Hse-sop-14 Transportation Logistics Safety Management 3j2k1v

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 2z6p3t

Overview 5o1f4z

& View Hse-sop-14 Transportation Logistics Safety Management as PDF for free.

More details 6z3438

- Words: 7,850

- Pages: 29

Transportation and Logistics Safety Management

Doc. No.: HSE/SOP-14 Rev: 00 Date of Rev.: Mar 15, 2017 Page 2 of 29

Document Revision/Review History

REVISION No.

Date

REVIEW Description

No.

Reviewed by

Date

A

B 00

15-03-2017

Development of procedure as per the requirement of HSE MS revamping task C

D

E

A

B 01 C

D

This document is the Intellectual Property of Descon. Any unauthorized use, including the modification and reproduction of the content is strictly prohibited. © Copyrights Ordinance 2002, All rights reserved.

Transportation and Logistics Safety Management

Doc. No.: HSE/SOP-14 Rev: 00 Date of Rev.: Mar 15, 2017 Page 3 of 29

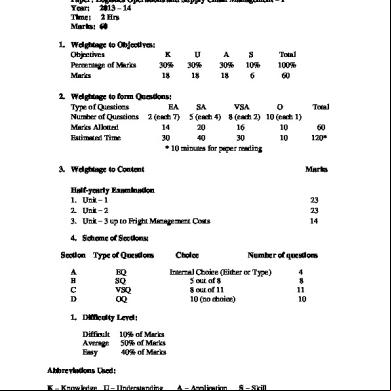

TABLE OF CONTENTS 1.

OBJECTIVE: .................................................................................................................. 4

2.

SCOPE: ......................................................................................................................... 4

3.

ROLES & RESPONSIBILITIES:..................................................................................... 4

4.

ABBREVIATIONS/ DEFINITIONS: ................................................................................ 5

5.

PROCEDURE: ............................................................................................................... 7

5.1 TRANSPORTATION SAFETY MANAGEMENT ............................................................ 7 5.2 TYPES OF VEHICLES .................................................................................................. 7 5.3 SELECTION OF VEHICLES .......................................................................................... 8 5.4 DRIVER’S SELECTION ................................................................................................. 8 5.5 HSE PLANNING AND MONITORING OF TRANSPORTATION OPERATION ............. 9 5.6 LOGISTIC SAFETY MANAGEMENT ........................................................................... 13 6.

REFERENCE AND RELATED DOCUMENTS: ............................................................ 17

This document is the Intellectual Property of Descon. Any unauthorized use, including the modification and reproduction of the content is strictly prohibited. © Copyrights Ordinance 2002, All rights reserved.

Transportation and Logistics Safety Management

Doc. No.: HSE/SOP-14 Rev: 00 Date of Rev.: Mar 15, 2017 Page 4 of 29

1. OBJECTIVE: This Procedure outlines the mechanism for planning, executing and monitoring of transportation/ logistic operation activities within the Organization to ensure the safety of Company’s personnel & asset.

2. SCOPE: This procedure shall be applicable and adhered at DESCON Headquarter, Business Divisions / Units and on all its Project sites and retrofits jobs.

3. ROLES & RESPONSIBILITIES: Chief Executive Officer

Shall be owner of this document and overview the compliance of guidelines and fulfillment of expectations outlined in this procedure.

Divisional Presidents / Head Business Units / Project Manager

Shall be responsible for the implementation of all the details given in this procedure wherever they are applicable in their respective areas of influence. Shall ensure availability of all resources required for the compliance of the details given in this document. Business Unit Head shall be responsible for providing authorization for the exemption against the fulfillment of any of the requirement of this document for a specific period of time under particular conditions giving details of controls put in place for that period in consultation with HSE Manager on Exemption format.

Division Head HSE/ In-charge HSE business unit / Site HSE Manager or In-charge

Shall be responsible for adequate communication, trainings and compliance audits along with advising to fill the gaps identified in implementation of the requirements as details given in this procedure. Shall be responsible for review of this procedure as per set frequency or on need basis.

Chief Compliance Officer

Shall coordinate for the revision of this document as per set frequency or as and when needed. Shall be responsible for conducting the compliance audits of this procedure.

This document is the Intellectual Property of Descon. Any unauthorized use, including the modification and reproduction of the content is strictly prohibited. © Copyrights Ordinance 2002, All rights reserved.

Transportation and Logistics Safety Management

Doc. No.: HSE/SOP-14 Rev: 00 Date of Rev.: Mar 15, 2017 Page 5 of 29

istration Manager

Manager shall be responsible for hiring and deploying competent drivers and safe vehicles along with their maintenance for transportation operations.

Procurement/ Logistics Manager

Procurement Manager shall be responsible for pre-qualification and contracting of approved Vendors and supplier Logistic Manager shall be responsible for planning, hiring and approved supplier/vendors along with smooth functioning of vehicles.

4. ABBREVIATIONS/ DEFINITIONS: BU

Business Unit

CEO

Chief Execution Officer

DEL

DESCON Engineering Limited

HSE

Health, Safety and Environment

HSEMS

Health, Safety and Environment Management System

I/C

In charge

PJI

Pre-Journey Inspection

PM/SM

Project Manager / Site Manager

POD

Proof of delivery

Projects

Construction and shutdowns / retrofit projects

SOP

Standard Operating procedure

TBTs

Tool Box talk

Business Travel

Company’s work related travelling irrespective of origin and destination other than usual travel from home to job-place by employee at his own.

Competent

Trained, experienced and able to perform the allocated task to the required standards in accordance with the applicable procedures, standards and legislation, without direct supervision

This document is the Intellectual Property of Descon. Any unauthorized use, including the modification and reproduction of the content is strictly prohibited. © Copyrights Ordinance 2002, All rights reserved.

Transportation and Logistics Safety Management

Company Vehicle

Contracted Vehicle

Doc. No.: HSE/SOP-14 Rev: 00 Date of Rev.: Mar 15, 2017 Page 6 of 29

Any vehicle (any car, van, bus, coach, truck, trailer, pickup truck, emergency vehicle (e.g. fire tender, ambulance)) that is directly owned, leased or rented by the company and being operated in connection with company business, including personal vehicles whilst used for company business. Any vehicle that is leased, directly owned, or rented by a contractor or sub-contractor, that provides services for the Company operations under formal (contractual) agreement.

Fatigue

Extreme physical or mental tiredness or exertion.

Herb Weight (Tare Weight)

The unladen weight of a vehicle as determined at registration.

Inspection

Inspection shall mean any physical activity, related to ensuring that a vehicle in its entire or an item of vehicle at a given location or environment, meets the specified design and operating standards as intended and is safe to operate or utilize for a specified period.

Journey Management Plan

A Journey Management Plan is typically a set process to follow for authorization, planning and undertaking road transport journeys in compliance with transportation safety requirements, with objective of safe transportation operation.

Lashing

Fastening devices made of chain or nylon webbing used to restrain loads

Lashing Point

A fitting or attachment on a vehicle or a load, specifically installed as a point to secure a lashing.

Light Vehicle

A Light Vehicle is any vehicle having a kerb weight of less than or equal to 4000 kg and having eight enger seats or less.

Logistics Operation

Operation involving transportation and delivery of good and materials

Non-routine Driving Task

A trip that has an elevated risk: e.g. night driving, or off-road driving

Routine Driving Task

A trip that has been assessed as low risk with only standard ALARP measures

This document is the Intellectual Property of Descon. Any unauthorized use, including the modification and reproduction of the content is strictly prohibited. © Copyrights Ordinance 2002, All rights reserved.

Transportation and Logistics Safety Management

Doc. No.: HSE/SOP-14 Rev: 00 Date of Rev.: Mar 15, 2017 Page 7 of 29

Repair

A measure whereby the original state of an appliance will be restored by rebuilding or exchanging parts or units. If essential parts with safety functions are to be rebuilt or exchanged, this is considered to be a ‘Major Repair’.

Substance Abuse

Substance abuse Includes alcohol, illegal drugs, prescribed or overthe-counter medicines not used in accordance with a doctor’s or the manufacturer’s guidance or any other substance introduced into the body in any way, which has a narcotic, depressant, stimulant, or character or mood altering effect, and which may impair judgment or work performance

Transportation operation

Operation intended to transport (travel) people from one place to another by using vehicles

5. PROCEDURE: This procedure details the planning, monitoring and management of transportation/ logistics safe operations as follows. a) b)

Transportation safety management Logistics safety management

5.1 Transportation Safety Management Transportation is one of the most critical part of our operations. Transportation safety management shall be done to prevent and control all the transportation related hazards and risks at respective Office, Project site, external roads (high ways). Competent drivers and Safe (fit) Vehicle, both are required to ensure safe transportation. istration department of the respective Office, Project site, shall implement transportation safety management system, through effective planning and arrangements in pursuance of zero transportation incident. In case of projects sites, In-charge istration along with PM/ SM of respective Project shall be completely responsible for transportation safety management. Transportation safety management system shall be conducted as follows. a. Effective site lay-outing planning for traffic routes within office premises, Sites, external roads. b. Safe vehicle. c. Competent driver.

5.2 Types of Vehicles There are two main categories of vehicles used for company transportation operations as mentioned below. This document is the Intellectual Property of Descon. Any unauthorized use, including the modification and reproduction of the content is strictly prohibited. © Copyrights Ordinance 2002, All rights reserved.

Transportation and Logistics Safety Management

Doc. No.: HSE/SOP-14 Rev: 00 Date of Rev.: Mar 15, 2017 Page 8 of 29

5.2.1 Company owned vehicles Any vehicle (car, van, bus, coach, truck, trailer, pickup truck, emergency vehicle (e.g. fire tender, ambulance)) that is directly owned, leased or rented by the company and being operated in connection with company business, including personal vehicles whilst used for company business. All vehicles owned by company shall be certified fit for use as per company criteria before asg for any transportation activity. 5.2.2 Contracted Vehicles Any vehicle that is leased, directly owned, or rented by a contractor, that provides services for the Company operations under formal (contractual) agreement.

5.3 Selection of Vehicles 5.3.2 Company Vehicles All vehicles owned by company shall be certified fit for use as per company criteria before asg for any transportation activity see Annexure. A-Vehicles Standard fitness Safety Criteria (DESCON & Contractors) 5.3.3 Contractor vehicles All transporters/ suppliers vehicles shall be prequalified before contracting and asg for any job as per company HSE contractor prequalification criteria. I/C shall make sure that contracted vehicles are maintained after regular intervals as needed. AnnexureA, Vehicles Standard fitness Safety Criteria (DESCON & Contractors). 5.3.3.1 Pre-qualification of Transporter/Supplier All transporters/ suppliers shall be prequalified before contracting and asg any job as per the Company SOP- 41 Contracts and Contractor HSE Management.

5.4 Driver’s Selection Drivers deployed for assigned jobs shall meet the following criteria a. b. c. d.

All drivers shall have valid driving license with experience of at least 5 years Drivers shall have specific driving qualifications certificate from the approved training providers. Maximum age limit for drivers is 63 years Must be medically examined prior to hiring/selection & annually and shall possess current medical fitness certificates.

This document is the Intellectual Property of Descon. Any unauthorized use, including the modification and reproduction of the content is strictly prohibited. © Copyrights Ordinance 2002, All rights reserved.

Transportation and Logistics Safety Management

Doc. No.: HSE/SOP-14 Rev: 00 Date of Rev.: Mar 15, 2017 Page 9 of 29

5.5 HSE Planning and Monitoring of Transportation Operation HSE planning for transportation operation shall be done by establishing transportation safety plan specific to the nature of Project Site, Office and Facility, plan includes, route surveys, traffic safety rules, transportation safety signage, transportation risk management, vehicles fitness, driver competency and behavior assessment. 5.5.1 Journey management Plan & Transportation Risk Assessment Journey Management Plan A process that incorporates the conducting of a risk assessment to identify major hazards and ensure that the journey and the risk are assessed, verified and an action plan is implemented and monitored to address these hazards Regardless of a trip purpose and in the interest of improving business performance, the reduction of the risk by removing the requirement of the journey is the most effective risk reduction option so managers/line supervisors are required to evaluate specifically the need of all journeys required to be executed in their respective areas to allow unavoidable only for Company’s operations. All risks associated with general & specific (main highway near project) transportation activities shall be assessed and documented following HSE SOP-08, “Hazard Identification, Risk Assessment & Control”, HSE-FRM-01, JSA Form. The risk assessment shall also consider drifting snow, dust, smoke, fog, heavy rains, security risks and regional and local driving practices. The risk assessment conducted shall be revised subjected to the following conditions. 1. 2. 3.

after a major traffic incident When significant route / vehicle/ destination changes are introduced Periodically – Every Year

Journey management plan shall be established for routine and non- routine driving task that inherits high risk level like, night driving, off road driving etc. Night Driving Authorization For night driving special permission from Site Management shall be taken on form as attached. 5.5.2 Vehicle Selection & Fitness All vehicles owned by company or Contracted shall meet Company criteria as mentioned in Appendix-A Vehicles Standard fitness Safety Criteria (DESCON & Contractors).Prequalified vehicles shall have maximum of five years old registration. Vehicles used for company operations shall not model be five years

This document is the Intellectual Property of Descon. Any unauthorized use, including the modification and reproduction of the content is strictly prohibited. © Copyrights Ordinance 2002, All rights reserved.

Transportation and Logistics Safety Management

Doc. No.: HSE/SOP-14 Rev: 00 Date of Rev.: Mar 15, 2017 Page 10 of 29

5.5.3 Vehicle Maintenance Vehicles deployed on transportation activity shall be maintained well in order to ensure safe operation. All scheduled and non-scheduled maintenance shall be done as per manufacturer instructions 5.5.4 Driver Competency & Training In charge istration shall ensure that the allocated/assigned drivers are competent and trained and meet the following. Driver’s Selection Criteria a. All drivers shall have valid driving license with experience of at least 5 years b. Drivers shall have specific driving qualifications certificate from the approved training providers. c. Maximum age limit for drivers is 55 years d. Must be medically examined and shall possess current medical fitness certificates. Driver’s Induction and Training a. HSE Induction shall be provided to all drivers before asg to jobs. b. Driver shall be trained on the principles of the defensive driving techniques c. Periodic safety briefings, meetings and refresher trainings shall be conducted for drivers when and as required. As a minimum the following topics shall be covered in the defensive driving training conducted for drivers. a. b. c. d. e. f. g. h. i. j.

Company HSE policy Defensive driving techniques Journey management techniques Alertness and fatigue management Effects of medication and substance abuse Vehicle restraint systems and safety equipment Pre-trip checks and proper seating position Local driving hazards, regulations and culture Skill assessment and/or commentary drive Emergency response planning and prepared

5.5.5 Driver’s Responsibilities It is the responsibility of every driver to follow applicable laws and regulations regarding traffic and shall ensure strict compliance to the following driving safety rules. a) b) c)

Always obey the Speed Limits & Safety rules as mentioned on the safety signs. Wear a seat belt at all times. Always use the directional signals.

This document is the Intellectual Property of Descon. Any unauthorized use, including the modification and reproduction of the content is strictly prohibited. © Copyrights Ordinance 2002, All rights reserved.

Transportation and Logistics Safety Management

Doc. No.: HSE/SOP-14 Rev: 00 Date of Rev.: Mar 15, 2017 Page 11 of 29

d) e) f) g) h) i) j) k) l)

Ensure all other occupants of the vehicle are wearing seatbelts Wear sturdy footwear when driving (not slippers, flip-flops or loose sandals). Wear the correct PPE if working with hazardous materials. Ensure luggage is securely fastened and stowed correctly. Conduct the pre-check before riding the vehicle. Ensure that emergency equipment/contents are available in vehicle. Ensure all doors are closed correctly before moving off. Ensure all engers are wearing seatbelts before moving off. Use only assigned driver blue key, never lend your blue key to any one or leave inside the vehicle. m) Never drive if too tired to concentrate. n) Never drive if under the influence of alcohol, drugs or medication. o) Only use a vehicle that has been approved for the journey. p) Use Journey Management System. q) Vehicles must not be left unattended with the engine running. r) Report all vehicle related accidents / near misses. s) Ensure that they are licensed for the vehicle that they are operating. t) Drive safely and show consideration to other road s. u) Switch off vehicle engine and mobile phone when re-fuelling. v) Do not use mobile phone while operating a motor vehicle. Free headset can be used to receive emergency calls only, to place or receive a call: park your vehicle safely and use your mobile phone and radio communication. 5.5.6 Driving Behavior Monitoring & Management The Driving behavior is monitored using an HSE observation cards system by istration 1. 2. 3. 4.

No. of seat belt and their conditions Harsh Breaking Harsh acceleration Over steering

Company employees raise the violation notices to I/C . I/C also keep a track of violation notices maintaining a log sheet and records the history of Verbal Warning, Written Warning, and Terminations etc. The violation counter against each driver will be turned to zero in every six months. Company Drivers shall be certified medically and screened against substance abuse. In Vehicle Monitoring shall be installed (where applicable) to assist in the improvement of driver performance. The data captured allows clear visibility of driver behavior and compliance to Company safe driving standard.

This document is the Intellectual Property of Descon. Any unauthorized use, including the modification and reproduction of the content is strictly prohibited. © Copyrights Ordinance 2002, All rights reserved.

Transportation and Logistics Safety Management

Doc. No.: HSE/SOP-14 Rev: 00 Date of Rev.: Mar 15, 2017 Page 12 of 29

This driver’s performance shall be identified and analyzed by the appointed IVMS s through regular data analysis (where available). 5.5.7 Driver Incentive Programs In order to motivate the Drivers towards safe driving, best drivers are recognized every month for their safe driving efforts based on the number transportation trips and . 5.5.8 General HSE Guidelines for Transportation activities As per general driving guide lines, in all kind of road surfaces the drivers shall ensure that: a. All vehicles used shall be fitted with seat belts, istration encourage and ensure the installation and use of seat belts in all personnel vehicles. All belts shall be functioning, inspected regularly and worn correctly by drivers and engers. b. Night driving shall generally be prohibited and avoided as far as possible and if required then it must be authorized by I/C and Project Manager c. Follow defensive driving requirements d. Avoid sudden brakes. e. Speed limits and road safety signs should be strictly followed f. Do not drive during foggy weather, rainy conditions, sand storms and any conditions where low visibility prevails g. Does not use of mobile phones while driving, ensure seat belt compliance and do not smoke while driving h. Follow traffic law; any violations will be directly ed to the respective drivers and fines shall be recovered from individual s as in reference to disciplinary actions. i. Motorcycles (two, three wheel) shall not be used for business activities. 5.5.9 Rules for Parking 1. Park vehicles in marked spaces only. 2. Do not park in spaces that are reserved for special people vehicles or emergency response. 3. Do not block other vehicle. 4. When parking follow the seven rules of safe parking a) b) c) d) e) f) g)

Always park so, the first move in the vehicle is forward – you may have to reverse park at the end of your trip, if so, make sure that the rear is clear. Sound the horn before you start to reverse. Back immediately never trust the scene you checked to stay the same. Back slowly. As you back, check both side-mirrors. Don't back further than necessary. Use a ground guide.

This document is the Intellectual Property of Descon. Any unauthorized use, including the modification and reproduction of the content is strictly prohibited. © Copyrights Ordinance 2002, All rights reserved.

Transportation and Logistics Safety Management

5.5.10

Doc. No.: HSE/SOP-14 Rev: 00 Date of Rev.: Mar 15, 2017 Page 13 of 29

Emergency Preparedness a. Fire extinguishers shall be made available in the transportation vehicle b. First aid box shall be made available on the large commuting Vehicles. c. Three sets of reflective triangles are provided to each large vehicle shall be used in case of an emergency break down d. Shall have effective means of communication between drivers and back office of respective in case of any emergency and unwanted happening.

5.6 Logistic Safety Management Logistics safety management shall be planned and carried out by ensuring that the following requirements are fulfilled and implemented as mentioned below a) Prequalification of transporters/ suppliers. b) HSE Planning for Logistics operations c) Logistics Journey Management.

5.6.1 Prequalification of transporters/ suppliers All transporters/ suppliers shall be prequalified before contracting and asg any job as per company HSE prequalification criteria.

5.6.2 HSE Planning for logistic Operation Initial Planning & Pre-Journey Preparation Logistic safety planning and pre journey preparation shall be done by considering various job factors proactively so that all hazards, risk factors shall be evaluated prior commencement of the trip as follows. a.

Risk assessment All risks associated with general & specific logistics/transportation activities shall be assessed and documented following HSE SOP-08, “Hazard Identification, Risk Assessment & Control”, HSE-FRM-01, JSA Form. The risk assessment shall also consider drifting snow, dust, smoke, fog, heavy rains, security risks and regional and local driving practices. The risk assessment conducted shall be revised subjected to the following conditions. 1. 2. 3.

b.

After a major traffic incident When significant route / vehicle/ destination changes are introduced Periodically – Every Year

Route surveys Before starting logistic activity and asg trucks to any routes for cargo, a suitable and sufficient road survey shall be done in order to assess and document the following:

This document is the Intellectual Property of Descon. Any unauthorized use, including the modification and reproduction of the content is strictly prohibited. © Copyrights Ordinance 2002, All rights reserved.

Transportation and Logistics Safety Management

c.

Route Summary a) b) c) d) e) f) g) h) i) j) k) l)

d.

Doc. No.: HSE/SOP-14 Rev: 00 Date of Rev.: Mar 15, 2017 Page 14 of 29

Type of road Physical condition of the road Number of bridges Height of bridges Capacity of the bridges in the route Difficult road diversions and turns details Round-about details Road permit requirements Critical Over Head Power lines in case of loss material & oversized cargo. Nearest police station details Nearest hospital details Total distance

Route map 1. Assess the distance and directions of the route 2. Land marks and nature, terrain and type of roads 3. Load restrain inspection points & Lay bays

Driver Selection a. Assign the drivers While asg the drivers care shall be taken to ensure whether they are experienced for the job. Driver shall be familiar with the assigned route – Ensure that he is supplied with the road survey (route summary) details for reference in time of need. b. Drivers HSE Induction HSE induction of the driver should be done before asg any driving job, this induction includes, introduction of transportation risk assessment, first aid, defensive driving techniques, emergency response preparedness etc. c. Logistic Supervisor briefing While dispatching the fleet, the driver shall be given HSE briefing about the assigned journey, after dispatching, the truck and the driver shall reach to the respective loading site and the concerned supervisor. After loading, a Delivery Note shall be issued to the driver capturing the following details (as applicable). 2. 3. 4. 5.

Unique reference number Date Delivery to Delivery by

This document is the Intellectual Property of Descon. Any unauthorized use, including the modification and reproduction of the content is strictly prohibited. © Copyrights Ordinance 2002, All rights reserved.

Transportation and Logistics Safety Management

6. 7. 8. 9. 10. 11. 12.

Doc. No.: HSE/SOP-14 Rev: 00 Date of Rev.: Mar 15, 2017 Page 15 of 29

Delivered location Delivery Truck No Container number (if applicable) Provision to enter Date & Time of delivery Provision to enter Receivers Name & Company Stamp Confirmation of receipt of goods statement Liability Statement.

d. Assign the Vehicles Vehicles selected and assigned for transportation shall base on the load tonnage. The load shall be of different category varying from 1-5ton, 6-10 tons, 11-20 tons and 20 and appropriate vehicles shall be selected and approved by company for the assigned job. While asg the vehicles care shall be taken by vendor to ensure whether they are approved for the job of the intended client or not. All the trucks that are assigned to the trips shall be inspected & qualified by company or by transporter for the contracted jobs. e. Conduct Pre-Journey Inspection of the vehicle The pre-journey inspection is conducted using a check list. It ensures that the fleet and the driver are in conformance to the project, operations and safety requirements for that particular trip. If any faults identified at this stage need to be rectified prior to dispatching the vehicle for the assigned trip. (For details refer annexure-A pre journey inspection checklist). In this stage the truck and the driver get qualified for the trip.

Trip/ Journey Management a. Loading at Origin Cargo can be loaded from origin or at manufacturer locations. Logistics vendor/ Supplier shall be completely responsible for the safe lifting, loading and securing of the loads. All activities shall be suitably evaluated for risks and risk assessment shall be recorded. The control measures referred in the risk assessment shall be implemented without any failure. All loads transported in a pick-up truck or other cargo vehicle shall be securely fastened, and must not exceed the manufacturer’s specifications and legal limits for the vehicle. b. Transporting the load While transporting the load, Logistics supplier shall ensure to secure the load safely throughout the trip. Logistics suppliers/Vendor driver/ helper is responsible to ensure the loaded items are secured using high quality polyester lashing belts and metal chains. c. Oversized cargos This document is the Intellectual Property of Descon. Any unauthorized use, including the modification and reproduction of the content is strictly prohibited. © Copyrights Ordinance 2002, All rights reserved.

Transportation and Logistics Safety Management

Doc. No.: HSE/SOP-14 Rev: 00 Date of Rev.: Mar 15, 2017 Page 16 of 29

The oversized cargos are only allowed to transport cargo after a formal risk assessment is carried out before the transportation starts with suitable arrangement, communications & approvals. Refer SOP. No.08 (Hazard Identification Risk assessment & Control) & Oversized Cargo Handling Checklist Annex-F. The night journey needs to be notified to the company/client for their approvals along with the regulatory authorities and necessary communication across the network.

d. Containerized Cargo For transporting containers, the container twist locks shall be used to secure the containers on the top of the trailer. The loads shall be re-inspected to confirm its integrity if any of the following condition prevails 1. If the delivery destination is far, for every 100 kilometers truck shall be safely parked and re-inspected to ensure the integrity of the load 2. If the driver happened to apply a harsh break which can alter the stability and alignment of the loads 3. In case of any events that are suspected to alter the stability and alignment of the loads e. Unloading & Delivery Unloading of the items shall be done at the delivery point. Once the drivers reach the delivery location, he shall report I/C store Materials coordinator. He shall then wait for the instructions and unload the items accordingly. Having delivered the material, the driver shall ensure to obtain required signatures of I/C Store or materials coordinator on the delivery note as a proof of delivery (POD). f.

Proof of Delivery Management In charge Store shall sign & return the POD after ensuring all the items/Packing list are safely transported and delivered at project site/ Delivery location. Record of POD is maintained at Site/Delivery point by store in charge & materials coordinator.

5.6.3 HSE Guidelines for Logistics Operations

Seat belts shall be worn by both driver and co enger at all the time during travel All large logistics vehicles (trailers) shall be fitted with reverse alarms For the long distance missions the driver shall check and ensure the working of lights, indicators, break system, tire pressure as minimum For every 100 kilo meters the driver shall check and ensure the integrity of securing lash belts and positioning of the cargo materials

This document is the Intellectual Property of Descon. Any unauthorized use, including the modification and reproduction of the content is strictly prohibited. © Copyrights Ordinance 2002, All rights reserved.

Transportation and Logistics Safety Management

Doc. No.: HSE/SOP-14 Rev: 00 Date of Rev.: Mar 15, 2017 Page 17 of 29

For interim rests and any other requirement, the driver shall stop and park the vehicle on a lawful manner in line with traffic law. Clear the area in order to ensure safe overtaking if required. Proper turning room and good visibility for the drivers shall be ensured All heavy duty trucks shall be parked in a safe place as per instruction of materials coordinator/ incharge ware house Keep and maintain safe distance between the vehicles In case of any oversize cargo transport, convoys will be deployed as per the local rules and regulations to ensure the safety during transport. All types of cylinders shall be transported as per company guidelines SOP-22 storage and handling of compressed gas cylinders.

5.6.4 Emergency Preparedness

First aid box shall be made available on the vehicle Fire extinguishers to be made available in the fleet to use in case of fire Three sets of reflective triangles are provided to each vehicle to be used in case of an emergency break down All logistics vehicle traveling in remote areas shall have suitable means of communication, either radio or mobile phones

6. REFERENCE AND RELATED DOCUMENTS: Vehicles Standard fitness Safety Criteria Driving Conditions Checklist for Inspection Pre-Journey Inspection Checklist (Logistic Vehicles) Oversized Cargo Handling Checklist Oversized Cargo inspection Checklist for drivers Lashing Inspection checklist Journey Management Plan National transportation safety board of America National Highway Traffic Safety istration of America Occupational Safety & Health istration (OSHA) National Highway Authorities, Govt. of Pakistan

Annexure-A Annexure-B Annexure-C Annexure-D Annexure-E Annexure-F Annexure-G Annexure-H

This document is the Intellectual Property of Descon. Any unauthorized use, including the modification and reproduction of the content is strictly prohibited. © Copyrights Ordinance 2002, All rights reserved.

Transportation and Logistics Safety Management

Doc. No.: HSE/SOP-14 Rev: 00 Date of Rev.: Mar 15, 2017 Page 18 of 29

ANNEXURES

This document is the Intellectual Property of Descon. Any unauthorized use, including the modification and reproduction of the content is strictly prohibited. © Copyrights Ordinance 2002, All rights reserved.

Transportation and Logistics Safety Management

Doc. No.: HSE/SOP-14 Rev: 00 Date of Rev.: Mar 15, 2017 Page 19 of 29

A- Vehicles Standard fitness Safety Criteria (DESCON & Contractors) General Vehicle Requirements 1. 2. 3.

All vehicles shall be ed and licensed in accordance with the applicable legal authorities. All vehicles shall be of adequate capacity and of a design suitable for the work for which they are allocated. No structural modification should be made to the vehicle without the manufacturers’ approval and Descon E & P authority

Light Vehicles (Transportation) a. b. c. d. e. f. g. h. i. j. k. l.

m.

All seats shall be fitted with seat belts & head rests All vehicles shall be fitted with a serviceable air conditioning system Air bags shall be fitted for front enger and the driver One 2-Kg Dry Powder Fire extinguisher shall be provided in the vehicle One First Aid kit and a flashlight/ torch An approved In-vehicle Monitoring System (IVMS) shall be fitted to light vehicles (if applicable) Driver and enger side mirrors will be fitted to all vehicles Each vehicle shall have three “disabled vehicle” markers (e.g. reflective triangle) available for deployment All light vehicles shall be fitted with high resolution rear fog lights and front driving lights. All light vehicles shall have spare tire, jack and an appropriate vehicle tool kit. Small half-width emergency wheels fitted by some manufacturers are not satisfactory All tires shall be of the same size, same brand, ply-rating tread pattern, profile and in good condition with a minimum of 2 mm tread depth. Tire must be replaced every 40,000 km or when torn, damaged, cracked or tread depth is less than 2 mm. Tires age must not exceed 2 years from the date of installation on the vehicle. All light vehicles shall have a high-level rear brake light in addition to the conventional fitted brake lights. Non-slip pedal pads to be fitted for the brake clutch and accelerator pedals.

n. Reliable source of communication shall be available to back office in case of emergency o. For desert driving all standard requirements shall be adhered. p. All local and legal requirements prescribed for the vehicle shall be met. q. In

case

of

towing

because

of

any

breakage/failure,

follow

manufacturer

recommendations. This document is the Intellectual Property of Descon. Any unauthorized use, including the modification and reproduction of the content is strictly prohibited. © Copyrights Ordinance 2002, All rights reserved.

Transportation and Logistics Safety Management

Doc. No.: HSE/SOP-14 Rev: 00 Date of Rev.: Mar 15, 2017 Page 20 of 29

Logistic Trailers (Carriers) In addition to the light vehicle standards, the following shall apply: a. Have at least one spare wheel, which will be securely mounted. b. A band of painted alternate yellow and black chevrons or reflective tape on the bumper at least 150mm high, across the entire rear width of the vehicle. c. Lighting which shall include side -lights, fog -lights, reverse- lights, rear -lights, brake lights and indicator/hazard lights. d. The trailer must have coupling chains, if not attached by fifth wheel. e. If the vehicle is a semi-trailer, the trailer shall be fitted with side restraints to contain long loads, e.g. casings and tubular. f. If the vehicle is a rigid type with a box body, then drop sides, and tailgate, hinges and securing pins must be fitted. g. Side and rear under -run protection must be fitted. h. All trailers are to have proper braking systems fitted. i. All airbrakes shall are to be “fail-safe” upon loss of air pressure j. In case of towing because of any breakage/failure, follow manufacturer recommendations.

This document is the Intellectual Property of Descon. Any unauthorized use, including the modification and reproduction of the content is strictly prohibited. © Copyrights Ordinance 2002, All rights reserved.

Transportation and Logistics Safety Management

Doc. No.: HSE/SOP-14 Rev: 00 Date of Rev.: Mar 15, 2017 Page 21 of 29

B- Driving Conditions 1. Driving in Fog Providing precise rules for driving in fog is very difficult. International Standards do not give a safe visibility distance, this is because people’s individual interpretations of visibility in fog vary greatly and conditions can change quickly. In case of driving in fog;

Keep vehicle speed down (drivers must not expect to be able to drive at their normal speed) Dipped headlights must be used (side lights / parking lights are not sufficient) Fog lights must be switched on Use your wipers to remove the fog from the vehicle's windscreen Set heater controls to ‘de-mist’ Keep in the left hand lane while driving in fog Keep a safe distance between your vehicle and the vehicle ahead of you. Some drivers make the mistake of relying on the driver in front and follow their every move. This can lead to a multiple accident, because if the driver in front makes mistake, then the ones following will not have time or space to take avoiding action Don’t use hazard warning lights while driving in fog. These lights should only be used to indicate danger or a defect in the vehicle Apply the vehicle brakes early and gradually to avoid swerving due to excessive braking Use the horn (if necessary) to alert vehicles to your presence Take extra care while driving. Hard surfaced roads may well be slippery. Look for road markings to show the direction If the vehicle must be stopped, then pull off the road and use the hazard warning lights to indicate the vehicle's position. Ensure the tire pressure as per manufacturer recommendations.

2. Driving in Rain The following are guidelines for driving in rain: Reduce speed and only apply brakes gently. The rain will reduce the grip between the vehicle's tires and the road. Stopping distances are increased substantially Use windscreen wipers, when necessary, to keep a clear windscreen Keep and maintain enough distance from the vehicle in front. Switch on vehicle lights if visibility is poor Stay in your lane and avoid overtaking vehicles Even after it has stopped raining the road surface may still be slippery - drive with care Ensure the tire pressure as per manufacturer recommendations.

This document is the Intellectual Property of Descon. Any unauthorized use, including the modification and reproduction of the content is strictly prohibited. © Copyrights Ordinance 2002, All rights reserved.

Transportation and Logistics Safety Management

Doc. No.: HSE/SOP-14 Rev: 00 Date of Rev.: Mar 15, 2017 Page 22 of 29

3. Driving on slippery surface Road surfaces may become slippery if there is a liquid spill, if it has recently rained or is foggy. If this occurs use the following guidelines.

Reduce speed gently Do not reduce or increase speed suddenly (the grip between the vehicle's tires and the road may be severely reduced) that whatever has made the road surface slippery may stay on the tires after you have ed through it. Drive with extra care and test the brakes gently. Ensure the tire pressure as per manufacturer recommendations.

4. Driving in desert Great care should be taken while driving in the desert, as it is a very hazardous environment. The following are guidelines for driving in desert:

Whenever possible avoid mid-day travel, when the sun is directly overhead. The sand is softest at this time of day and rocks and other potential hazards are hard to see because of the lack of shadows The best time to travel is early morning, when some moisture has formed on the sand during the night, making the going firmer Desert travel at night should be avoided unless absolutely necessary, because of poor visibility and the likelihood of getting lost or having an accident Stick to the established route and do not take short cuts. Vehicles that are stuck or lost away from the established routes are harder to find If you come across someone who has got stuck in soft sand, do not attempt to drive up to them. Stop your vehicle on firm ground and approach on foot If traveling in convoy with another vehicle, do not follow too closely. This enables better forward vision and if the front vehicle gets stuck, the following one can avoid also getting stuck If tire pressures have been adjusted for desert driving make sure that they are re-adjusted when returning to a hard surfaced road Don't drive down slip-faces unless absolutely necessary, in which case use caution When traveling on soft sand avoid hard braking or sudden acceleration (especially in low gears), since this will dig the tires in and the vehicle may become stuck. Ensure the tire pressure as per manufacturer recommendations.

5. Driving in a sand storm In the event of being caught in a sand storm: Do not attempt to drive through the storm, poor visibility can easily result in an accident Put the vehicle hazard lights on and pull off the road This document is the Intellectual Property of Descon. Any unauthorized use, including the modification and reproduction of the content is strictly prohibited. © Copyrights Ordinance 2002, All rights reserved.

Transportation and Logistics Safety Management

Doc. No.: HSE/SOP-14 Rev: 00 Date of Rev.: Mar 15, 2017 Page 23 of 29

Park with the rear of the vehicle facing the direction of the storm, this will help to prevent windscreen damage your destination and inform them of your location and estimated delay time (if the estimate turns out to be incorrect your destination and update them) Wait inside the vehicle until the storm clears

6. Driving in a dust cloud Vehicles travelling on gravel or sand roads frequently cause dust clouds. They are usually of very short duration. Dust clouds can be seen long before they are entered, giving plenty of time for preparation.

Switch on dipped headlights Reduce speed, and keep to the right of the track Keep a safe distance back from the cloud If visibility becomes very bad, pull off the road until the dust subsides Do not overtake in dust cloud conditions Watch out for others trying to overtake and be prepared to take avoiding action

7. Driving at night The following are guidelines for driving at night:

Keep speed down to a level that is appropriate to the surface being driven on and how far can be seen ahead Dipped headlights must be used (side lights / parking lights are not sufficient) Only use headlights on full beam when there are no vehicles ahead. to dip headlights when coming across another vehicle. Keep a safe distance between your vehicle and the vehicle ahead of you. Some drivers make the mistake of following and relying on the tail lights of the vehicle in front. This can lead to a multiple accident, because if the driver in front makes a mistake, then the ones following will not have time or space to take avoiding action. Take extra care while driving at night. Look for road markings to show the direction and any markings indicating road under repair.

This document is the Intellectual Property of Descon. Any unauthorized use, including the modification and reproduction of the content is strictly prohibited. © Copyrights Ordinance 2002, All rights reserved.

Transportation and Logistics Safety Management

Doc. No.: HSE/SOP-14 Rev: 00 Date of Rev.: Mar 15, 2017 Page 24 of 29

C- Checklist for Inspection (Transportation Vehicles before USE) Sr.# 1

Parts to Check

Tick

Lights Including high & low beam, Tail, Dash, Indicators, Reversing lights The following vehicles fluid have been checked Radiator coolant

2

3 4 5 6 7 8 9 10 11 12 13

Engine oil

Brake fluids

Battery distilled water

Vehicle all windows & mirrors should be clean Windshield must be free from cracks The vehicles reversing alarm functioning correctly Brakes are working Vehicles Alarm functioning All tires including the spare are in good condition Seat belts are in working conditions & Shade covers are available The exhaust is in good working conditions The vehicle body in general in good condition Fire extinguishers, First aid kit, Water, torch/flares. Jack, Spare tire & Tool Kit.

This document is the Intellectual Property of Descon. Any unauthorized use, including the modification and reproduction of the content is strictly prohibited. © Copyrights Ordinance 2002, All rights reserved.

Transportation and Logistics Safety Management

Doc. No.: HSE/SOP-14 Rev: 00 Date of Rev.: Mar 15, 2017 Page 25 of 29

D- Pre-Journey Inspection Checklist (Logistic Vehicles) (To be filled by Logistics Transporter / Suppliers) Vehicle No.

Date & Time:

Driver Name:

From:

Client:

To:

Documents / Approvals: Sr. No

Checklist

1. 2. 3.

Valid for the vehicle. Valid for the driver (license to operate) HSE Training (induction) for the driver.

Y/N

Vehicle Inspection: Sr. No

Checklist

1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14.

Tires in good condition. Lights adequate. Flashing Reverse Alarm available and working (if applicable). First-aid box available. Valid Fire Extinguishers available. Truck cabin cleanliness to the standard. No visible damage to the truck. 3 safety triangles available. Checking the oil level. Radiator water level. Checking the wiper. Checking the wiper water level. Checking the side and fog lights. Spark arrester.

Y/N

Securing Accessories Inspection: Sr. No

Checklist

1. 2. 3.

Adequate number of belts to secure the load. Physical condition of the belts according to Standard. Rubber Steel Slides in place.

Logistics Coordinator Descon

Y/N

Logistics Supplier/Vendor

Transportation and Logistics Safety Management

Doc. No.: HSE/SOP-14 Rev: 00 Date of Rev.: Mar 15, 2017 Page 26 of 29

E- Oversized Cargo Handling Checklist Sr. No

Activity

1.

Receive information about transportation of oversized cargo.

2.

Receive Lifting Cargo.

3.

Review heavy lifting drawing.

4.

Prepare transport drawing.

5.

Forward Transport drawing to applicable locations.

6.

Apply for the road permit.

7.

Receive permit.

8. 9. 10. 11. 12. 13. 14. 15.

Responsibility

Document/Record

Ask driver to park the trailer at safe location. Walk around the trailer and visually inspect the cargo. Ensure saddles/s are firmly placed. Proceed ahead with lifting operations as per Lifting Procedure. Supervise the lifting as per drawing. Ensure cargo is correctly placed on the container. Check and ensure the lashings are done properly. Check and ensure necessary lights and reflective stickers are in place to indicate oversized cargo.

Logistics Coordinator Descon

Logistics Supplier/Vendor

Transportation and Logistics Safety Management

Doc. No.: HSE/SOP-14 Rev: 00 Date of Rev.: Mar 15, 2017 Page 27 of 29

F- Oversized Cargo inspection Checklist for drivers Sr. No 1. 2. 3. 4. 5. 6.

7. 8. 9.

10

11. 12.

Activity Park the trailer at safe location. oversize permit. Walk around the trailer and visually inspect the cargo. Ensure saddles/s are firmly in place. Check and ensure the lashings are done properly. Check and ensure necessary lights and reflective stickers are in place to indicate oversized cargo. Visually inspect the complete trailer. Driver has given tool box talk Record the verification results in oversized cargo inspection form.

Responsibility

Document/Record Oversize Permit

Toolbox talk record Completed oversize inspection form (if applicable)

If the result of inspection is satisfactory, allow the cargo to move, or else ask for the rectification of defects. Re-inspect the cargo and trailer to ensure that cargo is safe to move. Maintain the records of inspection and re-inspection.

Logistics Coordinator Descon

Logistics Supplier/Vendor

Transportation and Logistics Safety Management

GSr. No 1. 2. 3.

4. 5.

6. 7. 8.

Doc. No.: HSE/SOP-14 Rev: 00 Date of Rev.: Mar 15, 2017 Page 28 of 29

Lashing Inspection checklist

Activity Collect the PJI CHECKLIST FORM Sheet from the driver. Move around the truck/trailer. Visually inspect all lashing belts/chains. Ensure that; Belts are not torn out Belt buckles are not defective. Two belts are not ed by a knot etc. the ratings of the belt/chain. Pull the belt/chain and ensure that it is tight as required. In case of doubt ask the driver to re-lash it. Ensure that belts are tied to a proper lashing point. Ensure that cargo is lashed by sufficient belts/chains and at proper distance. Sign the PJI CHECKLIST FORM and allow the truck/ trailer to leave.

Logistics Representative / Descon

Responsibility

Document/Record PJI CHECKLIST FORM Sheet

Completed checklist form

Logistics Supplier/Vendor

PJI

Transportation and Logistics Safety Management

Doc. No.: HSE/SOP-14 Rev: 00 Date of Rev.: Mar 15, 2017 Page 29 of 29

H- Journey Management Plan

HSE Manager

I/C istration

Doc. No.: HSE/SOP-14 Rev: 00 Date of Rev.: Mar 15, 2017 Page 2 of 29

Document Revision/Review History

REVISION No.

Date

REVIEW Description

No.

Reviewed by

Date

A

B 00

15-03-2017

Development of procedure as per the requirement of HSE MS revamping task C

D

E

A

B 01 C

D

This document is the Intellectual Property of Descon. Any unauthorized use, including the modification and reproduction of the content is strictly prohibited. © Copyrights Ordinance 2002, All rights reserved.

Transportation and Logistics Safety Management

Doc. No.: HSE/SOP-14 Rev: 00 Date of Rev.: Mar 15, 2017 Page 3 of 29

TABLE OF CONTENTS 1.

OBJECTIVE: .................................................................................................................. 4

2.

SCOPE: ......................................................................................................................... 4

3.

ROLES & RESPONSIBILITIES:..................................................................................... 4

4.

ABBREVIATIONS/ DEFINITIONS: ................................................................................ 5

5.

PROCEDURE: ............................................................................................................... 7

5.1 TRANSPORTATION SAFETY MANAGEMENT ............................................................ 7 5.2 TYPES OF VEHICLES .................................................................................................. 7 5.3 SELECTION OF VEHICLES .......................................................................................... 8 5.4 DRIVER’S SELECTION ................................................................................................. 8 5.5 HSE PLANNING AND MONITORING OF TRANSPORTATION OPERATION ............. 9 5.6 LOGISTIC SAFETY MANAGEMENT ........................................................................... 13 6.

REFERENCE AND RELATED DOCUMENTS: ............................................................ 17

This document is the Intellectual Property of Descon. Any unauthorized use, including the modification and reproduction of the content is strictly prohibited. © Copyrights Ordinance 2002, All rights reserved.

Transportation and Logistics Safety Management

Doc. No.: HSE/SOP-14 Rev: 00 Date of Rev.: Mar 15, 2017 Page 4 of 29

1. OBJECTIVE: This Procedure outlines the mechanism for planning, executing and monitoring of transportation/ logistic operation activities within the Organization to ensure the safety of Company’s personnel & asset.

2. SCOPE: This procedure shall be applicable and adhered at DESCON Headquarter, Business Divisions / Units and on all its Project sites and retrofits jobs.

3. ROLES & RESPONSIBILITIES: Chief Executive Officer

Shall be owner of this document and overview the compliance of guidelines and fulfillment of expectations outlined in this procedure.

Divisional Presidents / Head Business Units / Project Manager

Shall be responsible for the implementation of all the details given in this procedure wherever they are applicable in their respective areas of influence. Shall ensure availability of all resources required for the compliance of the details given in this document. Business Unit Head shall be responsible for providing authorization for the exemption against the fulfillment of any of the requirement of this document for a specific period of time under particular conditions giving details of controls put in place for that period in consultation with HSE Manager on Exemption format.

Division Head HSE/ In-charge HSE business unit / Site HSE Manager or In-charge

Shall be responsible for adequate communication, trainings and compliance audits along with advising to fill the gaps identified in implementation of the requirements as details given in this procedure. Shall be responsible for review of this procedure as per set frequency or on need basis.

Chief Compliance Officer

Shall coordinate for the revision of this document as per set frequency or as and when needed. Shall be responsible for conducting the compliance audits of this procedure.

This document is the Intellectual Property of Descon. Any unauthorized use, including the modification and reproduction of the content is strictly prohibited. © Copyrights Ordinance 2002, All rights reserved.

Transportation and Logistics Safety Management

Doc. No.: HSE/SOP-14 Rev: 00 Date of Rev.: Mar 15, 2017 Page 5 of 29

istration Manager

Manager shall be responsible for hiring and deploying competent drivers and safe vehicles along with their maintenance for transportation operations.

Procurement/ Logistics Manager

Procurement Manager shall be responsible for pre-qualification and contracting of approved Vendors and supplier Logistic Manager shall be responsible for planning, hiring and approved supplier/vendors along with smooth functioning of vehicles.

4. ABBREVIATIONS/ DEFINITIONS: BU

Business Unit

CEO

Chief Execution Officer

DEL

DESCON Engineering Limited

HSE

Health, Safety and Environment

HSEMS

Health, Safety and Environment Management System

I/C

In charge

PJI

Pre-Journey Inspection

PM/SM

Project Manager / Site Manager

POD

Proof of delivery

Projects

Construction and shutdowns / retrofit projects

SOP

Standard Operating procedure

TBTs

Tool Box talk

Business Travel

Company’s work related travelling irrespective of origin and destination other than usual travel from home to job-place by employee at his own.

Competent

Trained, experienced and able to perform the allocated task to the required standards in accordance with the applicable procedures, standards and legislation, without direct supervision

This document is the Intellectual Property of Descon. Any unauthorized use, including the modification and reproduction of the content is strictly prohibited. © Copyrights Ordinance 2002, All rights reserved.

Transportation and Logistics Safety Management

Company Vehicle

Contracted Vehicle

Doc. No.: HSE/SOP-14 Rev: 00 Date of Rev.: Mar 15, 2017 Page 6 of 29

Any vehicle (any car, van, bus, coach, truck, trailer, pickup truck, emergency vehicle (e.g. fire tender, ambulance)) that is directly owned, leased or rented by the company and being operated in connection with company business, including personal vehicles whilst used for company business. Any vehicle that is leased, directly owned, or rented by a contractor or sub-contractor, that provides services for the Company operations under formal (contractual) agreement.

Fatigue

Extreme physical or mental tiredness or exertion.

Herb Weight (Tare Weight)

The unladen weight of a vehicle as determined at registration.

Inspection

Inspection shall mean any physical activity, related to ensuring that a vehicle in its entire or an item of vehicle at a given location or environment, meets the specified design and operating standards as intended and is safe to operate or utilize for a specified period.

Journey Management Plan

A Journey Management Plan is typically a set process to follow for authorization, planning and undertaking road transport journeys in compliance with transportation safety requirements, with objective of safe transportation operation.

Lashing

Fastening devices made of chain or nylon webbing used to restrain loads

Lashing Point

A fitting or attachment on a vehicle or a load, specifically installed as a point to secure a lashing.

Light Vehicle

A Light Vehicle is any vehicle having a kerb weight of less than or equal to 4000 kg and having eight enger seats or less.

Logistics Operation

Operation involving transportation and delivery of good and materials

Non-routine Driving Task

A trip that has an elevated risk: e.g. night driving, or off-road driving

Routine Driving Task

A trip that has been assessed as low risk with only standard ALARP measures

This document is the Intellectual Property of Descon. Any unauthorized use, including the modification and reproduction of the content is strictly prohibited. © Copyrights Ordinance 2002, All rights reserved.

Transportation and Logistics Safety Management

Doc. No.: HSE/SOP-14 Rev: 00 Date of Rev.: Mar 15, 2017 Page 7 of 29

Repair

A measure whereby the original state of an appliance will be restored by rebuilding or exchanging parts or units. If essential parts with safety functions are to be rebuilt or exchanged, this is considered to be a ‘Major Repair’.

Substance Abuse

Substance abuse Includes alcohol, illegal drugs, prescribed or overthe-counter medicines not used in accordance with a doctor’s or the manufacturer’s guidance or any other substance introduced into the body in any way, which has a narcotic, depressant, stimulant, or character or mood altering effect, and which may impair judgment or work performance

Transportation operation

Operation intended to transport (travel) people from one place to another by using vehicles

5. PROCEDURE: This procedure details the planning, monitoring and management of transportation/ logistics safe operations as follows. a) b)

Transportation safety management Logistics safety management

5.1 Transportation Safety Management Transportation is one of the most critical part of our operations. Transportation safety management shall be done to prevent and control all the transportation related hazards and risks at respective Office, Project site, external roads (high ways). Competent drivers and Safe (fit) Vehicle, both are required to ensure safe transportation. istration department of the respective Office, Project site, shall implement transportation safety management system, through effective planning and arrangements in pursuance of zero transportation incident. In case of projects sites, In-charge istration along with PM/ SM of respective Project shall be completely responsible for transportation safety management. Transportation safety management system shall be conducted as follows. a. Effective site lay-outing planning for traffic routes within office premises, Sites, external roads. b. Safe vehicle. c. Competent driver.

5.2 Types of Vehicles There are two main categories of vehicles used for company transportation operations as mentioned below. This document is the Intellectual Property of Descon. Any unauthorized use, including the modification and reproduction of the content is strictly prohibited. © Copyrights Ordinance 2002, All rights reserved.

Transportation and Logistics Safety Management

Doc. No.: HSE/SOP-14 Rev: 00 Date of Rev.: Mar 15, 2017 Page 8 of 29

5.2.1 Company owned vehicles Any vehicle (car, van, bus, coach, truck, trailer, pickup truck, emergency vehicle (e.g. fire tender, ambulance)) that is directly owned, leased or rented by the company and being operated in connection with company business, including personal vehicles whilst used for company business. All vehicles owned by company shall be certified fit for use as per company criteria before asg for any transportation activity. 5.2.2 Contracted Vehicles Any vehicle that is leased, directly owned, or rented by a contractor, that provides services for the Company operations under formal (contractual) agreement.

5.3 Selection of Vehicles 5.3.2 Company Vehicles All vehicles owned by company shall be certified fit for use as per company criteria before asg for any transportation activity see Annexure. A-Vehicles Standard fitness Safety Criteria (DESCON & Contractors) 5.3.3 Contractor vehicles All transporters/ suppliers vehicles shall be prequalified before contracting and asg for any job as per company HSE contractor prequalification criteria. I/C shall make sure that contracted vehicles are maintained after regular intervals as needed. AnnexureA, Vehicles Standard fitness Safety Criteria (DESCON & Contractors). 5.3.3.1 Pre-qualification of Transporter/Supplier All transporters/ suppliers shall be prequalified before contracting and asg any job as per the Company SOP- 41 Contracts and Contractor HSE Management.

5.4 Driver’s Selection Drivers deployed for assigned jobs shall meet the following criteria a. b. c. d.

All drivers shall have valid driving license with experience of at least 5 years Drivers shall have specific driving qualifications certificate from the approved training providers. Maximum age limit for drivers is 63 years Must be medically examined prior to hiring/selection & annually and shall possess current medical fitness certificates.

This document is the Intellectual Property of Descon. Any unauthorized use, including the modification and reproduction of the content is strictly prohibited. © Copyrights Ordinance 2002, All rights reserved.

Transportation and Logistics Safety Management

Doc. No.: HSE/SOP-14 Rev: 00 Date of Rev.: Mar 15, 2017 Page 9 of 29

5.5 HSE Planning and Monitoring of Transportation Operation HSE planning for transportation operation shall be done by establishing transportation safety plan specific to the nature of Project Site, Office and Facility, plan includes, route surveys, traffic safety rules, transportation safety signage, transportation risk management, vehicles fitness, driver competency and behavior assessment. 5.5.1 Journey management Plan & Transportation Risk Assessment Journey Management Plan A process that incorporates the conducting of a risk assessment to identify major hazards and ensure that the journey and the risk are assessed, verified and an action plan is implemented and monitored to address these hazards Regardless of a trip purpose and in the interest of improving business performance, the reduction of the risk by removing the requirement of the journey is the most effective risk reduction option so managers/line supervisors are required to evaluate specifically the need of all journeys required to be executed in their respective areas to allow unavoidable only for Company’s operations. All risks associated with general & specific (main highway near project) transportation activities shall be assessed and documented following HSE SOP-08, “Hazard Identification, Risk Assessment & Control”, HSE-FRM-01, JSA Form. The risk assessment shall also consider drifting snow, dust, smoke, fog, heavy rains, security risks and regional and local driving practices. The risk assessment conducted shall be revised subjected to the following conditions. 1. 2. 3.

after a major traffic incident When significant route / vehicle/ destination changes are introduced Periodically – Every Year

Journey management plan shall be established for routine and non- routine driving task that inherits high risk level like, night driving, off road driving etc. Night Driving Authorization For night driving special permission from Site Management shall be taken on form as attached. 5.5.2 Vehicle Selection & Fitness All vehicles owned by company or Contracted shall meet Company criteria as mentioned in Appendix-A Vehicles Standard fitness Safety Criteria (DESCON & Contractors).Prequalified vehicles shall have maximum of five years old registration. Vehicles used for company operations shall not model be five years

This document is the Intellectual Property of Descon. Any unauthorized use, including the modification and reproduction of the content is strictly prohibited. © Copyrights Ordinance 2002, All rights reserved.

Transportation and Logistics Safety Management

Doc. No.: HSE/SOP-14 Rev: 00 Date of Rev.: Mar 15, 2017 Page 10 of 29

5.5.3 Vehicle Maintenance Vehicles deployed on transportation activity shall be maintained well in order to ensure safe operation. All scheduled and non-scheduled maintenance shall be done as per manufacturer instructions 5.5.4 Driver Competency & Training In charge istration shall ensure that the allocated/assigned drivers are competent and trained and meet the following. Driver’s Selection Criteria a. All drivers shall have valid driving license with experience of at least 5 years b. Drivers shall have specific driving qualifications certificate from the approved training providers. c. Maximum age limit for drivers is 55 years d. Must be medically examined and shall possess current medical fitness certificates. Driver’s Induction and Training a. HSE Induction shall be provided to all drivers before asg to jobs. b. Driver shall be trained on the principles of the defensive driving techniques c. Periodic safety briefings, meetings and refresher trainings shall be conducted for drivers when and as required. As a minimum the following topics shall be covered in the defensive driving training conducted for drivers. a. b. c. d. e. f. g. h. i. j.

Company HSE policy Defensive driving techniques Journey management techniques Alertness and fatigue management Effects of medication and substance abuse Vehicle restraint systems and safety equipment Pre-trip checks and proper seating position Local driving hazards, regulations and culture Skill assessment and/or commentary drive Emergency response planning and prepared

5.5.5 Driver’s Responsibilities It is the responsibility of every driver to follow applicable laws and regulations regarding traffic and shall ensure strict compliance to the following driving safety rules. a) b) c)

Always obey the Speed Limits & Safety rules as mentioned on the safety signs. Wear a seat belt at all times. Always use the directional signals.

This document is the Intellectual Property of Descon. Any unauthorized use, including the modification and reproduction of the content is strictly prohibited. © Copyrights Ordinance 2002, All rights reserved.

Transportation and Logistics Safety Management

Doc. No.: HSE/SOP-14 Rev: 00 Date of Rev.: Mar 15, 2017 Page 11 of 29

d) e) f) g) h) i) j) k) l)

Ensure all other occupants of the vehicle are wearing seatbelts Wear sturdy footwear when driving (not slippers, flip-flops or loose sandals). Wear the correct PPE if working with hazardous materials. Ensure luggage is securely fastened and stowed correctly. Conduct the pre-check before riding the vehicle. Ensure that emergency equipment/contents are available in vehicle. Ensure all doors are closed correctly before moving off. Ensure all engers are wearing seatbelts before moving off. Use only assigned driver blue key, never lend your blue key to any one or leave inside the vehicle. m) Never drive if too tired to concentrate. n) Never drive if under the influence of alcohol, drugs or medication. o) Only use a vehicle that has been approved for the journey. p) Use Journey Management System. q) Vehicles must not be left unattended with the engine running. r) Report all vehicle related accidents / near misses. s) Ensure that they are licensed for the vehicle that they are operating. t) Drive safely and show consideration to other road s. u) Switch off vehicle engine and mobile phone when re-fuelling. v) Do not use mobile phone while operating a motor vehicle. Free headset can be used to receive emergency calls only, to place or receive a call: park your vehicle safely and use your mobile phone and radio communication. 5.5.6 Driving Behavior Monitoring & Management The Driving behavior is monitored using an HSE observation cards system by istration 1. 2. 3. 4.

No. of seat belt and their conditions Harsh Breaking Harsh acceleration Over steering

Company employees raise the violation notices to I/C . I/C also keep a track of violation notices maintaining a log sheet and records the history of Verbal Warning, Written Warning, and Terminations etc. The violation counter against each driver will be turned to zero in every six months. Company Drivers shall be certified medically and screened against substance abuse. In Vehicle Monitoring shall be installed (where applicable) to assist in the improvement of driver performance. The data captured allows clear visibility of driver behavior and compliance to Company safe driving standard.

This document is the Intellectual Property of Descon. Any unauthorized use, including the modification and reproduction of the content is strictly prohibited. © Copyrights Ordinance 2002, All rights reserved.

Transportation and Logistics Safety Management

Doc. No.: HSE/SOP-14 Rev: 00 Date of Rev.: Mar 15, 2017 Page 12 of 29

This driver’s performance shall be identified and analyzed by the appointed IVMS s through regular data analysis (where available). 5.5.7 Driver Incentive Programs In order to motivate the Drivers towards safe driving, best drivers are recognized every month for their safe driving efforts based on the number transportation trips and . 5.5.8 General HSE Guidelines for Transportation activities As per general driving guide lines, in all kind of road surfaces the drivers shall ensure that: a. All vehicles used shall be fitted with seat belts, istration encourage and ensure the installation and use of seat belts in all personnel vehicles. All belts shall be functioning, inspected regularly and worn correctly by drivers and engers. b. Night driving shall generally be prohibited and avoided as far as possible and if required then it must be authorized by I/C and Project Manager c. Follow defensive driving requirements d. Avoid sudden brakes. e. Speed limits and road safety signs should be strictly followed f. Do not drive during foggy weather, rainy conditions, sand storms and any conditions where low visibility prevails g. Does not use of mobile phones while driving, ensure seat belt compliance and do not smoke while driving h. Follow traffic law; any violations will be directly ed to the respective drivers and fines shall be recovered from individual s as in reference to disciplinary actions. i. Motorcycles (two, three wheel) shall not be used for business activities. 5.5.9 Rules for Parking 1. Park vehicles in marked spaces only. 2. Do not park in spaces that are reserved for special people vehicles or emergency response. 3. Do not block other vehicle. 4. When parking follow the seven rules of safe parking a) b) c) d) e) f) g)

Always park so, the first move in the vehicle is forward – you may have to reverse park at the end of your trip, if so, make sure that the rear is clear. Sound the horn before you start to reverse. Back immediately never trust the scene you checked to stay the same. Back slowly. As you back, check both side-mirrors. Don't back further than necessary. Use a ground guide.

This document is the Intellectual Property of Descon. Any unauthorized use, including the modification and reproduction of the content is strictly prohibited. © Copyrights Ordinance 2002, All rights reserved.

Transportation and Logistics Safety Management

5.5.10

Doc. No.: HSE/SOP-14 Rev: 00 Date of Rev.: Mar 15, 2017 Page 13 of 29

Emergency Preparedness a. Fire extinguishers shall be made available in the transportation vehicle b. First aid box shall be made available on the large commuting Vehicles. c. Three sets of reflective triangles are provided to each large vehicle shall be used in case of an emergency break down d. Shall have effective means of communication between drivers and back office of respective in case of any emergency and unwanted happening.

5.6 Logistic Safety Management Logistics safety management shall be planned and carried out by ensuring that the following requirements are fulfilled and implemented as mentioned below a) Prequalification of transporters/ suppliers. b) HSE Planning for Logistics operations c) Logistics Journey Management.

5.6.1 Prequalification of transporters/ suppliers All transporters/ suppliers shall be prequalified before contracting and asg any job as per company HSE prequalification criteria.

5.6.2 HSE Planning for logistic Operation Initial Planning & Pre-Journey Preparation Logistic safety planning and pre journey preparation shall be done by considering various job factors proactively so that all hazards, risk factors shall be evaluated prior commencement of the trip as follows. a.

Risk assessment All risks associated with general & specific logistics/transportation activities shall be assessed and documented following HSE SOP-08, “Hazard Identification, Risk Assessment & Control”, HSE-FRM-01, JSA Form. The risk assessment shall also consider drifting snow, dust, smoke, fog, heavy rains, security risks and regional and local driving practices. The risk assessment conducted shall be revised subjected to the following conditions. 1. 2. 3.

b.

After a major traffic incident When significant route / vehicle/ destination changes are introduced Periodically – Every Year

Route surveys Before starting logistic activity and asg trucks to any routes for cargo, a suitable and sufficient road survey shall be done in order to assess and document the following:

This document is the Intellectual Property of Descon. Any unauthorized use, including the modification and reproduction of the content is strictly prohibited. © Copyrights Ordinance 2002, All rights reserved.

Transportation and Logistics Safety Management

c.

Route Summary a) b) c) d) e) f) g) h) i) j) k) l)

d.

Doc. No.: HSE/SOP-14 Rev: 00 Date of Rev.: Mar 15, 2017 Page 14 of 29

Type of road Physical condition of the road Number of bridges Height of bridges Capacity of the bridges in the route Difficult road diversions and turns details Round-about details Road permit requirements Critical Over Head Power lines in case of loss material & oversized cargo. Nearest police station details Nearest hospital details Total distance

Route map 1. Assess the distance and directions of the route 2. Land marks and nature, terrain and type of roads 3. Load restrain inspection points & Lay bays