two Components Magnetic Brush Fusing System

Remar k

Dual Lamp heating

OEK (Option Enable Key) Smart DAA, Single LIU

UK Kentinental

Specification (2/2) Item

Main Processor Device Memory Physical Interface

Power Consumption (TBD) Machine Life

UI

SCX-6555N Orion2(500MHz) + CIP5+Hyper3

Option : 256MB ( max 512MB ) 256MB System Memory 7” Color TFT LCD

Parallel IEEE1284

Not

IEEE 1394

Not

USB Ethernet

Hi-Speed USB 2.0 10/100/1000 base TX

Wireless

Not

Operating / Standby / LowPower / Sleep

Remark Samsung Printing

900W / 180W / 80W / 35W

Machine Life 5 Years or 1,500,000 Pages Average Monthly Print Volume 12,500 Pages - DADF Feed Roller : 250,000 P - Tray Paper Feed Roller : 250,000P - Transfer Roller : 125,000 P - F Unit : 250,000P Normal / Low-Power / Sleep 5 / 25 / 40 seconds

800x480 pixels

For Print / Scan / FW Upgrade

Max.1500W

which comes first

Etc. Life

FCOT FPOT FAX

@ Platen

Normal / Low-Power / Sleep 8/ 25 / 40 seconds Compatibility Communication System Modem Speed

ITU-T G3, Super G3 PSTN / PABX 33.6Kbps

Memory: 16MB Battery Back-Up 72H

K ey Features

C ompetitive performance

Easy of use

Save time

R educe cost

• • • •

Two-sided output with standard L arge Touch screen ( 800x480 ) Fast FCOT ( 5 sec @ Platen ) Finisher with staple ( 50 sheets ) • Easier GUI to read and use • Easy to install ( CRU & Option )

• Fast speed ; FCOT ; 5sec @ Platen • Staple and collate with finisher • M ultiple functions simultaneuously

• Low Cost per Page ; Separate D rum & toner container • reduce paper cost with standard duplex function

- Easy of use Customer Installable CRU Design

Slide-in Finisher Slide-in Fax module

Easy to upgrade memory

Easy to install Drum & Toner Cartridge

III. SCX-6555N series Mechanism

Agenda

I.

General Specification

II.

Process

III.

Disassembly

Ⅰ. General Specification

Objectives

Ⅰ. Understanding the General specifications of SCX-6555N Ⅱ. Comprehension of the feature of major elements

Ⅰ. General Specification

Overall Spec. Feature

SCX-6555N

Size(W x D x H)

633*506*641mm (Standard) 633*506*1180mm (Full-Option:HCF+SCF)

Weight(Net)

Power Consumption

45.5kg (Standard)

Printing mode

900 W

Sleep mode

30 W

Printing/Copy

55/57 db

Standby

30/37 db

Noise

Ⅰ. General Specification

Printing

SCX-6555N

Mono Laser Printing

Printer Type Printing Speed

Resolution

Simplex : 53 ppm(A4)/55ppm(LTR)

Duplex

: 48ipm(A4)/50ipm(LTR)

Addressable 1200 x 1200 dpi over

Power Save

40 sec

Stand-by

8 sec

FPOT

Warm-up Time(Cold start) Toner Cartridge

Consumable

Less than 60 seconds

23K

Ⅰ. General Specification

Tray

Capacity (75gr/0.1mm)

SCX-6555N

Main Tray Optional Tray Manual Tray

520 sheets 100 sheets

Optional Cassette(SCF)

520 sheets

Optional Cassette(HCF)

2100 sheets 500 sheet (facedown stacking) N/A (face up to rear side)

Capacity of Output There is a bin-full sensor to measure paper capacity

Ⅰ. General Specification

Option

SCX-6555N

Optional Tray(Tray-2)

520 sheets

Optional Tray(HCF)

2100 sheets

Finisher

Single staple type : 50 sheets

Ⅰ. General Specification

Review

Ⅰ. What is the printing speed of SCX-6555N ?

Ⅱ. Process

Objectives

Ⅰ. Understanding the product configuration and CRU part Ⅱ. Comprehension of System Layout

Ⅱ. Process Product Configuration

Ⅱ. Process Customer Installable CRU Design

Slide-in Finisher Slide-in Fax module

Easy to upgrade memory

Easy to install Drum & Toner Cartridge

Ⅱ. Process

1. System Layout 1-1. Feeding Section

Feeding Method : Universal Cassette Type Feeding Standard : Center Loading Feeding Capacity : Cassette 520 Sheets (75g/ ㎡ Standard Paper) Manual Feed 100 Sheets(75g/ ㎡ Standard Paper ) 20 Sheets( OHP, Envelope, etc.) SCF 520 Sheets (Option) HCF 2100 Sheets (Option) Paper Detecting Sensor : Photo Sensor Paper Size Sensor : Tact Switch

Cassette

MPF

HCF

Ⅱ. Process

1. System Layout 1-2. Transfer Ass’y In Warranty( Life time) : Within 125,000 sheets printing

Ⅱ. Process

1. System Layout 1-3. Drive Ass’y Main Motor Ⅰis for Pick-up, MPF and Registration Main Motor Ⅱ is for OPC rotation Toner Motor is for Toner feeding F Motor is for F and Exit roller Duplex Motor is for Duplex feeding Exit Motor is for stable stacking Toner Motor

Main Motor Ⅰ Duplex Motor Main Motor Ⅱ

Exit Motor F Motor

Ⅱ. Process

1. System Layout 1-4. F Ass’y Fusing Type : [Dual Lamp Heating, 750W/650W] Heat Roller :[ø40 with 0.15 Crown ] Pressure Roller : [ø50 electrically conductive] Thermistor – Temperature Detecting Sensor non- thermistor 1EA, thermistor 2EA Thermostat – Overheat Protection Device F Bias : 300V on the P/R tube Trouble Open Heat Error

Temperature Control concept 80℃ below for 15 sec after power on.

Over Heat Error (F High Error)

225℃ over for 3 sec.

Low Heat Error (F Low Error)

10℃ below than target Temp. for 20 sec.

Ⅱ. Process

1. System Layout 1-5. LSU LSU consists of LD(Laser Diode) and polygon motor control. When the controller generate the printing signal LD will turn on and Polygon motor starts.If the receiving part in LSU detect the beam and then Hsync is generated. When the rotation of polygon motor is steady, it is time of LSU ready status for printing. If either of two condition is not satisfied, LSU error is expected. Trouble

Polygon Motor Error

Hsync Error

Failure Analysis

No steady rotation of Polygon Motor

In spite of steady rotation of Polygon Motor, No the generation of the Hsync signal

Ⅱ. Process

1. System Layout 1-6. Scanner( DADF) Scanning Method: Color CCD Scan speed : Mono 55/Color 45m@300*300 FCOT (first copy out time) : within 5sec DADF Copy speed : simplex 55m(LTR) duplex 36m(LTR)

Ⅱ. Process

1. System Layout 1-7. Toner Cartridge Standard Toner : 23K life

Ⅱ. Process

1. System Layout 1-8. Finisher Stacking Capacity : up to 500 sheets Staple Capacity : 50 sheets Staple Cartridge Capacity : 5,000 staples/cartridge

Ⅱ. Process

1. System Layout 1-9-1. Optional Tray ( SCF) For customer convenience in managing paper Capacity : 520 sheets

1-9-2. Optional Tray ( HCF) For customer convenience in managing paper Capacity : 2100 sheets

Ⅱ. Process

Review

Ⅰ. What is the function of paper feeding sensor ? Ⅱ. Do you know life of Transfer Roller? Ⅲ. Do you know the function of Thermistor and Thermostat?

Ⅲ. Disassembly

Objectives

Ⅰ. Studying the method of disassemble parts from a complete whole Ⅱ. Comprehension of the function of each parts Ⅲ. Understanding the basic structures of major part

Ⅲ. Disassembly : FINISHER

(1) Pull the connector from the SET

(2) Pull the Finisher carefully from the SET with pushing the latch

(1)

(2) (3) Release the stacker from the Finisher in the direction of arrow (4) Use the latch to replace the staple unit

(3)

(4)

Ⅲ. Disassembly : DADF

(1) (1) Remove the a dime screw, and disassemble the cover in the indicated direction

(2) (2) Pull the Scanner from the SET in the direction of arrow

Ⅲ. Disassembly : Platen (1) Remove the two dime screws, and pull the stacker cover (2) Remove the two 3X10 screws after pulling the Cassette (1)

(2) (3) Open the front cover and remove the two screws (4) Remove the four screws (4X10)

(3)

(4)

(5) Remove the two pin locks and six screws (4X10) (6) Remove the three screws (4X10) and unplug the four connectors

(5)

(6)

Ⅲ. Disassembly : FAX

Remove the two thumb screws, and pull the FAX from the SET

Ⅲ. Disassembly : PBA (Main Board)

Unplug the connectors from the main board and remove 6 screws

Ⅲ. Disassembly : PBA (SMPS & F Board)

(1) Remove the one screw (2) Pull the SMPS and unplug the connectors

(1)

(2)

(3) Remove two screws, and pull the cover in the direction of arrow (4) Remove the one screw, unplug the connectors and pull the F board

(3)

(4)

Ⅲ. Disassembly : Transfer Roller

Push the latch in the two directions and pull the Transfer Roller

Ⅲ. Disassembly : F Ass’y

Remove the four thumb screws, and pull the F Ass’y in the direction of arrow

Ⅲ. Disassembly : Exit Ass’y

(1)

(1) Remove the five 3X10 screws and the exit cover

(2)

(2) Remove the four 3X10 screws and pull the Exit Ass’y in the direction of arrow

Ⅲ. Disassembly : LSU

Remove the five screws (including one ground screw) and pull the LSU in the direction of arrow

Ⅲ. Disassembly : Drive-Exit Ass’y

2 1

(1) Pull the fan in the direction of arrow 1 (2) Remove the four 3X10 screws(yellow circled) and unplug the threw connector (blue circled) from the motors (3) Pull the Drive-Exit Ass’y in the direction of arrow 2

Ⅲ. Disassembly : Drive-Main Ass’y

2

3

1

(1) Unplug the mold e-ring and pull the three clutch (see arrow 1) (2) Remove the duct in the direction of arrow 2(outside direction) and unplug the four connectors (blue circled: main 1,2 motor, dc motor, fan) (3) Remove the seven 3X10 screws and pull the Drive-Main Ass’y in the direction of arrow 3(outside direction)

Ⅲ. Disassembly :MP Ass’y

(1) Remove the one 3X10 screw, and release the one gear and press in the yellow circle

(2) Remove the one 3X10 screw and friction pad

(1)

(2) (3) Remove the two 3X10 screws

(4) Release the MP Ass’y from the SET in the direction of arrow (pull & up)

(3)

(4)

Ⅲ. Disassembly

Review

Ⅰ. To separate the LSU Unit, What should you do?

Ⅳ. Troubleshooting

Objectives

Ⅰ. Building ability to deal with various problems raised in the field by reviewing troubleshooting Ⅱ. Check the solution of each problem. Ⅲ. Check the difference of each Jam.

Ⅳ. Troubleshooting : Double Feed Error Sheet Guide Retard : JC63-00747A MEA Unit-Roller PU : JC97-02259A

Double feeding occurs

MEA Unit-Cassette : JC97-02273A

Is there the Sheet Guide Retard in the regular position?

Yes

Is there any problem in the MEA Unit-Roller PU(Pick-up)?

Yes

NO

NO

Adjust the Sheet Guide Retard to the regular position

Replace the MEA UnitRoller PU (Pick-up)

NG Re-printing OK/NG?

Replace the MEA UnitCassette OK

OK End

End

Ⅳ. Troubleshooting :JAM0(Jam at Tray1) Check where the jammed paper is located

Leg-M_Act No Paper : JC61-01350A

MEA Unit-Roller PU : JC97-02259A

Photo Interrupter : 0604-001095

Leg-M_Act Ready DP : JC61-01435A

Clutch:

Motor DC-Main :

HVPS :

MEA Unit-Cassette : JC97-02273A

OK Paper still inside the Tray ?

NO

Check if the Photo Interrupter(Registration Sensor) works or not

Pull out the tray and start the printing job with Leg-M_Act No Paper on by lift upside. Check if the MEA Unit-Roller PU is rolling or not

NO

OK End

End

- You can make sure of it by actuating the Leg-M_Act Ready DP. If it does not work, replace the HVPS.

OK

Check the Clutch and the Motor DC-Main work or not. If needed, replace them.

Yes Replace the MEA Unit-Cassette or the MEA Unit-Roller PU

End

NO

Yes

Does the MEA UnitRoller PU rotate?

Check if any object or obstruction is on the path before the forward roller. If any, remove it or them.

OK End

Ⅳ. Troubleshooting :JAM1(Registration Jam, Jam at F) Check where the jammed paper is located

Lead edge of paper is located between the LegM_Act Ready DP and LegM_Actuator Exit?

Leg-M_Act Ready DP : JC61-01435A

Leg-M_Actuator Exit : JC61-01384A

Photo Interrupter : 0604-001095

Photo Interrupter : 0604-001095

HVPS:

End

NO

Push the Leg-M-Act Ready DP down, and check if it returns back quickly.

NO

Replace the Leg-M_Act Ready DP

Yes Yes Check if any object or obstruct is on the path. If any, remove it. OK End

Does the Photo Interrupter (registration sensor) work properly? Yes

NO

Replace HVPS

Check the Photo Interrupter (Exit Sensor) works properly or not.

End

NO Replace HVPS

End

Ⅳ. Troubleshooting : Document JAM Check if there is Document jam message regardless of removing the document form DADF tray

Yes

Either the Motor step-DADF or PBA SubDADF are defected. Replace ELA HOUDADF Sub Ass’y

NO Error message is disappeared? Check if driving unit works

NO Yes

NO

Replace the PBA Main-MFP

Replace MEA UNITHOLDER DADF RUBBER

Either the Motor-DADF or PBA Sub-DADF are defected. Replace ELA HOU-DADF Sub Ass’y

NO

Check if DADF is pulling Document

Motor -DADF :

PBA Sub-DADF :

ELA HOU-DADF Sub :

MEA UNIT-HOLDER ADF RUBBER:

PBA Main-MFP :

End Yes

Ⅳ. Troubleshooting : Over Heat Error (F High Error) ELA HOU-F Check how the LED is displayed

Over Heat Error

Is the same LED message shown

NO OK

Turn off the printer and wait for 5minute

Yes Turn off the printer. Replace the ELA HOU-F

Turn on the printer End NO

Is the same LED message shown again? Yes

Try to do print job

Turn off the printer. Replace the ELA HOU-F

End

Ⅳ. Troubleshooting : Low Heat Error (F Low Error) ELA HOU-F Check how the LED is displayed

Low Heat Error

Is the same LED message shown

NO OK

Yes

Try to reboot

Turn off the printer. Replace the ELA HOU-F Turn on the printer End NO

Is the same LED message shown again? Yes

Try to do print job

Turn off the printer. Replace the ELA HOU-F

End

Ⅳ. Troubleshooting

Review

I. What is most frequently happened trouble? II. Can you classifying each “Paper Jam”? (Jam0, Jam1, Document Jam) III. Do you have more question for troubleshooting?

IV. SCX-6555N series Hardware

Agenda I. II. III. IV.

General Specification Hardware Structure Summary of Major Parts Trouble Shooting

Ⅰ. General Specification

Objectives

I.

To make you aware of the key specification points

Ⅰ. General Specification Item Major Function

SCX-6555N Standard

Option

Copy Speed

Print Speed

Printing Technology

- Copy - Direct Print & N/W Print - Direct Scan (USB) - DADF - HDD(80GB SATA) N/W Scan FAX SCF (520 sheet ) HCF (2100 sheet) Finisher with Stapler

Simplex Copy

Ext. Memory: 256MB Stand: Short/Tall 55 m/Ltr, 53 m/A4

Duplex Copy

Up to 65% speed of simplex

Simplex Print

Up to 55 ppm/Ltr, 53 ppm/A4

Duplex Print

Up to 50 ipm/Ltr, 48 ipm/A4

Printing Method 4 Beam LASER Scanning Unit and Electro-Photography Photoconductive OPC Materials Developing SystemTwo Components Magnetic Brush Fusing System

2 Halogen LAMP F

Remark

OEK (Option Enable Key) Smart DAA, Single LIU Max. x3 Tray Stapling: Portrait, Landscape (Left-Top 1 position) DDR2 UK Kentinental

Ⅰ. General Specification Item

Main Processor Device Memory Physical Interface

Power Consumption Machine Life

UI

SCX-6555N

HYPER3, ORION

Samsung Printing, MARVEL

256MB System Memory 80GB HDD 7” color TFT LCD (with TSP)

Option : 256MB (DIMM Slot 1EA)

Parallel IEEE1284

Not

IEEE 1394

Not

USB Ethernet

Hi-Speed USB 2.0 1Gbit Ethernet

Wireless

Not

Operating / Standby / Low- 900W / 180W / 80W / 35W Power / Sleep Machine Life Average Monthly Print Volume

Remark

5 Years or 1,500,000 Pages 12,500 Pages

FCOT

- DADF Feed Roller : 250,000 P - Pick-up Roller : 250,000P - Transfer Roller : 125,000 P - F Unit : 250,000P Normal / Low-Power / Sleep5 / 25 / 40 seconds

FPOT

Normal / Low-Power / Sleep8/ 25 / 40 seconds

800 x 480 dots – SEC LCD

For Print / Scan / FW Upgrade

Max.1500W which comes first

Etc. Life

FAX

Compatibility Communication System Modem Speed

ITU-T G3, Super G3 PSTN / PABX 33.6Kbps

@ Platen

Ⅰ. General Specification

Review

Ⅰ. What kind of functions are standard option in SCX-6555N? Ⅱ.Is there any function for the to copy many documents automatically?

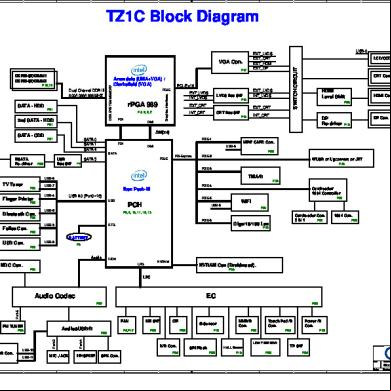

Ⅱ. Hardware Structure (Block Diagram) BLOCK DIAGRAM

1

Main Block Diagram

Ⅱ. Hardware Structure

(Configuration)

Hardware Configuration

Operation

Rear-Side View

Inner Connections

LIU

USB HOST LSU

DIMM

HVPS

HDD

SMPS

FDB

Ⅲ . Summary of Major Parts

Objectives

I.

Understanding the organization and function of major parts

Ⅲ . Summary of Major Parts 1. Main PBA Introduction UI I F

SCANNER LSU

HVPS Cover Open

F

DADF CI P5

LIU IF

EXIT

USB HOST

U

BLDC MTR

HYPER3 USB DEVI CE

DEV

REGI

USB HOST

U MOTORS

ORI ON Net wor k

PAPER EMPTY SIZE

DIMM

SPEAKER FI NI SHER DUPLEX

FLASH_ROM

SMPS

* MAIN Processor (1) ORION2(ARM9 core) - for MAIN SYSTEM BUS (2) HYPER3(SEC, ARM 1020E) - for Video Controller, Engine, LSU… (3) CIP5 : Color Image Processor

SCF

HDD_IF

AIR _TEMP

IF

* External Interface Ports (1) USB - 2.0 DEVICE 1 - 2.0 HOST 2 (2) N/W(Gigabit) (3) RJ45 for telephone(with Optional Fax Kit (4) Finisher IF

Ⅲ . Summary of Major Parts 1. Main PBA 1.2. U – ORION2 (88F5281)

Ⅲ . Summary of Major Parts 1. Main PBA 1.2. U – HYPER3

Ⅲ . Summary of Major Parts 2. DADF Board Duplex Automatic Document Feeder

Descriptions A DADF board controls 2 stepping motors, 2 clutches, 1 solenoid,10 sensors By using U(S3F443FX ) having 80MHz Core Frequency. A DADF board s customer to copy Max 100 sheets of documents automatically. In this reason, SCX-6555N series has a DADF module in standard option. Also 6555N’s DADF is serving up to 65% of Duplex speed. And this happens to make one more paper path for high speed paper feeding.

Ⅲ . Summary of Major Parts

2.1. DADF Block Diagram

Descriptions

• MPU: S3F443FX (Refer to the next page) • Motor Drive Block - Unipolar Motor Driver IC(SLA7066M): Most rollers are controlled by a SLA7066M motor drive. - Bipolar Motor Driver IC(A3977): For Exit motor • Clock Generator(CY25814): SSCG converts crystal 12Mhz to 48MHz clock for MPU main clock.

Ⅲ . Summary of Major Parts 2.2. MPU (S3F443FX) The S3F443FX has been developed by using the ARM7TDMI core, CMOS standard cell, and data path compiler. The S3F443FX has been designed to only Big Endian. Most of the on-chip function blocks have been designed by using a HDL synthesizer. The S3F443FX has been fully verified in SAMSUNG ASIC test environment including internal Qualification Assurance Process.

FEARUES

• Memory system manager: 3 external memory banks. (If the internal flash ROM is not used for a boot code, nCS0 will be used for a boot ROM ) •Operating Voltage Range: Core=1.8V ,I/O=2.7–3.6V • Operating Frequency Range: Up to 80MHz (U core, SRAM, and Peripherals), up to 40MHz (Flash ROM) • Built-in 256Kbyte (64K ´ 32-bit) Flash memory • 8K-bytes (2K ´ 32-bit) internal SRAM for stack, data memory, and/or code memory • One channel UART • Six 16-bit internal timers with 8-bit pre-scaler and input Capture function • Power down mode: STOP and IDLE modes • One 8-bit basic timer and 3-bit watch-dog timer • Interrupt controller (Total of 21 interrupt sources including 3 external sources ) • Sixteen programmable I/O ports • One 8-Bit PWM • 64-pin LQFP

Ⅲ . Summary of Major Parts 2.3. DADF Sensor Configuration DADF Document Path

Document Paper Path Simplex : 1->2->3->4->6 Duplex : 1->2->3->4->5->4->3->7->6

Ⅲ . Summary of Major Parts 3. OPE Board

800*480 color TFT LCD U(S3C2413C): ARM9 Based 32bit RISC Processor. Flash ROM(32MB): OP Operating program F/W DDR2(64MB): System Program and Data Buffer BLU : LED type / with TSP(Touch Screen )

Ⅲ . Summary of Major Parts

3.1. OPE Board Block Diagram

Ⅲ . Summary of Major Parts 3.2. U (S3C2413) KEY FEARUES

Ⅲ . Summary of Major Parts

. FAX Board

SPECIFICATIONS •LINE CONNECTION: PSTN or PABX (RJ-11)

•Compatibility: ITU-T G3, Super G3 •Communication System: PSTN/PABX •Modem Speed: 33.6Kbps •TX Speed: 3 sec * Standard Resolution, MMR, 33,6Kbps * Phase "C" by ITU-T No.1 Chart in Memory transmission with ECM •Scan Speed Platen-> 2 sec / A4 ADF-> 5.5 sec / A4 * Scan time: 2 sec/A4 @ 203x98dpi * Scan setup time : 3.5 sec •Receive Mode: Fax, TEL, ANS/FAX •Compression: MH/MR/MMR/JBIG/JPEG •ECM: Yes •Resolution Std: 203*98dpi Fine: 203*196dpi S.Fine: 203x392dpi, 300*300dpi, 406x392dpi •Contrast: Adsustable 5 levels •Fax Memory: 32MB (in HDD)

Ⅲ . Summary of Major Parts

1. FAX Board Block Diagram

Ⅲ . Summary of Major Parts

2. FAX Board Types Parallel VS Serial

DESCRIPTIONS

The FAX unit has a parallel and a serial type according to PSTN. - How to connect a serial fax first. 1) s can use fax by connecting line cord into Line RJ11. 2) 2’nd phone can be used by 4 line cord. - Parallel Fax 1) s can use fax by connecting line cord into Line RJ11. 2) If an want to use a 2’nd phone, just connect to External RJ11.

Ⅲ . Summary of Major Parts 5. SMPS PBA

Descriptions

It supplies electric power to a Main Board and other boards through a Main Controller by +5V,+24V from 110V/220V power input. It has safety protection modes for over current and load.

SPECIFICATION

General Input/Output Voltage 1) AC 110V (90V ~ 135V) 2) AC 220V(180V ~ 270V) 3) Input Current: 3.214 [A] (rms) 4) Output Power: 192W/Max.270W DC 5V:24W~30W(0.6A ~ 6.0A) DC 24V: 168W~240W(0A ~ 10A)

Ⅲ . Summary of Major Parts 5.1. SMPS PBA SMPS

24V(CON71-1,3,4): LSU, OPE, HVPS, DEVE, etc use on all other components except below 24V powers. 24VM(CON71-7,9,10): Make 24VS for units with regard to safety like a fan. 24VO(CON71-13, 15): Option (SCF, Finisher) 5V(CON 71-19, 21, 22, 25, 26): It is a source to make all other power, 3.3V and 1.2V used in IC, U and etc.

Ⅲ . Summary of Major Parts

6. FDB PBA FDB (F DRIVE BOARD)

SPECIFICATION

General Input/Output Voltage 1) AC 110V (90V ~ 135V) 2) AC 220V(180V ~ 270V) 3) Output Power: 800[W] (800[W]/100V~120V=8A) (800[W]/220V~240V=4A)

Descriptions FDB(F DRIVE BOARD) is controlled by MCB’s AC lamp control signal. It can handle the F Assy’ by providing AC voltage.

Ⅲ . Summary of Major Parts

7. HVPS PBA HVPS (High Voltage Power Supply) SPECIFICATION

General Input Voltage 1)DC 5V (4.75 ~ 5.25V) 2)DC 24V(21.6V∼27.6V) •General Output Voltage 1)MHV: -1200V±3% 2)Fu-Bias: 220V±5% 3)DEV:-500V±3% 4)THV(+):1400V±3% 5)THV(-):-1300V±20% 6)DTS: -1800V±3%

Descriptions

HVPS Part outputs the high voltage for THV(+),(-)/MHV/DEV/DTS/FU-BIAS by DC 24V input and the output high voltage is provided into OPC Cartridge and Transfer Roller. It helps transfer toner to media well.

Ⅲ . Summary of Major Parts

8. SCF / HCF Description A SCF PBA is a option cassette controlling in SCX6555N. Max. 3 cassettes are connected on a purpose of feeding paper. It consists one controller(S3F443FX) and two motor drive IC to control feeding timing through Uart communication with a Main controller. This PBA is also used in HCF. Key funtion is same with SCF and HCF & SCF can be able to be composed together.

Feeding Control

POWER

-

+24V Power

2

3.3V

POWER

-

+3.3V Power

3

GND

POWER

-

Signal Ground

4

TxD

OUT

-

Data Transmission

5

RxD

IN

-

Data Receive

6

nBUSY

OUT

LOW

SCF TxD Line Busy

7

nCMDREQ

OUT

LOW

Command Request

8

Reserved1

I/O

LOW

Reserved

9

Reserved2

I/O

LOW

Reserved

1'st S CF

24V

CF

1

1'st S

Remark s

2'nd SCF

Description

F HC

Active Level

F

Direction

SC

Signal Name

3 'r d

No.

The following example shows the order to select SCF. Example) - Event with 2nd SCF operating: 2’nd SCF -> 1’st SCF -> 3’rd SCF - Event with 3rd SCF operating: 3’rd SCF -> 2’nd SCF -> 1’st SCF -Event with 1st SCF operating: 1’nd SCF -> 3’st SCF -> 2’rd SCF

Ⅲ . Summary of Major Parts

9. Finisher Description A Finisher PBA is a Finisher controlling in SCX-6555N for option. It also consists one controller(S3F443FX), two motor drive IC and LPEC1 for expandable I/O IC to control a finisher through Uart communication with a Main controller.

Ⅲ . Summary of Major Parts

0. Main Sensor Units SCX-6555N Configuration of Sensors

DESCRIPTION

① Bin Full Sensor :Check overflowing of Paper on Stacker ② Regi Sensor :Two Regi Sensor for checking precise paper position ③ Exit Sensor :Check paper position on F ④ Duplex Jam :Check paper position on Duplex path1 ⑤ Paper Empty Sensor :Check Paper empty on a cassette ⑥ Duplex Ready :Check paper ready on Duplex path ⑦ Cassette Detect :Check cassette insertion ⑧ Paper Limit :Check raising paper up to feeding position ⑨ Paper Low Sensor :Check the number of paper below 100 pages ⑩ SCF Feed :Check where a paper feeding path ⑪ SCF Door Open Sensor :Check SCF door open ⑫ MPF Empty Sensor :Check paper empty on MPF

Ⅲ . Summary of Major Parts

0.1. Main Sensor Units

Troubleshooting Tips

All Sensors could be checked on the Diagnostics mode. However you can also check the defectiveness with a normal controller. Here are some tips for troubleshooting. - To check Defectiveness of a sensor.

Each sensor should be measured with a normal main controller as following as shown. ① Bin Full Sensor : To check full of paper on stacker ② Regi Sensors :The position of two Regi Sensors are tiny different for top margin of the paper fed on path. ③ Exit Sensor : To check paper jam on f. ④ Duplex Jam : To check paper jam on Duplex path. ⑤ Duplex Ready : To check Paper edge for developing timing. ⑥ Paper Empty Sensor : To check paper empty on a cassette. ⑦ Cassette Detect : To check a tray inserted on. ⑧ Paper Limit : To check paper up limit. ⑨ Paper Low Sensor : To check the number of paper below 100 pages ⑩ SCF Feed(SCF PBA): To check the top margin of a paper. ⑪ SCF Door Open Sensor(SCF PBA): To check side door of SCF. ⑫ MPF Empty Sensor : To check MPF paper empty.

Ⅲ . Summary of Major Parts

1. Miscellaneous POWER SAVER - LOW POWER mode : 15min(default) , MCB controls F’s temp so that power consumtion could be lower than STANDBY. - SLEEP mode : 45min(30min after LOW POWER), machine provides minimum power.(LCD,FANS and F are offed) * can change default time(up to 120min) - OFF mode : controlled by button in UI . Almost every electrical device is turned off(under 1W)

Ⅳ . Troubleshooting

Objectives

I.

To give some solutions with trouble

Ⅲ . Troubleshooting 1. No Power Engine isn’t warming up & LCD does not display anything on.

Check whether the LED on Main PBA is flickered on (+5V Check)

OFF - +5V N.G

N.G

Check +5V ON SMPS

Replace Main PBA

O.K ON/BLINK - +5V O.K

Each Check +24V On Main PBA

N.G

Each Check +24V ON SMPS

O.K

O.K

Check +3.3V

O.K

N.G

Replace Main PBA Replace SUB PBA

Replace SMPS

N.G

Replace SMPS Replace Main PBA

Ⅲ . Troubleshooting 2. No Display on LCD Engine is warming up properly but LCD does not display anything on.

Check +24V On OP PBA

O.K

Check the BLU Harness on OP PBA

O.K

Replace OP PBA or LCD

N.G

Check Connecting Harness between OP & MAIN PBA

O.K

Check +24V On MAIN PBA

N.G N.G

Connect Harness

O.K

Replace OP PBA Replace MAIN PBA or SMPS

Ⅲ . Troubleshooting 3. LSU Error

LSU error massage is displayed

Check LSU_5V/24VS with side cover closed

O.K

N.G

Check 5V/24VM on Main PBA

N.G

Replace MAIN PBA or SMPS

O.K

Replace LSU Reinstall Developer

N.G

Replace OPC

Ⅲ . Troubleshooting 4. Cover Open The cover open massage displays on even when the print cover is closed.

Is the Hook lever Ok?

N.G

Replace Side Cover

O.K

Check Micro Switch

N.G

Replace Micro Switch

O.K

Replace Main PBA

Ⅲ . Troubleshooting 5. F Error Low Heat Error is displayed on LCD

Wire connections between FDB and other devices are all correct?

N.G

Make wire connections to be completed

O.K

Replace FDB PBA Check resistance AC connector below 10ohm

Replace MCB PBA

O.K

Replace F

N.G

Go to Cover Open Session

O.K

N.G

In FDB PBA Check Lamp 1 sig(con. No. 2) Relay On sig(con no.5)

N.G

O.K

IN FDB PBA Check 24V (in 6pin connector No1)

Ⅳ. Troubleshooting

Review

Ⅰ. Do you have any question for troubleshooting?

V. SCX-6555N series CRU

Agenda I.

General Specification

II.

Process

III.

Troubleshooting

IV.

Block Diagrm

Ⅰ. General Specification

Objectives

Ⅰ. Understanding the general specifications of CRU of SCX-6555N Ⅱ. Comprehension of the feature of major elements

Ⅰ. General Specification

Overall Spec. Feature

Drum Cartridge

Toner Cartridge

Size(WxDxH)

108x110x356mm

81x211x351mm

Weight(Net)

2.0 kg

1.1 kg

Capacity

80K

23K

Amounit of Developer/Toner

Developer 300g

Toner 680g

Development Method

2 component magnetic brush system

Ⅰ. General Specification

Drum Cartridge Drum Type Coated Type

Φ 30 Organic Photo Conductor (OPC) UCL (Under Coated Layer)

Developer Roller

Φ 25 Magnetic Roller

Charger Type

Charge Roller

Charger Roller Cleaner

Urethane Foam Cleaning Roller

OPC Cleaning type

Counter Blade Cleaning (Rubber Blade)

Developer

Carrier + Toner (300 g)

CRUM

SCRUM Type

Ⅰ. General Specification

Toner Cartridge Toner Supply Type

Urethane Feed Roller

Toner Type

Non Magnetic Pulverized Toner

Paddle

Two Paddles + Film Type

Waste Toner

With Waste Toner Bottle

CRUM

SCRUM Type

Ⅰ. General Specification

Review