Rcd Ebara Absorption Chiller 3w960

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 2z6p3t

Overview 5o1f4z

& View Rcd Ebara Absorption Chiller as PDF for free.

More details 6z3438

- Words: 7,980

- Pages: 24

DIRECT.FIRED ABSORPTION CHILLER.HEATER

'i;*

g;'l t)-+:ii

2.:+,: :,)r*l .:!E

iii

L+1:,

ti;ti

,rtli

nio.

RCDsenbsfb a newly desffied compactand hlgh Pertormanc hetter and desffied considering

{r\*.

q'r.fl{lAr

'-r{*..

Using a newly developed microprocessor, high performance is realized in operating.

1. Energysaving with minimizedstartup. Startup time of the system has been cr,it short with an optimized flow rate of circulating solution responsive to the startup operationquickly. This reduce fuel consumption.

4. Operatingconditionis displayedon the digitally. Operating information such as the chilled/hot water temperature,the cooling water temperature,the solution temperature and the other followings listed hereunder are displayed on the control . Temperature in the high temperature generator. . ouflet temp. of the high temperature generator. . lnlet temp. of the high temperature generator. . Dew point temp. of the high temperature generaror. lnlet or Outlet temperature of the chilled/hot water. Inlet or Outlet temperature in the cooling water. Chiller-Heater operating time. Operating time of the refrigerant pump. Number of start/stop operations of the unit

Q

o

3

c

Measurement in temperature. . Temperature of the exhaust gas. . Temperature of the evaporating refrigerant. ' Temperature of the refrigerant condensation. ' Temperature of the solution in absorber. Fuel control valve indicator. Combustion time Operating time of the solution pump. Number of combustion start/stop ooerations.

6 5 a

5. Preventionfunction for unusual shut down on failure are equipped.

o c c

)

o

o o o E 0)

With confinuous monitoringoperating conditions by sensors equipped in the unit, stoppage of the system on failures or fault is minimized in controlling system before the system goes to failures. . Dew-point control of the high temperature generator. . Solution temperature control of the high temperature generator. etc.

l

Elapsed time after the combustion start(min)

^

2. Reducingdilution time at the time of operating interruption. By checking the operatingconditionat shut down, minimum diluting time is determinedautomatically. over dilution is avoided automatically,and this contribute to the energy saving.

3. Interlocking circuits of auxiliary devices are equippedas a standard. An interlockingcircuit are equipped for chilled/hot water, cooling water pumps and a fan of cooling tower as a standard. The operating cost may be reduced with protective meas-ures such as a start/stop circuit for the fan on the cooling tower for cooling water temperature control and a freeze-proof circuit with thermo-sensorsfor winter season are equipped as a standard.

6. Pre-alarm system ensure preventive maintenance. With pre-alarm systems, magnitude of scale/slime fouling in the cooling water tubes and timing for replacing some parts of the unit are informed well in advance' . . . .

Temperature rising in the exhaust gas. Rising in the internal pressure. Replacement timing of the burner part. Fault in thermo-sensors. *Temperature rising in the inlet of cooling water. {

x mark indicates

that only counting

. Rising in LTD of cooling water. . Overload in the purge pump. . Replacement timing for respective oarts. . Abnormal in level control in high temPerature generator. * Temperature rising of the cooling water at the inlet/outlet' * Temperature rising in the solution of the high temperature generator. is made without

displaying

any pre-alarm.

7, A circuit for power-failureis equipped with a standard. For a power-failure within the minutes, the unit may start automatically after the power is recovered. The unit will shut down with alarm if the power failure lasts more than ten minutes.

DirectFiredAbsorptionChiller-Heater ol equippedwithlatest microprocess or environment, CONTENTS In an application of inverter control of solution puffiF, saving energy has been realized in the whole range from partial loads to rated loads of cooling mode. Installation costs may be reduced at no control of cooling water temperature and further saving in energy consumptiong as operation is feasible as 15'C at the inlet of cooling water.

0.30

s I PartLoadPerformance

E z

I E

a c

22.c

E z

15c

o

; c

v.4u

x

n ro

o o 6

(,

The graphic chart shows; Energy saving is 40olocompared with original model when the refrigerationcapacity is 40% and the inlet temperature of the cooling water is 27"C. Note 1) The combustion rates shown herein based on a gross calorific value 11,000kca1/m2(NTP) of gas. Note 2) This graphic chart is applicabte to the model 015 through 050. Note 3) An area surroundedby the dotted lines is the area for available loads .which is derived from using respective average wet bulb. Note 4) The % of energy saving is based on the first developedunit. Note 5) 1rns/(h.USRI)(NTP):9.2343ms/kW(NTP)

Equippedwith a low Nox burner, 60ppm attainedat the fuel gas 13A.

less based

Oz Oolo,

Compared with the oonventional type, reductions of 2Ooloin width; 15o/oin height 2Oolotn setup space have been attained(Comparison reference in 360 tons class).

RCD036 (New

.......5 C o o l i n ga n d h e a t i n gc y c l e Standard Specification Table (Energy saving 260lo) Series N Cooling operation per annual : 2 , 0 0 0h o u r so r l e s s . . . . . . . . . . . . . ' . 6 Series L Cooling operation per annual : 4 , 0 0 0 h o u r so r l e s s . . . . . . . . . . . . . . . 8 Series H Cooling operationper annual : morethan 4,000hours............10 S h i p p i n gD i m e n s i o n s. . . . . . . . . . . . . - - - - . - . . 1 2 Thermal Insulation ( C o l da n d H o t S u r f a c e ) . . . . . . . . . . . . . . . 1 3 .........-..-...14 D i m e n s i o n. s. . . . . . . . . .'........15 Foundation ..'...16 T e c h n i c a li n f o r m a t i o n ...........17 C o n t r o lp a n e l Sample power board R e m o t es t a r t / s t o ps i g n a l . . . . ' . . . . . . . . . . 1 9 ......2O Start/stop flow chart Standard delivery scope and o p t i p n a ls p e c i f i c a t i o n s . . . . . . . . . . . . . . . 2 2 Combustion system diagram and technical relating for exhaust gas

I I t

Evaporator

LowTemp.Generator Gondenser

PurgeUnit

HighTemp. Generator

:

I

SolutionHeatExchangers

BurnerUnit

l--l :StrongLiErsolution lMediumLiBrSolution f-l

:Weat

Tl

: Evaporated refrigerant

N

:ruttyctosed

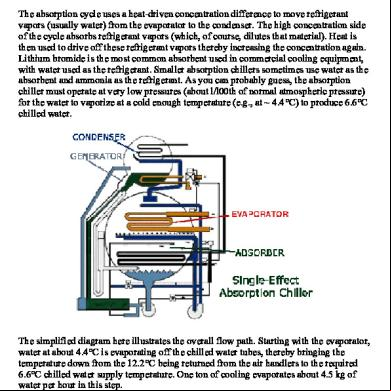

Refrigerant evaporates in an evaporator and cools down chilled water. The evaporated refrigerant is absorbed into the solution in the absorber. The solution absorbed the refrigerant become weak and sends to the high and low temperature generator respectively through the heat-excangers pumped up by the solution pump. The weak solution turns to a concentrated(strong)solution after heating by the burner in the high temperature generator.The solution becomes medium strong solution in the low temperature generator heated by refrigerant(steam) generated in the high temperature generator. The strong solution in the high and medium strong solution in the low temperature are mixed together and back to absorber through the both solution heat-exchangers, in which absorbs the refrigerant evaporated from the evaporator. The generated refrigerant in the low temperature generator move to the condenser and condensed by the cooling water. Condensed refrigerant back to evaporator.

l>- Hotwater OUT

. MediumLiBrSolution l-l

:WeakLiBrSotution . Refrigerant (HzO)

: Evaporated refrigerant l<- Hotwater [--l IN ffi iFuttyopened

Fuel

The high temperature steam(refrigerant) generated in the high temperature generator is moved through valve and condensed in the evaporator and heating up hot water for heating. The refrigerant is down to and mixed up with medium weak solution in the absorber.Then pump up to the high temperaturegenerator by solution pump. The medium weak solution generates steam(refrigerant vapor) in the high temperature generator.

Model(RCDFI

1{0t5

t{018

il021

1{025

il028

]t032

11036

Cooling Capacity

usRt{kw}150{528}

Heating Capacity

kcal/h{kW}400,000{465}480,000{558}5 60,000{651} 666,ooo{774} 742,000{853} 854,000{993} 960,000{1117

FlowRate o:t c'o

=

Q,/mtn

Plessure Dlop

180{633} 210{73e} 250{87e} 280{e85} 32O{1125} 360{1266}

1810

2120

2520

2820

3230

3630

8.2{80}

7.4{73}

7.7{75}

6.3{62}

6.3{62}

6.4{63}

4

4

4

4

3

3

3

1510

mAq{kPa} 7.8{76}

'El

S llo.of E CJ

PipeConnection Size

A(mm)

100

100

125

125

150

15 0

150

FlowRate

Q,/min

2500

3000

3500

4170

4670

5330

6000

12{118}

12.5{123}

e.5{e3}

10{e8}

10{e8}

o:t cr('

Drop = Plessure := il0.ol ct ct

mAq{kPa} 1 1 . 5 { 1 1 3 } 12.5{123}

Elt

3+1

3+1

3+1

3+1

2+1

2+1

2+1

125

125

150

150

200

200

200

CJ

PipeConnection Size

A(mm)

eoo{8.82}eoo{8.82} e00{8.82}

Ualue Gas {gross) PipeConneclionA(mm)

Supply Pressure mmAq{kPa}1 50{1.47} 150{1.47} 150{1.47}

150{1.47}

80

100

100

125

80

80

80

4500 Consumption Nm'/h (Coolinsl

99.9

119.9

139.9

166.5

186.5

213.2

239.8

Consumption ll|eatinql

109.8

131.8

153.9

182.8

203.7

233.4

263.5

kcal/llm3

Nm3/h

200{1.e6} 200{1.e6} 200{1.e6} 2oo{1.e6}2oo{1.e6}2oo{1.e6}200{1.e6} Supply Pressure mmAdkPa) Ualue = Gas (grossl PipeConnectionA(mm) 50 50 50 80 80 80 BO q:t

trsAl Consumption il000 (Coolinsl kcal/ilmg Consumption llleatinol Consumplion (Coolingl Kerusene Consumption ll|eatinsf Voltagex Cycle

Nm3/h

40.9

49.1

57.2

68.1

76.3

87.2

98.1

Nm3/h

44.9

53.9

62.9

74.8

83.3

95.9

107. 8

0/h

48.6

58.3

68.0

81.0

90.7

103.7

116. 6

0/h

53.9

64.7

75.5

89.8

100.0

115 . 1

129.4

VX Hz

200x 50/60. 220x60

kw

0 .1 5

0.15

Pump' = Solution

kw

2.2+O.4

2.2+O.4

2.2+O.4

:>

kw

1.5

1.5

1.5

2.2

2.2

10.0(5.5)

10.5(8)

13.0(8)

13.5(8)

Refrigelant Pump q:t ct ct-

CJ CJ o:, t+l

Burner Fan Gas

Powel Supply CapaciU kVA(mm') 10.0(5.5) $izel Ittliring

Burner Fan* |lil Pumn Kerosene

kw

1+0.25

Pouler Supply Capacity kVA(mm') 10.0(5.5) $izel lWirins

Connection Sizeof Exhaust Gas l|eatTransfer fueaof Gh

mm m2

1+0.25

0.3

0.3

1.5+0.25 1.5+0.25 2.2+O.4 13.0(8)

12.0(8)

350x310 450X 310

450x370

480X 370

13.8

16.1

11.7

0.3

o.4

3 . 2 + O . 4 3.2+O.75 3.2+O.75 3.2+O.75

10.0(5.5)

9.7

0.3

14.0(141

3.7 15.0(14)

15.0(14)

2.2+O.4

2.2+O.4

14.O(14)

14.o(14)

450x430 480X430 19.6

3.7

21.4

515x460 23.6

1t040

It045

1t050

lt000

]t070

Dimensions Model

4OO{14O7} 450{1583} 500{175e} 600{2,110}7 00{2,462} '1,067,000{1241} 1,201,000{1397} 1,334,000{1551} 1,604,000{1,965} 1,871,000{2,'176}

Weight

Water Volume in Chiller-Heater

Shipping Weight Operating Chilled/Hot Cooling Weight Water Water (MAX)

L

W

H

mm

mm

mm

t

t

0

0

N015 3575

1825

1900

5.4

7.4

210

290

RcDP

4030

4540

5040

6,050

7,060

6.6{65}

6.1{60}

6.1{60}

7.6{74}

7.8{76}

N018 3575 1870 1940

5.9

8.0

250

340

3

3

3

3

3

N021 3605 2020 2050

6.7

9.2

300

410

150

200

200

200

200

2150 2160 7.8

10.4

350

480

6670

7500

8340

10,000

1 1 ,670

N025 3605

N028 4675 2105 2100

8.9

12.2 380

560

N032 4675 2280 2170

9.9

13.5

440

630

10{e8}

e.5{e3}

10{e8}

2+1

2+1

2+1

2+1

2+1

N036 4700 2340 2250 10.1 15.0 490

700

200

250

250

250

250

N040 4725 2350 2340 1 1 . 8 16.5

540

780

N045

4810 2415 2480

13.1

18.4

610

920

e.8{e6} 10.5{103}

e00{8.82} eoo{8.82} eoo{8.82} eoo{8.82} eoo{8.82} 80

80

80

80

80

N050

4810 2465 2550 14.O

19.7

680

1010

266.4

299.7

333.1

399.7

466.3

N060

5860 2875 2750 15.7

23.O 820

1210

292.9

329.7

366.2

440.3

513.6

N070

5860 2975 2945

26.2

1410

200{1.e6} 200{1.e6} 2oo{1.e6}e00{8.82} eoo{8.82} 80

80

80

65

80

109

122.6

1 3 6 .3

163.5

190.8

119.8

134.9

149.8

180.1

210.1

129.6

145.8

162.0

194.4

226.8

143.8

161. 9

179.8

216.3

252.2

200x 50/60. 220X60

o.4

o.4

o.4

o.4

o.4

3.7+O.75 3.7+O.75' 3.7+O.75 5.5+0.75 5.5+0.75 3.7

3.7

5.5

5 .5

7 .5

16 .0 (1 4 )

16.0(14)

18.O(22)

20(22)

22.5(22\

3.7+O.4

3.7+O.4

16 .5 (1 4 )

16.5(14)

568x460

550X 515

5 5 0 X5 6 8

545X7'13

6 9 2 X 667

27.1

29.5

32.5

38.3

44.6

3.7+O.75 5.5+0.75 5.5+0.75 17.0(141 21.5(22)

21.5(22)

17.9

960

Note 1) The standard chilled water temperatureis 12"c at the inlet and 7"C at the outlet, the cooling water temperature is 32"C at theinlet and 37.5'c at the outlet and the hot water temperature 60'C at the outlet. Note 2) The fouling factor of the chilled/hot water and the cooling water is assumed as 0.0001meh"C/kcat(0.000086m2K/W). Note 3) The capacity of burner fan may be changed on the combustion volume and the gas specification. Note 4) The standard design pressureof the chilled/hot water and the cooling water is 8 kgf/cmz (gauge pressure) iO.ZA Hl|pa) Note 5) Chiller-Heateris designed in accordancewith JIS 8g622. Note 6) Standarddeliveryis one piece shippingas the standard. Note 7) The net calorific value of kerosene is defined as g32oKcal/0 (Specific gravity 0.8). Note 8) Dimensionin width may vary dependenton the gas specification. Please check the outline drawing in detail. The values shown herein is based on the supply specificationat 2OOmmAq(060 and 070 are at the supply on gOOmmAq). Note 9) The wiring size is used for reference.

Lol5

Model(RC0P)

1018

t02l

t025

1028

r032

r036

Capacity Cooling

usRt{kw}150{528}

Heating Capacity

854,000{993}960,000{111 742,000{863} 660,ooo{774} 400,000{465}480,000{558}560,o0o{651} kcaUh{kW}

o:, GE

=

180{633}

210{73e} 250{87e} 280{e85} 320{1125} 360{1266}

1810

2120

2520

2820

3230

3630

8.2{80}

7.4{73}

7.7{75}

6.3{62}

6.3{62i

6.4{63}

4

4

4

4

3

3

3

1510

FlowBate

Q,/min

Prcssure Drup

mRq{tPa} 7.8{76}

'El

=

llo.of

CJ

Size PipeConnection

A(mm)

100

100

125

125

150

150

150

Flowflate

A /min

2500

3000

3500

4170

4670

5330

6000

12{118}

12.5{123}

e.5{e3}

10{e8}

10{eB}

o:, CE Dlop = Plessure := lrlo.of ct e

mAq{kPa} 1 1 . 5 { 1 1 3 } 12.5{123}

Et

3+1

3+1

3+1

3+1

2+1

2+1

2+1

125

125

150

150

200

200

200

CJ

Size PipeConnection

A(mm)

Ptessure mmAq{kPa}1 5 0 { 1 .4 7} 150{ 1.47} 150{ 1.47} 150{1.47} e00{8.82} e00{8.82} eoo{8.82} Supply GasUalue (grossl PipeConnection A(mm) 80 BO 125 80 100 100 BO 4500 Consumption lCoolinql kcal/llm3 Consumption Il|eatingl

Nm3/h

99.9

119.9

139.9

166.5

186.5

213.2

239.8

Nm"/h

1 0 9 .8

131.8

153.7

182.8

203.7

233.4

263.5

200{1.e6} 200{1.e6} 2oo{1.e6}200{1.e6} 200{1.e6} 200{1.e6} 200{1.e6} Pressure mmAqikPa) Supply

o:t

Ualue Gas (grossl PipeConnection A(mm) (r3Al Consumption 11000 ICoolinsl kcal/ilm3 Consumption

(]|eatingl

50

50

50

BO

80

80

80

Nm3/h

40.9

49.1

57.2

68.1

76.3

87.2

98.1

Nm'/h

44.9

53.9

62.9

74.8

83.3

95.9

107. 8

48.6

58.3

68.0

81.0

90.7

103.7

116.6

53.9

64.7

75.5

89.8

100.0

115. 1

129.4

Gonsumption 0 / h KeroseneIGoolinsf Consumption 0 / h [fleatinsl x Cycle Uoltage Pump Refrigemnt Pump = Solution o:l

200x 50/60. 220x60

VXHz

KW

0 .1 5

0.15

kw

2.2+O.4

2.2+O.4

2.2+O.4

kw

1.5

1.5

1.5

2.2

10(5.5)

10.5(8)

13(8)

0.3

0.3

0.3

0.3

o.4

3 . 2 + O . 4 3.2+O.75 3 . 2 + O . 7 5 3.2+O.75

ct CL

Fan Bumer

=>

C5 C5

!? l!

Gas

Capacity Power Su0ply kVA(mm') 10(5.5) Sizel {Wiring Fan* llil Burner 1+0.25 KW

Pump |(erosene

Supply Capacily Poww kVA(mm') 10(5.5) Shel {Whins

Gas Sizeof Exhaust Connection Areaof Gh HeatTransfer

1+0.25 10(5.5)

2.2

3.7

3.7

15(14)

15(14)

1.5+0.25 1.5+0.25 2.2+O.4

2.2+O.4

2.2+O.4

12(8)

14(14)

14(14)

14(14\

11(8)

13.5(B)

mm

3 5 0 X310

450X 310

450x370

480x 370

450X 430

480X430

515X460

m2

9 .7

11.7

13.8

16.1

19.6

21.4

23.6

t040

t045

t050

t000

r070

4OO{14o7} 450{1583} 5oo{175e} 600{2,110}7 00{2,462}

Dimensions Model

RcDR

1,067,000{1241} 1,201,000{1397} 1,334,000{1551} 1,604,000{1,965} 1,871,000{2,176}

Weight

Water Volume in Chiller-Heater

Shipping Operating Chilled/Hot Cooling Weight Weight Water Water (MAX)

L

W

H

mm

mm

mm

1900 5.5

t

t

0

0

7.4

210

290

4030

4540

5040

6,050

7,060

L015

3575

1825

. 6 .6 {6 5 }

6.1{60}

6.1{60}

7.6{74}

7.8{76}

L018

3575

1870 1940

5.9

8.0

250

340

3

3

3

3

3

LO21

3605 2020 2050

6.7

9.2

300

410

150

200

200

200

200

LO25

3605

2150 2160

7.8

10.4

350

480

6670

7500

8340

10,000

1028

4675

2150 2100

8.7

12.2 380

560

10{e8}

e.5{93}

1o{e8}

L032

4675 2280 2170

9.9

13.5

440

630

2+1

2+1

2+1

2+1

2+1

L036

4700 zUO 2250 10.5 15.0 490

700

200

250

250

250

250

L040 4725 2350 2340 1 1 . 6 16.5

540

780

L045

13.2 18.4

610

920

L050 4810 2465 2550 14.O 19.7

680

1010

1 1 ,670

e.8{e6} 10.5{1m}

eoo{8.82} e00{8.82} eoo{8.82} eoo{8.82} e00{8.82}

4810 2415 2480

80

80

80

80

80

266.4

299.7

333.1

399.7

466.3

1060 5860 2875 2750 15.7

23.O 820

1210

292.9

329.7

366.2

440.3

513.6

L070 5860 2975 2945

26.2

1410

200{1.e6} 200{1.e6} 2oo{1.e6}eoo{8.82} eoo{8.82} 80

100

100

65

80

109

122.6

136.3

163.5

190.8

119.8

134.9

149.8

180.1

210.1

129.6

145.8

162.0

194.4

226.8

143.8

161. 9

179.8

216.3

252.2

200x 50/60. 220x60

o.4

o.4

o.4

o.4

o.4

3.7+O.75 3.7+O.75 3.7+O.75 5.5+0.75 5.5+0.75 3.7

3.7

5.5

16(14)

16(14)

18(22)

3.7+O.4

3.7+O.4

3.7+0.75

16.5(14)

16.5(14)

17(14')

21.5(22)

568X460

550X 515

550x568

5 4 5 X7 1 3

692x667

27.1

29.5

32.5

38.3

44.6

5 .5

20(22r,

5.5

22.5(22\

5.5+0.75 5.5+0.75 21.5(22)

17.9

960

Note 1) The standard chilled water temperature is 12"Cat the inlet and 7"C at the outlet, the cooling water temperature is 32'C at theinlet and 37.5'C at the outlet and the hot water temoerature 60"C at the outlet. Note 2) The fouling factor of the chilled/hot water and the cooling water is assumedas 0.0001m2h"C/kcal (0.000086m2K/W). Note 3) The capacity of burner fan may be changed on the combustion volume and the gas specification. Note 4) The standard design pressureof the chilled/hot water and the cooling water is 8 kgf/srnz (gauge pressure) {O.ZAVpa} Note 5) Chiller-Heateris designed in accordancewith JIS 88622. Note 6) Standarddeliveryis one piece shippingas the standard. Note 7) The net calorific value of kerosene is defined as 8320Kcal/ 0 (Specific gravity 0.8). Note 8) Dimensionin width may vary dependenton the gas specification. Please check the outline drawing in detail. The values shown herein is based on the supply specificationat 2OOmmAq(060 and 070 are at the supply on 900mmAq). Note 9) The wiring size is used for reference.

1|0l5

ModelIRCDPf

l|0t8

l|02l

1|025

}|028

l|032

|l030

Capacity Cooling

usRt{kwi135{475}

]|eating Capacity

400,000{465}480,000{558}5 66,000{651} 666,ooo{774} 742,000{863i854,000{993} kcal/h{kttr|}361,ooo{420}

et GEI

=

150{528}

180{633} 210{73e} 250{87e} 280{e85} 320{1125}

1510

1810

2120

2520

2820

3230

5.7{56}

5.5{54}

5.4{53}

5{ae}

4.8{47}

5{ae}

4

4

4

4

3

3

3

FlowRate

0 /min

Drop Prcssure

mlq{rPa} 6.3{62}

1360

=t

32 c)

€t 6tr

=

llo.ol Size PipeConnection

A(mm)

100

100

125

125

150

150

150

Flowflate

Q,/min

2250

2500

3000

3500

4170

4670

5330

e.5{e3}

s{88}

e{88}

e{88}

8{78}

8{78}

s{28}

3+1

3+1

3+1

3+1

2+1

2+1

2+1

125

125

150

150

200

200

200

Dlop Prcssule

mAq{kPa}

ED

:= llo.of c, C' CJ

PipeConnection Size

A(mm)

PressuremmAq{kPa}100{0.e8} 100{0.e8} 100{0.s8} 100{0.e8} eoo{8.82} eoo{8.82} e00{8.82} Supply Gas Ualue (grossl PipeConnection A(mm) 100 100 125 80 80 50 80 4500 Consumption Nm3/h 213.2 119.9 139.9 166.5 186.5 89.9 99.9 lCoolinnl kcal/llm3 Consumption Nm"/h 203.7 234.4 109.8 131.8 153.7 182.8 98.8 {ilsatingf 2oo{1.e6}200{1.e6} 200{1.e6} 200{1.s6} 200{1.e6} 2oo{1.e6}2oo{1.e6} PressuremmAq{kPd Supply

€t

GasValue {grossf PipeConnection A(mm)

fl3n1 Consumption Nm"/h il000 lCoolinnl kcal/llm3 Consumption Nm'/h

l1|eatinsf Consumption 0 / h tGoolinnl Kerossne Consumption 0 l h ll|eatingf Uoltagex Cycle Pump Refrigerant Pump' = Solution

ct

50

50

50

80

80

80

80

36.8

40.9

49.1

57.2

68.1

76.3

87.2

40.5

M.9

53.9

62.9

74.8

83.3

95.9

43.7

48.6

58.3

68.0

81.0

90.7

103.7

48.7

53.9

64.7

75.5

89.8

100.0

115. 1

0.3

o.4

200x 50/60. 220x60

VX Hz

kw

0 .1 5

0.15

kw

2.2+O.4

2.2+O.4

2.2+O.4

kw

1.5

1.5

1.5

2.2

2.2

3.7

10.5(5.5)

10.5(8)

13(8)

13.5(8)

15(14)

15(14)

2.2+O.4

2.2+O.4

14(141

14(141

0.3

0.3

0.3

3.2+O.4 3.2+O.75 3.2+O.75 3.2+O.75

ct CL

BumelFan

'6 ct ot trt

Gas

Powu $upply Capacily kVA(mm')10.5(5.5) Size) lWirins Fan* Oil kw Bumsr 1+0.25

Pump Kerusene

Sumly Gapacily Pows kVA(mm') (ltliilns $izsl

Gas Connection Sizeof Exhaust Arcaof Gh lleatTmnsfer

mm m2

10(8)

1+0.25 10(8)

350x310 450X 310 9.7

11.7

1.5+0.25 1.5+0.25 2.2+O.4 11(8)

3.7

12(8)

14(14)

450X370

450x370

450X430

480x430

515x460

13.8

16.1

19.6

21.4

23.6

H040 360{1266}

1|045

1|050

H060

l|070

4OO{14O7} 450{1583} 540{1,899} 600{2,110}

Dimensions Model

RcDP

960,000{1117} 1,067,000{1241} 1,201,000{1397} 1,467,000{1,706} 1,604,000{1,g65}

L

W

H

mm

mm

mm

Weight

WaterVolume in Chiller-Heater

Shipping Weight Operating Chilled/Hot Cooling Weight Water Water (MAX)

t

t

a

o

3630

4030

4540

5,440

6,050

H015 3575

1825 1900

5.5

7.4

210

290

5.3{52}

4.8{47}

5{4e}

6.5{64}

6{5e}

H018 3575

1870 1940

5.9

8.0

250

340

3

3

3

3

3

3605 2020 2050

6.7

9.2

300

410

150

200

200

200

200

H025 3605 2150 2160

7.8

10.4

350

480

6000

6670

7500

9,020

10,000

H028 4675 2105 2100

8.7

12.2

380

560

8.5{83}

8{78}

8.5{78}

8{78}

8{7s}

H032 4675 2280 2170

9.9

13.5

440

630

2+1

2+1

2+1

2+1

2+1

H036

10.5

15.0

490

700

200

250

250

250

250

H040 4725 2350 2340 1 1 . 6 16.5

540

780

900

900

H045

4810 2415 2480

13.2 18.4

610

920

H050

4810 2465 2550

14.O

19.7

680

1010

eoo{8.82} eoo{8.82} e00{8.82}

H021

4700 2340 2250

80

80

80

80

80

239.8

266.4

299.7

359.7

399.7

H060 5860 2875 2750

15.7

23.O 820

1210

263.5

292.9

329.7

402.7

440.3

H070

17.9

26.2

1410

900

900

65

80

200{1.e6} 200{1.e6} 200{1.e6} 80

80

98.1

109

122.6

147.2

163.5

107.8

119. 8

134.9

164.7

180.1

1 1 6 .6

129. 6

145.8

175.0

194.4

129.4

143.8

1 6 1 .9

197.8

216.3

80

200 x 50/60. 220X60

o.4

o.4

o.4

o.4

o.4

3.7+O.75 3 . 7+ O . 7 5 ' 3.7+O.75 5.5+0.75 5.5+0.75 3.7

3.7

5.5

5 .5

16(14)

16(14)

18(22)

20(22)

3.7+O.4

3.7+O.4

16.5(14)

16.5(14)

17(41

568x460

550X 515

5 5 0 X5 6 8

5 4 5 X7 1 3

6 9 2 X 667

27.1

29.5

32.5

38.3

44.6

7.5

22.5(22)

3.7+O.75 5.5+0.75 5.5+0.75 21.5(22)

21.5(22)

5860

2975 2945

960

Note 1) The standard chilled water temperature is i2"c at the inlet and 7'C at the outlet, the cooling water temperature is 32.C at theinlet and 37.5'c at the outlet and the hot water temperature 60"C at the outlet. Note 2) The fouling factor of the chilled/hot water and the cooling water , is assumedas 0.0001m2h"C/kcat (0.0OOO86m2K/W). Note 3) The capacity of burner fan may be changed on the combustion volume and the gas specification. Note 4) The standard design pressureof the chilled/hot water and the cooling water is 8 kgf/srnz (gauge pressure) {O.zA N/pa} Note 5) Chiller-Heateris designed in accordancewith JIS 8g622. Note 6) Standarddeliveryis one piece shippingas the standard. Note 7) The net calorific value of kerosene is defined as g32oKcal/ 0 (Specific gravity 0.8). Note 8) Dimensionin width may vary dependenton the gas specification. Please check the outline drawing in detail. The values shown herein is based on the supply specificationat 2OOmmAq(060 and 070 are at the supply on 900mmAq). Note 9) The wiring size is used for reference.

r

w

1

I

Lr

l-

=l

High temperatureshell

Low temperatureshell

NOl5

N018

NO21 NO25 NO28 NO32 NO36 NO40

N045

NO50 NO60 NO70

L1(mm) Wl(mm) H1(mm)

3575

3575

3605

4810

4810

1235

1275

1900

1940

weight(t) Max.shipping

4.4

4.7

5.4

2470 965

Model o E iso hp x o

d 9

='

s o

f !EO

dp ao d r O i'E E o

.9 E

L2(mm) W2(mm) H2(mm)

f

aE('

EE

ge =' I

o

= !!o = E d o

drO F.C E o

.9

-

[#

EE =' I g

=

o o

gE e iio i.E E'n

.9 :E

4675

4700

1345

1415

1385

1425

1505

1545

1595

1645

1850

1910

2050

2160

2100

2170

2250

2340

2480

2550

2750

2945

7.6

8.4

9.2

10.1

10.8

13

14.7

2470

6.0 2980

7.O

2800

2980

3220

3260

3300

3600

3690

3900

3900

965

1055

1115

1110

1165

1175

1145

1195

1190

1280

1300

2330

2390

2700

2900

2.6 2.9

3.0 3.4

2430 3.2 3.6

3.8

4.4

4.2

4.8

1805

1885

1960

2070

2075

't.2

1.3

1.5

1.7

1.9

$reight(0 Max.shipping

1.3

1.4

1.7

1.9

2.2

Ll(mm) Wl(mm) Hl(mm)

2100 2.3 2.6

2240 2.4 2.7

4725

LO45

LO50 LO60

LO70

4810

4810

5860

5860

1275

1345

1415

1385

1425

1505

1545

1595

1645

1850

1910

1900 1940

2050

2160

2100

2170

2250

2340

2480

2550

2750

2945

6.0 2980

7.O

7.6

8.4

9.2

10.1

10.8

13

14.7

2980

3220

3260

3300

3660

3690

3900

3900

1280 1300 2700 2900 4.4 3.8

1235 4.4

4.7

5.4

2470

2470

2800

965

965

1055

1115

1110

1165

1175

1145

1195

1190

1805

1885

1960

2070

2075

2100

2240

2390

weight(t) Max.shipping

1.2

1.3

1.5

1.7 .1.9

1.9

2.3

3.0

2430 3.2

2.2

2.6

2.4 2.7

2330 2.6 2.9

3.4

3.6

Ll(mm) Wl(mm) Hl(mm)

1.7

1.3

1.4

H015

H018

HO21 HO25 HO28 HO32 HO36 HO40

3575

3575

3605

1235 1275 1900 1940

4.2

HO45

HO50

HO60 HO70

4675

4675

4700 4725

4810

4810

5860

1345

1415

1385

1425

1505

1545

1595

1645

1850

1910

2050

2160 2100

2170

2250

2340 9.2 3300

2480

2550

2750

2945

4.4

4.7

5.4

6.0

7.O

7.6

8.4

L2(mm) W2(mm) H2(mm) weight(0 Max.shipping

2470

2470

2800

2980

2980

3220

3260

5860

10.1

10.8

13

14.7

3660

3690

3900

3900 1300 2900

965

965

1055

1115

1110

1165

1175

1145

1195

1190

1280

1805

1885

1960

2070

2075

2240

1.3

1.5

1.7

1.9

2.4

2330 2.6

2390

1.2 1.3

3.0

2430 3.2

1.7

1.9

2.2

2100 2.3 2.6

2.7

2.9

3.4

3.6

2700 3.8 4.2

1.4

4.8

3605

weight(t) Max.shipping

weight(t) Max.shipping

5860

LO32 LO36 LO40 4675 4700 4725

LOl8 3575

L2(mm) W2(mm) H2(mm) weight(t) Max.shipping

5860

LO21 LO25 LO28 3605 3605 4675

LOl5 3575

weight(t) Max.shipping

Model E 5

4675

weight(t) Max.shipping

Model E

3605

4.4 4.8

*For the excessiveheatingVp€{Htype),the hightemp€rature dhell-sideis upgradedto the cla65of on6-€tepupper6izeand for the superexcessiveheating and volume. may b6 upgradedto the cla65of two-stspuppersize in dimensions rcgenerator tpe(F type),the hightemperatu.e

12

Low temperature shell

High temperature Hig

Cotd N\SSinsulation-work N\\\\] paft

part Hightemperature shellhotinsulation.work

Gold insulation-workpart . Evaporatorshell . Evaporatorwater box and box cover . Refrigerantpumpand piping

. . . .

part Lowtemperature shellhotinsulation.work . . . . .

High temperaturegenerator Frontsmoke chamber Rearsmokechamber Solutionpiping

Hot WV)insulation-work V.1//./1 paft

Solution heat exchanger Solution piping Steam header Refrigerantvapor piping Absorber shell (unit m2)

Model (RCDP) N015 Insulationarea(Cold) 8 Lowtemperature shell 6.3 lnsulation atea High temperature shell 7.7

N018

Total

(Ho0

14

8.5

NO21 NO25 NO28 NO32 NO36 NO40 NO45 I

NO50 NO60 NO70

10

11

12

13

14.5

15.5

16.5

18.5

20

9.9

10.3

10.8

11.4

15.5

15. 9

6.5

7.1

7 .7

8.8

9.2

8.0

9.4

10.3

11.2

12.8

13.5

14.7

17.2

17.6

20.5

21.7

14.5

1 6 .5

18

20

22

23.4

25

28

29

36

37.6 (unit m2)

Model (RCDF) ,!ors ,lors "1o21 ,1025 Insulationarea(Cold) 8 8.5 I 10 Low temperature shell 6.3 7.1 7.7 6.5 Insulalion alea High temperature shell 7 .7 8.0 9.4 10.3 {Ho0

Total

14

14.5

1 6 .5

18

rL08

11

,5m 12 9.2

HLo4o '\oqs ,Lm 14.5 15.5 16.5

,!m

13

18.5

,Lo/o 20

9.9

10.3

10.8

11.4

15.5

15.9

20.5 36

37.6

"Lm

8.8 '11.2

12.8

13.5

14.7

17.2

17.6

20

22

23.4

25

28

29

21.7

13

RCD N015^,N025

Leav exhaust gas -

,r ZZOf

Cooling water outlet( 4 B)--

l+t I

lt

Tube removal space (can be on other side)

Lowtemp. generator

-

Chilled/ Hot water inlet(eB)-

W

<-

pipiin"g l\ l l I Burnerunit

Evaporator .-..-

|

I

/

Cooling water outlet( 4 B)

,r ,,/

R i ghtsi de

[3690 : 028-050

Leav exhaustgas

Tube removal space (can be on othei side)

4610: 060-070

Absorber

Low temp generaror

Purgetank H i g ht e m p generator

tr1

-r +

i r+}i L---*I

,r'

j

Fuel gas inlet(pB)

Front side

RCD N02g-N070 Chilled/Hot-. b water outlet(eB) \ f-i*.

-r

-

_;

Left side

,-

-

_____J c

. , \ \

Chilled/ Hot wateroutlet(eB) C h i l l e d/ H o tw a t e ri n l e t ( e B )

b ,

r

r-----Fuel gas prpilng

Burnerunit

R i ghtsi de Left side Front side

NO50 NO60 NO70 NO40 NO45 NO28 NO32 NO36 NO25 1415 1700 1775 1390 1415 1300 1320 1375 1310 425 440 530 550 400 350 375 280 345 335 2360 2BBO 2880 2320 2360 2320 2320 2320 1810 1810 2645 2285 2450 1995 2070 2215 1870 1920 480 600 B I B 8 6 6 6 4 4 5 6 500 530 450 370 365 540 550 495 530 560 560 790 820 625 650 675 545 565 605 470 490 560 2690 2190 2690 2150 2150 2190 2150 2150 1615 1630 1615 2945 2480 2550 2750 2170 2250 2340 2160 2100 1940 1900 435 450 530 540 400 350 380 360 335 285 300 2720 2220 2720 2180 2180 2220 2180 21BO 1655 1640 1640 10 10 10 8 10 8 8 I 6 6 5 5 250 250 250 250 250 250 250 250 250 165 165 165 490 510 400 370 380 380 370 390 280 335 395 2BO 2540 2040 2540 2040 2040 2040 2050 2040 1550 1550 1550 1550 2 2 3 3 3 3 3 2 2 3 3 2 1520 1240 1470 1165 1190 1215 1020 1130 1010 895 915 975 2000 1805 1900 1720 1790 1755 1605 1615 1445 1410 1470 1375 665 475 470 280 305 640 5 260 175 505 520 125 702 692 480 568 515 568 480 450 515 450 450 350 667 460 550 545 430 460 550 430 370 370 310 310 5860 4810 4810 5860 4675 4700 4725 4675 3600 3606 3575 3575 2875 2975 2415 2465 2340 2350 2150 2105 22BO 1975 1825 1870 2750 2945 2480 2550 2250 2340 2160 2100 2170 1940 2050 1900 23.5 18.0 20.8 15.3 16.9 12.5 13.9 7.7 9.7 11.3 Maxshipping weight t 7.4 6.9 26.2 23.0 16.5 18.4 19.7 13.5 15.0 10.4 12.2 7.4 8.0 8.4 Operationweight t and valuesare basedon the In this table,standardrequirements Dimensions of gas piping,combustionvotum€,type of gas mayvaryby the supplypressure. of 060 & 070). mmAq(caseof 015-050),goommAq(Case Eupplyon the standard,13A,or LNG,2OO Model(RCDG) a mm b mm Chilled/hot c mm water d mm e inch t mm s mm h mm Cooling mm water mm k mm inch m mm n mm Gas o mm p inch q mm r mm Exhaust mm s gas t mm u mm L mm Outline w mm dimensions H mm

NO15 't2't5

N018 1215 295 1810 500

NO21 1265 320 1810 560 5 515 525 1630 2050 335 1655

L(Tuberemovalspace) __; (canbe on otherside)

I

il 1

Model bolts(015-025) bolts(028-070) Low temp shell

Dase

I

Model 8-n150Anchorhole(01 5-025) 8-!1 90 Anchorhole(028-070)

_

_

l

t

High temp.shell

(unit mm) Model a

b c d

e f

s h I

k I m n o p q f

s t

u v w x

v z L

NOl5 3200 1880 1130 840 350 1380 895 565 420 1310 -170

N018 3200 1920 1170 840 350 1380 915 585 420 1310 -170

550 840 120 940

550 880 120 980 175 't605

175

1605 220 100 100 150 325 470 100 130 650 2905

220 100 100 150 325 490 100 130 650 2905

NO21 3200 2040 1240 890 350 1380 975 620 445 1640 160 600 950 120 1050 175 1935 220 100 100 150 350 525 100 130 700 2905

NO2s 3200 2110 1310 890 350 1380 1010 655 445

1640 160 600 1020 120 1120 175 1935 220 100 100 150 350 560 100 130 700 2905

NO28 4180 2130 1280 940 400 1860 1020 640 470 1640 -340

NO32 4180 2220 't320

650 990 110 1090 200 1950 230 120 130 170 375 545 100 130 750 3915

990 400 1860 1130 660 495 't845 -115

NO36 4180 2320 1400 990 400 1860 1165 700 495 1845 -115

N040 4180 2360 1440 990 400 1860 1190 720 495 1845 -115

650 1030 130 1130 200 2175 230 100 130 170 400 565 100 150 800 3915

650 1110 130 1210 200 2175 230 100 130 170 400 605 120 150 800 3915

650 1150 130 1250 200 2175 230 100 130 170 400 625 120 150 800 3915

NO45 4180 24BO 1490 1040 400 1860 1215 745 520 2205 245 700 1200 130 1300 200 2535 230 100 130 170 425 650 140 150 850 3915

NO50 4180 2530 1540 1040 400 1860 1240 770 520 2205 2450 700 1250 130 1350 200 2535 230 100 130 170

425 675 140 150 850 3915

NO60 5180 2900 1800 1160 400 2340 1470 900 580 2400 -40

NO70 5180 3020 1940 1260 400 2340 1520 970 630 2400 -40

800 1500 150 1600 200 2750 250 100 150 150 480 800 190 150 960 '5000

900 1540 150 1740 200 2750 250 100 150 150 530 870 120 150 1060 5000

15

RecommendedPiping Flow Diagram (Symbols) e

Cooling tower

: P r e s s u r eg a u g e

ri) \-/ : Temperature indicator {-/ : Flow meter

Cooling water blow valve

'7-

: Strainer : Check valve

L- w"rt" w"t"t

WaterPump Cooling

A i r C o n d i t i o n i n gu n i t

*c1

,(2

t 3

*4

Expansion tank

Valve for chemical cleaning

*5 ,t 6

i-_ : Unit encircled with the square dotted line are those equipment under the scope of our scope of supply. When the temperature of cooling water is below 15'C, the temperature control of the cooling water is required. The start/stop control device for the fan of the cooling tower is provided as the standard. The maximum operating pressure in the chilled/hot water cooling water is 8 kgfl cm2(0.78MPa). The using flange is the JIS 10 kg / cm 2 FF flange. Provide the

*7 * 8 {.9

comparison flanges by others. Drainage plugs(PT 3/4\ are arranged at the bottom of chilled/hot and cooling water box, therefore, install the stop valves as required and extend the piping up to the ditch as cases may requrre.

ExhaustGas(Tochimney)

Install the drainage at the bottom of flue and chimney as required. For the chimney and flue, care must be exercised in deg and planning not to allow chimney in common use with other incinerator or engine generator or other devices. In design and planning, sharp corners or flue area must be avoided. Cooling tower shall be located far from the outlet of chimney to avoid water pollution. For chemical cleaning, Install the stop valves for cleaning between the unit and each stop valve at the inlet or outlet.

For eificient operationof the unit for a long time, ii is necessarywater qualitycontrol.The followingtable showsa qualityguidelineof the coolingwater compiledby the Japan Refrigerationand Air conditioningAssociation(JM). Quality standard of feed water

Quality standard of cooling water Items pH(25oC) (pSlcm) Electricconductivity(2soC,) Q

0) E Chlorideions(mgCl-/ o) 0) Sulfate ions(mgSO2-+/ E P

(U

lJ

c (!

a

(mgCaCOs/ 0) Acidconsumption(pH4.8)

Values of standard 6.5-8.2

Tendencies Corrosion Scale/Slime

C

800 or less

C

200 or less

C

200 or less

o o

o

E o Chlorideions(mgCl-/ 0)

!

o

0\ Total hardness(mgOaOOs/

200 or less

o

0) Calcium hardness(mgCaOOs/

150or less

0) lonizedsilica(mgSiOz/

50 or less

o c

Note 1) As the JRA standard,other items are also listed for your reference.

pH(25oC) (pSlcm) Electricconductivity(2soC,)

P

o

100 or less

Item

(E E C, F

a

Valubs of standard 6.0-8.0 300 or less 50 or less

Sulfate ions(mgSO2z/0 )

50 or less

(mgCa0Og/ 0) Acidconsumption(pH4.8) 0l Total hardness(mgOaOOs/ gCaCOs/0) Calcium hardness(m 0) lonizedsilica(mgSiOz/

50 or less 70 or less 50 or less 30 or less

r

(Membrane Sheet)

Appearance of Conkol,Fontandsideviews

ABSORPTION CHILLER/H EATER o o o o o o ct>o o C' z F

tu

o F a

(f

=

z.

z

a f (n

F l

tIJ

o_ o

o

UJ E. L! a a

(J E f O U

o

O

Lu

<;i <;; >6 >ii (ru O c c 9;-l z.o-

STATUI3 Ati.t O OPERATION C

o

o STOF

o

o

o

STOF

SOLUTIONREFRIGERANT BANNER PUMP PUMP FAN

@

@

I a UHILLEIJ/HO -JWATER TEMP

o JTOF

OIEMPMEASURING

VWATEFI

TEMP

^CAPACITY CONTROI VVAI VF POSITION

C

TIME hr OC0MBUSTI0N TIME hr O 0PEBATING UtrILLtrH/NE NN.AFF

N V

TCOMBUSTION JoN-oFF timcs

TEMP ODATA&TIME OSETTING OMAINTENANCE OSETTINGITEM1 ITEM OSETTINGITEM4 OSETTING ITEM€ OSETTINGITEM7 OSETTING

RATINGTIME hr

OOPTION OSETTINGITEM2 OSETTINGITEM5 ITEM8 OSETTING

OREMOTE OCOOLINGOAUTO oLocAt O HEATING OMANUA SELECT CAPACITY ]PERATION CONTROL COOL/HEAT VALVE

NP18-341

Three-wireConnectionDiagram

PowerSupply

Note1) Whenpowersourceis grounded, phase "s" mustbe gr6unded. E--

-], equipedwithchiller-heater ELBl 3OAFlOAT

!r'J tonuo't'"''t

i

i

i

\r-i-J 88AP Vacuumpump powerterminal (Knifeswitch) 5 1A P MAXO.75KW

Rl ls1 lT1

\_______J PS (ToK01)

W4

I E Solutionpump

Purgepump(Option)

P a l l a d i u m Palladium heater

I

_::__l 17

x6OHz 200Vx 50Hz, 2OO|22OY

100v

t

Polarity3

')

l

@ 6 6 d

\ ""t

(TB2) 1 @ - 2 @ - C Oo 3 @ - 4 @ - C1o-

R S T ffBO)

0Ol @002 o

r outsideoDeralion _ _ I Instruction

REMoTE ffi:r

'r Seismic (Note7)

(oploru)o.* RS4 @SL1 o

5q 6q-

1 S€llSOl

r / i r - - (Note 4)

"

' -

(TB2) -o RS3 -o RS4 @SL1

--*

... _. 1 Remotestartsignalll(Note 3) ' € I Remotestop signalJ _ _ _ l <-e

rr

<-e <-e

c1 6-

7q 8ql-

c1 {-

CHILLER,/HEATERe q loql c 1 d -

-t Chilled/hotwaterpumpinterlock + CoolingwaterPumPinterlock l:

...oj ....j

ICL t c

(Note2) I Fan,coolingtowerinterlock lE .| Limitswitch,of motorvalve |5 .. I Outsideemergencystopsignall | (Note2) . Seismicsensor J'

___) .+

.t GasleaksensorI .. l(Note2) I Abnormalroom J' _ _ _ J tempsensor ...{j

rrBT)

f

z _ _

waterpumpI Chilled/hot Startsignal L

- - - -

Fan,coolingtower Start signal ro (D o z f

oo o 6

VentilatingFan Start signal Answer back underoperalion

o o

a o

Stop On cooling Failure

|l

<

-

-

-

Pre-alarm i a- instruction Onremote I (Note6) L <- -

-@ 11 -<sl^'12 -@ 13 -o't4 -o 15 -€ 16 -o 17 -@ 18 -o 19 -o 20 -@ 21 -@ 22 -o 23 -a 24 -@ 25 -o 26 -a 27 -o 28 -o 29 -€ 30

Note. 1. This diagramillustratesconnectingwking to/ftom the chiller-heater,the remote (option)and auxiliarydevices 2. Among input signals,utilize any input signal you need after removingany short circuit in the (in-housework finished) 3. Wiring may vary dependingon the type of remote start/stop signals. Refer the circuit diagramof remotestart/stop signals.When the remote (optional)is utilized' the remotestart/stop signals is canied out on the communicationcable, there is no need for this wiring. 4. The communicationcable may be usedthe week cunent instrumentcable(JGSno.364) JKEV-SO.gxlP of the Japan cable industry association standard. Please remindthe following points in th€ installationwork. *The maximumlengrthof communicationcable may be limited at 50o m or less. :tThe cable holds polarity,therefore,handle it accordingly an example of recommendedinstallation. Terminal no. RS3'To connect with the white cable" Terminal no. RS4'To connect with the black cable. *. The shield must be groundedwith by either one of the earth terminals'

18

For out-put signals,select any signal necessary' Pteasespecify necessarysignals for selecting among the preset keys on the control of the unit. 7. lt is possibleto insert the switching of seismic senson into the remote(optional). 8. For connectionwiring with auxiliarydevices, rThe timer for startingthe dilution is included in the control of the unit. *During the heatingoperation,the circuits for cooling water pump and for the fan in the cooling tower are automaticallydeenergized. {. The start/stop control circuit for the fan in the cooling tower is installed as the standard(includinga sensor). *The freeze-proofoperatingcircuit for winter is installedas the standard(includinga sensor). * For the pump interlock signal,24 VDC is applied' 9. Anange wiring separatelybetween200V circuits and low voltage circuits.

5. 6.

for Ghilled/Cooling WaterPumpandCoolingTowerFan SampleWiring Diagram Power board(to be prepared by other)

41fi

_t_

-_1-

-.....-..€lr

-I

o--T-7

-_l_

J t r

,i-T?

_L

-_[

,

r

l

€ q) c

RemoteStart/StopSignalGircuitDiagram Standardequipment (selectionusing switch) A Type

o

CL F

E

Drya*b s Pulse(momentary) signal ON

OFF

Optionalequipment(installedat factory)

B Type Dry a Hold(continuous) signal

C Type

D Type

DC24Va*a s Pulse(momentary) signal

ON,/OFF

ON

OFF

E Type

DC24Va s Hold(continuous) signal

AC24Va*a s Pulse(momentary) signal

F Type AC24Va Hold(continuous) signal

ON/OFF

o

Ee 6E oE

DC 24V

DC 24V

o

o

o o ! Y G

fo.

I'l'T" I'T'?"

gi oE

5s Terminal NO.

19

Start-Up

CWline startsuspended

c-HPPF)- H-HP00)

of normal {ln caseof unconfirm 'operation within3 minutesafter CHW/HWpumpON)

llotes 1 . ( ) Indicates the digital on the '

This unit has various safety devices not only for safety operation but also for protecting the unit. (1) Safety device for triP. With activation of the following devices, the unit will stop automatically with closing the shutoff valve of fuel and sounding buzzer simultaneously.The error message number displayed on the control inform the fault. (2) .Safety device for automatic control. The following equipment and device will control automatically for a safety operation. """ To @ netrigerant overflow pipe prevent abnormal concentration of @

solution. To Overflow PiPe crystallizationof solution'

Prevent

Error number

. Chilledwater, Low temPerature . Refrigerant,Low temPerature. . Chilled water, low flow rate {

20

Sorts of safetY device

Normal Stop

Auto control stop suspended

ilotes (c-0ooo) (H-0000)

1. ( ) Indicatesthe digitalon the .

EmergencyStop

Errorcode (Er.xxxx)

l{otes 1. (

) Indicates the digital on the .

21

Summaryof StandardScopeof Supply. Scope in the delivery

Items

Scope in the delivery

Items

Remarks

Base machine

o

External piping work

X

Control

C

Externalwiring work

X

System wiring and piping Solution(LiB0

c o

Connecting piping (A-C) for cooling water is not required.

Flue and chimney work

X

I n i t i a lc h a r g i n go n l y .

Final paintingover the unit

X

Remarks arenotincluded. Companion{langes Nointerlock wiringis included. Control factory work.

is

Refrigerant Transportfrom factoryto port Yokohama

X

Note 3)

lnsulationwork for the unit

X

o

FOB Yokohama

Witnessed test

X

to thesite from,Yokohama Transportation

X

X

Supervisinginstallationat the site

X

Experts' attendance contract is required.

Cooling water temperature control Thermometers,Pressuregauges

Mortaringanchor bolt

X

Flow meter

X

Recuperation

X

Drain valve, Air vent valve

X

Dispositionof packing materials

X

Anchor bolts

X

Nitrogen gas for storage Test operation and adjustment

X

lnstructionmanual

o

Three(3)sets

Fuse

C

Spares

Foundation

X

X

Experts' attendance contract is reouired.

painted

at

For chilled/hot water, for cooling water.

X

Nore 1) Supplies for water, elechicity, gas snd orher consumed items arc rcqu$ted to provid€ at the tjme of installation, test ope€tion and adjuslhent operalion. Note4Te;p€atU€contrlfolthecoolingwatelisrqundifthetemp€€tuGatth€in|etofthecoo|ingwate|iS15cdeqreesorless.Thedan/siopcilcuitforth€fnofcoo|ing tower is provided as the standad equipment (including a themal sensod. Note 3) Pure waler is rcquned which shall be mad€ in accodance with Eb8tss r€quilsm€nt.

lnquiry

Optional The following items are provided as optional. . Marine type water box . Automatic purge unit . Special water box design pressure . Lower than 7 degrees at the outlet of chilled water. . Low cooling water flow rate requirement. . Exhaustgas silencer . Remote . Multi-unit control . Automatic tube cleaning device(ETACS) . Dual fuel burner . Heating capacity increase

At inquiryfollowing informationare required. . Cooling capacity. . Temperatureat the inlet and outlet of the chilled water and/or it's flow rate. . Temperature at the inlet and outlet of the cooling water and/ or it's flow rate. . Heating capacity. . Temperatureat the inlet and outlet of the hot water and/or it' s flow rate. . Type of fuel, supply pressure,calorific volue, specific gravity. . Power/voltage, frequency. . Type of service and average annual cooling operation time.

GombustionSystemDiagram(Oil-Fired) B a l a n c i n gp i p e ( n o t e 4 )

Symbol

Symbol

r'eLfl oooo( ,o o o o

i;,tr'v

Blower

-11-

?

Fuel cut-off valve

_'9*

Oil volume adjusting valve

r

,60

P r e s s u r eg a u g e

tl

T

J)+

Valve

Flow meter

A

Nozzletip

S*

Safety valve

o

Oil distributingpipe

@

Oil filter

c

Fuel injectionpump

.T.

Pressuregaugeplug

.J-\F

O

).va

Check valve Air dumper

Note 1. Make sure the oil pressure at 0.1-0.35k9/cm2Gat the tie point. 2. Make sure removing water with a drainage on the bottom of service tank 3. Install a oil filter (2Omicrons)separating oil and water at the connection port of the unit and the oil supply side. The oil filter is an accessory part of the unit(Kerosene-Firedtype). 4. Balance pipe must be installed for preventing miss-fire. Make sure no stagnant oil or air in the piping.

22

Cock Air piping

F l e x i b l eh o s e

CombustionSystemDiagram(Gas-Fired) oLow pressure gas supply

o H i g hp gas su

Symbol

Symbol

r--

w F D

Pilotburner

-fl ru

Main burner

Safetyshut valve

.\7 -v D<-

Gaspressure adjuster

Batterfly valve with control motol Jpper limitswitch gas pressure

iaF

Symbol

Blower

-+

(PAI

Y

(a Y

_9_

Cock Gas piping

Out of Scope

F-)

Salety shutvalvewith gaspressure regulalor

{Pr)

gauge Pressure

fj

ower limitswitch gas pressure Switch, wind pressure

Strainer

I

Hose end cock, pressure gauge

Ptug, _T- pressure gauge

T

Air piping

I

Cock with pressure gaugecock

Technicallnformationfor ExhaustGas. Gas (13A) 260/oenergy saving type Tvpe

RCDG

Heat trausfer area of Gh Fuel consumption Exhaust gas temperature Exhaust gas I Wel flow I Drv Oxygen residue NOx Combustion air flow

62

Nma/h

Iots

I018

io21

Io25

Io28

Iogz

l036

Io+o

Io45

io5o

Io6o

Iozo

9.7 44.9

11.7

16.1 74.8

19.6 83.8

21.4 95.8

23.6 107.8

27.1 119.8

29.5 134.8

32.5 149.7

38.3

53.9

13.8 62.9

180.1

44.6 210.1

679.3 580.6

815.5 696.9

951.7 813.3

2725 2329

3179 2717

11.5

14

16

46

53.8

Iozo

oc Nm3/h olo

ppm mglmin(2OoC)

235 1 1 3 1 . 7 1267.9 1449.5 1631.0 1812.6 2039.5 2265.O 967.2 1083.5 1238.7 1393.9 1549.0 1743.O 1935.6 5 60(0z:0o/o) 19 21.5 24.5 27.5 30.5 34.5 38.5

Oil (Kerosene) 260/oenergy saving type Type

RCDK

tot5

I018

Io21

Iozs

to28

Iogz

Ios6

io4o

I045

toso

Iooo

Heat trausfer area of Gh

1n3

9.7

11.7

13.8

16.1

19.6

21.4

23.6

27.1

29.5

32.5

38.3

44.6

Fuel consumption

0/h

53.9

64.7

75.4

89.8

100.6

115.0

129.3

143.7

161.7

179.6

216.3

252.2

638 572

766 687

892

1063 '953

1191 1068

1361

1530

1372

1701 1525

1914 1716

2126 1906

2560

1220

2295

2985 2676

0

0

0

0

0

Exhaust gas temperature

Exhaustgas I flow I Oxygen residue

NOx Dust SOx

Wet Orv

oc Nms/h

235 800

olo

ppm g/Nm3 Nms/h

4 MAX. 1OO

MAX.0.05 0

0

0

0

0

0

0

23

EBARA =

E;ltAA/A

Equipment & Systems Co.,Ltd. nrtrigeration

HeadOffice & Sales Department Japan 5-1-13Haneda,Ohta-ku,Tokyo,144-0043 Phone:+81-3-3743-7767Fax:+81-3-3743-2242

EBARA conpoRAroN HeadOffice: Japan Ohta-ku,Tokyo,144-8510 11-1,HanedaAsahi-cho, 11 Fax:+81-3-3745-3356 Phone:+81-3-3743-61 TOKYO Cable:EBARAMAIN lnt'l Telex:J22988EBARATYO

& Distributors Offices O: Liaison IEUROPE ITALY Oltaty Office(Vicenza) +39-0444-522-818 HUNGARY ORegaleKFT +36-1-212-2099

IASIA OF CHINA PEOPLE'SREPUBRIC OBeijingOffice 50-7 +86-10-6590-81 Equipment Co.,Ltd. OYantaiEbaraAir Conditioning 186 +86-535-632-1 TAIWAN OTaipei Office +886-2-3567-1 310 SINGAPORE SingaporePte.,Ltd. OEbara Engineering +65-6865-5240 INDONESIA OP.f. EbaraIndonesia +62-21-874-0852 THAILAND OEbaiaThailand.,Ltd. +66-2-216-4935

IMIDDLE.EAST IRAN Corporation OK-O-AEngineers +98-21-Bg8-0292

All specificationsare subjectto changewithoutnotice @EBARACORP.2004 Printedin Japan

Printedon recycledpaper

28-010-E09 1181@JD-A(AB)M

'i;*

g;'l t)-+:ii

2.:+,: :,)r*l .:!E

iii

L+1:,

ti;ti

,rtli

nio.

RCDsenbsfb a newly desffied compactand hlgh Pertormanc hetter and desffied considering

{r\*.

q'r.fl{lAr

'-r{*..

Using a newly developed microprocessor, high performance is realized in operating.

1. Energysaving with minimizedstartup. Startup time of the system has been cr,it short with an optimized flow rate of circulating solution responsive to the startup operationquickly. This reduce fuel consumption.

4. Operatingconditionis displayedon the digitally. Operating information such as the chilled/hot water temperature,the cooling water temperature,the solution temperature and the other followings listed hereunder are displayed on the control . Temperature in the high temperature generator. . ouflet temp. of the high temperature generator. . lnlet temp. of the high temperature generator. . Dew point temp. of the high temperature generaror. lnlet or Outlet temperature of the chilled/hot water. Inlet or Outlet temperature in the cooling water. Chiller-Heater operating time. Operating time of the refrigerant pump. Number of start/stop operations of the unit

Q

o

3

c

Measurement in temperature. . Temperature of the exhaust gas. . Temperature of the evaporating refrigerant. ' Temperature of the refrigerant condensation. ' Temperature of the solution in absorber. Fuel control valve indicator. Combustion time Operating time of the solution pump. Number of combustion start/stop ooerations.

6 5 a

5. Preventionfunction for unusual shut down on failure are equipped.

o c c

)

o

o o o E 0)

With confinuous monitoringoperating conditions by sensors equipped in the unit, stoppage of the system on failures or fault is minimized in controlling system before the system goes to failures. . Dew-point control of the high temperature generator. . Solution temperature control of the high temperature generator. etc.

l

Elapsed time after the combustion start(min)

^

2. Reducingdilution time at the time of operating interruption. By checking the operatingconditionat shut down, minimum diluting time is determinedautomatically. over dilution is avoided automatically,and this contribute to the energy saving.

3. Interlocking circuits of auxiliary devices are equippedas a standard. An interlockingcircuit are equipped for chilled/hot water, cooling water pumps and a fan of cooling tower as a standard. The operating cost may be reduced with protective meas-ures such as a start/stop circuit for the fan on the cooling tower for cooling water temperature control and a freeze-proof circuit with thermo-sensorsfor winter season are equipped as a standard.

6. Pre-alarm system ensure preventive maintenance. With pre-alarm systems, magnitude of scale/slime fouling in the cooling water tubes and timing for replacing some parts of the unit are informed well in advance' . . . .

Temperature rising in the exhaust gas. Rising in the internal pressure. Replacement timing of the burner part. Fault in thermo-sensors. *Temperature rising in the inlet of cooling water. {

x mark indicates

that only counting

. Rising in LTD of cooling water. . Overload in the purge pump. . Replacement timing for respective oarts. . Abnormal in level control in high temPerature generator. * Temperature rising of the cooling water at the inlet/outlet' * Temperature rising in the solution of the high temperature generator. is made without

displaying

any pre-alarm.

7, A circuit for power-failureis equipped with a standard. For a power-failure within the minutes, the unit may start automatically after the power is recovered. The unit will shut down with alarm if the power failure lasts more than ten minutes.

DirectFiredAbsorptionChiller-Heater ol equippedwithlatest microprocess or environment, CONTENTS In an application of inverter control of solution puffiF, saving energy has been realized in the whole range from partial loads to rated loads of cooling mode. Installation costs may be reduced at no control of cooling water temperature and further saving in energy consumptiong as operation is feasible as 15'C at the inlet of cooling water.

0.30

s I PartLoadPerformance

E z

I E

a c

22.c

E z

15c

o

; c

v.4u

x

n ro

o o 6

(,

The graphic chart shows; Energy saving is 40olocompared with original model when the refrigerationcapacity is 40% and the inlet temperature of the cooling water is 27"C. Note 1) The combustion rates shown herein based on a gross calorific value 11,000kca1/m2(NTP) of gas. Note 2) This graphic chart is applicabte to the model 015 through 050. Note 3) An area surroundedby the dotted lines is the area for available loads .which is derived from using respective average wet bulb. Note 4) The % of energy saving is based on the first developedunit. Note 5) 1rns/(h.USRI)(NTP):9.2343ms/kW(NTP)

Equippedwith a low Nox burner, 60ppm attainedat the fuel gas 13A.

less based

Oz Oolo,

Compared with the oonventional type, reductions of 2Ooloin width; 15o/oin height 2Oolotn setup space have been attained(Comparison reference in 360 tons class).

RCD036 (New

.......5 C o o l i n ga n d h e a t i n gc y c l e Standard Specification Table (Energy saving 260lo) Series N Cooling operation per annual : 2 , 0 0 0h o u r so r l e s s . . . . . . . . . . . . . ' . 6 Series L Cooling operation per annual : 4 , 0 0 0 h o u r so r l e s s . . . . . . . . . . . . . . . 8 Series H Cooling operationper annual : morethan 4,000hours............10 S h i p p i n gD i m e n s i o n s. . . . . . . . . . . . . - - - - . - . . 1 2 Thermal Insulation ( C o l da n d H o t S u r f a c e ) . . . . . . . . . . . . . . . 1 3 .........-..-...14 D i m e n s i o n. s. . . . . . . . . .'........15 Foundation ..'...16 T e c h n i c a li n f o r m a t i o n ...........17 C o n t r o lp a n e l Sample power board R e m o t es t a r t / s t o ps i g n a l . . . . ' . . . . . . . . . . 1 9 ......2O Start/stop flow chart Standard delivery scope and o p t i p n a ls p e c i f i c a t i o n s . . . . . . . . . . . . . . . 2 2 Combustion system diagram and technical relating for exhaust gas

I I t

Evaporator

LowTemp.Generator Gondenser

PurgeUnit

HighTemp. Generator

:

I

SolutionHeatExchangers

BurnerUnit

l--l :StrongLiErsolution lMediumLiBrSolution f-l

:Weat

Tl

: Evaporated refrigerant

N

:ruttyctosed

Refrigerant evaporates in an evaporator and cools down chilled water. The evaporated refrigerant is absorbed into the solution in the absorber. The solution absorbed the refrigerant become weak and sends to the high and low temperature generator respectively through the heat-excangers pumped up by the solution pump. The weak solution turns to a concentrated(strong)solution after heating by the burner in the high temperature generator.The solution becomes medium strong solution in the low temperature generator heated by refrigerant(steam) generated in the high temperature generator. The strong solution in the high and medium strong solution in the low temperature are mixed together and back to absorber through the both solution heat-exchangers, in which absorbs the refrigerant evaporated from the evaporator. The generated refrigerant in the low temperature generator move to the condenser and condensed by the cooling water. Condensed refrigerant back to evaporator.

l>- Hotwater OUT

. MediumLiBrSolution l-l

:WeakLiBrSotution . Refrigerant (HzO)

: Evaporated refrigerant l<- Hotwater [--l IN ffi iFuttyopened

Fuel

The high temperature steam(refrigerant) generated in the high temperature generator is moved through valve and condensed in the evaporator and heating up hot water for heating. The refrigerant is down to and mixed up with medium weak solution in the absorber.Then pump up to the high temperaturegenerator by solution pump. The medium weak solution generates steam(refrigerant vapor) in the high temperature generator.

Model(RCDFI

1{0t5

t{018

il021

1{025

il028

]t032

11036

Cooling Capacity

usRt{kw}150{528}

Heating Capacity

kcal/h{kW}400,000{465}480,000{558}5 60,000{651} 666,ooo{774} 742,000{853} 854,000{993} 960,000{1117

FlowRate o:t c'o

=

Q,/mtn

Plessure Dlop

180{633} 210{73e} 250{87e} 280{e85} 32O{1125} 360{1266}

1810

2120

2520

2820

3230

3630

8.2{80}

7.4{73}

7.7{75}

6.3{62}

6.3{62}

6.4{63}

4

4

4

4

3

3

3

1510

mAq{kPa} 7.8{76}

'El

S llo.of E CJ

PipeConnection Size

A(mm)

100

100

125

125

150

15 0

150

FlowRate

Q,/min

2500

3000

3500

4170

4670

5330

6000

12{118}

12.5{123}

e.5{e3}

10{e8}

10{e8}

o:t cr('

Drop = Plessure := il0.ol ct ct

mAq{kPa} 1 1 . 5 { 1 1 3 } 12.5{123}

Elt

3+1

3+1

3+1

3+1

2+1

2+1

2+1

125

125

150

150

200

200

200

CJ

PipeConnection Size

A(mm)

eoo{8.82}eoo{8.82} e00{8.82}

Ualue Gas {gross) PipeConneclionA(mm)

Supply Pressure mmAq{kPa}1 50{1.47} 150{1.47} 150{1.47}

150{1.47}

80

100

100

125

80

80

80

4500 Consumption Nm'/h (Coolinsl

99.9

119.9

139.9

166.5

186.5

213.2

239.8

Consumption ll|eatinql

109.8

131.8

153.9

182.8

203.7

233.4

263.5

kcal/llm3

Nm3/h

200{1.e6} 200{1.e6} 200{1.e6} 2oo{1.e6}2oo{1.e6}2oo{1.e6}200{1.e6} Supply Pressure mmAdkPa) Ualue = Gas (grossl PipeConnectionA(mm) 50 50 50 80 80 80 BO q:t

trsAl Consumption il000 (Coolinsl kcal/ilmg Consumption llleatinol Consumplion (Coolingl Kerusene Consumption ll|eatinsf Voltagex Cycle

Nm3/h

40.9

49.1

57.2

68.1

76.3

87.2

98.1

Nm3/h

44.9

53.9

62.9

74.8

83.3

95.9

107. 8

0/h

48.6

58.3

68.0

81.0

90.7

103.7

116. 6

0/h

53.9

64.7

75.5

89.8

100.0

115 . 1

129.4

VX Hz

200x 50/60. 220x60

kw

0 .1 5

0.15

Pump' = Solution

kw

2.2+O.4

2.2+O.4

2.2+O.4

:>

kw

1.5

1.5

1.5

2.2

2.2

10.0(5.5)

10.5(8)

13.0(8)

13.5(8)

Refrigelant Pump q:t ct ct-

CJ CJ o:, t+l

Burner Fan Gas

Powel Supply CapaciU kVA(mm') 10.0(5.5) $izel Ittliring

Burner Fan* |lil Pumn Kerosene

kw

1+0.25

Pouler Supply Capacity kVA(mm') 10.0(5.5) $izel lWirins

Connection Sizeof Exhaust Gas l|eatTransfer fueaof Gh

mm m2

1+0.25

0.3

0.3

1.5+0.25 1.5+0.25 2.2+O.4 13.0(8)

12.0(8)

350x310 450X 310

450x370

480X 370

13.8

16.1

11.7

0.3

o.4

3 . 2 + O . 4 3.2+O.75 3.2+O.75 3.2+O.75

10.0(5.5)

9.7

0.3

14.0(141

3.7 15.0(14)

15.0(14)

2.2+O.4

2.2+O.4

14.O(14)

14.o(14)

450x430 480X430 19.6

3.7

21.4

515x460 23.6

1t040

It045

1t050

lt000

]t070

Dimensions Model

4OO{14O7} 450{1583} 500{175e} 600{2,110}7 00{2,462} '1,067,000{1241} 1,201,000{1397} 1,334,000{1551} 1,604,000{1,965} 1,871,000{2,'176}

Weight

Water Volume in Chiller-Heater

Shipping Weight Operating Chilled/Hot Cooling Weight Water Water (MAX)

L

W

H

mm

mm

mm

t

t

0

0

N015 3575

1825

1900

5.4

7.4

210

290

RcDP

4030

4540

5040

6,050

7,060

6.6{65}

6.1{60}

6.1{60}

7.6{74}

7.8{76}

N018 3575 1870 1940

5.9

8.0

250

340

3

3

3

3

3

N021 3605 2020 2050

6.7

9.2

300

410

150

200

200

200

200

2150 2160 7.8

10.4

350

480

6670

7500

8340

10,000

1 1 ,670

N025 3605

N028 4675 2105 2100

8.9

12.2 380

560

N032 4675 2280 2170

9.9

13.5

440

630

10{e8}

e.5{e3}

10{e8}

2+1

2+1

2+1

2+1

2+1

N036 4700 2340 2250 10.1 15.0 490

700

200

250

250

250

250

N040 4725 2350 2340 1 1 . 8 16.5

540

780

N045

4810 2415 2480

13.1

18.4

610

920

e.8{e6} 10.5{103}

e00{8.82} eoo{8.82} eoo{8.82} eoo{8.82} eoo{8.82} 80

80

80

80

80

N050

4810 2465 2550 14.O

19.7

680

1010

266.4

299.7

333.1

399.7

466.3

N060

5860 2875 2750 15.7

23.O 820

1210

292.9

329.7

366.2

440.3

513.6

N070

5860 2975 2945

26.2

1410

200{1.e6} 200{1.e6} 2oo{1.e6}e00{8.82} eoo{8.82} 80

80

80

65

80

109

122.6

1 3 6 .3

163.5

190.8

119.8

134.9

149.8

180.1

210.1

129.6

145.8

162.0

194.4

226.8

143.8

161. 9

179.8

216.3

252.2

200x 50/60. 220X60

o.4

o.4

o.4

o.4

o.4

3.7+O.75 3.7+O.75' 3.7+O.75 5.5+0.75 5.5+0.75 3.7

3.7

5.5

5 .5

7 .5

16 .0 (1 4 )

16.0(14)

18.O(22)

20(22)

22.5(22\

3.7+O.4

3.7+O.4

16 .5 (1 4 )

16.5(14)

568x460

550X 515

5 5 0 X5 6 8

545X7'13

6 9 2 X 667

27.1

29.5

32.5

38.3

44.6

3.7+O.75 5.5+0.75 5.5+0.75 17.0(141 21.5(22)

21.5(22)

17.9

960

Note 1) The standard chilled water temperatureis 12"c at the inlet and 7"C at the outlet, the cooling water temperature is 32"C at theinlet and 37.5'c at the outlet and the hot water temperature 60'C at the outlet. Note 2) The fouling factor of the chilled/hot water and the cooling water is assumed as 0.0001meh"C/kcat(0.000086m2K/W). Note 3) The capacity of burner fan may be changed on the combustion volume and the gas specification. Note 4) The standard design pressureof the chilled/hot water and the cooling water is 8 kgf/cmz (gauge pressure) iO.ZA Hl|pa) Note 5) Chiller-Heateris designed in accordancewith JIS 8g622. Note 6) Standarddeliveryis one piece shippingas the standard. Note 7) The net calorific value of kerosene is defined as g32oKcal/0 (Specific gravity 0.8). Note 8) Dimensionin width may vary dependenton the gas specification. Please check the outline drawing in detail. The values shown herein is based on the supply specificationat 2OOmmAq(060 and 070 are at the supply on gOOmmAq). Note 9) The wiring size is used for reference.

Lol5

Model(RC0P)

1018

t02l

t025

1028

r032

r036

Capacity Cooling

usRt{kw}150{528}

Heating Capacity

854,000{993}960,000{111 742,000{863} 660,ooo{774} 400,000{465}480,000{558}560,o0o{651} kcaUh{kW}

o:, GE

=

180{633}

210{73e} 250{87e} 280{e85} 320{1125} 360{1266}

1810

2120

2520

2820

3230

3630

8.2{80}

7.4{73}

7.7{75}

6.3{62}

6.3{62i

6.4{63}

4

4

4

4

3

3

3

1510

FlowBate

Q,/min

Prcssure Drup

mRq{tPa} 7.8{76}

'El

=

llo.of

CJ

Size PipeConnection

A(mm)

100

100

125

125

150

150

150

Flowflate

A /min

2500

3000

3500

4170

4670

5330

6000

12{118}

12.5{123}

e.5{e3}

10{e8}

10{eB}

o:, CE Dlop = Plessure := lrlo.of ct e

mAq{kPa} 1 1 . 5 { 1 1 3 } 12.5{123}

Et

3+1

3+1

3+1

3+1

2+1

2+1

2+1

125

125

150

150

200

200

200

CJ

Size PipeConnection

A(mm)

Ptessure mmAq{kPa}1 5 0 { 1 .4 7} 150{ 1.47} 150{ 1.47} 150{1.47} e00{8.82} e00{8.82} eoo{8.82} Supply GasUalue (grossl PipeConnection A(mm) 80 BO 125 80 100 100 BO 4500 Consumption lCoolinql kcal/llm3 Consumption Il|eatingl

Nm3/h

99.9

119.9

139.9

166.5

186.5

213.2

239.8

Nm"/h

1 0 9 .8

131.8

153.7

182.8

203.7

233.4

263.5

200{1.e6} 200{1.e6} 2oo{1.e6}200{1.e6} 200{1.e6} 200{1.e6} 200{1.e6} Pressure mmAqikPa) Supply

o:t

Ualue Gas (grossl PipeConnection A(mm) (r3Al Consumption 11000 ICoolinsl kcal/ilm3 Consumption

(]|eatingl

50

50

50

BO

80

80

80

Nm3/h

40.9

49.1

57.2

68.1

76.3

87.2

98.1

Nm'/h

44.9

53.9

62.9

74.8

83.3

95.9

107. 8

48.6

58.3

68.0

81.0

90.7

103.7

116.6

53.9

64.7

75.5

89.8

100.0

115. 1

129.4

Gonsumption 0 / h KeroseneIGoolinsf Consumption 0 / h [fleatinsl x Cycle Uoltage Pump Refrigemnt Pump = Solution o:l

200x 50/60. 220x60

VXHz

KW

0 .1 5

0.15

kw

2.2+O.4

2.2+O.4

2.2+O.4

kw

1.5

1.5

1.5

2.2

10(5.5)

10.5(8)

13(8)

0.3

0.3

0.3

0.3

o.4

3 . 2 + O . 4 3.2+O.75 3 . 2 + O . 7 5 3.2+O.75

ct CL

Fan Bumer

=>

C5 C5

!? l!

Gas

Capacity Power Su0ply kVA(mm') 10(5.5) Sizel {Wiring Fan* llil Burner 1+0.25 KW

Pump |(erosene