Revision Cards (nebosh) 6zv4c

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 2z6p3t

Overview 5o1f4z

& View Revision Cards (nebosh) as PDF for free.

More details 6z3438

- Words: 3,244

- Pages: 44

Health & Safety at Work act etc 1974 Section 2 2.1 General duty to ensure so far as reasonable practicable the health & safety of employees

Section 3

2.2a Provision & maintenance of safe plant & SSOW

Visitors disclosure of information

Section 4

Public contractor

Sharing workplace Section 5

2.2b Safe use, handling, storage and transport of materials

Emission

2.2c Information, Instruction, Training and Supervision

Section 6

2.2d Safe access and regress 2.2e Adequate safe facilities 2.3.3Policy 2.2.4/5

Manufacturers

Health & Safety at Work act etc 1974

Section 7 Employee duty

Safety rep

Section 8

2.2.6Consultation with safety reps

Employees not to interfere

2.2.7Establish committee if requested by 2 reps in writing

Section 9 Charge for PPE

Section 37 Prosecution of Director / Managers

Section 33 Not to obstruct inspector

Whistle Blowing

Employee good faith Prescribed People

Law = The Public Interest Disclosure act 1998

-Union Safety rep

Employees must have reasonable belief of one or more of the following Breach of legal obligation

-Employer -H&S advisor -Professional body -HSE

Whistle Blowing Prescribed people

Employee good faith

Employees protected against -loss of job -victimisation

Protected disclosure

-if job lost, case for unfair dismissal

A criminal offence

Miscarriage of justice

Danger to the H&S of an individual Danger to the environment

Domino Theory Event 5

Heinrich / Bird Loftus

Effect - injury

Event 4

Domino Theory

Accident Event 3

Natural culmination of a series of events leads to a preventable injury occurring

Chain of events

Unsafe act or condition

Remove as to prevent accident Event 2

Event 1

Fault of person

Ancestry / social environment

Bird & Loftus developed Heinrich model to include management influence Benefits •

Structured accident investigation

•

Bird & Loftus version encourages the search for underlying causes

Limitations •

Simplistic straight chain thinking

•

Heinrich model restricts the findings of underlying causes

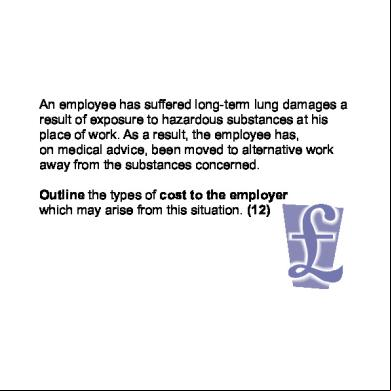

Compensation Amounts Compensation Amounts Special known Loss of earnings up to trial Modifications of house Travel expenses Special care Medical costs Legal expenses General not know After care Pain & Suffering Impact upon family life Loss of ability Loss of quality of life Loss of future earnings

Reducing the risk of component failure Reduce the risk of component failure Burning in Regular inspection Monitoring of conductions ,e.g.. temp Planned replacement Information, e.g.. Life span Component design Life Span Collection of failure information Failure mode analysis Introduction of parrelet systems Standby systems Planned preventative maintenance

Factors that affect perception Factors that affect perception Age Experience Physical ability Personality Attitude Intelligence Information received Knowledge Design & ergonomics Knowledge & experience Training Senses Visual Audio Smell Feel Environmental factors, e.g. noise Drugs & alcohol Fatigue e.g.. Shifts Nature of hazard

Gaining Workforce Commitment Gaining Workforce Commitment

Training

Leading from the front

Finding out reasons for resistance

Consultation with employees

Get their input

Use of step by step instructions

E.g. pilot schemes

Setting out clearly the reasons and benefits of the proposed change

Produce positive

Get everyone involved

Demonstrate weakness in existing system

Accident Interview Techniques Put person at ease by explaining purpose of investigation

Finish interview on a positive note – perhaps what witness thinks can be done to improve Repeat witness back to them to check that it is fully understood

Take notes May need to adjust language for witness

Accident Interview Techniques

Listen without interruption Careful Question Phrasing •What happened •What did you see •What times •Where •When •How •Who •Not why

Interview ASAP after the event

Interview person at the scene if possible (props easily available, help memory)

Invite witness to have accompanying person

Benefits of staying with HSG65 No cost for certificates / maintain certification

Existing system may be working well

HSG65 is used by the enforcing bodies HSG65 was created to address the requirements of Reg5 MHSR99

Benefits of staying with HSG65

Audits are generally carried out by health & safety specialist

Organisation could be exposed during change over OHSAS model may be too sophisticated for smaller companies Increased paperwork

Cost of change over

Consideration when developing an audit program Applicable legislation Monitoring systems for results

Resource required to audit

Training for auditor

Consideration when developing an audit program

Frequency of audits

Scoring system Time required

Aspects to be audited e.g.. Elements of HSG65

Benefits of OHSAS18001 External regulation e.g.. customer

Customer demand

Clearer standard for benchmarking

Recently accredited to ISO standard (2007)

Benefits of OHSAS18001 More prescriptive system

External assessment

International recognition

Benefits of Integrated Management Systems Team approach Improved and/or equal culture for all standards/disciplines Equal business priority

Benefits of Integrated Management Systems

Reduction in costs •Combined audits •Less duplicates •Same format used

Holistic approach to risk management

Equal influence

•Combined information systems

Benefits of separate management systems Existing systems may work well Resistance to change

Business exposure during integration period

Benefits of Separate Management Systems

Customer demand •ISO/OHSAS required •Complex auditing

One discipline may require a more complex system to meet business needs

Potential loss of professional disciplines required

Health & Safety / Environmental have a minimum legal requirement

Multiple causation Benefits •Thorough accident investigation

May be more use than one underlying cause

•Identification of all underlying causes including effects of managers and management systems

Not only if happens in sequence

•Encourages the use of a more systematic accident analysis such as fault tree analysis

Multiple causation Thorough accident investigation requires all cause to be identified Failings usually interact with each other causing incident, can be major

Look at all factors including culture, management

HSWA 74 & Disabled person considerations Section 2 Welfare provisions

1. General duty H&S of employees

Safe access and regress

Workplace circumstances

Reasonably practicable measures to ensure safe

Appropriate means of training & providing information

HSWA 74 & Disabled person considerations Nature of disability

Safe plant Adaptation of SSOW to suit

Disability discrimination act 1995 Unlawful for employer to discriminate against a disabled person when he employs Consider effectiveness of modifications. E.g. fire alarm effectiveness

Not to discriminate during recruitment

Disability discrimination act & Disabled person considerations Equal promotion prospects

Reasonable adjustments

Emergency procedures Workplace layout

•Premises, access /egress, welfare

Vicarious Liability Breach of civil law Means to pay claimant

Employers liability insurance

Cases •Lister Vs Romford Ice & Cold Storage

Vicarious Liability

•Hudson Vs Ridge manufacturing (competent fellow employees)

Employee employed by employer

Defences •Volenti non fit injuries •Contributory negligence •Not acting within scope of employment •Not employed •No injury or unforeseeable

Tort of negligence committed by employee Negligent act cause injury or loss to third party

Employee acting in course of employment

Near miss systems Clearly definition of ‘near Miss’

Who will report near misses

Positive for reporters Training required

Define reporting lines to ensure actions are implemented

Ease of reporting, clear, straight forward format

Considerations when developing a near miss system Consultation with employee

Building of a fair blame culture

Provision of information, instruction and training

Purpose and Benefits of Near Miss Data Helps get everyone involved in safety

Near misses have the potential to become an accident’

Identifies opportunities for improvements

Identifies inadequate health and safety management and/or elements of the management system

Purpose & Benefits of near miss data

Investigation of near misses and carrying out improves/implementing preventative measures

Shows management commitment through action follow up and feed back Data analysis can show trends and reoccurring issues – indicates areas to improve

Identifies inadequate training Helps to identify inadequate SSOW

Proactive approach to incident management

Design of controls Easy to use e.g.. Toggles / switches

Keep number to minimum

A change of system state should only occur after operation of a control

Space between each control

Control design Arrange of controls in sequence of use Stop controls should be easy to activate Controls should be kept next to the display that gives the reading of its output

Operating a control should require a positive action by the operator with immediate effect

System restarts should only occur after operating a control Labels & shape put to effective use

Design of Displays Digital for quantative information Emergency displays should be clearly identifiable

Direct relation between readout and control

Dials with pointers to convey qualative readings Use of colours to give clear indication of a change in state

Correct number of controls, too many will overload operators

Display design Lights used for status readings

VDU’s to show process overview

Characteristics Of A Positive Safety Culture Reporting of hazards by employees

Open communication between managers and shop floor

Management commitment

Leadership by managers

Potentially low accident rates

Characteristics Of A Positive Safety Culture Availability of funds and resources

Mutual trust Strong participation by employees

Good quality of health and safety training

Strategic role of H&S profession Ensuring organisation is legally compliant and keeping up to date with legislation changes

Policy development and setting of objectives Managing enforcing bodies

Strategic role of H&S profession

Auditing & identifying further opportunities for improvement

Advising senior managers

Developing strong good safety culture Involvement in reactive monitoring e.g. accident investigation

Developing / agreeing plans for improvement, short and long term

Formulating & developing elements of the H&S management systems

Employer responsible for negligent act of contract vicarious liability Case: Mersey docks & harbour board Vs Coggins & Griffiths Act caused harm or loss to third party

Contractor under control of employer

Employer responsible for negligent act of contract vicarious liability

Acting in course of employment

Employer authorises negligent act

Contractor carrying act over which employer has control

Requirement of Reg7 MHSR1999 Person competent to advise Exemption for partners if one or more is competent

Information on temporary workers

Preference is internal appointment

Appoint one or more persons

Requirement of Reg7 MHSR1999

Provision of information on health & safety issues to externally appointed (consultant)

Arrangements for cooperation if more than one

Number of and time available sufficient for size, risk and risk distribution of the company

Typical client / contract for work carried out Responsibilities for emergency planning

Contractor to maintain legal compliance

Provision of competent persons

Clients right to stop work if unsafe

Define safety responsibilities between client & contractor

Employer liability insurance

Typical client / contract for work carried out

The requirement that the contractor has RAs, SSOW,MSs Clients right to monitor safety standards of contractors

Requirement to attend site H&S induction before workers start work on site

The contractor / client supplies appropriate welfare

Limitations of measuring H&S performance by accidents / incidents Reactive

Absence of incident does not mean good procedures in place Accident data may be small hence not being easy to see trends

Data is subject to random fluctuation

Does not reflect chronic health issues

May take long time for data to provide trends

Limitations of measuring H&S performance by accidents / incidents

Under reporting particularly when targets are set

Data is a measure of failure not success

Data measures effectiveness of previous safety measures not new measures

Historic performance can not predict future performance

Contracts Contract must not be to commit a crime

Not mentally incapacitated at the time of the contract

An offer from one party & acceptance from another can be verbal or written

Elements of legally enforceable contract

The intention to create legal relations

Legal considerations •Money •Undertaking work/tasks

Genuine consent gives the of contract e.g.. No misinterpretations

Parties involved must have legal capacity to do so e.g.. adult

HAZOP Create action plan for improvement

Design stage of process

Define scope

•Owner •What •When Team effort

Identify possible preventative measures

HAZOP Appropriate specialist •Engineers •Health & safety advisor

Assess impact of deviations

•Operators

•No flow •Flow

•Managers Identify possible deviations from normal running

•Defined Hazop leader Process broken down into sections to analyse

Why a PTW system may not be used Too bureaucratic Difficult to organise control measures

Potential hazards not fully identified

Difficult system to use

Why a PTW system may not be used

Absence of competent person to authorise

Poor safety culture e.g.. Routine work

Lack of information, instruction, training and supervision Permit not specific to task Too time consuming

Reasons to establish effective consultation with employees Statutory requirement

Improving perception about value of H&S

•Health and safety (consulting with employees reg 1996)

Reasons to establish effective consultation with employees

Promotion of good safety culture through employee involvement

Promote employee ownership

Identification of improvement opportunities Information from shop floor

Practicable Where technology or knowledge exists must be implemented

Cases

Not as high a duty as Absolute but higher duty than reasonably practicable

•Adsett vs K & L steel founders (technology not known, silica dust)

Practicable

Cost of precautions is not a factor

Reasonable Practicable Balance of cost vs risk

One factor must be grossly disproportionate to the other Duty not as strict as Absolute or practicable

Reasonable Practicable Decision is reached to implement precaution or not after balancing

Cases •Edwards vs National coal board (shoring up of roadway) NCB found liable as risk and consequences was greater than cost •Marshall Vs Gotham (gypsum mine)

Reasons why accidents should be investigated

Obtain information/evidence for any future civil claim

Establish causes both immediate and underlying causes

To ensure future preventative actions can be defined and implemented

Assess whether further training and/or supervision is required

Investigation could provide useful information for evaluating the costs of accidents

Information gathered from investigation can be used to evaluate whether current precautions are adequate, also SSOW and existing risk assessments are they adequate

Reasons why accidents should be investigated Assess compliance with legal requirements

Demonstrate management commitment

Accident investigation

Interview all parties involves ASAP, e.g. injured party, witnessess

Take photos, make sketches take measurements of scene

Obtain and CCTV footage that may be available

Identify immediate causes/underlying causes

Accident investigation Identify environmental factors that could have contributed to the accident e.g. poor light, noise, wet conditions

Look at training records that may exist for people involved in accident

Look at any relevant procedures that are in place

Look at any RA/SSOW in place

Analysing accident investigation data

Existing health and safety culture

Examine information objectively i.e with a view to identify the causes Look at job factors involved e.g. distractions

Quality of supervision

Look at any organisational factors which may have contributed

Analysing accident investigation data

Assess human factors that may have been involved e.g. fatigue, stress, alcohol

Competence of person involved e.g. training/supervision

Where procedures adequate e.g. RA/SSOW

Plant/equipment factors e.g. serviceable/inspected

Take into any environmental factors that may have exited e.g. noise, light, air condition

Gain Of Workforce To Improve Health And Safety Culture

Ensure positive is given

Consultation, co-operation, participation, competence, commitment

Show management commitment by leading from the front

Talk to the workforce, get their input

Introduce new consultation forums

Understand current employee perception of health and safety

Gain Of Workforce To Improve Health And Safety Culture

Set health and safety targets and create plans for improvement, communicate these plans to all of the workforce

Have informal discussion, team meetings etc Introduce new improved safety policy's and programmes e.g. behavioural safety programme

Increase employee participation e.g. risk assessments. H & S meetings

Demonstrate good resource for H &S

Train them, - show the benefits of improved safety conditions

Consideration For Emergency Planning Including COMAH Site • • • • • • • • • • • • • • • • • • • • • • • •

Identification of roles and responsibilities of key individuals in the planning stage e.g. technical , engineers, safety advisors, key managers Consider the quantities involved e.g. flammables stored Provision of information to local authorities Possible causes of major incident e.g. fire in flammable tank farm Estimating the likely extent of damage e.g. dispersion analysis of a gas release/explosion Staff and equipment required to control the incident/minimise impact, call out arrangements Setting up of an incident control team Resources needed to deal with incident e.g. specialists Raising the alarm both on site and off Evacuation for both site and nearby residents/shelter arrangements Training for staff in emergency plans arrangements Action to minimize extent e.g. shutting of service Search and rescue arrangements Notification of emergency services and HSE Control and management on site including roles and responsibilities for emergencies incident team Provision of information for emergency service e.g. location of hazards and potential impact Control of spillages/pollution, toxicity/flammability and possible adverse effects Clean up/decontamination procedures Dealing with the press Consultation with emergency services e.g. technical advice Emergency plan testing arrangements Establishing control centres Site plans information Business continuity

Human Failure Human Failure

Errors Not deliberate

Skill based errors

Slips of action Actions not as planned •Steps in wrong order •Too soon •Too late •Too strong •Too weak •Up rather than down

Violations deliberate

Mistakes

Lapses Memory •Forget to carry out action •Lose place in task •Example forget to turn something on

Routine •Normal way of work

Doing the wrong thing believing it to be right

Rule based • rules of familiar procedure •Apply wrong rule •Apply rules to wrong situation

Knowledge based •Unfamiliar circumstance •Apply knowledge •Eg mechanic

Situational •Job pressure •Time •Rule not safe at time •Incorrect equipment

Exceptional •Emergency situations •Something goes wrong •Not carry out safely decisions taken, normally due to time won’t allow

European Law Regulations – Apply directly in member states – Go straight into member law – If conflict with National law European prevails – Rarely used Directives – – –

Can be applied to all or individual Lay down objectives what achievement is required Directives have to be implemented by member states.

Decisions – – –

Can be made by Council or commission Biding upon those they address Main use is to allow a member state to depart from a requirement of a EU treaty

Articles of Treaty of Rome Article 95 – – –

Intended to remove barriers to trade/ensure unrestricted movement and sale Harmonised product standards E.g. Machinery Directive

Article 137 – – –

Setting of minimum standards of health and safety Harmonisation and improvement of workplace health and safety standards E.g. Frame work directive 6 pack

Procedure for making regulations under HSWA1974

Power to make regs given to secretary of state by section 15 HSWA Subject matter of reg should fall within schedule 3 of the act

If vote against they are annulled

ed it no vote against

Proposals must lie before both houses of parliament for 40 days

Procedure for making regulations under HSWA1974

Consultation between secretary and HSC and other relevant government bodies must occur

HSC could make proposal to secretary of state

Cost vs Benefit Analysis as applies to proposed regulation

Identify overall value to society of proposed regulation

Comparison with cost of implementing the regulation

Finally the calculated monetary values are compared and a decision is reached Cost vs Benefit Analysis as applies to proposed regulation

Cot and benefits both converted into monetary values

Cost adjusted for different time scales of implementation and benefits that may occur

Cost of benefit in of prevention of death, injury and ill health

Ensuring Safety of other workers while construction work is undertaken

Contractors informed of any site hazards

Agree schedule/time frame for work

PTW system may be required for abnormal activities Monitoring of contractor health and safety performance Ensure all waste removed controlled

Provision of information on things such as g in/out procedures

Ensuring Safety of other workers while construction work is undertaken

Site induction procedure

Office employees fully informed of location and nature of work Establish emergency procedures for contractors and normal staff during the work Presence of asbestos and control measures Safe storage of hazardous materials

Barrier area of, close sections where work carried out

Section 3

2.2a Provision & maintenance of safe plant & SSOW

Visitors disclosure of information

Section 4

Public contractor

Sharing workplace Section 5

2.2b Safe use, handling, storage and transport of materials

Emission

2.2c Information, Instruction, Training and Supervision

Section 6

2.2d Safe access and regress 2.2e Adequate safe facilities 2.3.3Policy 2.2.4/5

Manufacturers

Health & Safety at Work act etc 1974

Section 7 Employee duty

Safety rep

Section 8

2.2.6Consultation with safety reps

Employees not to interfere

2.2.7Establish committee if requested by 2 reps in writing

Section 9 Charge for PPE

Section 37 Prosecution of Director / Managers

Section 33 Not to obstruct inspector

Whistle Blowing

Employee good faith Prescribed People

Law = The Public Interest Disclosure act 1998

-Union Safety rep

Employees must have reasonable belief of one or more of the following Breach of legal obligation

-Employer -H&S advisor -Professional body -HSE

Whistle Blowing Prescribed people

Employee good faith

Employees protected against -loss of job -victimisation

Protected disclosure

-if job lost, case for unfair dismissal

A criminal offence

Miscarriage of justice

Danger to the H&S of an individual Danger to the environment

Domino Theory Event 5

Heinrich / Bird Loftus

Effect - injury

Event 4

Domino Theory

Accident Event 3

Natural culmination of a series of events leads to a preventable injury occurring

Chain of events

Unsafe act or condition

Remove as to prevent accident Event 2

Event 1

Fault of person

Ancestry / social environment

Bird & Loftus developed Heinrich model to include management influence Benefits •

Structured accident investigation

•

Bird & Loftus version encourages the search for underlying causes

Limitations •

Simplistic straight chain thinking

•

Heinrich model restricts the findings of underlying causes

Compensation Amounts Compensation Amounts Special known Loss of earnings up to trial Modifications of house Travel expenses Special care Medical costs Legal expenses General not know After care Pain & Suffering Impact upon family life Loss of ability Loss of quality of life Loss of future earnings

Reducing the risk of component failure Reduce the risk of component failure Burning in Regular inspection Monitoring of conductions ,e.g.. temp Planned replacement Information, e.g.. Life span Component design Life Span Collection of failure information Failure mode analysis Introduction of parrelet systems Standby systems Planned preventative maintenance

Factors that affect perception Factors that affect perception Age Experience Physical ability Personality Attitude Intelligence Information received Knowledge Design & ergonomics Knowledge & experience Training Senses Visual Audio Smell Feel Environmental factors, e.g. noise Drugs & alcohol Fatigue e.g.. Shifts Nature of hazard

Gaining Workforce Commitment Gaining Workforce Commitment

Training

Leading from the front

Finding out reasons for resistance

Consultation with employees

Get their input

Use of step by step instructions

E.g. pilot schemes

Setting out clearly the reasons and benefits of the proposed change

Produce positive

Get everyone involved

Demonstrate weakness in existing system

Accident Interview Techniques Put person at ease by explaining purpose of investigation

Finish interview on a positive note – perhaps what witness thinks can be done to improve Repeat witness back to them to check that it is fully understood

Take notes May need to adjust language for witness

Accident Interview Techniques

Listen without interruption Careful Question Phrasing •What happened •What did you see •What times •Where •When •How •Who •Not why

Interview ASAP after the event

Interview person at the scene if possible (props easily available, help memory)

Invite witness to have accompanying person

Benefits of staying with HSG65 No cost for certificates / maintain certification

Existing system may be working well

HSG65 is used by the enforcing bodies HSG65 was created to address the requirements of Reg5 MHSR99

Benefits of staying with HSG65

Audits are generally carried out by health & safety specialist

Organisation could be exposed during change over OHSAS model may be too sophisticated for smaller companies Increased paperwork

Cost of change over

Consideration when developing an audit program Applicable legislation Monitoring systems for results

Resource required to audit

Training for auditor

Consideration when developing an audit program

Frequency of audits

Scoring system Time required

Aspects to be audited e.g.. Elements of HSG65

Benefits of OHSAS18001 External regulation e.g.. customer

Customer demand

Clearer standard for benchmarking

Recently accredited to ISO standard (2007)

Benefits of OHSAS18001 More prescriptive system

External assessment

International recognition

Benefits of Integrated Management Systems Team approach Improved and/or equal culture for all standards/disciplines Equal business priority

Benefits of Integrated Management Systems

Reduction in costs •Combined audits •Less duplicates •Same format used

Holistic approach to risk management

Equal influence

•Combined information systems

Benefits of separate management systems Existing systems may work well Resistance to change

Business exposure during integration period

Benefits of Separate Management Systems

Customer demand •ISO/OHSAS required •Complex auditing

One discipline may require a more complex system to meet business needs

Potential loss of professional disciplines required

Health & Safety / Environmental have a minimum legal requirement

Multiple causation Benefits •Thorough accident investigation

May be more use than one underlying cause

•Identification of all underlying causes including effects of managers and management systems

Not only if happens in sequence

•Encourages the use of a more systematic accident analysis such as fault tree analysis

Multiple causation Thorough accident investigation requires all cause to be identified Failings usually interact with each other causing incident, can be major

Look at all factors including culture, management

HSWA 74 & Disabled person considerations Section 2 Welfare provisions

1. General duty H&S of employees

Safe access and regress

Workplace circumstances

Reasonably practicable measures to ensure safe

Appropriate means of training & providing information

HSWA 74 & Disabled person considerations Nature of disability

Safe plant Adaptation of SSOW to suit

Disability discrimination act 1995 Unlawful for employer to discriminate against a disabled person when he employs Consider effectiveness of modifications. E.g. fire alarm effectiveness

Not to discriminate during recruitment

Disability discrimination act & Disabled person considerations Equal promotion prospects

Reasonable adjustments

Emergency procedures Workplace layout

•Premises, access /egress, welfare

Vicarious Liability Breach of civil law Means to pay claimant

Employers liability insurance

Cases •Lister Vs Romford Ice & Cold Storage

Vicarious Liability

•Hudson Vs Ridge manufacturing (competent fellow employees)

Employee employed by employer

Defences •Volenti non fit injuries •Contributory negligence •Not acting within scope of employment •Not employed •No injury or unforeseeable

Tort of negligence committed by employee Negligent act cause injury or loss to third party

Employee acting in course of employment

Near miss systems Clearly definition of ‘near Miss’

Who will report near misses

Positive for reporters Training required

Define reporting lines to ensure actions are implemented

Ease of reporting, clear, straight forward format

Considerations when developing a near miss system Consultation with employee

Building of a fair blame culture

Provision of information, instruction and training

Purpose and Benefits of Near Miss Data Helps get everyone involved in safety

Near misses have the potential to become an accident’

Identifies opportunities for improvements

Identifies inadequate health and safety management and/or elements of the management system

Purpose & Benefits of near miss data

Investigation of near misses and carrying out improves/implementing preventative measures

Shows management commitment through action follow up and feed back Data analysis can show trends and reoccurring issues – indicates areas to improve

Identifies inadequate training Helps to identify inadequate SSOW

Proactive approach to incident management

Design of controls Easy to use e.g.. Toggles / switches

Keep number to minimum

A change of system state should only occur after operation of a control

Space between each control

Control design Arrange of controls in sequence of use Stop controls should be easy to activate Controls should be kept next to the display that gives the reading of its output

Operating a control should require a positive action by the operator with immediate effect

System restarts should only occur after operating a control Labels & shape put to effective use

Design of Displays Digital for quantative information Emergency displays should be clearly identifiable

Direct relation between readout and control

Dials with pointers to convey qualative readings Use of colours to give clear indication of a change in state

Correct number of controls, too many will overload operators

Display design Lights used for status readings

VDU’s to show process overview

Characteristics Of A Positive Safety Culture Reporting of hazards by employees

Open communication between managers and shop floor

Management commitment

Leadership by managers

Potentially low accident rates

Characteristics Of A Positive Safety Culture Availability of funds and resources

Mutual trust Strong participation by employees

Good quality of health and safety training

Strategic role of H&S profession Ensuring organisation is legally compliant and keeping up to date with legislation changes

Policy development and setting of objectives Managing enforcing bodies

Strategic role of H&S profession

Auditing & identifying further opportunities for improvement

Advising senior managers

Developing strong good safety culture Involvement in reactive monitoring e.g. accident investigation

Developing / agreeing plans for improvement, short and long term

Formulating & developing elements of the H&S management systems

Employer responsible for negligent act of contract vicarious liability Case: Mersey docks & harbour board Vs Coggins & Griffiths Act caused harm or loss to third party

Contractor under control of employer

Employer responsible for negligent act of contract vicarious liability

Acting in course of employment

Employer authorises negligent act

Contractor carrying act over which employer has control

Requirement of Reg7 MHSR1999 Person competent to advise Exemption for partners if one or more is competent

Information on temporary workers

Preference is internal appointment

Appoint one or more persons

Requirement of Reg7 MHSR1999

Provision of information on health & safety issues to externally appointed (consultant)

Arrangements for cooperation if more than one

Number of and time available sufficient for size, risk and risk distribution of the company

Typical client / contract for work carried out Responsibilities for emergency planning

Contractor to maintain legal compliance

Provision of competent persons

Clients right to stop work if unsafe

Define safety responsibilities between client & contractor

Employer liability insurance

Typical client / contract for work carried out

The requirement that the contractor has RAs, SSOW,MSs Clients right to monitor safety standards of contractors

Requirement to attend site H&S induction before workers start work on site

The contractor / client supplies appropriate welfare

Limitations of measuring H&S performance by accidents / incidents Reactive

Absence of incident does not mean good procedures in place Accident data may be small hence not being easy to see trends

Data is subject to random fluctuation

Does not reflect chronic health issues

May take long time for data to provide trends

Limitations of measuring H&S performance by accidents / incidents

Under reporting particularly when targets are set

Data is a measure of failure not success

Data measures effectiveness of previous safety measures not new measures

Historic performance can not predict future performance

Contracts Contract must not be to commit a crime

Not mentally incapacitated at the time of the contract

An offer from one party & acceptance from another can be verbal or written

Elements of legally enforceable contract

The intention to create legal relations

Legal considerations •Money •Undertaking work/tasks

Genuine consent gives the of contract e.g.. No misinterpretations

Parties involved must have legal capacity to do so e.g.. adult

HAZOP Create action plan for improvement

Design stage of process

Define scope

•Owner •What •When Team effort

Identify possible preventative measures

HAZOP Appropriate specialist •Engineers •Health & safety advisor

Assess impact of deviations

•Operators

•No flow •Flow

•Managers Identify possible deviations from normal running

•Defined Hazop leader Process broken down into sections to analyse

Why a PTW system may not be used Too bureaucratic Difficult to organise control measures

Potential hazards not fully identified

Difficult system to use

Why a PTW system may not be used

Absence of competent person to authorise

Poor safety culture e.g.. Routine work

Lack of information, instruction, training and supervision Permit not specific to task Too time consuming

Reasons to establish effective consultation with employees Statutory requirement

Improving perception about value of H&S

•Health and safety (consulting with employees reg 1996)

Reasons to establish effective consultation with employees

Promotion of good safety culture through employee involvement

Promote employee ownership

Identification of improvement opportunities Information from shop floor

Practicable Where technology or knowledge exists must be implemented

Cases

Not as high a duty as Absolute but higher duty than reasonably practicable

•Adsett vs K & L steel founders (technology not known, silica dust)

Practicable

Cost of precautions is not a factor

Reasonable Practicable Balance of cost vs risk

One factor must be grossly disproportionate to the other Duty not as strict as Absolute or practicable

Reasonable Practicable Decision is reached to implement precaution or not after balancing

Cases •Edwards vs National coal board (shoring up of roadway) NCB found liable as risk and consequences was greater than cost •Marshall Vs Gotham (gypsum mine)

Reasons why accidents should be investigated

Obtain information/evidence for any future civil claim

Establish causes both immediate and underlying causes

To ensure future preventative actions can be defined and implemented

Assess whether further training and/or supervision is required

Investigation could provide useful information for evaluating the costs of accidents

Information gathered from investigation can be used to evaluate whether current precautions are adequate, also SSOW and existing risk assessments are they adequate

Reasons why accidents should be investigated Assess compliance with legal requirements

Demonstrate management commitment

Accident investigation

Interview all parties involves ASAP, e.g. injured party, witnessess

Take photos, make sketches take measurements of scene

Obtain and CCTV footage that may be available

Identify immediate causes/underlying causes

Accident investigation Identify environmental factors that could have contributed to the accident e.g. poor light, noise, wet conditions

Look at training records that may exist for people involved in accident

Look at any relevant procedures that are in place

Look at any RA/SSOW in place

Analysing accident investigation data

Existing health and safety culture

Examine information objectively i.e with a view to identify the causes Look at job factors involved e.g. distractions

Quality of supervision

Look at any organisational factors which may have contributed

Analysing accident investigation data

Assess human factors that may have been involved e.g. fatigue, stress, alcohol

Competence of person involved e.g. training/supervision

Where procedures adequate e.g. RA/SSOW

Plant/equipment factors e.g. serviceable/inspected

Take into any environmental factors that may have exited e.g. noise, light, air condition

Gain Of Workforce To Improve Health And Safety Culture

Ensure positive is given

Consultation, co-operation, participation, competence, commitment

Show management commitment by leading from the front

Talk to the workforce, get their input

Introduce new consultation forums

Understand current employee perception of health and safety

Gain Of Workforce To Improve Health And Safety Culture

Set health and safety targets and create plans for improvement, communicate these plans to all of the workforce

Have informal discussion, team meetings etc Introduce new improved safety policy's and programmes e.g. behavioural safety programme

Increase employee participation e.g. risk assessments. H & S meetings

Demonstrate good resource for H &S

Train them, - show the benefits of improved safety conditions

Consideration For Emergency Planning Including COMAH Site • • • • • • • • • • • • • • • • • • • • • • • •

Identification of roles and responsibilities of key individuals in the planning stage e.g. technical , engineers, safety advisors, key managers Consider the quantities involved e.g. flammables stored Provision of information to local authorities Possible causes of major incident e.g. fire in flammable tank farm Estimating the likely extent of damage e.g. dispersion analysis of a gas release/explosion Staff and equipment required to control the incident/minimise impact, call out arrangements Setting up of an incident control team Resources needed to deal with incident e.g. specialists Raising the alarm both on site and off Evacuation for both site and nearby residents/shelter arrangements Training for staff in emergency plans arrangements Action to minimize extent e.g. shutting of service Search and rescue arrangements Notification of emergency services and HSE Control and management on site including roles and responsibilities for emergencies incident team Provision of information for emergency service e.g. location of hazards and potential impact Control of spillages/pollution, toxicity/flammability and possible adverse effects Clean up/decontamination procedures Dealing with the press Consultation with emergency services e.g. technical advice Emergency plan testing arrangements Establishing control centres Site plans information Business continuity

Human Failure Human Failure

Errors Not deliberate

Skill based errors

Slips of action Actions not as planned •Steps in wrong order •Too soon •Too late •Too strong •Too weak •Up rather than down

Violations deliberate

Mistakes

Lapses Memory •Forget to carry out action •Lose place in task •Example forget to turn something on

Routine •Normal way of work

Doing the wrong thing believing it to be right

Rule based • rules of familiar procedure •Apply wrong rule •Apply rules to wrong situation

Knowledge based •Unfamiliar circumstance •Apply knowledge •Eg mechanic

Situational •Job pressure •Time •Rule not safe at time •Incorrect equipment

Exceptional •Emergency situations •Something goes wrong •Not carry out safely decisions taken, normally due to time won’t allow

European Law Regulations – Apply directly in member states – Go straight into member law – If conflict with National law European prevails – Rarely used Directives – – –

Can be applied to all or individual Lay down objectives what achievement is required Directives have to be implemented by member states.

Decisions – – –

Can be made by Council or commission Biding upon those they address Main use is to allow a member state to depart from a requirement of a EU treaty

Articles of Treaty of Rome Article 95 – – –

Intended to remove barriers to trade/ensure unrestricted movement and sale Harmonised product standards E.g. Machinery Directive

Article 137 – – –

Setting of minimum standards of health and safety Harmonisation and improvement of workplace health and safety standards E.g. Frame work directive 6 pack

Procedure for making regulations under HSWA1974

Power to make regs given to secretary of state by section 15 HSWA Subject matter of reg should fall within schedule 3 of the act

If vote against they are annulled

ed it no vote against

Proposals must lie before both houses of parliament for 40 days

Procedure for making regulations under HSWA1974

Consultation between secretary and HSC and other relevant government bodies must occur

HSC could make proposal to secretary of state

Cost vs Benefit Analysis as applies to proposed regulation

Identify overall value to society of proposed regulation

Comparison with cost of implementing the regulation

Finally the calculated monetary values are compared and a decision is reached Cost vs Benefit Analysis as applies to proposed regulation

Cot and benefits both converted into monetary values

Cost adjusted for different time scales of implementation and benefits that may occur

Cost of benefit in of prevention of death, injury and ill health

Ensuring Safety of other workers while construction work is undertaken

Contractors informed of any site hazards

Agree schedule/time frame for work

PTW system may be required for abnormal activities Monitoring of contractor health and safety performance Ensure all waste removed controlled

Provision of information on things such as g in/out procedures

Ensuring Safety of other workers while construction work is undertaken

Site induction procedure

Office employees fully informed of location and nature of work Establish emergency procedures for contractors and normal staff during the work Presence of asbestos and control measures Safe storage of hazardous materials

Barrier area of, close sections where work carried out