Guidance To Prepare Wps-pqr For Welding k2x36

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 2z6p3t

Overview 5o1f4z

& View Guidance To Prepare Wps-pqr For Welding as PDF for free.

More details 6z3438

- Words: 474

- Pages: 1

WPS ‐ PQR 1 WPS-Welding Procedure is the Procedure, in written format, by the Fabricator/Manufacturer, giving

details about base metal metal, welding groove groove, filler metals and instructions that are followed in the welding, to make good and quality welding, Code: ASME Sec IX, AWS D.1.1, API1104 2 Welding is done, following the Procedure(WPS) 3 The welded piece(originally, in the form of plate or pipe) is cut into test speciments/test coupens. 4 PQR-These test specimens are tested in the Lab(for mechanical and metallurgical tests, visual test) and

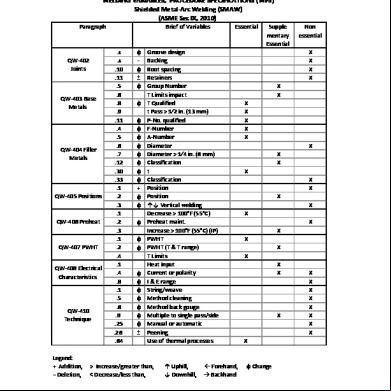

the welding parameters (during actual welding, PWHT etc ) and test results are recorded. Reason to have many WPS: One WPS is made to meet a set of specific welding parameters. If we change the parameters, then we check, whether the parameter is essential or non essential variable. If it is essential variable, then new WPS is prepared Each WPS should have their specimen tested and PQR is made for that WPS prepared. WPS. So So, each WPS has its own PQR PQR. If it is non essential, variable, then , no need to make a new WPS and qualification(sometime, WPS alone, need amended). ASME Sec IX, gives the QW-XXX reference numbers, on the sample WPS-PQR, so that we can find whether the data is essential variable or not.

If the PQR meets the test acceptance criteria, then the WPS is said , as, WPS is qualified. Steps to make WPS: Study y the P.O., Product

Prepare list of WPS

Prepare Weld Map

References & Approval Codes to prepare WPS & PQR:

Prepare WPS (before welding)

ASME Sec IX (most common) AWS D1.1 (for Structures)

Welding

Cut the test piece into Test Specimen/ Test coupen

Prepare additional Coupens & test . Or change the weld parameters in WPS and retest.

Lab Testing

API 1104 (for Country Pipelines) Test is not ok. WPS Rejected

Prepare PQR . Evaluate the results.

WPS: Aim: To have good and quality weld To the test and to get WPS qualified. Preparation for WPS: 1 Reporting Forms: Select the code for approval & select the sample form from the Code 2 Forms can also be selected from Lincon Electric WPS and from other people who had already approved WPS 3 Vendors are also preparing detailed step by step WPS, with good practices to produce quality welds. 4 Collect welding parameter details: Base metal: Plate or Pipe(for testing), from rolled/ forged/ cast/ extruded form & its spec.

Results are satisfactory & Test is Ok and WPS is qualified

PQR

Welding

1 List/ record the parameters during welding, PWHT etc and record the test results

2 Evaluate the rest results and certify whether the test had ed and if so, declare WPS is qualified

Weld metal: Welding Process(SMAW/GTAW/SAW etc) /Filler/welding practices Welder: Already has some basic welding experience & some qualification Prepared by: Annamalai-JGC

details about base metal metal, welding groove groove, filler metals and instructions that are followed in the welding, to make good and quality welding, Code: ASME Sec IX, AWS D.1.1, API1104 2 Welding is done, following the Procedure(WPS) 3 The welded piece(originally, in the form of plate or pipe) is cut into test speciments/test coupens. 4 PQR-These test specimens are tested in the Lab(for mechanical and metallurgical tests, visual test) and

the welding parameters (during actual welding, PWHT etc ) and test results are recorded. Reason to have many WPS: One WPS is made to meet a set of specific welding parameters. If we change the parameters, then we check, whether the parameter is essential or non essential variable. If it is essential variable, then new WPS is prepared Each WPS should have their specimen tested and PQR is made for that WPS prepared. WPS. So So, each WPS has its own PQR PQR. If it is non essential, variable, then , no need to make a new WPS and qualification(sometime, WPS alone, need amended). ASME Sec IX, gives the QW-XXX reference numbers, on the sample WPS-PQR, so that we can find whether the data is essential variable or not.

If the PQR meets the test acceptance criteria, then the WPS is said , as, WPS is qualified. Steps to make WPS: Study y the P.O., Product

Prepare list of WPS

Prepare Weld Map

References & Approval Codes to prepare WPS & PQR:

Prepare WPS (before welding)

ASME Sec IX (most common) AWS D1.1 (for Structures)

Welding

Cut the test piece into Test Specimen/ Test coupen

Prepare additional Coupens & test . Or change the weld parameters in WPS and retest.

Lab Testing

API 1104 (for Country Pipelines) Test is not ok. WPS Rejected

Prepare PQR . Evaluate the results.

WPS: Aim: To have good and quality weld To the test and to get WPS qualified. Preparation for WPS: 1 Reporting Forms: Select the code for approval & select the sample form from the Code 2 Forms can also be selected from Lincon Electric WPS and from other people who had already approved WPS 3 Vendors are also preparing detailed step by step WPS, with good practices to produce quality welds. 4 Collect welding parameter details: Base metal: Plate or Pipe(for testing), from rolled/ forged/ cast/ extruded form & its spec.

Results are satisfactory & Test is Ok and WPS is qualified

PQR

Welding

1 List/ record the parameters during welding, PWHT etc and record the test results

2 Evaluate the rest results and certify whether the test had ed and if so, declare WPS is qualified

Weld metal: Welding Process(SMAW/GTAW/SAW etc) /Filler/welding practices Welder: Already has some basic welding experience & some qualification Prepared by: Annamalai-JGC