Https Sisweb.cat.com Sisweb Sisweb Techdoc Techdoc Print Page1 2g203x

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 2z6p3t

Overview 5o1f4z

& View Https Sisweb.cat.com Sisweb Sisweb Techdoc Techdoc Print Page1 as PDF for free.

More details 6z3438

- Words: 658

- Pages: 2

G3516E Generator Set GAS00001-UP(SEBP3934 - 37) - Systems & Components

Page 1 of 2

Previous Screen

Welcome: m410pjc Product: GENERATOR SET Model: G3516E GENERATOR SET GAS Configuration: G3516E Generator Set GAS00001-UP

Systems Operation G3516C and G3516E Engines Media Number -KENR6834-06

Publication Date -01/08/2013

Date Updated -05/08/2013

i02601326

Compressor By SMCS - 1050

A rapid reduction in the generator's power output can cause a rapid increase in the engine speed. The increased engine speed causes the turbocharger to produce boost pressures that are greater than the requirement for the engine operation. Turbocharger surge - In response to the excess pressure in the air inlet system, the flow of air across the turbocharger compressor wheel is reversed. This reversal of the air flow is called a turbocharger surge. During a turbocharger surge, the turbocharger overspeeds temporarily. This places a greater axial load on the thrust bearing and higher than normal torque on the shaft. The turbocharger surge can result in severe damage to the turbocharger. The compressor by group reduces the opportunity for a turbocharger surge.

https://sisweb.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 04-08-2016

G3516E Generator Set GAS00001-UP(SEBP3934 - 37) - Systems & Components

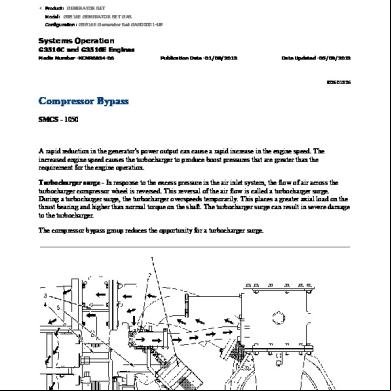

Illustration 1

Page 2 of 2

g00926843

Flow of the compressed air/fuel mixture during activation of the compressor by group (50 Hz arrangement) (1) Actuator for the by valve (2) By valve (3) Throttle (4) Throttle actuator (5) Fuel metering valve

The master Electronic Control Module (ECM) monitors the engine speed. The ECM responds to a rapid increase in the engine speed by sending a command signal to actuator (1). This causes the actuator to move a shaft that is connected to a plate inside by valve (2). The by valve opens. The by valve is connected before throttle (3). Tubing is connected from the by valve to the inlet for the turbocharger compressor. When the by valve is opened, the compressed air/fuel mixture is diverted through the tubing away from the throttle. This reduces the back pressure that is caused by excessive pressure in the air inlet system. Note: The by valve for the 60 Hz arrangement is connected to two sets of tubing: one set of tubing is connected to the inlet for the right turbocharger and the other set of tubing is connected to the inlet for the left turbocharger. Additionally, the ECM sends two other command signals. A command to throttle actuator (4) opens the throttle in order to reduce the resistance that contributes to back pressure. A command to fuel metering valve (5) reduces the fuel supply in order to reduce the engine speed and the turbocharger's speed. The combined effect of these actions reduces the opportunity for a turbocharger surge. The ECM determines a time period that is required for opening of the by valve. After the time period has expired, the ECM sends a command signal to actuator (1) in order to close the by valve. Normal operation resumes. The compressor by group is also operated during engine shutdown. This reduces the opportunity for a turbocharger surge during engine shutdown. Additionally, any air/fuel mixture that may have been trapped in the tubing is purged. Active By The compressor by valve is commanded to a wide range of positions if the engine is equipped with an Auxiliary Sensing Module (ASM). This is called active by. The ASM uses inputs from the manifold air pressure sensor and the boost pressure sensor in order to determine the pressure drop across the throttle plate. The ASM determines the amount of active by that is required in order to maintain the desired pressure drop across the throttle plate. The ASM transfers the information to the master ECM via the Cat Data Link. The master ECM sends a command to the actuator for the by valve in order for the by valve to move to the desired position. Copyright 1993 - 2016 Caterpillar Inc. All Rights Reserved.

Thu Aug 4 00:45:06 UTC+0100 2016 m410pjc

Private Network For SIS Licensees.

https://sisweb.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 04-08-2016

Page 1 of 2

Previous Screen

Welcome: m410pjc Product: GENERATOR SET Model: G3516E GENERATOR SET GAS Configuration: G3516E Generator Set GAS00001-UP

Systems Operation G3516C and G3516E Engines Media Number -KENR6834-06

Publication Date -01/08/2013

Date Updated -05/08/2013

i02601326

Compressor By SMCS - 1050

A rapid reduction in the generator's power output can cause a rapid increase in the engine speed. The increased engine speed causes the turbocharger to produce boost pressures that are greater than the requirement for the engine operation. Turbocharger surge - In response to the excess pressure in the air inlet system, the flow of air across the turbocharger compressor wheel is reversed. This reversal of the air flow is called a turbocharger surge. During a turbocharger surge, the turbocharger overspeeds temporarily. This places a greater axial load on the thrust bearing and higher than normal torque on the shaft. The turbocharger surge can result in severe damage to the turbocharger. The compressor by group reduces the opportunity for a turbocharger surge.

https://sisweb.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 04-08-2016

G3516E Generator Set GAS00001-UP(SEBP3934 - 37) - Systems & Components

Illustration 1

Page 2 of 2

g00926843

Flow of the compressed air/fuel mixture during activation of the compressor by group (50 Hz arrangement) (1) Actuator for the by valve (2) By valve (3) Throttle (4) Throttle actuator (5) Fuel metering valve

The master Electronic Control Module (ECM) monitors the engine speed. The ECM responds to a rapid increase in the engine speed by sending a command signal to actuator (1). This causes the actuator to move a shaft that is connected to a plate inside by valve (2). The by valve opens. The by valve is connected before throttle (3). Tubing is connected from the by valve to the inlet for the turbocharger compressor. When the by valve is opened, the compressed air/fuel mixture is diverted through the tubing away from the throttle. This reduces the back pressure that is caused by excessive pressure in the air inlet system. Note: The by valve for the 60 Hz arrangement is connected to two sets of tubing: one set of tubing is connected to the inlet for the right turbocharger and the other set of tubing is connected to the inlet for the left turbocharger. Additionally, the ECM sends two other command signals. A command to throttle actuator (4) opens the throttle in order to reduce the resistance that contributes to back pressure. A command to fuel metering valve (5) reduces the fuel supply in order to reduce the engine speed and the turbocharger's speed. The combined effect of these actions reduces the opportunity for a turbocharger surge. The ECM determines a time period that is required for opening of the by valve. After the time period has expired, the ECM sends a command signal to actuator (1) in order to close the by valve. Normal operation resumes. The compressor by group is also operated during engine shutdown. This reduces the opportunity for a turbocharger surge during engine shutdown. Additionally, any air/fuel mixture that may have been trapped in the tubing is purged. Active By The compressor by valve is commanded to a wide range of positions if the engine is equipped with an Auxiliary Sensing Module (ASM). This is called active by. The ASM uses inputs from the manifold air pressure sensor and the boost pressure sensor in order to determine the pressure drop across the throttle plate. The ASM determines the amount of active by that is required in order to maintain the desired pressure drop across the throttle plate. The ASM transfers the information to the master ECM via the Cat Data Link. The master ECM sends a command to the actuator for the by valve in order for the by valve to move to the desired position. Copyright 1993 - 2016 Caterpillar Inc. All Rights Reserved.

Thu Aug 4 00:45:06 UTC+0100 2016 m410pjc

Private Network For SIS Licensees.

https://sisweb.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 04-08-2016