Column Design To Bs8110 Template 3366e

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 2z6p3t

Overview 5o1f4z

& View Column Design To Bs8110 Template as PDF for free.

More details 6z3438

- Words: 1,120

- Pages: 6

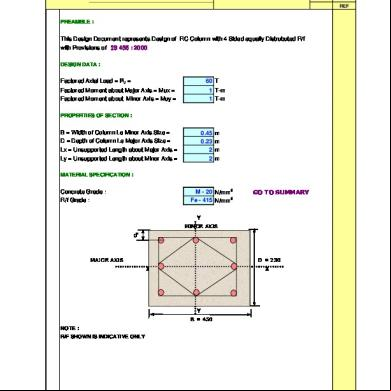

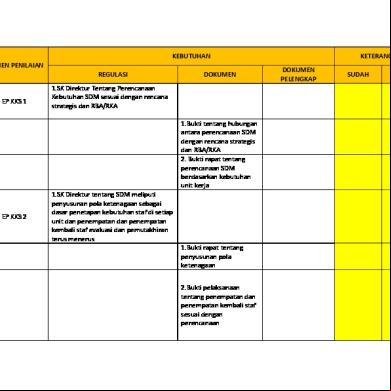

CLIENT PROJECT Location Sub-Location REF

UNITED ENGINEERING SERVICES LTD. PIARCO GENERATOR BUILDING

Date By

9-Jun-15 M Rampersad

Structural Frame RC Column Design

DESCRIPTION

RC COLUMN DESIGN

OUTPUT

CLIENT PROJECT Location Sub-Location

Date By

UNITED ENGINEERING SERVICES LTD. PIARCO GENERATOR BUILDING

9-Jun-15 M Rampersad

Structural Frame RC Column Design

REF

DESCRIPTION

OUTPUT

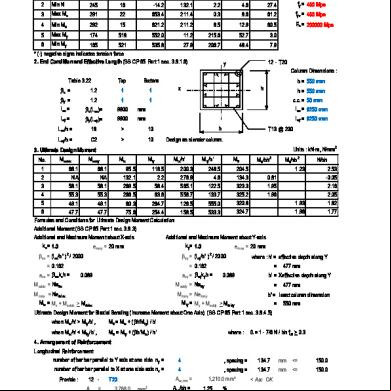

References Used 1

Reinforced Concrete Design, 4th ed, Moseley & Bungey

2

BS8110: 1997, Structural Use of Concrete

3

STAAD Model analysis

4

ASTM A615: 04, Std. Spec for Deformed & Plain Carbon Steel Bars etc.

MEMBER GEOMETRY Geometric data

450

450.0

mm

450

Member depth, h =

450.0

mm

450

mm 2 N/mm

Cover to reinforcement =

40.0

Conc. compressive strength, fcu =

30.0

Tension rfct strength, fy =

420.0

Shear rfct strength, fyv =

280.0

N/mm N/mm2

Length between restraints, LO =

3500.0

mm

20.0

mm

450 40 00

4 4

Member width, b =

Nominal aggregate size

2

OK against cover

Min. allowable bar spacing =

25.0 mm

Effective depth, h' =

400.0 mm

400

Effective width, b' =

410.0 mm 2,160,000,000 Nm

410

bd2fcu term = Gross cross-sectional area, Ag =

202,500 mm

410

2

Check effective height & slenderness X-X axis condition at TOP

1.0

condition at BOTTOM

2.0

end restraint beta,

2 - Tbl 3.19 2 - Cl. 3.8.1.6.1

0.80 2,800 mm

Effective height (major axis), lex = LO =

2 - Cl. 3.8.1.3.

Classification (short or slender) =

6.2 Short

Y-Y axis condition at TOP

3.0

condition at BOTTOM

2.0

end restraint beta,

2 - Tbl 3.19 2 - Cl. 3.8.1.6.1

Effective height (minor axis), ley = LO =

2 -Cl. 3.8.1.3.

Classification (short or slender) =

0.95 3,325 mm 7.4 Short

Slenderness limit 2 - Cl. 3.8.1.7

Slenderness limit (LO should be <60* min dimension) =

27,000 mm

Slenderness limit OK

CLIENT PROJECT Location Sub-Location

Date By

UNITED ENGINEERING SERVICES LTD. PIARCO GENERATOR BUILDING

9-Jun-15 M Rampersad

Structural Frame RC Column Design

REF

DESCRIPTION

OUTPUT

ULS LOAD DATA Axial load, N =

150.0 50.0

kN kNm

150kN

Moment about major axis, MX = Moment about minor axis, MY =

20.0

kNm

20kNm

Max shear force, V =

75.0

kN

STAAD Member Ref =

115

Load Case =

114

3

1 - Sxn 9.4.4

150kN 50kNm

1 - Tbl 9.4

20kNm

Check MX/h' =

125.0 kN

Check MY/b' =

48.8 kN

N/bdfcu =

0.02 [unitless]

coefficient beta, =

1.00 [unitless]

beta*(h'/b') =

0.98 [unitless]

50kNm

Since Mx/h'>My/b', Use single axis design moment about X-axis Use M'x as the design moment, M =

69.5 kNm

Total steel required, As req = (see supplemental calcs)

2 1,040 mm

REINFORCEMENT CHECKS 2 - Cl. 3.4.4.4

Calculation for reinforcement

Select bar diameter = Specify number of bars = Compression C i steel t l provided, id d As prov = Number of layers = Min. spacing between bars =

20 mm 4 Nr 2 1,260 mm 2 330.0 mm

Spacing OK

Provide 4Nr T20 bars in 2 layer(s) Check for minimum steel 2 - Tbl. 3.25

100 AS/AC =

0.62 %

2 - Cl. 3.12.5.3

Recommended value (Minimum) =

0.40 %

Min. steel OK

2 - Cl. 3.12.6.2

Recommended value (Maximum) =

4.00 %

Max. steel OK

SHEAR REINFORCEMENT CHECKS 2 - Cl. 3.4.5.2

Design (Actual) shear stress, = V/bvd V=

75.0 kN

bv = b =

450 0 mm 450.0

d=

400.0 mm

∴ Design (actual) shear stress, =

2 0.42 N/mm

CLIENT PROJECT Location Sub-Location

PIARCO GENERATOR BUILDING

9-Jun-15 M Rampersad

Structural Frame RC Column Design

REF 2 - Cl. 3.4.5.2

Date By

UNITED ENGINEERING SERVICES LTD.

DESCRIPTION Check limits, < lesser of 0.8√fcu or 5N/mm

OUTPUT

2

0.8√fcu =

2 4.38 N/mm

Shear limit OK

Design concrete shear stress, c =0.79*(100AS/bvd)1/3*(400/d)1/4*fcu multiplier /m (100AS prov/bvd)1/3 =

2-Tbl 3.8 Note 2 2-Tbl 3.8 Note 2 2-Tbl 3.8 Note 2

(400/d)

1/4

∴ c 2 - Tbl 3.16

2 - Tbl 3.7

=

fcu multiplier = =

0.89 [unitless] 1.00 [unitless] 2 1.06 N/mm 2 0.60 N/mm

Check range of to c

< c

Yes 0.74

c < < (c+0.4): Use Asv/sv = 0.4b/0.87fyv (c+0.4) < < 0.8√fcu (or 5.0): Use Asv/sv = b(-c)/0.87fyv

0 4 No 0.74 No -0.33

Shear reinforcement requirement Shear reinforcement ratio required, Asv/sv =

0.74

Select bar diameter =

10

Specify bar spacing =

150

Shear reinforcement ratio provided, Asv/sv = Provide R10 at 150mm centres

1.05

Use nominal links

CLIENT PROJECT Location Sub-Location

Date By

UNITED ENGINEERING SERVICES LTD. PIARCO GENERATOR BUILDING

9-Jun-15 M Rampersad

Structural Frame RC Column Design

REF

DESCRIPTION

OUTPUT

Supplemental Calculation for A S REQ Note: This is an iterative process where an assumption is made for the steel provided (A' S ) and tested to see if this provides an intersection point on the M-N interaction diagram. 1. Guess an initial value of A' S 2. See if this results in a p point exactlyy on the curve of the M-N interaction diagram 3. If this does, then use Excel Goal-Seek to derive the depth of the neutral axis (x)

1-Eg 9.3

Try A S =

520 mm

Depth of neutral axis, x =

44.0 mm

compressive steel strain, tensile steel strain, Design yield strain,

sc = s =

y = f Y / M /E S =

2

0.0003 0.0283 0.0018

balanced neutral axis, x bal =

262.9 mm

Depth of stress block, s = 0.9x =

39.6 mm

strains OK neutral axis depth OK

From yield strain curve f SC (compression) = E S SC

63.6 N/mm

2

f SC (tension) = E S S

5663.7 N/mm

2

For compression N(e+h/2-d 2 ) = 0.45f CU bs(d-s/2) + f SC A' S (d-d') 0.45f CU bs(d-s/2) = e = M/N =

91463239 Nmm 463.4 mm

N(e+h/2-d 2 ) =

97262195 Nmm

To allow for the area of concrete displaced, f SC =

351.7 N/mm

f SC (d-d') =

126618 Nmm

2

IF((C117-C115)/C119<0,C73*C28/100,(C117-C115)/C For tension N = 0.45f CU bs + f SC A' S +f S A S

∴

A S = (0.45f CU bs - f SC A' S -N)/f S 0.45f CU bs =

240566 N

f SC A' S =

182893 N

∴

A' S =

Total steel required, A S REQ =

2

520 mm 2 1,040 mm

CLIENT PROJECT Location Sub-Location

Date By

UNITED ENGINEERING SERVICES LTD. PIARCO GENERATOR BUILDING

9-Jun-15 M Rampersad

Structural Frame RC Column Design

REF

DESCRIPTION

OUTPUT

N/bh = 2

M/bh = 18.0

0.74 0.76

M‐N interaction diagram g

16.0 14.0 12.0

N N/bh

10.0 80 8.0 6.0

M‐N Interaction Diagram Load point

4.0 2.0

M/bh2

0.0 0.00

0.50

1.00

1.50

2.00

2.50

3.00

UNITED ENGINEERING SERVICES LTD. PIARCO GENERATOR BUILDING

Date By

9-Jun-15 M Rampersad

Structural Frame RC Column Design

DESCRIPTION

RC COLUMN DESIGN

OUTPUT

CLIENT PROJECT Location Sub-Location

Date By

UNITED ENGINEERING SERVICES LTD. PIARCO GENERATOR BUILDING

9-Jun-15 M Rampersad

Structural Frame RC Column Design

REF

DESCRIPTION

OUTPUT

References Used 1

Reinforced Concrete Design, 4th ed, Moseley & Bungey

2

BS8110: 1997, Structural Use of Concrete

3

STAAD Model analysis

4

ASTM A615: 04, Std. Spec for Deformed & Plain Carbon Steel Bars etc.

MEMBER GEOMETRY Geometric data

450

450.0

mm

450

Member depth, h =

450.0

mm

450

mm 2 N/mm

Cover to reinforcement =

40.0

Conc. compressive strength, fcu =

30.0

Tension rfct strength, fy =

420.0

Shear rfct strength, fyv =

280.0

N/mm N/mm2

Length between restraints, LO =

3500.0

mm

20.0

mm

450 40 00

4 4

Member width, b =

Nominal aggregate size

2

OK against cover

Min. allowable bar spacing =

25.0 mm

Effective depth, h' =

400.0 mm

400

Effective width, b' =

410.0 mm 2,160,000,000 Nm

410

bd2fcu term = Gross cross-sectional area, Ag =

202,500 mm

410

2

Check effective height & slenderness X-X axis condition at TOP

1.0

condition at BOTTOM

2.0

end restraint beta,

2 - Tbl 3.19 2 - Cl. 3.8.1.6.1

0.80 2,800 mm

Effective height (major axis), lex = LO =

2 - Cl. 3.8.1.3.

Classification (short or slender) =

6.2 Short

Y-Y axis condition at TOP

3.0

condition at BOTTOM

2.0

end restraint beta,

2 - Tbl 3.19 2 - Cl. 3.8.1.6.1

Effective height (minor axis), ley = LO =

2 -Cl. 3.8.1.3.

Classification (short or slender) =

0.95 3,325 mm 7.4 Short

Slenderness limit 2 - Cl. 3.8.1.7

Slenderness limit (LO should be <60* min dimension) =

27,000 mm

Slenderness limit OK

CLIENT PROJECT Location Sub-Location

Date By

UNITED ENGINEERING SERVICES LTD. PIARCO GENERATOR BUILDING

9-Jun-15 M Rampersad

Structural Frame RC Column Design

REF

DESCRIPTION

OUTPUT

ULS LOAD DATA Axial load, N =

150.0 50.0

kN kNm

150kN

Moment about major axis, MX = Moment about minor axis, MY =

20.0

kNm

20kNm

Max shear force, V =

75.0

kN

STAAD Member Ref =

115

Load Case =

114

3

1 - Sxn 9.4.4

150kN 50kNm

1 - Tbl 9.4

20kNm

Check MX/h' =

125.0 kN

Check MY/b' =

48.8 kN

N/bdfcu =

0.02 [unitless]

coefficient beta, =

1.00 [unitless]

beta*(h'/b') =

0.98 [unitless]

50kNm

Since Mx/h'>My/b', Use single axis design moment about X-axis Use M'x as the design moment, M =

69.5 kNm

Total steel required, As req = (see supplemental calcs)

2 1,040 mm

REINFORCEMENT CHECKS 2 - Cl. 3.4.4.4

Calculation for reinforcement

Select bar diameter = Specify number of bars = Compression C i steel t l provided, id d As prov = Number of layers = Min. spacing between bars =

20 mm 4 Nr 2 1,260 mm 2 330.0 mm

Spacing OK

Provide 4Nr T20 bars in 2 layer(s) Check for minimum steel 2 - Tbl. 3.25

100 AS/AC =

0.62 %

2 - Cl. 3.12.5.3

Recommended value (Minimum) =

0.40 %

Min. steel OK

2 - Cl. 3.12.6.2

Recommended value (Maximum) =

4.00 %

Max. steel OK

SHEAR REINFORCEMENT CHECKS 2 - Cl. 3.4.5.2

Design (Actual) shear stress, = V/bvd V=

75.0 kN

bv = b =

450 0 mm 450.0

d=

400.0 mm

∴ Design (actual) shear stress, =

2 0.42 N/mm

CLIENT PROJECT Location Sub-Location

PIARCO GENERATOR BUILDING

9-Jun-15 M Rampersad

Structural Frame RC Column Design

REF 2 - Cl. 3.4.5.2

Date By

UNITED ENGINEERING SERVICES LTD.

DESCRIPTION Check limits, < lesser of 0.8√fcu or 5N/mm

OUTPUT

2

0.8√fcu =

2 4.38 N/mm

Shear limit OK

Design concrete shear stress, c =0.79*(100AS/bvd)1/3*(400/d)1/4*fcu multiplier /m (100AS prov/bvd)1/3 =

2-Tbl 3.8 Note 2 2-Tbl 3.8 Note 2 2-Tbl 3.8 Note 2

(400/d)

1/4

∴ c 2 - Tbl 3.16

2 - Tbl 3.7

=

fcu multiplier = =

0.89 [unitless] 1.00 [unitless] 2 1.06 N/mm 2 0.60 N/mm

Check range of to c

< c

Yes 0.74

c < < (c+0.4): Use Asv/sv = 0.4b/0.87fyv (c+0.4) < < 0.8√fcu (or 5.0): Use Asv/sv = b(-c)/0.87fyv

0 4 No 0.74 No -0.33

Shear reinforcement requirement Shear reinforcement ratio required, Asv/sv =

0.74

Select bar diameter =

10

Specify bar spacing =

150

Shear reinforcement ratio provided, Asv/sv = Provide R10 at 150mm centres

1.05

Use nominal links

CLIENT PROJECT Location Sub-Location

Date By

UNITED ENGINEERING SERVICES LTD. PIARCO GENERATOR BUILDING

9-Jun-15 M Rampersad

Structural Frame RC Column Design

REF

DESCRIPTION

OUTPUT

Supplemental Calculation for A S REQ Note: This is an iterative process where an assumption is made for the steel provided (A' S ) and tested to see if this provides an intersection point on the M-N interaction diagram. 1. Guess an initial value of A' S 2. See if this results in a p point exactlyy on the curve of the M-N interaction diagram 3. If this does, then use Excel Goal-Seek to derive the depth of the neutral axis (x)

1-Eg 9.3

Try A S =

520 mm

Depth of neutral axis, x =

44.0 mm

compressive steel strain, tensile steel strain, Design yield strain,

sc = s =

y = f Y / M /E S =

2

0.0003 0.0283 0.0018

balanced neutral axis, x bal =

262.9 mm

Depth of stress block, s = 0.9x =

39.6 mm

strains OK neutral axis depth OK

From yield strain curve f SC (compression) = E S SC

63.6 N/mm

2

f SC (tension) = E S S

5663.7 N/mm

2

For compression N(e+h/2-d 2 ) = 0.45f CU bs(d-s/2) + f SC A' S (d-d') 0.45f CU bs(d-s/2) = e = M/N =

91463239 Nmm 463.4 mm

N(e+h/2-d 2 ) =

97262195 Nmm

To allow for the area of concrete displaced, f SC =

351.7 N/mm

f SC (d-d') =

126618 Nmm

2

IF((C117-C115)/C119<0,C73*C28/100,(C117-C115)/C For tension N = 0.45f CU bs + f SC A' S +f S A S

∴

A S = (0.45f CU bs - f SC A' S -N)/f S 0.45f CU bs =

240566 N

f SC A' S =

182893 N

∴

A' S =

Total steel required, A S REQ =

2

520 mm 2 1,040 mm

CLIENT PROJECT Location Sub-Location

Date By

UNITED ENGINEERING SERVICES LTD. PIARCO GENERATOR BUILDING

9-Jun-15 M Rampersad

Structural Frame RC Column Design

REF

DESCRIPTION

OUTPUT

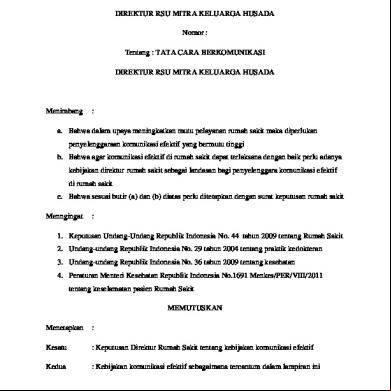

N/bh = 2

M/bh = 18.0

0.74 0.76

M‐N interaction diagram g

16.0 14.0 12.0

N N/bh

10.0 80 8.0 6.0

M‐N Interaction Diagram Load point

4.0 2.0

M/bh2

0.0 0.00

0.50

1.00

1.50

2.00

2.50

3.00