Sample Written Preventive Maintenance Program 6lx66

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 2z6p3t

Overview 5o1f4z

& View Sample Written Preventive Maintenance Program as PDF for free.

More details 6z3438

- Words: 902

- Pages: 3

SITE NAME Preventive Maintenance Program Purpose

The SITE NAME preventive maintenance program applies to all facilities and departments that house industrial operations or equipment that could cause serious physical harm to employees if equipment safety-related components fail. The preventive maintenance program includes facilities related safety equipment such as ventilation systems, emergency alarms, sprinklers, breathing air compressors, pressure vessels, and non-facilities items such as vehicles, material handling gear, noise mufflers on equipment, etc. Ultimately, the preventive maintenance program is focused on ensuring a formal process for maintaining safety features of equipment exists, and ing building components are operating properly in order to prevent occupational injuries and illnesses as a result of exposure to safety and health related hazards. Policy SITE NAME employs the concepts and principles of the Occupational Safety and Health istration’s Voluntary Protection Programs (VPP). OSHA VPP guidance requires that a site have a comprehensive preventive maintenance system that

includes the following components:

A written preventive and predictive maintenance system for monitoring and maintaining workplace equipment A defined equipment repair and replacement schedule that follows manufactures’ recommendations to prevent failure and creation of hazards/hazardous condition A system for documenting records of maintenance and repairs A preventive maintenance program that considers safety and health components of equipment

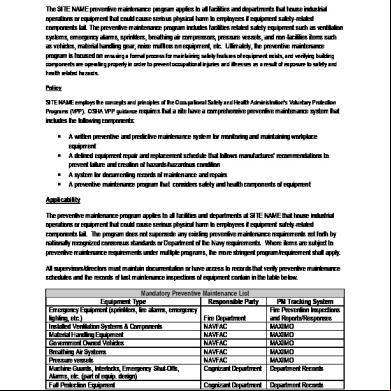

Applicability The preventive maintenance program applies to all facilities and departments at SITE NAME that house industrial operations or equipment that could cause serious physical harm to employees if equipment safety-related components fail. The program does not supersede any existing preventive maintenance requirements set forth by nationally recognized consensus standards or Department of the Navy requirements. Where items are subject to preventive maintenance requirements under multiple programs, the more stringent program/requirement shall apply. All supervisors/directors must maintain documentation or have access to records that preventive maintenance schedules and the records of last maintenance inspections of equipment contain in the table below. Mandatory Preventive Maintenance List Equipment Type Responsible Party Emergency Equipment (sprinklers, fire alarms, emergency lighting, etc.) Fire Department Installed Ventilation Systems & Components NAVFAC Material Handling Equipment NAVFAC Government Owned Vehicles NAVFAC Breathing Air Systems NAVFAC Pressure vessels NAVFAC Machine Guards, Interlocks, Emergency Shut-Offs, Cognizant Department Alarms, etc. (part of equip. design) Fall Protection Equipment Cognizant Department

PM Tracking System Fire Prevention Inspections and Reports/Responses MAXIMO MAXIMO MAXIMO MAXIMO MAXIMO Department Records Department Records

SITE NAME Preventive Maintenance Program Equipment may be added or removed from the mandatory preventive maintenance list as site operations and safety and health findings warrant change. All equipment not included in the table above will receive visual inspections specifically for the purpose of identifying safety-related preventive maintenance issues. Mission specific equipment used for research and development purposes will undergo a documented machine check prior to use to determine whether or not preventive maintenance is needed, and to identify any hazardous conditions associated with the equipment. In addition, the need for equipment maintenance is also identified during routine self inspections and by employees during daily visual pre-use equipment inspections.

Responsibilities Commanding Officer: The Commanding Officer is responsible to hold site personnel responsible for executing guidelines set in the preventative maintenance program. Safety & Health Staff: The Safety and Health Staff shall:

that all industrial equipment at the site goes through an initial pre-use analysis/machine check to ensure all safety features are operating properly.

that preventive maintenance inspections include the evaluation of equipment components designed to protect workers’ safety and health.

Provide technical oversight concerning the occupational safety and health aspects of the preventive maintenance program.

Review and approve systems used by all departments for preventive maintenance planning and recordkeeping.

Receive training in preventive maintenance topics as appropriate to their assigned duties.

Responsible Parties (see above Table): The Responsible Parties noted above shall:

Plan, schedule, and complete preventive maintenance inspections and scheduled maintenance actions for assigned items in a timely manner, in accordance with manufacturers’ recommendations and/or other applicable guidance. Utilize engineers or other appropriately qualified personnel to establish periodic inspection and preventive maintenance requirements for required items when manufacturers’ recommendations and/or other applicable guidance have not been established.

Document the completion of preventive maintenance activities for assigned items using logs/systems approved by the Safety Office.

Retain records of preventive maintenance inspections and scheduled maintenance for a period of at least 3 years after actions are accomplished.

Department Heads/Supervisors: It is the responsibility of the supervisors to do the following:

Maintain an inventory of all equipment in his/her facility that requires preventive maintenance based on either manufactures’ guide or SITE NAME preventive maintenance policy

SITE NAME Preventive Maintenance Program

Coordinate preventive maintenance activities with responsible parties

Inform the Safety Office when new equipment is purchased that requires periodic preventive maintenance.

Ensure all employees performing preventive maintenance receive appropriate item specific preventive maintenance training.

Employees: It is the responsibility of the employee to do the following:

Not perform maintenance on equipment without authorization

Conduct a visual inspection of equipment prior to use to ensure safety-related features are functioning properly.

Immediately notify supervisors of facility/equipment failures and/or problems noted in visual inspections.

Never by safety features or remove guards.

Documenting/Tracking Maintenance Activity SITE NAME uses both commercially off the shelf maintenance software for tracking facilities maintenance orders. For nonfacilities related preventive maintenance needs, the site uses and Microsoft Office programs such as Access and Excel to track a maintenance orders

The SITE NAME preventive maintenance program applies to all facilities and departments that house industrial operations or equipment that could cause serious physical harm to employees if equipment safety-related components fail. The preventive maintenance program includes facilities related safety equipment such as ventilation systems, emergency alarms, sprinklers, breathing air compressors, pressure vessels, and non-facilities items such as vehicles, material handling gear, noise mufflers on equipment, etc. Ultimately, the preventive maintenance program is focused on ensuring a formal process for maintaining safety features of equipment exists, and ing building components are operating properly in order to prevent occupational injuries and illnesses as a result of exposure to safety and health related hazards. Policy SITE NAME employs the concepts and principles of the Occupational Safety and Health istration’s Voluntary Protection Programs (VPP). OSHA VPP guidance requires that a site have a comprehensive preventive maintenance system that

includes the following components:

A written preventive and predictive maintenance system for monitoring and maintaining workplace equipment A defined equipment repair and replacement schedule that follows manufactures’ recommendations to prevent failure and creation of hazards/hazardous condition A system for documenting records of maintenance and repairs A preventive maintenance program that considers safety and health components of equipment

Applicability The preventive maintenance program applies to all facilities and departments at SITE NAME that house industrial operations or equipment that could cause serious physical harm to employees if equipment safety-related components fail. The program does not supersede any existing preventive maintenance requirements set forth by nationally recognized consensus standards or Department of the Navy requirements. Where items are subject to preventive maintenance requirements under multiple programs, the more stringent program/requirement shall apply. All supervisors/directors must maintain documentation or have access to records that preventive maintenance schedules and the records of last maintenance inspections of equipment contain in the table below. Mandatory Preventive Maintenance List Equipment Type Responsible Party Emergency Equipment (sprinklers, fire alarms, emergency lighting, etc.) Fire Department Installed Ventilation Systems & Components NAVFAC Material Handling Equipment NAVFAC Government Owned Vehicles NAVFAC Breathing Air Systems NAVFAC Pressure vessels NAVFAC Machine Guards, Interlocks, Emergency Shut-Offs, Cognizant Department Alarms, etc. (part of equip. design) Fall Protection Equipment Cognizant Department

PM Tracking System Fire Prevention Inspections and Reports/Responses MAXIMO MAXIMO MAXIMO MAXIMO MAXIMO Department Records Department Records

SITE NAME Preventive Maintenance Program Equipment may be added or removed from the mandatory preventive maintenance list as site operations and safety and health findings warrant change. All equipment not included in the table above will receive visual inspections specifically for the purpose of identifying safety-related preventive maintenance issues. Mission specific equipment used for research and development purposes will undergo a documented machine check prior to use to determine whether or not preventive maintenance is needed, and to identify any hazardous conditions associated with the equipment. In addition, the need for equipment maintenance is also identified during routine self inspections and by employees during daily visual pre-use equipment inspections.

Responsibilities Commanding Officer: The Commanding Officer is responsible to hold site personnel responsible for executing guidelines set in the preventative maintenance program. Safety & Health Staff: The Safety and Health Staff shall:

that all industrial equipment at the site goes through an initial pre-use analysis/machine check to ensure all safety features are operating properly.

that preventive maintenance inspections include the evaluation of equipment components designed to protect workers’ safety and health.

Provide technical oversight concerning the occupational safety and health aspects of the preventive maintenance program.

Review and approve systems used by all departments for preventive maintenance planning and recordkeeping.

Receive training in preventive maintenance topics as appropriate to their assigned duties.

Responsible Parties (see above Table): The Responsible Parties noted above shall:

Plan, schedule, and complete preventive maintenance inspections and scheduled maintenance actions for assigned items in a timely manner, in accordance with manufacturers’ recommendations and/or other applicable guidance. Utilize engineers or other appropriately qualified personnel to establish periodic inspection and preventive maintenance requirements for required items when manufacturers’ recommendations and/or other applicable guidance have not been established.

Document the completion of preventive maintenance activities for assigned items using logs/systems approved by the Safety Office.

Retain records of preventive maintenance inspections and scheduled maintenance for a period of at least 3 years after actions are accomplished.

Department Heads/Supervisors: It is the responsibility of the supervisors to do the following:

Maintain an inventory of all equipment in his/her facility that requires preventive maintenance based on either manufactures’ guide or SITE NAME preventive maintenance policy

SITE NAME Preventive Maintenance Program

Coordinate preventive maintenance activities with responsible parties

Inform the Safety Office when new equipment is purchased that requires periodic preventive maintenance.

Ensure all employees performing preventive maintenance receive appropriate item specific preventive maintenance training.

Employees: It is the responsibility of the employee to do the following:

Not perform maintenance on equipment without authorization

Conduct a visual inspection of equipment prior to use to ensure safety-related features are functioning properly.

Immediately notify supervisors of facility/equipment failures and/or problems noted in visual inspections.

Never by safety features or remove guards.

Documenting/Tracking Maintenance Activity SITE NAME uses both commercially off the shelf maintenance software for tracking facilities maintenance orders. For nonfacilities related preventive maintenance needs, the site uses and Microsoft Office programs such as Access and Excel to track a maintenance orders