Design Of Glass Column 1y4fd

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 2z6p3t

Overview 5o1f4z

& View Design Of Glass Column as PDF for free.

More details 6z3438

- Words: 641

- Pages: 8

ADVANCED DESIGN OF GLASS STRUCTURES Design of glass column Viorel Ungureanu European Erasmus Mundus Master Course

Sustainable Constructions under Natural Hazards and Catastrophic Events 520121-1-2011-1-CZ-ERA MUNDUS-EMMC

Objectives of the lecture Objectives Composite section Non-composite section Accidental situation

Worked example

•

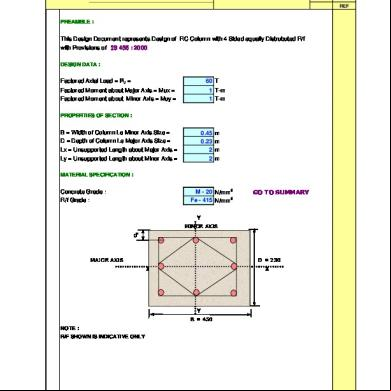

1) Assess the resistance of a glass column made of bundled tubes, ing a roof, as shown in the figure. Tubes are attached together by the use of adhesive which enables them to work as: a) a single composite section; b) a non-composite section. L= c1 4000 mm tube outside diameter d = 135 mm thickness t = 6 mm Design value of glass strength: in compression fcd = c2 400 MPa in tension ftd = 50 MPa

Design of glass column

a) Section A - A

L b) Section A - A after failure

116,91 184,41

67,5

2) Assess the resistance of the same column with two broken tubes - see the figure. 2

Composite section Objectives

Accidental situation

• tube outside diameter

d = 135 mm

• thickness

t = 6 mm

• area of one tube

A0

2

d 2 d 2t A0 4

y

• moment of inertia of one tube

z

67,5

Non-composite section

Tubes are attached by use of adhesive which enables them to work as a single composite section

116,91

Composite section

d 4 d 2t 4 I0 64

67,5

I0

• Moment of inertia of composite section Iy ,Iz

I y 3I 0 4 I 0 A0 r12

r = 116,91mm 1

I z I 0 4 I 0 A0 r22 2 I 0 A0 r32

r2 = 67,5mm r3 = 135,0mm

3

Composite section Objectives Composite section Non-composite section Accidental situation

• Maximal resistance in compression without buckling

N max cd 7 A0 • Critical force

N cr ,comp

2 EI 2 Lcr

• “safety factor” – restriction for capacity by Ncr/4

N Rd ,1

N cr ,comp 4

4

Non-composite section Objectives Composite section

Tubes without connection, each tube share axial load equally • Critical force of one tube

Non-composite section Accidental situation

N cr , 0

2 EI 0 2 Lcr

• Capacity of the column

N Rd , 2

7 N cr , 0 4

5

Accidental situation Objectives Composite section Non-composite section Accidental situation

2) Accidental situation – two broken tubes • New location of gravity axis

yT

3 A0 184,41 2 A0 67,5 5 A0

yT

116,91 184,41

67,5

• Moment of inertia IyT of 5 tube – composite section 2

2

I yT 3I 0 3 A0 184,41 yT 2 I 0 2 A0 yT 67,5 • Distance to the tensioned fibres dt • Distance to the compressed fibres dc • Critical force

N cr , yT

2 EI yT L2cr

yT 116,91 184,41

67,5

tensioned fibres

• Eccentricity of force

e 184,41 yT

6

Accidental situation Objectives Composite section Non-composite section Accidental situation

a) axial force + moment – tensioned fibres

I yT

W y ,tension

• Cross-section modulus

dt

• maximal allowed force for tensioned fibres

f td

N Ed N e Ed 5 A0 W y ,tension

N Ed

b) axial force + moment – compressed fibres • Cross-section modulus

W y ,compression

I yT dc

• maximal allowed force for compressed fibres

N Ed N Ed e f cd 5 A0 W y ,compression Conclusion:

N Ed

Preliminary resistance of glass column

7

Thank you for your attention [email protected] http://steel.fsv.cvut.cz/suscos

8

Sustainable Constructions under Natural Hazards and Catastrophic Events 520121-1-2011-1-CZ-ERA MUNDUS-EMMC

Objectives of the lecture Objectives Composite section Non-composite section Accidental situation

Worked example

•

1) Assess the resistance of a glass column made of bundled tubes, ing a roof, as shown in the figure. Tubes are attached together by the use of adhesive which enables them to work as: a) a single composite section; b) a non-composite section. L= c1 4000 mm tube outside diameter d = 135 mm thickness t = 6 mm Design value of glass strength: in compression fcd = c2 400 MPa in tension ftd = 50 MPa

Design of glass column

a) Section A - A

L b) Section A - A after failure

116,91 184,41

67,5

2) Assess the resistance of the same column with two broken tubes - see the figure. 2

Composite section Objectives

Accidental situation

• tube outside diameter

d = 135 mm

• thickness

t = 6 mm

• area of one tube

A0

2

d 2 d 2t A0 4

y

• moment of inertia of one tube

z

67,5

Non-composite section

Tubes are attached by use of adhesive which enables them to work as a single composite section

116,91

Composite section

d 4 d 2t 4 I0 64

67,5

I0

• Moment of inertia of composite section Iy ,Iz

I y 3I 0 4 I 0 A0 r12

r = 116,91mm 1

I z I 0 4 I 0 A0 r22 2 I 0 A0 r32

r2 = 67,5mm r3 = 135,0mm

3

Composite section Objectives Composite section Non-composite section Accidental situation

• Maximal resistance in compression without buckling

N max cd 7 A0 • Critical force

N cr ,comp

2 EI 2 Lcr

• “safety factor” – restriction for capacity by Ncr/4

N Rd ,1

N cr ,comp 4

4

Non-composite section Objectives Composite section

Tubes without connection, each tube share axial load equally • Critical force of one tube

Non-composite section Accidental situation

N cr , 0

2 EI 0 2 Lcr

• Capacity of the column

N Rd , 2

7 N cr , 0 4

5

Accidental situation Objectives Composite section Non-composite section Accidental situation

2) Accidental situation – two broken tubes • New location of gravity axis

yT

3 A0 184,41 2 A0 67,5 5 A0

yT

116,91 184,41

67,5

• Moment of inertia IyT of 5 tube – composite section 2

2

I yT 3I 0 3 A0 184,41 yT 2 I 0 2 A0 yT 67,5 • Distance to the tensioned fibres dt • Distance to the compressed fibres dc • Critical force

N cr , yT

2 EI yT L2cr

yT 116,91 184,41

67,5

tensioned fibres

• Eccentricity of force

e 184,41 yT

6

Accidental situation Objectives Composite section Non-composite section Accidental situation

a) axial force + moment – tensioned fibres

I yT

W y ,tension

• Cross-section modulus

dt

• maximal allowed force for tensioned fibres

f td

N Ed N e Ed 5 A0 W y ,tension

N Ed

b) axial force + moment – compressed fibres • Cross-section modulus

W y ,compression

I yT dc

• maximal allowed force for compressed fibres

N Ed N Ed e f cd 5 A0 W y ,compression Conclusion:

N Ed

Preliminary resistance of glass column

7

Thank you for your attention [email protected] http://steel.fsv.cvut.cz/suscos

8