Durapipe Abs Pipe Catalogue 4j371

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 2z6p3t

Overview 5o1f4z

& View Durapipe Abs Pipe Catalogue as PDF for free.

More details 6z3438

- Words: 25,361

- Pages: 72

Pipes, Fittings and Valves Imperial and Metric Systems

Technical Data and Dimensions

Complete system solutions At the forefront of development and manufacture of thermoplastic pipework for over half a century, Durapipe products are widely used in Utilities, Industrial and Building Services sectors around the world.

• Fully matched system • Wide range of manual and actuated valves

• Comprehensive technical

• Fully approved ... don’t take a chance with any other brand

2

Tel: +44 (0)1543 279909

Fax: +44 (0)1543 279450

Index page

page

Company Profile .....................................................................2

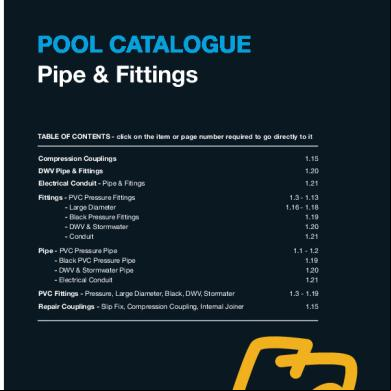

Index to ABS Metric Fittings ..................................................36 Pipe .....................................................................................37 Sockets.................................................................................38 Reducing bushes ...................................................................38 Reducers ..............................................................................39 Elbows 45° ...........................................................................39 Elbows 90° ...........................................................................39 Bends 90° ............................................................................40 Fabricated bends 90° .............................................................40 Tees 90° ..........................................................................40-41 Tees 45° ...............................................................................41 Caps ....................................................................................42 Socket unions........................................................................42 Socket union plain adaptors ....................................................42 Socket union threaded adaptors ..............................................42 Socket union nuts ..................................................................43 Imperial/metric socket adaptors ...............................................43 Female threaded adaptors.......................................................43 Male threaded adaptors..........................................................43 Female composite unions .......................................................44 Male composite unions...........................................................44 Wall brackets ........................................................................44 Hose adaptors .......................................................................44 Stub flanges ..........................................................................45 Blank flanges ........................................................................45 Valve plates...............................................................45 Backing rings ........................................................................46 Flat gaskets/stub flanges.........................................................47 ‘O’ ring for socket unions ........................................................47 Cobra pipe clips ....................................................................48 Durapipe one-step solvent cement and Eco-cleaner ...................48 VK Double union ball valves ...................................................48 Multiport ball valves...............................................................49 Single union ball check valves.................................................50 Air release valves ...................................................................50 Y type strainers .....................................................................50 VM Diaphragm valves ............................................................51 Pressure relief valves..............................................................51 FK Butterfly valves.................................................................52 Pipe trays .............................................................................53 De-burring tools.....................................................................53 Wheel cutters ........................................................................53

Durapipe ABS .....................................................................4-5 Durapipe ABS pipework .......................................................6-7 Material Properties and Product Selection Guide .......................8 Comparison of ABS Imperial and Metric Sized Pipe .................11 Index to ABS Imperial Fittings ..........................................12-13 Pipe .....................................................................................14 Sockets plain ........................................................................15 ‘O’ ring sockets......................................................................15 Reducing sockets ...................................................................15 Saddles ................................................................................15 Reducing bushes ..................................................................16 Elbows 45° ...........................................................................16 Elbows 90° plain ...................................................................16 Bends 90° ............................................................................17 Bends 45° ...........................................................................17 Bends 221⁄2° .........................................................................17 Tees 90° ...............................................................................18 Tees 45° ...............................................................................18 Caps ....................................................................................19 Socket unions........................................................................19 Socket union plain adaptors ....................................................19 Socket union threaded adaptors ..............................................19 Socket union nuts ..................................................................20 Imperial/metric socket adaptors ...............................................20 Sockets plain/BSP threaded ...................................................20 Reducing bushes ...................................................................20 Barrel nipples........................................................................21 Hexagon nipples ....................................................................21 Adaptors male/female.............................................................21 Adaptors female/male........................................................21-22 Composite unions ..................................................................22 Hose adaptors .......................................................................22 Tank connectors.....................................................................23 Elbows 90° plain/BSP threaded ..............................................23 Sockets BSP threaded............................................................23 Hexagon nipples ....................................................................23 Back nuts .............................................................................24 Plugs....................................................................................24 Caps ....................................................................................24 Elbows 90° BSP threaded ......................................................24 Reducing bushes ...................................................................25 Flanges full face ...............................................................25-26 Flanges stub serrated .............................................................26 Flanges blanking...............................................................26-27 Gaskets flat ...........................................................................27 ‘O’ ring for socket union..........................................................27 Gaskets full face ....................................................................28 Backing rings ........................................................................29 Valve plates...............................................................30 Cobra pipe clips ....................................................................30 Saddle clips ..........................................................................30 Durapipe one-step solvent cement and Eco-cleaner ...................31 VK Double union ball valves ...................................................31 Multiport ball valves...............................................................32 Single union ball check valves.................................................33 Air release valves ...................................................................33 Y type strainer .......................................................................33 VM Diaphragm valves ............................................................34 Pressure relief valves..............................................................34 FK Butterfly valves.................................................................35

Durapipe ABS Design and Installation Guide ...........................54 Flow Nomogram ....................................................................55 Calculating Expansion and Contraction.....................................56 Additional Important Information ...........................................59 Durapipe ABS ting Guide (up to 8"/225mm)......................60 Durapipe ABS ting Guide (for 10"/250mm and 12"/315mm) .........................................62 Notes ...................................................................................65 Drying Times.........................................................................65 Durapipe ABS Thixotropic Solvent Cement and Eco-cleaner........65 Branch Connections ...............................................................66 The use of Bushes, Reducers and Threaded adaptors ................67 General Information/Approvals ...............................................68 Product Specification (Imperial) .............................................69 Product Specification (Metric)................................................70 Other Durapipe UK Systems .................................................71

email: [email protected]

web: www.durapipe.co.uk

3

Durapipe ABS The market leader in pipe systems for environmental control Durapipe ABS - the proven industrial pipework system combining corrosion resistance, toughness and economy

Quality

Environment and Conservation

Fully approved Items in the Durapipe ABS product range are assessed to several important international standards, listed on page 68.

Certificate No. FM 34819

Energy conservation is an issue that affects everyone. It is significant that manufacture of Durapipe ABS pipework uses considerably less energy than is required to produce the equivalent metal system. ABS can also be re-worked to avoid scrap. Additionally, the thermal properties of ABS, compared with those of metals, may result in cost savings in lagging. Durapipe UK operates an environmental management system that has been successfully assessed against the BS EN ISO 14001 environmental management standard.

Quality control Our commitment to quality is reflected by our operation of an independently assessed quality management system ed under BS EN ISO 9001.

Reliability Manufactured under strict ISO 9001 quality control procedures, Durapipe ABS offers consistency, reliability and complete reassurance to designer, installer and end-.

Design Life Durapipe ABS systems have a 50 year design life with a residual safety factor of 2:1

4

Tel: +44 (0)1543 279909

Applications • • • • • • • • • • •

Chilled water/air conditioning Water treatment Sewage treatment Process cooling water High purity water Effluent and chemical processing Film processing Electrolytic metal refining Food processing and soft drinks Pharmaceutical products Medical preparations

Fax: +44 (0)1543 279450

Major s

Supplementary Services

• Alstom

• National Air Traffic Control

• Anglian Water

• National Power

• Bank of Zambia

• Orange

We offer the following supplementary services: • Advice regarding use of all Durapipe products.

• Boots

• Palace of the Hague

• Installed cost comparison.

• BP

• Pedigree Pet Foods

• British Avionics

• Pfizer

• British Embassy, Muscat

• Rank Organisation

• British Energy

• Rolls Royce

• BT

• J. Sainsbury plc

• Coca Cola

• Schipol Airport

• DEFRA

• Science Research Centre

• Deluxe Laboratories Limited

• Severn Trent Water

• DML

• Sony UK Limited

• Dunlop

• Technicolor Limited

• Elga/US Filter

• Transco

• Ferrati

• United Kingdom Atomic Energy Authority

• Fisons

• Wellcome

• Product and application training seminars.

• Ford Motor Company • General Motors

Technical

• Harrods

Our experience and expertise is at your disposal. Our Technical team will be pleased to offer you design and installation advice.

• Hilton Hotels • Hyatt Regency • ICI • Kodak • Manchester airport

Availability

• Marks & Spencer

Durapipe ABS pipework is available from an extensive international network of distributors and stockists. Please ask for details of your nearest outlet.

• McDonalds

email: [email protected]

web: www.durapipe.co.uk

5

Durapipe ABS Pipework Materials

Wide temperature range

Durapipe ABS is manufactured from Acrylonitrile Butadiene Styrene, a material that can be blended to give different properties to suit each of the many end uses for which this versatile material is often chosen, such as household goods, DIY tools, automotive products or pressure pipework.

A major advantage of Durapipe ABS over other plastic systems is its ability to perform over a wide temperature range from –40ºC to +70ºC. (Note: usual precautions must be taken to prevent contents freezing.)

Comparative Temperature Ranges

140

Acrylonitrile: imparts chemical resistance.

Styrene: provides smooth surface finish. The formulation used by Durapipe ABS has been selected to optimise performance in respect of toughness, strength, chemical resistance, low temperature ductility, weathering, heat stability and ease of processing from raw material to finished product.

Temperature °C

Butadiene: provides impact strength and toughness.

0

-40

Wide operational temperature range, excellent durability and chemical resistance are some of the reasons why Durapipe ABS is so extensively specified. A highly versatile pipe system, available in Imperial and Metric sizes up to 12" and 315mm respectively, it is equally suitable for transportation of slurries as for potable water, chemicals, or high purity water.

ABS

PVC-U

CORZAN

AirLine Xtra

PP

-40° to 70°C

5° to 60°C

5° to 95°C

-20° to 50°C

-20° to 100°C

Tough and durable Superior flow

The Butadiene constituent of ABS affords exceptional resistance to accidental damage, a benefit which it retains, even at sub-zero temperatures.

Low fluid friction allows higher flow velocities than metal pipes, and also inhibits the formation of scale, with consequent savings in pump energy consumption, and reduced pressure drops.

Abrasion resistance Durapipe ABS offers good resistance to abrasion and erosion from aggressive slurries.

Smooth bore, unhibited flow

Corrosion free Durapipe ABS pipework is designed to handle a wide range of chemicals including moderately strong mineral acids and caustic solutions. Please refer to brochure D0238 Durapipe Chemical Resistance Data for further details.

Durapipe ABS resists the limescale build-up common in most metal pipe materials as shown in the picture above.

Durapipe ABS, unlike copper or steel, is free from corrosion.

6

Tel: +44 (0)1543 279909

Fax: +44 (0)1543 279450

Solvent weld ting of ABS. Pipe and fitting become as one.

Durapipe FIP Manual and Actuated Valves Durapipe FIP expertise and experience • System design and sizing advice • Valve and actuation selection advice • Full quality assurance to BS EN ISO 9001 • Complete actuation traceability - each item carries an individual serial number

Durapipe FIP service • Most valves are available within 48 hours of ordering A totally homogeneous system solvent weld ting - pipe and fitting become as one.

Fully complies with PED Non toxic

Fast, simple, high integrity ting

Materials used are selected for their toxicological properties, and suitability for conveying cold potable water.

Solvent welding is a simple process which produces a permanent t of strength equal to, or exceeding, the pipe itself. No special tools or equipment, or hot works permits, are required. •No electricity required •No flame or combustible gas bottles required on site •No site down-time due to electricity shut down •No hot works permits or need for site segregation •Permanent, secure ting •No special tools needed •Easy transition to other systems •Reduced installation time •Reduced installation costs •Light and easy to handle

No metallic stabilisers Durapipe ABS does not contain any harmful metallic stabilisers, and is widely used to convey high purity de-ionised water in semi-conductor and pharmaceutical applications.

Low installed costs The ease of handling and speed of ting of Durapipe ABS will generally result in the total installed cost being lower than for threaded, welded, or soldered metal systems.

Extensive product range The Durapipe ABS range comprises an extensive selection of Imperial and Metric pipes in various pressure ratings, plus a wide selection of fittings.

Lightweight At one-sixth the weight of steel pipes, Durapipe ABS is much easier to handle, especially during installation at site.

email: [email protected]

The European Parliament Pressure Equipment Directive 97/23/EC requires that pressure equipment should meet essential safety requirements (including design, manufacture and testing) and must satisfy an appropriate conformity procedure. Durapipe FIP fully complies with these requirements and operates within a full Quality Assurance system to ISO 9001. For full technical details about Durapipe FIP valves and actuation please ask for a copy of our manual and actuated valve technical guide D0894.

Wide range of valves and actuation The Durapipe valve range is comprehensive, including many commonly required flow control products. This includes ball, butterfly, diaphragm, non-return, solenoid and air release types and is complemented by pneumatic or electrical actuation. Importantly, we have a department dedicated to valves and actuation, able to provide expert advice about product selection and system design.

web: www.durapipe.co.uk

7

Material Properties and Product Selection Guide Properties and Product Selection Guide Chemical Resistance and Performance Data

Typical Applications

Unsuitable for the Following Uses

Sizes and ting Information

Moderately strong mineral acids

Chilled water,

Applications over 70ºC

Metric; 16mm to 315mm OD

Caustic and ammoniacal solutions

low temperature brine,

bleaches

Imperial:

3/8"

to 12" NB

Most inorganic salt solutions

potable water

solvents

ted by solvent cement welding

Some detergents

process water

domestic hot water

Threaded fittings available

Temperature range -40ºC to +70ºC

foodstuffs

flammable substances

Pressure rating at 20ºC Imperial Sizes Pipe

3/8" - 2" 2" - 4" 6" 8" 10" & 12"

9, 12 and 15bar (Classes C, D, E & T) 9, 12 and 15bar (Classes C, D & E) 9 and 12bar (Class C & D) 9bar (Class C) 6bar (Class B)

Solvent Fittings

3/8"

- 6" 8" 10" & 12"

15bar (Class E)* 9bar (Class C) 6bar (Class B)

Threaded Fittings

3/8"

12bar (Class D)* 9bar (Class C)

- 3"

4" VK Ball Valves

3/8" 21/2"

Other Valves

3/8"

- 12"

10bar or 6 bar (PN10 or PN6)

Actuated Valves

3/8"

- 12"

10bar or 6 bar (PN10 or PN6)

2" - 4"

16bar (PN16) 10bar (PN10)

* Except 3" & 4" barrel nipples which are 9bar (Class C)

Metric Sizes Pipe

16mm - 250mm 315mm

10bar (PN10) 8bar (PN8)

Solvent Fittings

16mm - 250mm 315mm

10bar (PN10) 8bar (PN8)

Threaded Fittings

16mm - 75mm

10bar (PN10)

VK Ball Valves

16mm - 63mm 75mm - 110mm

16bar (PN16) 10bar (PN10)

Other Valves

16mm - 315mm

10bar or 6 bar (PN10 or PN6)

Actuated Valves

16mm - 315mm

10bar or 6 bar (PN10 or PN6)

Swept tees are 9bar (Class C) 3" & 4" socket unions are 9bar (Class C) 21/2" and 5" pipes are PN10 O ring sockets are rated one class lower than the corresponding plain socket. Class T pipe is thick walled, suitable for threading

8

Tel: +44 (0)1543 279909

Fax: +44 (0)1543 279450

Fracture mode

Materials

Durapipe ABS is a ductile material and the fracture mode resembles that of soft copper. Mechanical damage causes ductile distortion and tearing, the localised nature minimising the loss of pipe contents. In contrast, the fracture of brittle material is accompanied by rapid crack propagation and hazardous material fragmentation. The photograph illustrates the effect of impact upon Durapipe ABS pipe which, when compared with the brittle fracture mode exhibited by PVC-U pipework, is noticeably less dramatic.

Materials used for manufacture of pipes, fittings and valves are selected for their toxicological properties and suitability for conveyance of potable water as required by the appropriate international authorities. Durapipe ABS material is UK Water Regulations Advisory Scheme approved for cold water services and is listed in the Water Fittings and Materials Directory. Durapipe ABS material is approved by the Drinking Water Inspectorate, under Regulation 25, for use in the supply of water for drinking, washing, cooking, or food processing purposes. Durapipe ABS formulation does not contain any harmful metallic stabilizers.

Colour Durapipe ABS products are a mid-grey colour, generally in accordance with BS5252, colour ref. 18 B 21.

ABS

PVC-U

Durapipe ABS pipe and fittings Durapipe UK offer ABS pipework systems comprising pipes, fittings and valves, ed by solvent welding, together with associated accessories. Products are available available in Imperial sizes from 3/8" to 12" (nominal bore) and Metric sizes from 16mm to 315mm (outside diameter).

ABS and PVC-U Dimensions and standards Imperial The Durapipe ABS Imperial System is manufactured in accordance with the relevant British Standards. Kitemark licences are also held, where applicable, for both pipes and fittings.

Metric The Durapipe ABS Metric System is manufactured generally in accordance with the relevant international standards as shown below: ISO 15493 KIWA 49 and 549 DIN 8062 and 8063 Threaded fittings conform to the requirements of BS 21/DIN 2999/ISO7. Socket dimensions of Durapipe ABS Metric fittings for solvent welding comply with ISO/DIS 727-1.

email: [email protected]

web: www.durapipe.co.uk

9

Gaskets and seals

Maximum Pressure/Temperature Relationship

Gaskets and O Ring seals are made from EPDM except where stated otherwise.

When temperature of contents exceeds 20ºC the working pressure of the system must be reduced accordingly (see table below). 16.0

Ordering by code Imperial

Range

Shape

Size

ABS

Tee

3"

01

122

109

Metric

Range

Shape

Size

ABS

Tee

90mm

11

122

313

Maximum continuous working pressure (bar)

Code numbers should be used when ordering products e.g.

Cla

14.0

ss

12.0

Cla

ss

10.0

E

D

PN

10

8.0

Cla

6.0

Class

ss C

B

4.0 2.0 0 20

30

Abbreviations The following list of abbreviations is used in this catalogue: ABS - Acrylonitrile Butadiene Styrene BS - British Standards ISO - International Standards Organisation DIN - Deutsche Industrie Normen (German Industrial Standards) KIWA - Keuringsinstituut Voor Waterleidingartikelen (Netherlands) ANSI - American National Standards Institute BSP - British Standard Pipe Thread EPDM - Ethylene Propylene Rubber FPM - Fluorine Rubber (e.g. Viton®) PTFE - Polytetraflouroethylene (eg Teflon®) ® Dupont ed trade name.

40

50

60

70

Contents Temperature (°C)

The graph above is based on an ambient temperature of 20ºC For higher ambient temperatures, or where pipework is insulated, decrease the working pressure by 5% for every 10ºC above 20ºC ambient. Durapipe ABS systems are not recommended for use at temperatures in excess of 70ºC or below minus 40ºC.

Maximum pressure surges Durapipe ABS pipework can withstand pressure surges within the limitations detailed in 312 part:1973 and its amendment dated 1977. On no should pressure surges be allowed to exceed the maximum continuous working pressure calculated using the graph shown earlier.

Interchangeability Components in the imperial and metric ranges are not interchangeable, except for 21/2"/ 75mm and 5"/140mm.

Metal/ABS pipe weight comparison Pipe weight comparison (kg / M) Nominal Pipe Size (mm)

SS Sch. 40

Metal Pipe Carbon Steel Heavy Weight

15

1.28

1.45

1/2

25

Nearest Equivalent ABS Sizes Imperial NB Metric OD

Imperial Class C

ABS Pipe Imperial Class D

20

Imperial Class E

Imperial Class T

Metric

0.13

0.22

0.10

20

1.70

1.90

3/4

0.20

0.28

0.14

25

2.52

2.97

1

32

0.21

0.31

0.43

0.21

32

3.43

3.84

11/4

40

0.32

0.49

0.65

0.33

4.43

11/2

50

0.42

0.64

0.85

0.52

1.28

0.81

40

4.07

50

5.42

6.17

2

63

0.67

1.00

80

11.31

10.10

3

90

1.40

2.16

1.65

100

16.02

14.40

4

110

2.32

3.59

2.45

150

28.22

21.20

6

160

5.12

6.50

Pipe weights taken from: SS Sch. 40 - API Specification 5L for Line Pipe Carbon Steel Heavy Weight - CIBSE Guide Vol. B, Table B16.3 Piping Data

10

Tel: +44 (0)1543 279909

Fax: +44 (0)1543 279450

5.13

Comparison of ABS Imperial and Metric Sized Pipe Please refer to the pipe section in this brochure for pipe sizes available from Durapipe UK.

Tabulated below is a comparison of imperial and metric sized Durapipe ABS pipe. They are produced to different standards, but can be ed together using flanges or adaptors.

Threaded systems Imperial systems Class T ABS pipe can be machined to BSP parallel or BSP taper thread forms. Metric pipe is not produced with an outside diameter suitable for threading.

The systems are also designated differently; the imperial system refers to the nominal bore size; the metric system relates to the outside diameter. Both systems are produced with the outside diameter as the controlled dimension. This enables the same fitting of a particular size to be ed to all classes of pipe in that size.

Imperial System (BS 5391) Size Minimum mean (nominal bore) outside diameter (imperial) (mm) Class B 3/8

Minimum wall thickness (mm) Class C Class D

1 11/4 11/2 2 21/2 3 4

17.0 21.2 26.6 33.4 42.1 48.1 60.2 75.0 88.7 114.1

1.9 2.4 2.7 3.4 4.7 5.0 6.4

5 6

140.0 168.0

8.8 9.4

1/2 3/4

8 218.0 10 272.6 12 323.4 21/2" and 5" pipes are PN10 rated 315mm is rated at PN8

Metric System (BS 5556)

Class E

1.6 1.9 2.4 3.0 3.8 4.4 5.4 8.06 10.3

12.3

12.2 10.5 12.4

email: [email protected]

Class T

3.4 3.5 3.5 4.2 5.1 5.8 7.0

Size Minimum mean outside diameter outside diameter (mm) (mm)

16 20 25 32 40 50 63 75 90 110 125 140 160 200 225 250 315

web: www.durapipe.co.uk

16.0 20.0 25.0 32.0 40.0 50.0 63.0 75.0 90.0 110.0 125.0 140.0 160.0 200.0 225.0 250.0 315.0

Minimum wall thickness (mm) PN6 PN10

9.6 12.1

1.4 1.5 1.8 2.0 2.5 3.2 4.0 4.7 5.7 6.9 7.9 8.8 10.0 12.5 14.1 15.6 19.7

11

Index to ABS Imperial Fittings Note: Two-dimensional Auto-CAD drawings are available on www.durapipe.co.uk

12

Pipe (plain) page 14

Sockets (plain) page 15

‘O’ ring sockets (plain) page 15

Reducing sockets (plain) page 15

Saddles (plain) page 15

Reducing bushes (plain) page 16

Elbows 45° (plain) page 16

Elbows 90° (plain) page 16

Bends 90° short radius (plain) page 17

Bends 90° long radius (plain) page 17

Bends 45° long radius (plain) page 17

Bends 221⁄2° long radius (plain) page 17

Tees 90° (plain) page 18

Tees 90° (reducing) page 18

Tees 90° (swept plain) page 18

Tees 45° (plain) page 18

Caps (plain) page 19

Socket unions (plain) page 19

Socket union plain adaptors page 19

Socket union threaded adaptors page 19

Socket union nuts page 20

Imperial/Metric socket adaptors (plain) page 20

Sockets (plain/threaded) page 20

Reducing bushes (plain/threaded) page 20

Barrel nipples (plain/threaded) page 21

Hexagon nipples (plain/threaded) page 21

Adaptors male (plain)/ female (threaded) page 21

Adaptors female (plain)/ male (threaded) page 21

Adaptors female (plain)/ male (threaded) page 22

Composite unions female brass page 22

Composite unions male brass page 22

Hose adaptors (threaded) page 22

Tank connectors (plain/threaded) page 23

Elbows 90° (plain/threaded) page 23

Sockets (threaded) page 23

Tel: +44 (0)1543 279909

Fax: +44 (0)1543 279450

Hexagon nipples (threaded) page 23

Back nuts (threaded) page 24

Plugs (threaded) page 24

Caps (threaded) page 24

Elbows 90° (threaded) page 24

Reducing bushes (threaded) page 25

Flanges full face (drilled and undrilled) pages 25-26

Flanges stub serrated page 26

Flanges blanking (drilled and undrilled) pages 26-27

Gaskets flat page 27

‘O’ rings page 27

Gaskets full face page 28

Backing rings page 29

Valve plates page 30

Cobra clips page 30

*

Durapipe one-step solvent cement and Eco-cleaner page 31

Saddle clips page 30

*

Air release valves page 33

VK Double union ball valves (manual) page 31

*

Y type strainers page 33

*

*

Single union ball check valves page 33

Multiport ball valves page 32

*

*

VM Diaphragm valves page 34

Pressure relief valves page 34

*

FK Butterfly valves (manual) page 35

* For details of our full range of manual and actuated valves please ask for a copy of Valves Technical Catalogue D0894

email: [email protected]

web: www.durapipe.co.uk

13

ABS Pipe Imperial System

plain

Class B 87psig (6 bar) Size 10 12

Mean OD Thickness d1 t (mm) 273.1 323.9

11.1 13.1

Length

Weight

(m)

kg/m

6 6

9.50 13.30

Code

01 510 114 01 510 115

d1 (mean)

Class C 130psig (9 bar) Size 1 11⁄4 11⁄2 2 21⁄2 3 4 5 6 8

Mean OD d1 33.6 42.2 48.3 60.3 75.2 88.9 114.3 140.2 168.3 219.1

Thickness t (mm) 2.0 2.5 2.8 3.6 5.0 5.2 6.6 9.3 9.9 12.7

Length

Weight

(m) 6 6 6 6 5 6 6 5 6 6

kg/m 0.21 0.32 0.42 0.67 1.14 1.40 2.32 3.97 5.12 8.57

Code

t (mean) 01 511 104 01 511 105 01 511 106 01 511 107 11 555 312 01 511 109 01 511 110 11 555 316 01 511 112 01 511 113

* Note - 21/2" & 5" pipes dimensionally compatible with 75mm and 140mm PN10 Metric series and are manufactured in accordance with the general requirements of DIN 8061/8062.

Class D 173psig (12 bar) Size

Mean OD d1

6

168.3

Thickness t (mm) 12.8

Length

Weight

Code

(m) 6

kg/m 6.50

01 512 112

Length

Weight

Code

(m) 6 6 6 6 6 6 6 6 6

kg/m 0.09 0.13 0.20 0.31 0.49 0.64 1.00 2.16 3.59

Class E 217psig (15 bar) Size 3⁄8 1⁄2 3⁄4

1 11⁄4 11⁄2 2 3 4

Mean OD d1 17.1 21.4 26.7 33.6 42.2 48.3 60.3 88.9 114.3

Thickness t (mm) 1.7 2.0 2.5 3.1 3.9 4.5 5.6 8.3 10.6

01 01 01 01 01 01 01 01 01

513 513 513 513 513 513 513 513 513

101 102 103 104 105 106 107 109 110

Class T 173 psig (12 bar after threading) Size

Length

Weight

Code

(m)

kg/m

3⁄8

17.1

3.5

6

0.16

01 514 101

1⁄2

21.4 26.7 33.6 42.2 48.3 60.3

3.6 3.6 4.3 5.3 6.0 7.2

6 6 6 6 6 6

0.22 0.28 0.43 0.65 0.85 1.28

01 514102 01 514 103 01 514 104 01 514 105 01 514 106 01 514 107

3⁄4

1 11⁄4 11⁄2 2

14

Mean OD Thickness d1 t (mm)

Tel: +44 (0)1543 279909

Fax: +44 (0)1543 279450

Sockets

plain

Size

A

B

Z1

gms

3⁄8

21 26 32 41 52 60 74 88 108 136 171 201 257

32 38 43 50 60 66 78 94 104 135 163 191 249

2 2 3 3 4 2 4 4 4 5 7 9 11

4 6 12 24 41 62 114 230 355 595 1390 2269 3668

1⁄2 3⁄4

1 11⁄4 11⁄2 2 21⁄2 3 4 5 6 8

Code 01 01 01 01 01 01 01 11 01 01 11 01 01

100 100 100 100 100 100 100 100 100 100 100 100 100

101 102 103 104 105 106 107 312 109 110 316 112 113

A

Z1 B

‘O’ ring sockets Size

A

B

C

Z1

Pressure Class

gms

2 3 4 6 8

74 108 136 201 255

78 104 132 191 248

27 37 49 74 94

4 4 6 8 14

D D D C B

111 359 616 2353 3229

Code 01 01 01 01 01

305 305 305 305 305

107 109 110 112 113

A

‘O’ rings EPDM

Z1 C

B

Reducing sockets Size

A

B

C

Z1

gms

x 1⁄2 1 x 3⁄4 11⁄4 x 1 11⁄2 x 11⁄4 2 x 11⁄2 3x2 4x3 6x4 8x6

32 41 52 59 74 108 136 205 256

44 53 63 68 82 114 136 213 263

26 33 41 51 59 75 108 140 198

7 9 10 8 12 26 20 55 50

11 19 39 58 100 320 558 1975 3410

Saddles

plain B

E

Z1

gms

3⁄4

Size

A

2 x 11⁄4 60 136 48 33 90 3 x 11⁄2 76 140 60 46 158 4x2 95 140 74 58 230 6x2 71 154 73 86 225 Two saddles can be mounted diametrically opposite

Code 01 01 01 01 01 01 01 01 01

114 114 114 114 114 114 114 114 114

122 124 125 127 130 135 141 147 152

C

Z1 B

Code 01 01 01 01

126 126 126 126

A

B

129 134 140 146

email: [email protected]

A Z1 pipe centre line

web: www.durapipe.co.uk

E

15

Reducing bushes Size 1⁄2

B

x 3⁄8

plain Z1

17

2

gms 7

3⁄4

x 1⁄2 20 3 8 1 x 1⁄2 23 6 23 1 x 3⁄4 24 4 15 *11⁄4 x 1⁄2 28 12 21 *11⁄4 x 3⁄4 28 8 24 11⁄4 x 1 28 5 20 *11⁄2 x 1⁄2 30 13 26 *11⁄2 x 3⁄4 30 10 37 *11⁄2 x 1 30 7 40 11⁄2 x 11⁄4 31 4 19 *2 x 3⁄4 38 15 45 *2 x 1 38 15 45 *2 x 11⁄4 38 11 57 2 x 11⁄2 37 7 42 21⁄2 x 2 44 8 75 *3 x 11⁄2 51 21 130 *3 x 2 51 15 178 3 x 21⁄2 50 6 126 *4 x 3 65 12 277 5x4 78 15 413 *6 x 4 93 27 666 6x5 90 13 641 *8 x 6 110 23 1185 *Relief configuration (see drawing insert)

Elbows 45° A

C

Z1

gms

3⁄8

21 27 33 41 52 60 82 90 112 139 173 198 259

20 26 33 37 44 50 66 63 94 115 115 134 182

6 8 12 13 15 18 27 17 40 50 37 41 65

8 9 15 25 59 86 160 300 750 1300 1980 2390 5620

3⁄4

1 11⁄4 11⁄2 2 21⁄2 3 4 5 6 8

Elbows 90° A

C

Z1

gms

3⁄8

21 26 32 41 52 60 74 90 111 141 173 203 256

24 29 34 41 49 56 68 83 104 130 153 175 251

9 12 14 17 21 26 31 38 52 65 76 85 112

6 11 19 35 70 101 191 385 720 1505 2390 4075 6900

3⁄4

1 11⁄4 11⁄2 2 21⁄2 3 4 5 6 8

16

109 122 109 123 109 124 109 116 109 117 109 125 109 118 109 119 109 126 109 127 109 120 109 128 109 129 109 130 109 131 109 134 109 135 109 136 109 141 329 142 109 147 329 148 109 152

01 01 01 01 01 01 01 11 01 01 11 01 01

119 119 119 119 119 119 119 119 119 119 119 119 119

;; ;; ;;;; Z1

B

Code 101 102 103 104 105 106 107 312 109 110 316 112 113

Z1 C A

plain

Size 1⁄2

01 01 01 01 01 01 01 01 01 01 01 01 01 01 01 01 01 01 01 01 01 01 01

plain

Size 1⁄2

Code 01 109 121

Code 01 01 01 01 01 01 01 11 01 01 11 01 01

115 115 115 115 115 115 115 115 115 115 115 115 115

101 102 103 104 105 106 107 312 109 110 316 112 113

Tel: +44 (0)1543 279909

Z1 C

A

Fax: +44 (0)1543 279450

Bends 90°

short radius plain

Size

A

C

Z1

gms

1⁄2

26 33 40 51 62 73 93 111 140

56 65 85 108 134 165 195 226 280

43 45 63 81 102 126 150 172 216

20 45 65 130 290 560 810 1445 2400

01 01 01 01 01 01 11 01 01

118 118 118 118 118 118 118 118 118

gms 1535 3440 6696 9430 19070 29372 39305

01 01 11 01 01 01 01

Code 309 109 309 110 309 316 309 112 309 113 309 114 309 115

3⁄4

1 11⁄4 11⁄2 2 21⁄2 3 4

Bends 90° Size 3 4 5 6 8 10 12

Code 102 103 104 105 106 107 312 109 110

Z1 C

A

long radius plain

C 403 545 840 817 1174 1550 1754

E 98 138 280 207 362 534 534

R 305 407 560 610 812 1016 1220

R

C E

Tolerance on angle ±3°

Bends 45° Size

long radius plain

C

E

1 75 37 11⁄2 113 55 2 152 73 21⁄2 300 113 3 238 121 4 300 145 5 512 280 6 440 218 8 592 280 10 940 520 12 1030 520 Tolerance on angle ±3°

R

gms

102 152 203 300 305 407 560 610 812 1016 1220

51 156 322 429 1100 2290 5315 6290 11440 20289 26348

Bends 221⁄2°

long radius

Size

E

1 11⁄2 2 21⁄2 3 4 5 6 8 10 12 Tolerance on

C

76 38 110 57 113 73 172 112 202 114 262 152 322 210 385 229 503 305 711 508 750 508 angle ±3°

R

gms

102 152 203 300 305 407 560 610 812 1016 1220

46 143 274 319 857 1886 2513 5154 8962 15607 19702

C

Code 01 01 01 11 01 01 11 01 01 01 01

310 310 310 310 310 310 310 310 310 310 310

104 106 107 312 109 110 316 112 113 114 115

R

E

C

Code 01 01 01 11 01 01 11 01 01 01 01

311 311 311 311 311 311 311 311 311 311 311

104 106 107 312 109 110 316 112 113 114 115

email: [email protected]

R

E

web: www.durapipe.co.uk

17

Tees 90° plain Size 3⁄8 1⁄2 3⁄4

1 11⁄4 11⁄2 2 21⁄2 3 4 5 6 8

A

B

C

Z1

gms

21 26 32 41 52 59 74 90 113 143 172 205 257

49 58 69 83 101 113 137 172 204 244 307 355 468

25 29 34 42 50 53 70 87 105 121 153 175 240

10 11 15 19 23 25 31 36 44 54 72 88 100

7 13 23 43 92 133 249 510 926 1960 3200 4449 9600

Code 01 01 01 01 01 01 01 11 01 01 11 01 01

122 122 122 122 122 122 122 122 122 122 122 122 122

101 102 103 104 105 106 107 312 109 110 316 112 113

A Z1

B

Z1 C

Tees 90° reducing Size 3⁄4 x 1⁄2

1 1

x 1⁄2 x 3⁄4

A

A

B

C

D

Z1

gms

Code

32 40 40

64 70 76

32 36 38

26 26 32

17 17 20

22 40 41

01 124 122 01 124 123 01 124 124

D Z1

B

Z1 C

Tees 90° swept plain Size

A

1 41 11⁄2 62 2 78 21⁄2 92 4 139

B

C

115 160 195 210 315

79 105 125 125 190

D

Z1

Z2

79 57 57 105 74 74 125 87 87 125 81 81 190 127 127

Z3

gms

14 24 32 41 62

85 285 515 601 2080

A

Code 01 01 01 11 01

148 148 148 148 148

104 106 107 312 110

Swept tees are Class C rated

D

;;;; ;;;; ;;;; ;;;; ;;;; ;;;; ;;;; Z1

; ; ; ; ; ; ;

Z3 B Z2

C

Tees 45° plain Size

A

1⁄2

28 33 41 50 60 74

3⁄4

1 11⁄4 11⁄2 2

B

C

68 44 81 52 97 63 117 80 140 97 170 113

Z1

Z2

Z3

gms

34 41 49 61 80 90

27 32 39 52 67 73

7 8 9 10 12 15

30 45 80 194 298 546

Code 01 01 01 01 01 01

128 128 128 128 128 128

C

102 103 104 105 106 107

Z2

A Z3 Z1 B

18

Tel: +44 (0)1543 279909

Fax: +44 (0)1543 279450

Caps

plain

Size

A

B

gms

3⁄8

21 17 1⁄2 26 22 3⁄4 32 25 1 40 30 11⁄4 52 35 11⁄2 59 39 2 74 47 *21⁄2 94 59 3 109 65 4 136 84 * 21/2" End Cap PN10 rated

Socket unions

Code

3 5 9 20 33 48 90 180 268 465

01 01 01 01 01 01 01 11 01 01

A

B

Z1

Z2

gms

3⁄8

38 46 52 63 72 80 101 135 155 180

44 49 55 65 77 92 112 107 113 138

5 5 5 7 10 13 15 8 6 7

10 10 10 12 14 16 19 13 4 6

25 36 51 86 122 160 297 610 750 1155

3⁄4

101 102 103 104 105 106 107 312 109 110

A

B

plain

Size 1⁄2

140 140 140 140 140 140 140 149 140 140

1 11⁄4 11⁄2 2 *21⁄2 3 4 * 21/2" PN10 3" and 4" are Class C EPDM seal as standard For FPM seal order by type 204

Code 01 01 01 01 01 01 01 11 01 01

205 205 205 205 205 205 205 205 205 205

101 102 103 104 105 106 107 312 109 110

A

Z2

Z1 B

Socket union plain adaptors Size

A

B

gms

3⁄8

23 28 34 43 53 58 74

19 22 25 30 38 44 53

5 7 11 21 37 48 82

1⁄2 3⁄4

1 11⁄4 11⁄2 2

Code 01 01 01 01 01 01 01

206 206 206 206 206 206 206

101 102 103 104 105 106 107

A

B

Socket union threaded adaptors Size

A

B

gms

3⁄8

21 25 29 42 55 61 76

23 26 32 34 39 46 58

10 14 22 36 46 61 112

1⁄2 3⁄4

1 11⁄4 11⁄2 2

Code 01 01 01 01 01 01 01

207 207 207 207 207 201 207

101 102 103 104 105 106 107

email: [email protected]

A

B

web: www.durapipe.co.uk

19

Socket union nuts Size 3⁄8 1⁄2 3⁄4

1 11⁄4 11⁄2 2

A

B

gms

39 43 51 64 72 79 102

23 25 27 29 26 23 32

10 14 20 32 39 51 96

Code 01 01 01 01 01 01 01

208 208 208 208 208 208 208

101 102 103 104 105 106 107

A

B

Imperial/metric socket adaptors Size 1⁄2

x 20 3⁄4 x 25 1 x 32 11⁄4 x 40 11⁄2 x 50 2 x 63 3 x 90 4 x 110 6 x 160

Sockets

A

B

Z1

gms

26 31 40 50 59 74 107 134 195

37 41 49 58 67 78 105 130 183

3 3 3 2 3 2 3 6 8

7 12 25 45 62 114 355 690 1660

A

B

C

Z1

gms

1⁄2

27 33 42 52 60 75 110

38 44 51 55 61 70 107

17 20 23 22 26 29 52

4 2 5 4 2 2 3

8 14 30 46 65 114 378

1 11⁄4 11⁄2 2 3

Code 11 11 11 11 11 11 11 11 11

345 345 345 345 345 345 345 345 345

102 103 104 105 106 107 109 110 112

A

Z1 B

plain/BSP taper threaded

Size 3⁄4

plain

Code 01 01 01 01 01 01 01

101 101 101 101 101 101 101

102 103 104 105 106 107 109

A

Z1 C B

Reducing bushes Size 1⁄2

x 3⁄8 3⁄4 x 1⁄2 1 x 3⁄4

plain/BSP taper threaded

B

Z1

gms

Code

17 20 23

6 5 6

4 7 12

01 111 121 01 111 122 01 111 124

Z1

20

Tel: +44 (0)1543 279909

Fax: +44 (0)1543 279450

B

Barrel nipples

plain/BSP taper threaded

Size

B

D

gms

Code

3 4

128 153

30 36

252 525

01 316 109 01 316 110

D B

Hexagon nipples

male plain/BSP taper threaded

Size

A

B

D

gms

3⁄8

24 30 36 46 46 55 72

36 42 48 56 60 63 74

11 15 16 20 21 22 26

7 12 30 40 50 58 91

1⁄2 3⁄4

1 11⁄4 11⁄2 2

Code 01 01 01 01 01 01 01

107 107 107 107 107 107 107

101 102 103 104 105 106 107

A(A/F)

D B

Adaptors male/female

plain/BSP taper threaded

Size

A

B

Z1

gms

1⁄2

27 36 43 55 63 78

38 44 50 60 66 78

16 18 21 22 25 29

8 14 24 49 68 129

3⁄4

1 11⁄4 11⁄2 2

Code 01 01 01 01 01 01

153 153 153 153 153 153

102 103 104 105 106 107

A

Z1 B

Adaptors female/male

plain/BSP taper threaded

Size

A

B

D

Z1

gms

Code

3⁄8

22 27 35

35 45 48

10 12 14

20 28 28

5 9 14

01 151 101 01 151 102 01 151 103

1⁄2 3⁄4

A

D Z1 B

email: [email protected]

web: www.durapipe.co.uk

21

Adaptors female/male Size 1 11⁄4 11⁄2 2

plain/BSP taper threaded

A

B

D

Z1

gms

46 56 72 80

58 66 75 85

19 22 22 26

35 38 43 46

36 70 115 150

Code 01 01 01 01

151 151 151 151

104 105 106 107

A(A/F)

D Z1 B

Composite unions Size

A

B

plain/BSP parallel threaded female brass

Z1

1⁄2

40 42 3 3⁄4 48 49 3 1 55 59 11 11⁄4 65 68 9 11⁄2 79 75 12 2 88 90 14 Fitted with brass retaining nut Brass material to BS2872, WRAS

Z2

gms

7 9 12 10 14 14

165 290 310 450 800 950

Code 01 01 01 01 01 01

212 212 212 212 212 212

102 103 104 105 106 107

A(A/F)

Z1 approved

Z2 B

Composite unions Size

A

B

plain/BSP taper threaded male brass

Z1

gms

Code

1⁄2

40 54 3 175 3⁄4 48 74 3 320 1 55 86 8 420 11⁄4 65 94 10 620 11⁄2 78 108 13 1000 2 88 129 15 1200 Fitted with brass retaining nut. Brass material to BS2872, WRAS approved

Hose adaptors

01 01 01 01 01 01

217 217 217 217 217 217

102 103 104 105 106 107

BSP threaded

A

B

C

D

E

gms

Code

1⁄2

26 28 40

60 66 73

41 41 46

13 16 19

14 20 27

8 15 28

01 157 102 01 157 103 01 157 104

1

Z1 B

Size 3⁄4

A(A/F)

A(A/F)

E

C

D B

22

Tel: +44 (0)1543 279909

Fax: +44 (0)1543 279450

Tank connectors

plain/BSP threaded

Size

A

B

C

D

F

gms

Code

1⁄2

28 33

70 77

38 38

28 38

15 21

26 30

01 235 102 01 235 103

3⁄4

F A(A/F) C

D B

Elbows 90°

plain/BSP taper threaded

Size

A

C

Z1

gms

1⁄2

26 32 40 62 75

34 36 41 57 66

17 20 23 30 35

26 34 63 136 203

3⁄4

1 11⁄2 2

Code 01 01 01 01 01

116 116 116 116 116

102 103 104 106 107

Z1 C Z1 A

Sockets

plain/BSP taper threaded

Size

A

B

gms

1⁄2

26 33 41 51 62 75 110

38 43 51 54 63 72 107

12 22 34 60 87 132 437

3⁄4

1 11⁄4 11⁄2 2 3

Code 01 01 01 01 01 01 01

102 102 102 102 102 102 102

102 103 104 105 106 107 109

A

B

Hexagon nipples

plain/BSP taper threaded

Size

A

B

D

gms

3⁄8

24 30 36 46 46 55 72

38 46 50 59 67 73 81

14 18 19 13 27 29 33

6 12 30 40 55 75 125

1⁄2 3⁄4

1 11⁄4 11⁄2 2

Code 01 01 01 01 01 01 01

106 106 106 106 106 106 106

101 102 103 104 105 106 107

A(A/F)

D B

email: [email protected]

web: www.durapipe.co.uk

23

Back nuts

BSP threaded

Size

A

B

C

gms

3⁄8

25 28 33 45 50 60 79

11 13 13 16 18 19 21

29 38 38 54 58 69 91

5 8 15 18 19 31 65

1⁄2 3⁄4

1 11⁄4 11⁄2 2

Plugs

A

B

D

gms

3⁄8

11 13 14 17 22 27 37

19 23 28 30 35 38 45

10 14 15 17 22 22 26

3 5 8 12 30 36 50

3⁄4

1 11⁄4 11⁄2 2

159 159 159 159 159 159 159

01 01 01 01 01 01 01

155 155 155 155 155 155 155

101 102 103 104 105 106 107

C A(A/F)

B

plain/BSP taper threaded

Size 1⁄2

Code 01 01 01 01 01 01 01

Code 101 102 103 104 105 106 107

A(A/F)

D B

Caps

plain/BSP taper threaded

Size

A

B

D

gms

3⁄8

26 27 36 44 55 63 78 111

20 20 23 28 31 35 40 65

16 16 17 21 22 25 28 53

5 6 10 18 33 50 90 262

1⁄2 3⁄4

1 11⁄4 11⁄2 2 3

Elbows 90° A

C

Z1

gms

1⁄2

26 32 41 63 75

29 33 41 57 67

17 19 23 30 35

27 39 65 141 212

1 11⁄2 2

141 141 141 141 141 141 141 141

101 102 103 104 105 106 107 109

A

D B

plain/BSP taper threaded

Size 3⁄4

Code 01 01 01 01 01 01 01 01

Code 01 01 01 01 01

117 117 117 117 117

102 103 104 106 107

Z1 C

A

24

Tel: +44 (0)1543 279909

Fax: +44 (0)1543 279450

Reducing bushes Size

A

BSP threaded

B

D

gms

Code

x 3⁄8 24 25 3⁄4 x 1⁄2 30 27 1 x 3⁄4 36 31 Male thread taper Female thread parallel

10 11 12

5 10 13

01 113 121 01 113 122 01 113 124

1⁄2

A(A/F)

D B

Flanges full face

plain/drilled

BS10 Table D/E Size

A

B

1⁄2

96 21 3⁄4 105 24 1 115 27 11⁄4 140 33 11⁄2 150 37 2 166 45 3 199 60 *4 220 72 6 284 98 *4" BS10 Table D

D 10 10 10 10 10 10 11 14 22 has 4

Z1 P.C.D. 4 4 4 5 5 6 8 6 8 holes

No. of Holes

Hole Diameter

gms

Code

67 4 14 68 01 73 4 14 78 01 83 4 14 107 01 87 4 14 122 01 98 4 14 154 01 115 4 18 223 01 145 4 18 398 01 178 8 18 638 01 235 8 22 1340 01 and should be ordered as 01 317 110

130 130 130 130 130 130 130 130 130

102 103 104 105 106 107 109 110 112

A

Z1 D

BS4504 Table 16/3-10/3 Size

A

B

D

Z1 P.C.D.

1⁄2

96 105 115 140 150 166 199 220 284

21 24 27 33 37 45 60 72 98

10 10 10 10 10 10 11 14 22

4 4 4 5 5 6 8 6 8

3⁄4

1 11⁄4 11⁄2 2 3 4 6

65 75 85 100 110 125 160 180 240

B

No. of Holes

Hole Diameter

gms

4 4 4 4 4 4 8 8 8

14 14 14 18 18 18 18 18 22

68 78 107 122 154 223 398 638 1340

No. of Holes

Hole Diameter

gms

4 4 4 4 4 4 8 8

14 14 14 14 18 18 18 22

68 78 107 154 223 398 638 1340

Code 01 01 01 01 01 01 01 01 01

319 319 319 319 319 319 319 319 319

102 103 104 105 106 107 109 110 112

ANSI Class 150 Size

A

B

D

Z1 P.C.D.

1⁄2

96 105 115 150 166 199 220 284

21 24 27 37 45 60 72 98

10 10 10 10 10 11 14 22

4 4 4 5 6 8 6 8

3⁄4

1 11⁄2 2 3 4 6

60 70 80 98 121 152 190 241

Code 01 01 01 01 01 01 01 01

322 322 322 322 322 322 322 322

102 103 104 106 107 109 110 112

Note: Durapipe backing rings must be used in conjunction with full face flanges

email: [email protected]

web: www.durapipe.co.uk

25

Flanges full face

plain/undrilled

Size

A

B

D

Z1

gms

1⁄2

96 105 115 140 150 165 199 220 284

21 24 27 32 36 45 60 73 99

10 10 10 10 10 11 11 14 22

4 4 4 4 5 6 8 6 8

75 85 111 130 160 233 414 657 1417

3⁄4

1 11⁄4 11⁄2 2 3 4 6

Code 01 01 01 01 01 01 01 01 01

129 129 129 129 129 129 129 129 129

102 103 104 105 106 107 109 110 112

A

Z1 Note: Durapipe backing rings must be used in conjunction with full face flanges

Flanges Size

B

stub serrated

A

2 21⁄2 3 4 5 6 8 *10 *12 *Taper back

D

B

D

Z1

96 40 14 3 106 49 10 4 127 57 18 6 159 69 20 6 180 83 14 7 213 104 24 11 269 132 26 14 326 155 29 8 378 178 33 9 flange (see drawing insert)

gms 90 150 200 350 680 805 2075 2650 3900

Code 01 11 01 01 11 01 01 01 01

135 135 135 135 135 135 135 139 139

107 312 109 110 316 112 113 114 115

A

Z1 D B

Flanges blanking

drilled

BS10 Table D/E Size A 2 165 3 197 *4 214 6 286 8 337 *4" BS10 Table

No. of Hole B P.C.D. Holes Diameter gms 13 115 4 18 235 19 145 4 18 520 19 178 8 18 720 26 235 8 22 1575 26 292 8 22 2300 D has 4 holes and should be ordered as 01

Code 01 313 107 01 313 109 01 313 110 01 313 112 01 313 113 326 110

A

BS4504 Table 16/3 (1⁄2" to 8") 10/3 (1⁄2" to 6") Size 2 21⁄2 3 4 5 6 8

A 165 186 197 214 251 286 337

B 13 19 19 19 26 26 26

P.C.D. 125 145 160 180 210 240 295

No. of Holes 4 4 8 8 8 8 12

Hole Diameter 18 18 18 18 18 22 22

gms 235 568 520 720 1338 1575 2300

01 11 01 01 11 01 01

Code 323 107 323 312 323 109 323 110 323 316 323 112 323 113

No. of Holes 4 4 8 8 8

Hole Diameter 18 18 18 22 22

gms 235 520 720 1575 2300

01 01 01 01 01

Code 325 107 325 109 325 110 325 112 325 113

B

ANSI Class 150 Size 2 3 4 6 8

A 165 197 214 286 337

B 13 19 19 26 26

P.C.D. 121 152 190 241 298

Note: Durapipe backing rings must be used in conjunction with blank flanges

26

Tel: +44 (0)1543 279909

Fax: +44 (0)1543 279450

Flanges blanking Size 1 11⁄2 2 3 4 6 8

undrilled

A

B

gms

116 150 166 197 214 286 337

13 13 13 19 19 26 26

140 185 235 520 720 1575 2300

Code 01 01 01 01 01 01 01

131 131 131 131 131 131 131

104 106 107 109 110 112 113

A

Note: Durapipe backing rings must be used in conjunction with blank flanges

B

Gaskets flat Size 2 21⁄2 3 4 5 6 8 10 12

stub flange EPDM

A

B

gms

97 106 128 160 180 214 269 327 378

3.0 3.0 3.0 3.9 4.0 3.9 4.0 4.1 3.9

21 22 23 36 60 74 92 186 218

Code 03 13 03 03 13 03 03 03 03

431 411 431 431 411 431 431 411 411

107 312 109 110 316 112 113 114 115

A

B

‘O’ ring for socket union Size

B

gms

3⁄8

3.5 3.5 3.5 3.5 5.2 5.2 5.3 5.3 5.0 4.9

0.5 1 2 3 5 6 7 3 5 6

1⁄2 3⁄4

1 11⁄4 11⁄2 2 21⁄2 3 4

03 03 03 03 03 03 03 13 03 03

EPDM Code

Viton (FPM) Code

209 209 209 209 209 209 209 209 209 209

03 03 03 03 03 03 03 13 03 03

101 102 103 104 105 106 107 312 109 110

211 211 211 211 211 211 211 211 211 211

101 102 103 104 105 106 107 312 109 110

B

email: [email protected]

web: www.durapipe.co.uk

27

Gaskets full face

drilled EPDM

BS10 Table D/E Size 1⁄ 2 3⁄ 4

1 11⁄4 11⁄2 2 3 *4 6

A

B

P.C.D.

No. of Holes

Hole Diameter

gms

95 112 115 121 133 153 184 216 250

3.0 3.0 3.0 3.0 3.0 3.0 3.0 3.2 3.1

67 73 83 87 98 115 145 178 235

4 4 4 4 4 4 4 8 8

14 14 14 14 14 18 18 18 22

31 37 37 41 55 56 98 112 160

Code 03 03 03 03 03 03 03 03 03

410 410 410 410 410 410 410 410 410

102 103 104 105 106 107 109 110 112

A

*4" BS10 Table D has 4 holes and should be ordered as 03 409 110

B

BS4504 Table 16/3-10/3 Size

A

B

P.C.D.

No. of Holes

Hole Diameter

gms

1⁄ 2 3⁄ 4

95 112 115 121 133 153 184 216 280

3.0 3.0 3.0 3.0 3.0 3.0 3.0 3.2 3.1

65 75 85 100 110 125 160 180 240

4 4 4 4 4 4 8 8 8

14 14 14 18 18 18 18 18 22

31 37 37 41 55 56 98 112 160

03 03 03 03 03 03 03 03 03

408 408 408 408 408 408 408 408 408

P.C.D. 60 70 80 98 121 152 190 241

No. of Holes 4 4 4 4 4 4 8 8

Hole Diameter 14 14 14 14 18 18 18 22

gms 31 37 37 55 56 98 112 160

03 03 03 03 03 03 03 03

Code 426 102 426 103 426 104 426 106 426 107 426 109 426 110 426 112

1 11⁄4 11⁄2 2 3 4 6

Code 102 103 104 105 106 107 109 110 112

ANSI Class 150 Size 1⁄ 2 3⁄ 4 1 11⁄2 2 3 4 6

28

A 95 112 115 133 153 184 216 280

B 3.0 3.0 3.0 3.0 3.0 3.0 3.2 3.1

Tel: +44 (0)1543 279909

Fax: +44 (0)1543 279450

Backing rings

galvanised mild steel drilled

BS10 Table D/E Hole Dia.

Bolt Size

Weight gms

Code

4

14

M12x50

270

03 416 102

73

4

14

M12x50

300

03 416 103

83

4

14

M12x50

380

03 416 104

87

4

14

M12x50

380

03 416 105

68

98

4

14

M12x50

480

03 416 106

78

115

4

18

M16x65

880

03 416 107

8

92

127

4

18

M16x65

-

31 416 312

9

110

145

4

18

M16x70

1040

03 416 109

216

9

140

178

8

18

M16x80

1330

03 416 110

282

11

195

235

8

22

M20x90

2340

03 416 112

8

340

10

255

292

8

22

M20x100

2870

03 416 113

†10

405

15

308

356

12

22

M20x130

5870

03 407 114

12

458

21

364

406

12

26

M24x150

8990

03 407 115

Size

A

B

D

K

1⁄ 2

89

6

35

67

3⁄ 4

103

7

45

1

114

6

49

11⁄4

120

7

60

11⁄2

135

7

2

153

8

21⁄2

165

3

187

*4 6

No. of Holes

K

A

D

B

*4" BS10 Table D has 4 holes and should be ordered as 03 415 110 †10" only available in BS10 Table E drilling. The bore of the 10" and 12" backing rings is machined to mate with the taper of the stub flanges

BS4504 Table 16/3 (1⁄2" to 12") 10/3 (1⁄2" to 6") Hole Dia.

Bolt Size

Weight gms

Code

4

14

M12x50

310

03 421 102

75

4

14

M12x50

330

03 421 103

85

4

14

M12x50

390

03 421 104

60

100

4

18

M16x50

580

03 421 105

6

68

110

4

18

M16x50

880

03 421 106

8

78

125

4

18

M16x65

1020

03 421 107

186

9

92

145

4

18

M16x65

1280

13 421 312

3

200

8

110

160

8

18

M16x70

1310

03 421 109

4

221

8

140

180

8

18

M16x80

1370

03 421 110

5

251

11

167

210

8

18

M16x90

2060

13 421 316

6

286

11

195

240

8

22

M20x90

2460

03 421 112

8

339

11

255

295

12

22

M20x100

2780

03 421 113

10

405

15

308

355

12

26

M24x130

5850

03 403 114

12

458

21

364

410

12

26

M24x150

8990

03 407 115

Size

A

B

D

K

1⁄ 2

96

6

35

65

3⁄ 4

106

6

45

1

114

6

49

11⁄4

141

6

11⁄2

153

2

165

21⁄2

No. of Holes

BS4504 Table 10/3 (8") Size 8

A

B

D

K

No. of Holes

Hole Dia.

Bolt Size

Weight gms

Code

339

11

255

295

8

22

M20x100

2870

04 996 131

Note: The 8" backing ring drilled 10/3 is intended for use in conjunction with the 8" FK Butterfly valve.

ANSI Class 150 Size 1⁄ 2

A

B

D

K

No. of Holes

Hole Dia.

Bolt Size

Weight gms

Code

89

6

35

60

4

14

M12x50

240

03 425 102

3⁄ 4

98

6

45

70

4

14

M12x50

270

03 425 103

1

108

6

49

80

4

14

M12x50

330

03 425 104

11⁄4

118

6

60

90

4

14

M12x50

400

03 425 105

11⁄2

128

6

68

98

4

14

M12x50

420

03 425 106

2

153

8

78

121

4

18

M16x65

790

03 425 107

3

191

8

110

152

4

18

M16x65

1200

03 425 109

4

230

9

140

190

8

18

M16x70

1580

03 425 110

6

280

11

195

241

8

22

M20x90

2230

03 425 112

8

340

12

255

298

8

22

M20x100

3060

03 425 113

email: [email protected]

web: www.durapipe.co.uk

29

Valve plates

galvanised mild steel drilled

BS4504 Table 16/3 (1⁄2" to 8") 10/3 (1⁄2" to 6") Size

B

1⁄2

95 106 1 143 11⁄4 152 11⁄2 151 2 166 21⁄2 185 3 201 4 222 6 286 8 340 N = No. of holes 3⁄4

C

E

L

M

N

Weight gms

86 89 99 105 105 127 144 143 161 217 242 in base

50 75 75 75 74 101 125 127 151 228 280

14 14 14 14 14 14 14 14 14 14 14

16 16 16 16 16 17 22 22 24 33 31

2 2 2 2 2 2 2 2 3 3 3

370 450 560 950 1150 1380 2500 1650 2550 4100 6250

Cobra pipe clips

Code 03 03 03 03 03 03 31 03 03 03 03

458 458 458 458 458 458 459 458 458 458 458

102 103 104 105 106 107 312 109 110 112 113

C

L E B

Polypropylene

Size

A

B

C

D

G

Bolt/Screw size

gms

Code

3⁄ 8 1⁄ 2 3⁄ 4

– – – – 75 85 102 122 148 171 211 243

35 35 35 40 45 50 60 70 80 90 156 170

25 30 35 40 45 50 60 70 90 96 132 150

19 14 16 17 20 22 19 27 39 36 40 40

16 16 17 17 20 21 21 31 31 35 40 40

M.4/3BA/No 8 M.5/1BA/No 10 M.5/1BA/No 10 M.5/1BA/No 10 M.5/1BA/No 10 M.6/0BA/No 10 M.6/0BA/No 10 M.8 M.8 M.8 M.8 M.8

7 8 11 14 21 30 42 94 121 185 252 330

13 434 305 13 434 306 13 434 307 13 434 308 13 434 309 13 434 310 13 434 311 13 434 312 13 434 313 13 434 314 13 434 316 13 434 317

1 11⁄4 11⁄2 2 21⁄2 3 4 5 6

M

A C D G

B

Clips of size 1" and above are fitted with retaining strap Bolts/screws not supplied

Saddle clips

Polypropylene

Size

C

E

F

G

Bolt/Screw size

gms

3⁄ 8 1⁄ 2 3⁄ 4

13 18 21 23 29 34 38 50 65

37 41 45 56 65 67 87 122 156

– – – – – – – 8 13

14 14 16 16 16 16 22 34 38

M.4/3BA/No 8 M.4/3BA/No 8 M.5/2BA/No 10 M.5/2BA/No 10 M.5/2BA/No 10 M.5/2BA/No 10 M.6/0BA/No 12 M.10/3⁄8UNC M.10/3⁄8UNC

3 4 6 7 11 12 25 45 70

1 11⁄4 11⁄2 2 3 4

Code 03 03 03 03 03 03 03 03 03

455 101 455 102 455 103 455 104 455 105 455 106 455 107 455 109 455 110

C F G

Backing plate shown dotted supplied with 3" and 4" only Bolts/screws not supplied Bolt holes in 3" and 4" clips are not countersunk

30

Tel: +44 (0)1543 279909

Fax: +44 (0)1543 279450

E

Durapipe one-step solvent cement and Eco-cleaner gms ABS cement Eco-cleaner

Litres 125ml* 0.5 1.0

500 1100

Code ABS cement 03 461 394 03 461 395 03 461 396

500 –

Code Eco-cleaner 03 457 395 –

* 125ml size with roller-applicator Only Durapipe ABS solvent cement should be used for ting of ABS pipework systems

VK Double union ball valves Manual – EPDM seals d

DN

PN

L

Z

H

E

B

C

g

Code Plain

3/8 1/2 3/4

1 11/4 11/2 2 21/2 3 4

10 15 20

16 16 16

14.5 16.5 19

74 70 77

103 103 115

55 55 66

49 49 59

66 66 75

25 32 40

16 16 16

22.5 83 26 94 30 104

128 146 164

75 87 100

66 75 87

85 97 110

50 65

16 10

36 44

127 147

199 235

122 101 134 154 124 235

80 100

10 10

51 63

168 182

270 308

189 142 285 221 166 335

Threaded

195 H0 VKA 101 195 H0 VKA 102 315 H0 VKA 103 435 H0 VKA 104 655 H0 VKA 105 880 H0 VKA 106 1560 H0 VKA 107 2945 H0 VKA 312 4935 H0 VKA 109 7750 H0 VKA 110

H0 VKA B02 H0 VKA B03 H0 H0 H0 H0 H0 H0 H0

VKA VKA VKA VKA VKA VKA VKA

B04 B05 B06 B07 B08 B09 B10

Options: FPM seals (plain ends) FPM seals (threaded ends)

order H0 VKB *** order H0 VKB ***

Manual valves can be supplied with locking kits - further information is available from our Valve Department.

email: [email protected]

web: www.durapipe.co.uk

31

Multiport ball valves

Plain FPM – L port D

Size

Z

Z1

A

B

D

E

H

gms

Code

3⁄8

68 68 79

49 49 66

48 48 59

101 101 118

58 58 66

65 65 85

117 117 148

236 221 375

H0 MLB 101 H0 MLB 102 H0 MLB 103

89 104 107 125

74 82 98 109

69 81 96 113

134 158 167 197

67 78 88 88

97 109 128 145

163 185 228 248

554 809 1180 1828

1⁄2 3⁄4

1 11⁄4 11⁄2 2

H0 H0 H0 H0

MLB MLB MLB MLB

104 105 106 107

H A Z1 E Z

Options: Plain FPM Threaded FPM

L Port HO MLB *** HO MLB B**

T Port H0 MTB *** H0 MTB B**

C Port H0 MCB *** H0 MCB B**

B

Manual valves can be supplied with locking kits - further information is available from our Valve Department.

Position 1 90º

Position 2 180º

Position 3 180º

Operation

L

Diverting and isolating

T

Diverting or mixing

C

Diverting and mixing (has transflow position 10º to 80º)

= flow

32

Tel: +44 (0)1543 279909

Fax: +44 (0)1543 279450

Single union ball check valves

Plain ends – EPDM seals

Size

Z

A

B

gms

3⁄ 8 1⁄ 2 3⁄ 4

62

48

95

109

Code

62

48

95

100

H0 SRA 102

73

59

112

165

H0 SRA 103

H0 SRA 101

1

79

69

124

250

H0 SRA 104

11⁄4

94

96

148

610

H0 SRA 105

11⁄2

88

96

148

575

H0 SRA 106

2

105

103

177

798

H0 SRA 107

3

114

178

215

2757

H0 SRA 109

A

Z B

Options: EPDM seals (threaded ends) order H0 SRA B** FPM seals (plain ends) order H0 SRB *** FPM seals (threaded ends) order H0 SRB B** Note: Threaded version incorporates threaded union adaptor only - socket end to body of valve plain.

Air release valves

Plain ends – FPM seals A

Size

Z

A

B

gms

Code

3⁄ 8 1⁄ 2 3⁄ 4

62

48

95

109

H0 VAB 101

62

48

95

100

H0 VAB 102

73

59

112

165

H0 VAB 103

1

79

69

124

250

H0 VAB 104

11⁄4

94

96

148

610

H0 VAB 105

11⁄2

88

96

148

575

H0 VAB 106

105

103

177

798

H0 VAB 107

2

B

Z

Options: FPM seals (threaded ends) order H0 VAB B** Note: Threaded version incorporates threaded union adaptor only - socket end to body of valve plain.

Y type strainer Plain ends – EPDM seals Z

Z1

A

B

C

E

Code

B

1⁄ 2

40

54

30

84

48

110

66

88

H0 RVA 102

Z1

3⁄ 4

47

64

36

97

50

130

77

120

H0 RVA 103

1

53

68

44

110

62

150

90

196

H0 RVA 104

11⁄4

90

99

61

154

85

210

122

528

H0 RVA 105

11⁄2

83

99

61

154

85

210

122

450

H0 RVA 106

104

122

77

180

95

265

144

685

H0 RVA 107

Size

2

H

gms

(THREADED)

Z A E

H0 RVA B** H0 RVB *** H0 RVB B**

email: [email protected]

H

C

Options: EPDM seals (threaded ends) order FPM seals (plain ends) order FPM seals (threaded ends) order

web: www.durapipe.co.uk

33

VM Diaphragm valves Manual – plain d

DN

PN

B

B1

H

1/2

15 20 25 32 40

10 10 10 10 10

95 95 95 126 126

26 26 26 40 40

124 144 154 174 194

50 65

10 10

148 40 225 55

224 18 140 44.5 M8 39 284 23 215 100 M12 44

80 10 100 10

225 55 295 69

300 23 215 100 M12 51 7000 H0 VMA 209 350 23 250 120 M12 - 10500 H0 VMA 210

3/4

1 11/4 11/2 2 21/2 3 4

Options: FPM diaphragm order PTFE diaphragm order

h

H1

I

spigot ends EPDM

12 90 25 12 90 25 12 90 25 18 115 44.5 18 115 44.5

J

L

M6 M6 M6 M8 M8

16 19 23 27 32

g 700 700 700 1500 1500

Code H0 H0 H0 H0 H0

VMA VMA VMA VMA VMA

202 203 204 205 206

2400 H0 VMA 207 7000 H0 VMA 208

H0 VMB *** H0 VMC ***

Manual valves can be supplied with locking kits - further information is available from our Valve Department.

Pressure relief valves

EPDM seals

Size

D

Z

A

B

C

E

F

G

kg

C

Code

1⁄2

92

143

20.5

35

124

M6

25

12

0.7

H0 PRA 102

3⁄4

106

143

20.5

35

144

M6

25

12

0.7

H0 PRA 103

1

108

143

25.0

35

154

M6

25

12

0.7

H0 PRA 104

11⁄4

120

204

36.0

50

174

M8

44.5

16

1.5

H0 PRA 105

11⁄2

130

204

39.5

50

194

M8

44.5

16

1.5

H0 PRA 106

2

146

219

49.0

50

224

M8

44.5

16

2.4

H0 PRA 107

A

B

Options: FPM seals order H0 PRB 2**

E

G Z D

F

34

Tel: +44 (0)1543 279909

Fax: +44 (0)1543 279450

FK Butterfly valves Glass reinforced polypropylene with ABS disc hand operated Size

DN

PN

B2

B3

C

C1

g

U

21⁄2

65 80 100 125 150 200

10 10 10 10 10 10

80 93 107 120 134 161

164 178 192 212 225 272

272 272 272 330 330 420

110 110 110 110 110 122

1470 1870 2220 3100 3850 6750

4 8 8 8 8 8

3 4 5 6 8

Code H0 H0 H0 H0 H0 H0

FKA FKA FKA FKA FKA FKA

108 109 110 111 112 113

Options: FPM seals order H0 FKB ***

with gear box Size

DN

PN

B1

B2

B3

G

G1

G2

G3

21⁄2 3 4 5 6 8 10 12

65 80 100 125 150 200 250 300

10 10 10 10 10 10 10 8

80 93 107 120 134 161 210 245

174 188 202 222 235 287 317 374

146 160 174 194 207 256 281 338

48 48 48 48 48 65 88 88

135 135 135 144 144 204 236 236

39 39 39 39 39 60 76 76

125 125 125 200 200 200 250 250

g

U

2400 4 2800 8 3150 8 4450 8 5200 8 9300 8 18600 12 25600 12

Code HV HV HV HV HV HV HV HV

FKA FKA FKA FKA FKA FKA FKA FKA

108 109 110 111 112 113 114 115

Options: FPM seals order HV FKB ***

email: [email protected]

web: www.durapipe.co.uk

35

Index to ABS Metric Fittings Note: Two-dimensional Auto-CAD drawings are available on www.durapipe.co.uk

Pipe page 37

Sockets page 38

Reducing bushes page 38

Reducers page 39

Elbows 45° page 39

Elbows 90° page 39

Bends 90° page 40

Fabricated bends 90° page 40

Tees 90° equal page 40

Tees 90° reducing page 41

Tees 90°, swept plain page 41

Tees 45°, plain page 41

Caps, plain page 42

Socket unions page 42

Socket union plain adaptors page 42

Socket union threaded adaptors page 42

Socket union nuts page 43

Imperial/metric socket adaptors page 43

Female threaded adaptors page 43

Male threaded adaptors page 43

Female composite unions page 44

Male composite unions page 44

Wall brackets page 44

Hose adaptors page 44

Stub flanges serrated page 45

Blank flanges page 45

Valve plates page 45

Backing rings page 46

Flat gaskets/ stub flanges page 47

‘O’ rings for socket unions page 47

*

Cobra pipe clips page 48

Durapipe one-step solvent cement and Eco-cleaner page 48

*

Y type strainers page 50

VK Double union ball valves (manual) page 48

*

VM Manual diaphragm valves page 51

*

Multiport ball valves page 49

*

Pressure relief valves page 51

*

Single union ball check valves page 50

*

Air release valves page 50

*

FK Butterfly valves (manual) page 52

Pipe trays page 53

De-burring tools page 53

Wheel cutters page 53

* For details of our full range of manual and actuated valves please ask for a copy of Valves Technical Catalogue D0894.

36

Tel: +44 (0)1543 279909

Fax: +44 (0)1543 279450

ABS Pipe Metric System PN10 Size

plain

Thickness t mm

Mean Bore mm

Weight

Length

Da

Nom Bore DN

Code

kg/m

m

16 20 25 32 40 50 63 75 90 110 125 140 160 200 225

10 15 20 25 32 40 50 65 80 100 110 125 150 175 200

1.5 1.6 1.9 2.1 2.7 3.4 4.2 5.0 6.0 7.3 8.2 9.3 10.5 13.2 14.8

13.0 16.8 21.2 27.8 34.6 43.2 54.6 65.0 78.0 95.4 108.6 121.4 139.0 173.6 195.4

0.07 0.10 0.14 0.21 0.33 0.52 0.81 1.14 1.65 2.45 3.13 3.97 5.13 8.06 10.17

5 5 5 5 5 5 5 5 5 5 5 5 5 5 5

11 11 11 11 11 11 11 11 11 11 11 11 11 11 11

250 *315

250 300

16.1 20.8

217.8 273.4

12.31 20.00

5 5

11 555 320 11 555 323

555 555 555 555 555 555 555 555 555 555 555 555 555 555 555

305 306 307 308 309 310 311 312 313 314 315 316 317 318 319

Da

t

* 315mm is PN8 rated

email: [email protected]

web: www.durapipe.co.uk

37

Sockets Size

A

B

Z1

gms

16 20 25 32 40 50 63 75 90 110 125 140 160 200 225 250 315

21 25 31 41 50 62 78 88 107 126 146 171 182 223 260 286 355

31 37 42 49 58 68 81 93 108 131 149 163 184 220 250 272 339

3 3 2 3 4 4 4 3 4 7 7 7 8 8 11 10 11

5 7 12 25 45 77 154 230 380 690 1040 1390 1660 2390 3470 5760 9780

Z1

gms

3 3 9 8 6 17 13 11 5 20 16 7 7 23 15 9 25 10 9 8 35 27 10 21 33 13 12 33

2 4 5 6 13 32 29 19 25 60 36 47 65 200 224 110 252 200 220 260 320 405 460 109 1600 1250 2230 5080

Code 11 11 11 11 11 11 11 11 11 11 11 11 11 11 11 11 11

100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100

305 306 307 308 309 310 311 312 313 314 315 316 317 318 319 320 323

A

Z1 B

Reducing bushes Size

B

20 x 16 17 25 x 20 19 32 x 16 23 32 x 25 23 40 x 32 28 50 x 20* 33 50 x 25* 33 50 x 32* 32 50 x 40 32 63 x 25* 39 63 x 32* 39 63 x 50 39 75 x 63 46 90 x 50* 54 90 x 63* 54 90 x 75 55 110 x 63* 64 110 x 90 64 125 x 110 72 140 x 125 79 160 x 90 89 160 x 110* 89 160 x 140 89 200 x 160 110 225 x 160* 122 225 x 200* 122 250 x 225* 132 315 x 250* 165 *Configuration shown in inset

38

Code 11 11 11 11 11 11 11 11 11 11 11 11 11 11 11 11 11 11 11 11 11 11 11 11 11 11 11 11

109 109 109 109 109 109 109 109 109 109 109 109 109 109 109 109 109 109 109 109 109 109 109 109 109 109 109 109

412 415 417 419 423 424 425 426 427 429 430 432 438 442 443 444 449 451 459 467 473 474 476 487 495 496 499 503

Tel: +44 (0)1543 279909

Z1

B

Fax: +44 (0)1543 279450