Arca Valves 5f606f

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 2z6p3t

Overview 5o1f4z

& View Arca Valves as PDF for free.

More details 6z3438

- Words: 15,954

- Pages: 52

ARCAPRO 827A.E/X∗ - ∗∗∗ - ∗∗∗ - ∗ Electropneumatic Positioner for Linear and Quarter-turn Actuators Version without / with HART-Communication Operating Instructions

Reference no.: 827A-BA-03-12_gb

ARCA-Regler GmbH D - 47918 Tönisvorst

Page 1 von 52

Legal information Warning notice system This documentation notices you have to observe in order to ensure your personal safety, as well as to prevent damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are graded according to the degree of danger. DANGER indicates that death or severe personal injury will result if proper precautions are not taken. WARNING Indicates that death or severe personal injury may result if proper precautions are not taken. CAUTION With a safety alert symbol, indicates that minor personal injury can result if proper precautions are not taken. CAUTION Without a safety alert symbol, indicates that property damage can result if proper precautions are not taken. NOTICE Indicates that an unintended result or situation can occur if the corresponding information is not taken into . If more than one degree of danger is present, the warning notice representing the highest degree of danger will be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to property damage. Qualified Personnel The device may only be set up and used in conjunction with this documentation. Commissioning and operation of a device may only be performed by qualified personnel. Within the context of the safety notes in this documentation qualified persons are defined as persons who are authorized to commission, ground and label devices, systems and circuits in accordance with established safety practices and standards. Prescribed Usage Note the following: WARNING ARCA-positioner may only be used for the applications described in the relevant technical documentation. Proper transport, storage, installation, assembly, commissioning, operation and maintenance are required to ensure that the products operate safely and without any problems. The permissible ambient conditions must be adhered to. The information in the relevant documentation must be observed. Disclaimer of Liability We have reviewed the contents of this publication to ensure consistency with the hardware and software described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the information in this publication is reviewed regularly and any necessary corrections are included in subsequent editions.

Reference no.: 827A-BA-03-12_gb

ARCA-Regler GmbH D - 47918 Tönisvorst

Page 2 von 52

Table of Contents 1 2 3 3.1 3.2 3.3 3.3.1 3.3.2 3.3.3 3.3.4 3.3.5 4 4.1 4.2 4.2.1 4.2.2 4.3 4.4 4.5 4.5.1 4.5.2 5 5.1 5.1.1 5.1.2 5.2 5.2.1 5.2.2 6 7 7.1 7.1.1 7.1.2 7.2 7.2.1 7.2.2 7.3 8 8.1 8.2 8.3 9 10 11

Introduction General safety notes Description Function Structure Device Components Motherboard Electric Connections Pneumatic Connections Purging Air Switch Restrictors Mounting Safety notes for mounting Mounting Linear Actuator Mounting Kit for "Integrated Fitting Linear Actuator" Mounting Kit for "Linear Actuator IEC534" Mounting Kit for "Quarter-turn Actuator VDI/VDE 3845" Note on the Use of Positioners in Wet Environments Positioners exposed to strong acceleration forces or vibrations Slip clutch Leverage ratio switch Electric Connection Electric Connection, not intrinsically safe Basic device Options Connecting device with type of protection intrinsic safety Basic device Options Pneumatic Connections Commissioning Preparations for Linear Actuators Automatic Initialization of Linear Actuators Manual Initialization of Linear Actuators Preparations for Quarter-turn Actuators Automatic Initialization of Quarter-turn Actuators Manual Initialization of Quarter-turn Actuators Copying Initialization Data (Positioner Exchange) Overview of Parameters Parameters 1 to 5 Parameters 6 to 51 Parameters A to P Fault removal Service and Maintenance Technical Data

Reference no.: 827A-BA-03-12_gb

ARCA-Regler GmbH D - 47918 Tönisvorst

4 6 8 8 8 9 9 10 10 10 10 12 12 13 13 15 17 19 20 21 21 22 24 24 25 28 28 30 32 33 35 35 36 38 38 39 39 40 40 41 42 43 46 47

Page 3 von 52

1

Introduction

This operating instructions contains all information that will be required to connect and to commission the device. It is aimed at persons who install the device mechanically, connect it electrically and commission it. Information and tips for projecting, parameterization and service contains the manual that can ordered by us. This operating instruction is valid for devises from firmware 4.00.00 in not intrinsically safe and intrinsically safe version. The content reflects the technical status at the time of printing. We reserve the right to make technical changes in the course of further development.

Checking the consignment WARNING Using a damaged or incomplete device Danger of explosion − Do not use any damaged or incomplete devices.

Design of the nameplate 2

3

1

9

Stellungsregler 827A.X4-0BH-M10-G II 2 G Ex ia IIC T6/T4 Gb Ta = -30 …50/80°C TÜV 12 ATEX 085253 X

10 Mat-Nr. XXXXXXX

4

F-Nr. X XXXXXX

5

8

7

6

11

1 - Manufacturer 2 – Device name 3 - Type 4 - Consult operating instructions 5 - Safety class 6 - Auxiliary power (air supply) 7 - Approval 8 - ATEX marking for hazardous area 9 - Rated signal range 10 - Auxiliary power (voltage) 11 - Manufacturer serial number

Reference no.: 827A-BA-03-12_gb

ARCA-Regler GmbH D - 47918 Tönisvorst

Page 4 von 52

Type key

827A.∗ ∗ – ∗ ∗ ∗ – ∗ ∗ ∗ – ∗ Connection thread

electric / pneumatic

G N M P

M20x1,5 / G 1/4 1/2“ NPT / 1/4“ NPT M20x1,5 / 1/4“ NPT 1/2“ NPT / G 1/4

mechanical actuator

0 2

Standard without (for external potentiometer)

pneumatic

1 2

single-acting double-acting ( only stainless housing )

body

M aluminium E stainless housing

communication

0 without communication H HART

binary output

0 B S K

without binary outputs binary module slot initiator module module

analog - output

0 A

without analog - output analog module

connection basic device

2 4

2 - wire 2 / 3 / 4 - wire

Ex - certificate

E X

not explosion protected II 2 G Ex ia IIC T6/T4 Gb (Type 827A.X∗-A∗∗-∗∗∗-∗

only II2G Ex ia IIC T4 Gb)

series Transportation and storage CAUTION Insufficient protection during storage The packaging only provides limited protection against moisture and infiltration. − Provide additional packaging as necessary.

Environmental protection Devices described in this programming manual can be recycled owing to the low content of noxious substances in their version. Please a certified waste disposal company for eco-friendly recycling and to dispose of your old devices.

Reference no.: 827A-BA-03-12_gb

ARCA-Regler GmbH D - 47918 Tönisvorst

Page 5 von 52

2

General safety notes

Requirement for safe use This device left the factory in good working condition. In order to maintain this status and to ensure safe operation of the device, observe these instructions and all the specifications relevant to safety. Observe the information and symbols on the device. Do not remove any information or symbols from the device. Always keep the information and symbols in a completely legible state. Warning symbols on the device Symbol

Explanation of the warning symbols on the device Consult operating instructions Protect the device from shocks (otherwise the degree of protection is not guaranteed)

Laws and directives Observe the test certification, provisions and laws applicable in your country during connection, assembly and operation: − IEC 60079-14 (international) − EN 60079-14 (EG) − The working reliability regulation () Conformity with European directives The CE marking on the device shows conformity with the regulations of the following European guidelines: EMC 2004/108/EG

Directive of the European Parliament and of the Council on the approximation of the laws of the Member States relating to electromagnetic compatibility and repealing Directive 89/336/EEC.

ATEX 94/9/EG

Directive of the European Parliament and the Council on the approximation of the laws of the Member States concerning equipment and protective systems intended for use in potentially explosive atmospheres. .

LVD 2006/95/EC

Directive of the European Parliament and the Council on the approximation of the laws of the Member States relating to electrical equipment designed for use within certain voltage limits. The applied standards can be found in the EC conformity declaration of the device. Improver device modifications WARNING Improver device modifications Danger to personnel, system and environment can result from modifications to the device, particularly in hazardous areas. − Only carry out modifications that are described in the instructions for the device. Failure to observe this requirement cancels the manufacturer's warranty and the product approvals.

Reference no.: 827A-BA-03-12_gb

ARCA-Regler GmbH D - 47918 Tönisvorst

Page 6 von 52

Use in areas subject to explosion hazard WARNING Unsuitable device for the hazardous area Danger of explosion − Only use equipment that is approved for use in hazardous area and labelled accordingly. − Make sure that the device is suitable for the area of use. WARNING Loss of the safety of the device with type of protection "Intrinsic safety Ex i" If the device has already been operated in non-intrinsically safe circuits or with a higher voltage, the safety of the device is no longer ensured for use in hazardous areas. There is a danger of explosion. − Connect the device in "intrinsic safety" type of protection solely to an intrinsically safe circuit. − Observe the specifications for the electrical data in the certificate WARNING Impermissible accessories and spare parts Danger of explosion in areas subject to explosion hazard. − Only use original accessories or original spare parts. − Observe all relevant installation and safety instructions described in the instructions for the device or enclosed with the accessory or spare part. WARNING Open cable inlet or incorrect cable gland Danger of explosion in areas subject to explosion hazard. − Close the cable inlets for the electrical connections. Only use cable glands or plugs which are approved for the relevant type of protection. WARNING Exceeded maximum ambient or process media temperature Danger of explosion in areas subject to explosion hazard. If the maximum permissible ambient and process media temperatures are exceeded, the temperature class of the device is no longer valid. − Make sure that the maximum permissible ambient and process media temperatures of the device are not exceeded. CAUTION Electrostatic Sensitive Devices This device contains electrostatic sensitive devices. Electrostatic sensitive devices may be destroyed by voltages that are undetectable to a human. Voltages of this kind occur as soon as a component or an assembly is touched by a person who is not grounded against static electricity. The damage to a module as a result of overvoltage cannot usually be detected immediately. It may only become apparent after a long period of operation. Therefore, avoid electrostatic charge.

Reference no.: 827A-BA-03-12_gb

ARCA-Regler GmbH D - 47918 Tönisvorst

Page 7 von 52

Qualified Personnel Qualified personnel are people who are familiar with the installation, mounting, commissioning, and operation of the product. These people have the following qualifications: − They are authorized, trained or instructed in operating and maintaining devices and systems according to the safety regulations for electrical circuits, high pressures and aggressive as well as hazardous media. − For explosion-proof devices: They are authorized, trained, or instructed in carrying out work on electrical circuits for hazardous systems. − Hey are trained or instructed in maintenance and use of appropriate safety equipment according to the safety regulations.

3

Description

3.1

Function

− The electro-pneumatic positioner, in combination with the drive, forms a regulation system. The current position of the drive is detected using a servo potentiometer and is sent back as actual value x. The actual and target values are simultaneously displayed on the digital display. − The setpoint w forms a current applied to the positioner, which in two-wire mode is also used to power the positioner. In 3- and 4-wire mode, power is supplied through a 24-V power input. − The positioner works as a predictive five-point positioner, through whose output value ±∆y the integrated valves can be controlled by pulse length modulation. − These positioning signals cause pressure changes in the drive chamber(s) and thus a repositioning of the drive until the regulation deviation returns to zero. − Using three buttons and a digital display with the housing cover removed, operation (manual mode) and configuration (structuring, initialization, and parameterization) can be performed. − Normally the basic device has one binary input (BE1). This can be individually configured, and is particularly provided for blocking the operating levels. − To be able to use the positioner in a variety of mechanically different rotational and linear actuators, it has a friction clutch and a switchable gear. 3.2

Structure

The following chapters describe the mechanical and electrical structure, components, and principle functionality of the positioner. The positioner is used to adjust and regulate pneumatic drives. The positioner works electropneumatically, using compressed air as auxiliary power The positioner can e.g. regulate valves with: - Linear actuator (Figure 3-1) or - Quarter turn actuator VDI/VDE 3845 (Figure 3-2) For linear actuators, there are various add-on extensions available - NAMUR or. IEC 534 - integrated addition (ARCA, SAMSON) - integrated addition according to VDI/VDE 3847 You can mount the positioner on the usual drives and operate it with the usual drives.

Reference no.: 827A-BA-03-12_gb

ARCA-Regler GmbH D - 47918 Tönisvorst

Page 8 von 52

The device is available for single-acting and double-acting actuators and for potentially explosive applications and applications that are not potentially explosive.

1

4

2

1

3

3 2

5

1 2 3 4 5

Actuator Positioner, single-acting in metal-housing Lantern Manometer block, single-acting Valve

Figure 3-1 Positioner fitted to a linear actuator (single-acting)

3.3

1 Positioner, double-acting in plastic housing 2 Quarter-turn actuator 3 Manometer block, double-acting

Figure 3-2

Positioner fitted to a quarter-turn actuator (double-acting)

Device Components 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 1)

Input: supply air Output: Actuating pressure Y1 Display 1) Output: Actuating pressure Y2 Control buttons Restrictor 1) Restrictor Y1 1) Restrictor Y2 Silencer leverage ratio switch Slip clutch adjusting wheel Connection terminals motherboard Connection terminals for optional module Blinding plug Cable gland Terminal plate on cover Purging air selector

for double-acting drives

Figure 3-3 Structure

3.3.1 Motherboard The motherboard contains: - U - Memory - A/D-converter - Display - Operating buttons - Terminal strips to connect the optional module to the motherboard

Reference no.: 827A-BA-03-12_gb

ARCA-Regler GmbH D - 47918 Tönisvorst

Page 9 von 52

3.3.2

Electric Connections

The connecting terminals for the base device, the optional analog, binary and slot initiator modules are arranged at the front left-hand edge, and are displaced with respect to one another in a stepped pattern. An assembly cover secures the components against being pulled out, and prevents incorrect assembly.

3.3.3

Pneumatic Connections

The pneumatic connections (G1/4) are located on the right-hand side of the positioner

Actuating pressure Y1 in single-acting and double-acting actuators shaft Air supply Pz Actuating pressure Y2 on double-acting actuators Exhaust air outlet E with silencer on the bottom of the device Figure 3-4 Pneumatic connections

Connection versions In addition, the rear of the positioner has pneumatic connections for integrated fitting of single-acting linear actuators: - actuating pressure Y1 - exhaust air outlet E Except in cases of integrated ARCA fitting, these connections are closed by screws. The exhaust air outlet E can be used to supply the sensing area and the spring chamber with dry, instrumentation-quality air to prevent corrosion. Figure 3-6 illustrates the versions of the pneumatic connections for the various types of actuator, the positioning effect and the safety position after failure of the auxiliary power supply. CAUTION Before working on the control valve Note that before working on the control valve, you must first move it to the safety position. Make sure that the control valve has reached the safety position. If you only interrupt the pneumatic auxiliary power supply to the positioner, the safety position may in some cases only be attained after a certain delay period.

3.3.4

Purging Air Switch

The purging air switch is accessible when the housing is open above the pneumatic connection strip on the valve block. − In the IN position the interior of the housing is flushed by very small quantities of clean, dry instrumentationquality air. − In the OUT position, the purging air is fed directly outside.

Figure 3-5 Purging air switch on the valve block

Reference no.: 827A-BA-03-12_gb

ARCA-Regler GmbH D - 47918 Tönisvorst

Page 10 von 52

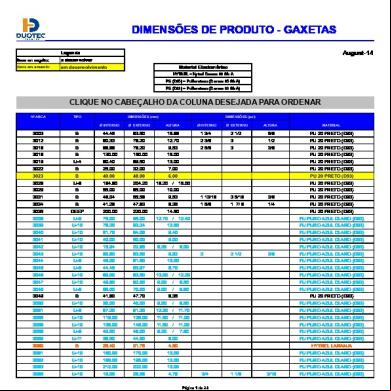

Actuating pressure Connection

Safety position following failure of the auxiliary power

Actuator type

electrical

Y1 Closed

pneumatic

Closed

Closed

Open

Open

On rotary actuators, it is usual to define the anti-clockwise direction of rotation – seen looking at the valve's operating shaft – as "OPEN".

Open

Y1

Closed

Open

Y2

Open

Y1 Closed

Closed Last position (before failure of auxiliary power)

Open

Y1

Closed

Y2 Closed

Y1

Open

Open

up

down

down

down

Y1 up

up

up

down

Y2 Y1

up down

up

up Last position (before failure of auxiliary power)

Y1

Y2

up

down

down

down

Figure 3-6 Pneumatic connection positioning effect

Reference no.: 827A-BA-03-12_gb

ARCA-Regler GmbH D - 47918 Tönisvorst

Page 11 von 52

3.3.5

Restrictors

Note The exhaust air valve is always open in the de-energized state. − In order to achieve floating times of > 1.5 s on small actuators, it is possible to reduce the air power by means of the restrictors Y1 and Y2. − By turning to the right, the air power is reduced until it is completely blocked − In order to adjust the restrictors, it is recommended that they are closed and then slowly opened (see initialization RUN3). − In case of double-acting valves, ensure that both restrictors have approximately the same setting.

hexagon socket 2,5 mm

Y1

Y2

Figure 3-7 Restrictors

4

Mounting

4.1

Safety notes for mounting

CAUTION Incorrect mounting The device can be damaged, destroyed or its functionality impaired through improper mounting. . − Before installing ensure there is no visible damage present on the device. − Make sure that process connectors are clean, and suitable gaskets and glands are used. −

Mount the device using suitable tools. CAUTION

Mechanical impact effect It is essential that the following sequence is observed during assembly in order to avoid injury or mechanical damage to the positioner/mounting kit: 1. Mechanically mount the positioner 2. Connect the auxiliary electrical power supply 3. Connect the pneumatic auxiliary power 4. Carry out the commissioning procedure NOTICE Loss of degree of protection Damage to device if the enclosure is open or not properly closed. The degree of protection specified on the nameplate is no longer guaranteed.

Reference no.: 827A-BA-03-12_gb

ARCA-Regler GmbH D - 47918 Tönisvorst

Page 12 von 52

CAUTION Humid environment/dry compressed air Install the positioner in a humid environment such that the positioner shaft does not freeze at low ambient temperatures. Ensure that water does not seep through an open enclosure or an open gland. Water may seep through if the positioner is not installed and connected on-site immediately and finally. As a general rule, the positioner must be operated only with dry compressed air. Therefore, use the customary water separator. An additional dryer is required in extreme cases. The use of dryers is especially important when you operate the positioner at low ambient temperatures. Set the Purge air switch to the "OUT" position when installing on the pneumatic block, above the pneumatic connections.

4.2

Mounting Linear Actuator

4.2.1

Mounting Kit for "Integrated Fitting Linear Actuator"

Included with the "integrated fitting linear actuator" are (see Figure 4-1 for identifying numbers): Serial no.

No. of items

Name

Note mounted on lever (2)

1

1

Driver pin l. with roller

2

1

Lever

3

2

Washer

B6.4 - DIN 125 - A2

4

1

Spring washer

A6 – DIN 137A- A2

5

1

Lock washer

A6 – DIN 127- A2

6

1

Cylinder head bolt

M6 x 25 DIN 7984 - A2

7

1

Hexagonal nut

M6 - DIN 934 - A4

8

1

Square nut

M6 - DIN 557 - A4

9

2

Cylinder head bolt

M8 x 65 - DIN 912 - A2

10

2

Lock washer

A8 - DIN 127 - A2

11

2

Screw plug

12

1

O-ring

13 x 2.5

Mounting procedure (see Figure 4-1) 1. Adjust the pin (1) on the previously assembled lever to the value of the stroke range given on the actuator or, if this is not available as a scale value, at the next largest scale value. In case of uncertainty with regard to the real actuator stroke (pneumatic actuators often have a travel resource) you always have to choose the next large scale value. The centre of the pin must be positioned at the scale value. The same value can later be set during the commissioning under the parameter 3.YWAY, in order to display the displacement in mm after the initialization. 2. Push the lever to the stop on the controller axis, and fix it with cylinder head screw (6). 3. Open the rear actuating pressure outlet by removing the screw (13) and the O-ring (14). 4. When fitting with spring chamber exhaust air supply open the exhaust air outlet by removing the screw (15) and the O-ring (16). 5. Seal the actuating pressure outlet with screw plug (11). When fitting with exhaust air supply remove exhaust air silencer and seal. 6. Insert the O-ring (12) in the intermediate bracket recess. 7. Locate the positioner on the actuator in such a way that the roller es between the pins (17). 8. Align the controller horizontally at the intermediate bracket, and assemble it with the screws (9) and lock washers (10).

Reference no.: 827A-BA-03-12_gb

ARCA-Regler GmbH D - 47918 Tönisvorst

Page 13 von 52

6 15

5 14

3

7 13

4

8

3 2

1

1)

16

1

2)

10

17

9

12 11

3) Figure 4-1 Mounting procedure for integrated fitting

Reference no.: 827A-BA-03-12_gb

ARCA-Regler GmbH D - 47918 Tönisvorst

Page 14 von 52

4.2.2

" Mounting Kit for "Linear Actuator IEC534

The "linear actuator IEC 534" mounting kit, stroke 3 … 35 mm, includes (see Figure 4-3 for identifying numbers): Serial no.

No. of items

Name

Note

1

1

NAMUR fitting angle IEC 534

Standardised connecting location for fitting bracket with rib, column or flat surface

2

1

Sensing hoop

Guides the roller with the driver pin and turns the lever arm

3

2

Clamping piece

Assembly of the sensing hoop to the actuator's spindle

4

1

Driver pin l. with roller

5

1

NAMUR lever

Mounted on lever (5) For stroke range 3 … 35 mm or (stroke range > 35 … 130 mm, order separately, see figure 4-2)

6

2

U-bolts

Only far actuators with columns

7

4

Hexagonal screw

M8 x 20 DIN 933–A2

8

2

Hexagonal screw

M8 x 16 DIN 933–A2

9

6

Lock washer

A8 - DIN 127–A2

10

6

Washer

B 8.4 - DIN 125–A2

11

2

Washer

B 6.4 - DIN 125–A2

12

1

Spring washer

A6 - DIN 137A–A2

13

3

Lock washer

A6 - DIN 127–A2

14

3

Cylinder head bolt

M6 x 25 DIN 7984–A2

15

1

Hexagonal nut

M6 - DIN 934–A4

16

1

Square nut

M6 - DIN 557–A4

17

4

Hexagonal nut

M8 - DIN 934–A4

Assembly procedure (see Figure 4-3) 1. Assemble the clamping pieces (3) using the hexagonal screws (14) and lock washers (13) to the actuator spindle. 2. Push the sensing hoop (2) into the cut-outs in the clamping piece. Adjust to the required length, and tightened the screws so that it is still just possible to push the sensing handle. 3. Adjust the pin (4) on the previously assembled lever to the value of the stroke range given on the actuator or, if this is not available as a scale value, at the next largest scale value. In case of uncertainty with regard to the real actuator stroke (pneumatic actuators often have a travel resource) you always have to choose the next large scale value. The centre of the pin must be positioned at the scale value. The same value can later be set during the commissioning under the parameter 3.YWAY, in order to display the displacement in mm after the initialization. 4. Push the lever to the stop on the controller axis, and fix it with cylinder head screw (14). 5. Assemble the fitting angle (1) with two hexagonal screws (8), lock washer (9) and washers (10) to the rear of the positioner. The choice of the hole row depends on the width of the actuator's intermediate bracket width. The roller should engage in the sensing hoop (2) as close to the spindle as possible, but must not touch the clamping piece. 6. Hold the positioner with the fixing angle to the actuator in such a way that the pin (4) es inside the sensing hoop (2). 7. Tighten the sensing hoop. 8. Prepare the assembly parts in accordance with the actuator type: - Actuator with a rib: hexagonal bolt (7), washer (10) and lock washer (9). - Actuator with a flat surface: four hexagonal bolts (7) with washer (10) and lock washer (9). - Actuator with columns: two U-bolts (6), four hexagonal nuts (17) with washer (10) and lock washer (9). 9. Attach the positioner with the previously prepared assembly parts to the intermediate bracket. Adjust the height of the positioner so that the horizontal position of the lever is achieved as close as possible to the centre of the stroke. The actuator's lever scale provides orientation here. It is essential that the horizontal lever position is ed through within the range of the stroke.

Reference no.: 827A-BA-03-12_gb

ARCA-Regler GmbH D - 47918 Tönisvorst

Page 15 von 52

90° 25

30 35

1 5

33°

10

15

90°

20

40

50

70

60

90

110 130

2

Figure 4-2 NAMUR lever 3 ... 35 mm (1), NAMUR lever > 35 … 130 mm (2)

2

14 13 11

13

15 16

12 11 5

14 3

4

1)

1

2)

9

10

8 1

10

3)

9 8 F ittin g to la n te rn w ith fla t s u rfac e 1 7 7 9

9

10

10

17 6 9 10 F ittin g to la n te rn w ith c o lum ns

4)

Figure 4-3 Mounting procedure for IEC 534 inear actuator

Reference no.: 827A-BA-03-12_gb

ARCA-Regler GmbH D - 47918 Tönisvorst

Page 16 von 52

4.3

Mounting Kit for “Quarter-turn Actuator VDI/VDE 3845"

Included with the "VDI/VDE 3845 quarter-turn actuator" mounting kit are (see Figure 4-4 for identifying numbers): Serial no. 2

No. of items 1

Name

Note

Coupling wheel

Fitted to the position shaft of the positioner

3

1

Driver pin

Fitted to the actuator's shaft stub

4

1

Labels

Display of the actuator position, consisting of: 4.1 and 4.2

4.1

8

Scale

Various divisions

4.2

1

Pointer

Reference point for scale

14

4

Hexagonal screw

DIN 933 - M6 x 12

15

4

Retaining washer

S6

16

1

Cylinder head bolt

DIN 84 - M6 x 12

17

1

Washer

DIN 125 – 6.4

18

1

Hexagonal socket bolt

Pre-assembled with coupling wheel

19

1

Hexagon key

For item 18

Assembly procedure (see Figure 4-4) 1. Attach the VDI/VDE 3845 fitting bracket ((9), actuator-specific, supplied by actuator manufacturer, see Figure 3-8) to the rear of the positioner, and fix it in place with the hexagonal screws (14) and retaining washers (15). 2. Stick the pointer (4.2) on the fitting bracket at the middle of the centring hole. 3. Push the coupling wheel (2) as far as it will go on the positioner axis, pull it back about 1 mm, and tighten the hexagonal socket bolt (18) with the supplied hexagonal key. 4. Place the driver pin (3) on the actuator's shaft stub and tighten it with cylinder head bolt (16) and washer (17). 5. Carefully place the positioner with the fitting bracket on the actuator so that the pin of the coupling wheel engages with the driver pin. 6. Align the positioner / fitting bracket centrally on the actuator, and screw tight (screws are not included with the supply, but are part of the actuator's fitting bracket!). 7. When commissioning according to chapter 7 has been completed, take the actuator to its end position and stick the scale (4.1) on to the coupling wheel (2) according to the direction of rotation and the turning range. The scale is self-adhesive!

Reference no.: 827A-BA-03-12_gb

ARCA-Regler GmbH D - 47918 Tönisvorst

Page 17 von 52

4 .2

9

15 14

2 18 9

1)

2) 16 17 3

3)

2

4 .1

2 0% 20

40

60

8 0 10 0 %

3

4)

5)

Figure 4-4 Mounting procedure for VDI/VDE 3845 quarter-turn actuator

Reference no.: 827A-BA-03-12_gb

ARCA-Regler GmbH D - 47918 Tönisvorst

Page 18 von 52

Section A - B

2 3 4 4.1 4.2 9 10 14 15 16 17 18

18 Positioner

Coupling wheel Driver pin Labels Scale Pointer VDI/VDE 3845-fitting bracket shaft Hexagonal screw M6 x 12 Retaining washer S6 Cylinder head boltM6 x 12 Washer Hexagon key

Quarter-turn actuator

Figure 4-5 Mounted positioner for quarter-turn actuator

Positioner fixing plane

Quarter-turn actuator a = 4 (0,16) b = 12 (0,47) Figure 4-6 Fitting bracket (supplied by actuator manufacturer), dimensions

4.4

Note on the Use of Positioners in Wet Environments CAUTION

Never clean the positioner with a high pressure cleaner. Protection class IP66 is inadequate for this. This information provides you with important notes on assembling the positioner in wet environments (frequent heavy rain and/or persistent tropical condensation) in which protection class IP66 is no longer sufficient, in particular when there is a risk that the water might freeze. Avoid the unfavourable mounting positions: − To prevent fluids seeping through during normal operation of the device, e.g. through exhaust air openings. −

Otherwise the digital display becomes poorly legible.

Reference no.: 827A-BA-03-12_gb

ARCA-Regler GmbH D - 47918 Tönisvorst

Page 19 von 52

Figure 4-7 Favourable and unfavourable installation positions

If local conditions force you to operate the positioner in an unfavourable installation position, you can prevent the entry of water through additional measures. Additional measures The steps necessary to prevent the entry of water depends on the installation position chosen. In certain cases you may need: - Threaded t with sealing rings (e. g. FESTO: CK -¼ -PK-6) - Plastic hose, approx. 20 to 30 cm (e. g. FESTO: PUN- 8x1,25 SW) - Cable ties (number and length depend on the local conditions) Procedure 1. Arrange the pipes in such a way that rainwater or condensation that runs along the length of the pipes can drop off before reaching the positioner's connection strip. 2. Check that the seals for the electrical connections are correctly seated. 3. Check that the seal of the housing cover is not damaged or soiled. Clean or replace it if necessary. 4. If possible, mount the positioner in such a way that the sintered bronze silencer on the underneath of the housing is pointing downwards (vertical installation position). If this is not possible, the silencer should be replaced by a plastic hose using a suitable threaded t. Assembling the Threaded t with Plastic Hose 1. Unscrew the sintered bronze silencer from the exhaust air opening on the underside of the housing. 2. Screw the threaded t mentioned above into the outlet opening. 3. Fit the plastic hose mentioned above to the threaded t and check that it is tightly seated. 4. Use a cable tie to fasten the plastic hose to the fittings in such a way that the opening is pointing downwards. 5. Check that the hose is not kinked, and that the exhaust air can flow out easily.

4.5

Positioners exposed to strong acceleration forces or vibrations

High acceleration forces occur on fittings that are heavily mechanically stressed, such as breakaway flaps, heavily shaking or vibrating valves or "steam hammer". These forces can be well outside the range specified in the technical data. In extreme cases this can result in displacement of the slip clutch or the leverage ratio switch. In these cases the positioner is fitted as standard with a locking device for the slip clutch with which displacement as a result of the above-mentioned influences is inhibited. The adjustment function is accessible beneath the black adjusting wheel of the slip clutch and recognisable on the yellow wheel with slots. The null point setting and slip clutch adjustment functions are marked with symbols on an auxiliary plate The clamping piece for the transmission leverage ratio switch is located under the terminals and is also fitted with a yellow adjusting wheel with slots.

Reference no.: 827A-BA-03-12_gb

ARCA-Regler GmbH D - 47918 Tönisvorst

Page 20 von 52

4.5.1

Slip clutch

Procedure After the positioner has been fitted and fully set into operation, the slip clutch can be locked as follows: 1. Place a commercial screwdriver of about 4 mm wide in a slot in the yellow wheel. 2. Turn the yellow wheel anti-clockwise with the screwdriver until it latches detectably. The slip clutch is thereby locked. 3. A locked slip clutch is to be recognised by an approximately 1 mm wide gap between the yellow and black wheel. 4. If a null point setting is necessary, e.g. after a drive change, the locking is released by a clockwise rotation up to the stop of the yellow wheel. After the null point setting the slip clutch can be fixed again as described above.

4.5.2

Leverage ratio switch

Starting from the neutral position (as-delivered condition) the leverage ratio switch can be adjusted as follows: 1. Plug a conventional 4 mm wide screwdriver into a slot in the yellow wheel. 2. Then turn the adjustment wheel in accordance to the chosen gearing position (33° or 90°) clockwise or anticlockwise until it snaps in audibly. 3. An adjusted fixed leverage ratio switch is recognizable from the asymmetric position of the adjustment wheel. 4. If you have to switch over the gearing, the adjustment has to be loosen by turning the adjustment wheel into neutral position first.

Figure 4-8 Locking the slip clutch and leverage ratio switch slip clutch and

leverage ratio switch

Figure 4-9 Arrester device

External Travel Acquisition External travel acquisition is a possibility for those cases in which the measures described above are not sufficient, such as when vibration is heavy and persistent, at particularly high or low ambient temperatures, or in the presence of nuclear radiation. In this case the special positioner (see Type Code) is used at a distance from the fitting. More information contains the appendix to the manual 827.EDP.

Reference no.: 827A-BA-03-12_gb

ARCA-Regler GmbH D - 47918 Tönisvorst

Page 21 von 52

5

Electric connection

Basic safety instructions WARNING Improper power supply Danger of explosion in hazardous areas as result of incorrect power supply, e.g. using alternating current instead of direct current. − Connect the device in accordance with the specified power supply and signal circuits. The relevant specifications can be found in the certificates or on the nameplate. WARNING Unsafe extra-low voltage Danger of explosion in areas subject to explosion hazard due to voltage flashover −

Connect the device to an extra-low voltage with safe isolation WARNING

Connecting device in energized state Danger of explosion in areas subject to explosion hazard. − Connect devices in hazardous areas only in a de-energized state. Exception: Circuits of limited energy may also be connected in the energized state in hazardous areas. WARNING Lack of equipotential bonding Danger of explosion through compensating currents or ignition currents through lack of equipotential bonding. − Ensure that the device is potentially equalized. Exception: It may be permissible to omit connection of the equipotential bonding for devices with type of protection "Intrinsic safety Ex i". WARNING Unprotected cable ends Danger of explosion through unprotected cable ends in hazardous areas. − Protect unused cable ends in accordance with IEC/EN 60079-14 WARNING Improper laying of shielded cables Danger of explosion through compensating currents between hazardous area and the non-hazardous area. − Only ground shielded cables that run into the hazardous area at one end. − If grounding is required at both ends, use an equipotential bonding conductor.

Reference no.: 827A-BA-03-12_gb

ARCA-Regler GmbH D - 47918 Tönisvorst

Page 22 von 52

WARNING Unsuitable cables and/or cable glands Danger of explosion in areas subject to explosion hazard if cables and/or cable glands are connected which do not match one another or comply with the technical requirements. Before taking the device into operation let the device adapt for several hours in the new environment. − Tighten the cable glands in accordance with the torques specified − When replacing cable glands use only cable glands of the same type. − After installations check that the cables are seated firmly. CAUTION Condensation in the device Damage to device through formation of condensation if the temperature difference between transportation or storage and the mounting location exceeds 20 °C − Before taking the device into operation let the device adapt for several hours in the new environment. CAUTION Ambient temperature too high Damage to cable sheath − At an ambient temperature ≥ 60 °C, use heat-resistant cables suitable for an ambient temperature at least 20 °C higher. CAUTION Connection of voltage source to current input Device damage if a voltage source is connected to the current input Iw (terminals 6 and 7). − Never connect the current input Iw to a voltage source, otherwise the positioner may be destroyed. − Always use a voltage source with a maximum output current of I = 20 mA. WARNING Version „Ex i“ As auxiliary power, control, and signal circuits, only certified intrinsically safe circuits may be connected. Owing the reasons pertaining to tightness (IP enclosure rating) and the required tensile strength, only use the cables having a diameter ≥ 8 mm for standard M20x1.5 cable gland, or use a suitable seal insert in case of smaller diameters. In the NPT version, the positioner is delivered with a coupling. When inserting a counter piece in the coupling, ensure that the maximum permissible torque of 10 Nm is not exceeded. Two-wire mode Note To maintain the auxiliary power, the current iy must be ≥ 3.6 mA

Reference no.: 827A-BA-03-12_gb

ARCA-Regler GmbH D - 47918 Tönisvorst

Page 23 von 52

5.1

Electric connection, not intrinsically safe

5.1.1

Basic device +

4 … 20 mA

E

6 7 8 9

J

A

+3 V

Positioner

Binary input 1

10

HART-Communicator

Figure 5-1 2- wire connection, not for explosive regions Type 827A.E2

+

4 … 20 mA

J

Positioner

2 3 4 5

E

6 7 8 9

A

+3 V

10

Binary input 1

HART-Communicator

Figure 5-2 2-wire connection, not for explosive regions Type 827A.E4

Reference no.: 827A-BA-03-12_gb

ARCA-Regler GmbH D - 47918 Tönisvorst

Page 24 von 52

+

18 … 30 V

2

P os itione r

3 U *) 4 … 20 m A

+

4 5 E

6

*)

A

7 8 9 10

J

B in aryinpu t 1

HA RT-Comm unic ator

*)

Figure 5-3

5.1.2

only for 3-wire co nne ct ion

3/4-wire connection not for explosive regions Type 827A.E4

Options

Analog module

+ UH

61

≤ 35 V

E J

62 +

Analog module

Figure 5-4 Analog module not for explosive regions

Binary module Binary module

+13 V

+ 11 12

≤ 30 V +4,5 V

21 22

≥ 1 +

BE2

3V

1K

+ ≤ 35 V

31 32

≤ 35 V

41 42

≤ 35 V

51 52

Fault signal

1K

+

Limit value A1

1K

+

Limit value A2

Figure 5-5 Binary module not for explosive regions

Reference no.: 827A-BA-03-12_gb

ARCA-Regler GmbH D - 47918 Tönisvorst

Page 25 von 52

Slot initiator module

Slot initiator module

+

31

8,2 V

+ 8,2 V

+ 8,2 V

32

41 42

51 52

2K1 10K

Fault signal

Limit value A1

Limit value A2

Figure 5-6 Slot initiator module not for explosive regions

module DANGER Low-voltage supply -Version not intrinsically safe When you supply the module in the non-intrinsically safe version with low voltage, you must be sure to observe the following safety rules before starting work on the device: 1. Isolate the device from power. Use a circuit breaker positioned near the device to do this. 2. Make sure that the device cannot be switched back on inadvertently. 3. Make sure the device is truly isolated from power. WARNING Protection against mechanical influences In order to guarantee the degree of protection IP66, you must protect the module against mechanical influences. This is achieved by selecting a suitable installation location or by installing a suitable protection device. This required protection applies to the operation of the module with the following voltages: - > AC 16 V - > DC 35 V, low voltage NOTICE Maximal values for terminals 41/42 und 51/52 The following maximum values concern only terminals 41, 42, 51, and 52: - Maximum voltage: AC 250 V or DC 24 V - Maximum current: AC/DC 4 A No safe separation between the terminals can be guaranteed.

Reference no.: 827A-BA-03-12_gb

ARCA-Regler GmbH D - 47918 Tönisvorst

Page 26 von 52

NOTICE To observe before connecting − Only qualified personnel is permitted to install and connect the module. − Isolate all wires from power and make sure the device is truly isolated from power. − Construct the cross-sectional area of the connection cables in such a way that it is appropriate for the permitted current load. − Selected the wires on the basis of the following rule: The temperature at which the wires are permitted to be used must be 25°C above the maximum ambient temperature.

C onta ct m od ule

+

1K 21 31

< 35 V

32

f ault s ign al

10K

+ m ax . A C 250 V 41 41

D C 24V

∼

A C /D C 4 A + m ax . A C 250 V D C 2 4V

∼

llim it v alu e A 1

42

51

lim it v al ue A 2

52

AC /D C 4 A

Figure 5-7 module not for explosive

Connecting the module (Figure 5-8) 1. 2. 3. 4. 5. 6.

Loosen the screw (18) on the transparent cover (19). Pull the transparent cover (19) up to the front end stop. Tighten every cable in the corresponding terminal. Slide the transparent cover (19) up to the end stop of the motherboard. Tighten the screw (18) on the transparent cover (19). Connect the cables of each switch to the lug of the printed circuit board in pairs. Use the provided cable tie (20) for this purpose.

18 19 20

Screw Cover Cable tie

Figure 5-8 Connection the cables

Reference no.: 827A-BA-03-12_gb

ARCA-Regler GmbH D - 47918 Tönisvorst

Page 27 von 52

5.2

Connecting device with type of protection intrinsic safety

5.2.1

Basic device

Region of no explosive hazard

+

EEx

Region of explosive hazard, Zone 1 or Zone 2

4 … 20 mA

E

6

A

7 8

J

9 10

Intrinsically safe power source

+3 V

Positioner

Binary input 1

Figure 5-9 2- wire connection, for explosive regions, Type 827A.X2

Region of no explosive hazard

Region of explosive hazard, Zone 1 or Zone 2

+

EEx

4 … 20 mA

2 3 4 5

J Intrinsically safe power source

E

6 7 8 9

Positioner A

+3 V

10

Binary input 1

HART-Communicator

Figure 5-10 2- wire connection, for explosive regions Ex Type 827A.X4

Reference no.: 827A-BA-03-12_gb

ARCA-Regler GmbH D - 47918 Tönisvorst

Page 28 von 52

Region of no explosive hazard

Region of explosive hazard, Zone 1 or Zone 2

+

EEx

18 … 30 V

2 3 4 5

U

4 … 20 mA

+

EEx

J

Intrinsically safe power sources

E

6 *)

*)

Positioner

A

7 8 9 10

+3 V

Binary input 1

HART-Communicator

*) only for 3-wire connection

Figure 5-11

3/4- wire connection, for explosive regions Ex Type 827A.X4

Intrinsically safe feed sources

Split-Range

L+

E Ex

+ 1 8 … 30 V

3

M

U

Device 1

2

4 5 Iy

E Ex

+ 0 /4 … 20 m A

E

6 I

7 M

Positio nin g rang e 1 A

8 9

+ 3V

10

#

BE 1

Device 2

2 3 4 5 E

6

P osit ion ing range 2 A

7 8 9 10

Region of n o hazard

+ 3V

#

BE 1

Region of e xplosive h azard, Zo ne 1 or Zone 2

Figure 5-12 Series connection of two positioners, e.g. split range (auxiliary power supplied separately

Reference no.: 827A-BA-03-12_gb

ARCA-Regler GmbH D - 47918 Tönisvorst

Page 29 von 52

5.2.2

Options

Analog module Region of e xplosive hazard, Zo ne 1 or Zone 2

Region of n o explosive h aza rd

EEx

+ UH

+ ≤ 30 V

U

61

E

62

J

J Ana log mo dule

+

Intrinsically safe p ower sources

Figure 5-13 Analog module for explosive regions

Binary module B inary m odule

+ ≤ 25,2 V EE x

ntrinsically safe switching am plifier m eeting DIN E N 60947-5-6 (old D IN 19234)

11 12

≥ 1 +

21 22

BE 2

3V

2K1

+ 8,2 V EE x

31 32

10K

Fault signal

2K1

+ 8,2 V EE x

41 42

+

10K

Lim it value A 1

2K1 8,2 V

EE x

R egion of no explosive hazard

51 52

10K

Lim it value A 2

R egion of explosive hazard, Zone 1 or Zone 2

Figure 5-14 Binary module for explosive regions

Reference no.: 827A-BA-03-12_gb

ARCA-Regler GmbH D - 47918 Tönisvorst

Page 30 von 52

Slot initiator module

Slot initiator module

Intrinsically safe switching amplifier meeting DIN EN 60947-5-6 (old DIN 19234)

2K1

+ 31

8,2 V

32

EEx

10K

Fault signal

2K1

+ 41

8,2 V

42

EEx

10K

Limit value A1

2K1

+ 51

8,2 V

52

EEx

Region of no explosive hazard

10K

Limit value A2

Region of explosive hazard, Zone 1 or Zone 2

Figure 5-15 Slot initiator module for explosive regions

module NOTICE Maximal values for terminals 41/42 und 51/52 The following maximum values concern only terminals 41, 42, 51, and 52: - Maximum voltage: DC 30 V - Maximum current: DC 100 mA - Maximum performance:750 mW No safe separation between the terminals can be guaranteed. NOTICE To observe before connecting − Only qualified personnel is permitted to install and connect the module. − Isolate all wires from power and make sure the device is truly isolated from power. − Construct the cross-sectional area of the connection cables in such a way that it is appropriate for the permitted current load. − Selected the wires on the basis of the following rule: The temperature at which the wires are permitted to be used must be 25°C above the maximum ambient temperature. − Operate the Ex-version only in intrinsically safe circuits with approved switching amplifiers. NOTICE Preparing the cables or stranded wires - Version intrinsically safe 1. Insulate the cables in such a way that the insulation is flush with the terminal when plugging in the wires. 2. Fit ferrules to the ends of stranded wires. module connecting see Figure 5-8

Reference no.: 827A-BA-03-12_gb

ARCA-Regler GmbH D - 47918 Tönisvorst

Page 31 von 52

C onta ct -m odu le Int rinsically safe switching am plifier me etin g DIN EN 6 0947 -5 -6 (old DIN 1923 4)

1K 21

+ 31

DC 8,2V

32

E Ex

10K

Fa ult signa l

+ U max DC 30V Imax 1 00 m A + U max DC 30V

41 41

lim it value A 1

42

51

lim it value A 2

52

Imax 100 m A

Region of n o explosive h aza rd

R egion o f explosive ha za rd , Zon e 1 o r Zo ne 2

Figure 5-16 module for explosive regions

6

Pneumatic Connections WARNING

For reasons of safety, the auxiliary pneumatic energy should only be connected after assembly when, in the presence of an electrical signal, the positioner is switched to the P-manual operating level (delivery status, see leaflet “Concise operating notes”). NOTICE Ensure correct air-quality! Oil-free, instrument quality air with no water or dust, solid material content max. 1 mg/m3 (standard atmospheric conditions), max. particle size 1 µm, oil content max. 0.1 mg/m3 (standard atmospheric conditions), pressurised dew point 20 K below the lowest ambient temperature. When working on the compressed air system ensure that any contamination present such as water, oil, swarf, soldering material residues etc. are expelled by blowing out Procedure - If appropriate, connect manometer block for air supply and actuating pressure. - Connection via internal thread G 1/4 DIN 45141 PZ Air supply 1,4 to 7 bar Y1 Actuating pressure 1 for single-acting and double-acting actuators Y2 Actuating pressure 2 for double-acting actuators E Exhaust air output (remove silencer if necessary) - Safety position at failure of auxiliary electrical power: Single-acting: Y1 vented Double-acting: Y1 max. actuating pressure (supply pressure) Y2 vented - Connect actuating pressure Y1 or Y2 (only on double-acting actuators) according to the desired safety position. - Connect air supply to PZ.

Reference no.: 827A-BA-03-12_gb

ARCA-Regler GmbH D - 47918 Tönisvorst

Page 32 von 52

Note So that spring-loaded pneumatic actuators can reliably exploit the maximum possible travel, it is necessary that the supply pressure exceeds the maximum required final pressure of the actuator by a sufficient margin. After installing the pneumatic connections, check the tightness of the entire control valve. Besides continuous air consumption, the positioner may try to compensate the position deviation due to leakage. This will lead to premature wear in the entire control unit.

7

Commissioning (see leaflet "Concise operating notes")

Basic safety instructions WARNING Improper commissioning in hazardous areas Device failure or danger of explosion in hazardous areas − Do not commission the device until it has been mounted completely and connected. − Before commissioning take the effect on other devices in the system into . WARNING Loss of explosion protection Danger of explosion in hazardous areas if the device is open or not properly closed. . WARNING Opening device in energized state Danger of explosion in areas subject to explosion hazard. − Only open the device in a de-energized state. − Check prior to commissioning that the cover, cover locks, and cable inlets are assembled in accordance with the directives. Exception: Devices having the type of protection "Intrinsic safety Ex i" may also be opened in energized state in hazardous areas. WARNING Water in compressed air line Device damage and possibly loss of type of protection. The factory setting for the purging air selector is "IN". In the "IN" position, water from the compressed air line may enter the device from the pneumatics during initial commissioning. − Before commissioning, make sure that no water is present in the compressed air line. If you cannot be sure that there is no water in the compressed air line: − Set the purging air selector to "OUT". In this way, you prevent water from the compressed air line from penetrating the device. − Only set the purging air selector to "IN" again when all water has been discharged from the compressed air line. NOTICE Loss of degree of protection Damage to device if the enclosure is open or not properly closed. The degree of protection specified on the nameplate is no longer guaranteed. − Make sure that the device is securely closed.

Reference no.: 827A-BA-03-12_gb

ARCA-Regler GmbH D - 47918 Tönisvorst

Page 33 von 52

WARNING Commissioning and operation with pending error If an error message appears, correct operation in the process is no longer guaranteed. − Check the gravity of the error − Correct the error − If the device is faulty: - Take the device out of operation. - Prevent renewed commissioning. NOTICE − During the initialization process, the operating pressure must be at least one bar more than that required to close or open the valve. However, the operating pressure should not be greater than the maximum permissible operating pressure for the actuator. − The leverage ratio switch can be set only when the positioner is open. Therefore, check this setting before closing the enclosure.

Safety notes for operation with natural gas For operation with natural gases actuator medium an electric connection acc to explosion protection „ia“ category 2G is needed. More information and safety notes see for manual 827A-GHB-natural gas General Information After installing the positioner on a pneumatic actuator, you must supply electric and pneumatic auxiliary power to it. The positioner is in the "P manual mode" before initialization. At the same time, "NOINI" blinks in the lower line of the digital display. Adjust the positioner as per the respective actuator with the help of the initialization process and by setting the parameters. If required, use the "PRST" parameter to cancel the adjustment of the positioner on the actuator. The positioner is again in the "P manual mode" after this process. Types of initialization -

Automatic initialization The initialization takes place automatically. In this case, the positioner determines, one after another, the effective working direction, the travel distance or rotation angle and the actuator's adjustment times and adjusts the control parameters to match the dynamic behaviour of the actuator.

-

Manual initialization The travel distance or rotation angle of the actuator can be set manually. The other parameters are automatically determined, just as in the case of automatic initialization. This function is useful on actuators with soft end stops

-

Copying Initialization Data (Positioner Exchange) In devices with HART functionality, the initialization data of one positioner can be read and copied into another positioner. This allows a faulty device to be exchanged, without having to interrupt a running process in order to carry out initialization. You have to define a few parameters for the positioner before initialization. Owing to the preset values, you cannot adjust further parameters for initialization. You can use a suitably configured and activated binary input to protect the configured settings against accidental adjustment.

Reference no.: 827A-BA-03-12_gb

ARCA-Regler GmbH D - 47918 Tönisvorst

Page 34 von 52

7.1

Preparations for Linear Actuators

1. Assemble the positioner with the appropriate mounting kit The position of the leverage ratio switch in the positioner is particularly important here. Stroke lever Position leverage ratio switch 5 to 20 mm short 33° (i.e. down) 25 to 35 mm short 90° (i.e. up) 40 to 130 mm long 90° (i.e. up n) 2. Connect a suitable source of current or voltage 3. Connect the actuator and the positioner to the pneumatic lines, and activate the positioner's auxiliary pneumatic power. 4. The positioner is now in the “P–manual" operating mode. The top line of the display now shows the current potentiometer voltage (P) in percent, e.g.: “P37.5“, while "NOINI" flashes on the bottom line:

5. Check that the mechanics can move freely over the entire active range by moving the actuator with the and buttons as far as the end positions. The value P5.0 may not be fallen below and P95.0 may not be exceeded. The difference of the two values must be greater than 25.0 You can move the actuator rapidly by pressing the button for the opposite direction as well while continuing to hold down the first direction button. 6. Now move the actuator so that the lever is horizontal. The display should show a value between P48.0 and P52.0. If this is not the case, make appropriate adjustments to the slip clutch. The closer you can get to the "P50.0" value, the more accurately the positioner can determine the travel.

7.1.1

Automatic Initialization of Linear Actuators

When you can move the actuator correctly, leave it in a central position and start the automatic initialization: 1. Hold the button pressed for longer than 5 s. This will bring you to the configuration mode Display:

2. Switch to the second parameter by pressing the Display: or

button briefly.

It is essential that this value matches the setting of the leverage ratio switch (33° or 90°)) button to move on to the following display: 3. Use the

You only have to set this parameter if you want to have the total stroke determined displayed in mm at the end of the initialization phase. To do this, you select the value in the display at which you have set the driver pin on the scale at the lever.

Reference no.: 827A-BA-03-12_gb

ARCA-Regler GmbH D - 47918 Tönisvorst

Page 35 von 52

4. Use the

button to move on to the following display:

5. Start the initialization by pressing the Display:

button for longer than 5 s.

"RUN1" to "RUN5" appear in sequence in the lower display during the initialization process. Depending on the actuator, the initialization process can take up to 15 min and it is completed when the following display appears:

The first line also contains the stroke that has been determined, in mm, if the lever length has been given with the 3.YWAY parameter. button: The following display appears after briefly pressing the

button for longer than 5 s. The software status will be disTo leave the Configuration mode, press the button is released, the device will be in manual operation mode. played after about 5 s. When the button. Your previous setYou can interrupt an initialization that is in progress at any time by pressing the tings will be retained. The parameters will only be returned to the factory settings if you have carried out a "Preset". After successful initialization slipping clutch and leverage ratio switch can be adjusted if necessary (see chapter 4.1.2).

7.1.2

Manual Initialization of Linear Actuators

With this function the positioner can be initialized without having to move the actuator hard against the end stops. The start and end positions of the travel are set manually. When you can move the actuator correctly, leave it in a central position and start the manual initialization. The other initialization steps (optimisation and control parameters) are carried out in the same way as under automatic initialization. 1. Hold the button pressed for longer than 5 s. This will bring you to the configuration mode Display:

2. Switch to the second parameter by pressing the Display: or

button briefly.

It is essential that this value matches the setting of the leverage ratio switch (33° or 90°)) button to move on to the following display: 3. Use the

You only have to set this parameter if you want to have the total stroke determined displayed in mm at the end of the initialization phase. To do this, you select the value in the display at which you have set the driver pin on the scale at the lever.

Reference no.: 827A-BA-03-12_gb

ARCA-Regler GmbH D - 47918 Tönisvorst

Page 36 von 52

4. Press the

button twice to move on to the following display:

5. Start the initialization by pressing the Display:

button for longer than 5 s.

6. After 5 s the display changes to:

(The potentiometer settings shown here and below are only illustrative examples.) and buttons to move the actuator to the position that you wish to define as the first of the Now use the button. This will the current position as end position 1, and will two end positions. Then press the move on to the next step. If the message "RANGE" appears on the lower line, the selected end position is outside the permitted measurement range. There are a number of ways to correct this error: - adjust the slip clutch until "OK" appears, then press the button again, or and buttons to move to a different end position, or - use the button. You must then change to P-manual operation and - interrupt the initialization by pressing the correct the travel and the displacement accession in accordance with chapter 7.1 7. When Step 6 has been successfully completed, the following display appears:

and buttons to move the actuator to the position that you wish to define as the second Now use the button. This will cause the current position to be ed as end position end position. Then press the 2. If the message "RANGE" appears on the lower line, the selected end position is outside the permitted measurement range. There are a number of ways to correct this error: - adjust the slip clutch until "OK" appears, then press the operating mode switch again, or - use the and buttons to move to a different end position, or - interrupt the initialization by pressing the button. You must then change to P-manual operation and correct the travel and the displacement accession in accordance with chapter 7.1 If the message "Set Middl" appears, the lever arm must be moved to a horizontal position with the aid of the and buttons, and the button then pressed. This will set the reference point for the sine correction on linear actuators. 8. The rest of the initialization will now proceed automatically. "RUN1" to "RUN5" will appear in sequence on the lower line of the display. The following display appears when the initialization has been completed successfully:

The first line also contains the stroke that has been determined, in mm, if the lever length has been given with the 3.YWAY parameter. button the lower line will again show 5.INITM. You are then once more in the After briefly pressing the Configuration operating mode To leave the Configuration mode, press the button for longer than 5 s. The software status will be displayed after about 5 s. When the button is released, the device will be in manual operation mode. After successful initialization slipping clutch and leverage ratio switch can be adjusted if necessary (see chapter 4.1.2).

Reference no.: 827A-BA-03-12_gb

ARCA-Regler GmbH D - 47918 Tönisvorst

Page 37 von 52

7.2

Preparations for Quarter-turn Actuators

In the positioner, place the leverage ratio switch in the 90° position (the usual adjustment angle for quarter-turn actuators). 1. Assemble the positioner with the appropriate mounting kit. 2. Connect a suitable source of current or voltage. 3. Connect the actuator and the positioner to the pneumatic lines, and activate the positioner's auxiliary pneumatic power 4. The positioner is now in the “P-manual“ .The top line of the display now shows the current potentiometer voltage (P) in percent, e. g.: “P37.5 “while “NOINI“ flashes on the bottom line

5. Check that the mechanics can move freely over the entire active range by moving the actuator with the and buttons as far as the end positions. The value P5.0 may not be fallen below and P95.0 may not be exceeded. The difference of the two values must be greater than 25.0. You can move the actuator rapidly by pressing the button for the opposite direction as well while continuing to hold down the first direction button.

7.2.1

Automatic Initialization of Quarter-turn Actuators

When you can move the actuator correctly through its range, leave it in a central position and start the automatic initialization: 1. Hold the button pressed for longer than 5 s. This will bring you to the configuration mode. Display:

2. Hold the Display:

button pressed for longer than 5 s. This will bring you to the configuration mode.

3. Switch to the second parameter by pressing the Display:

button briefly. This has automatically been set to 90°.

It is essential that this value matches the setting of the leverage ratio switch (33° or 90°) 4. Use the button to move on to the following display:

5. Start the initialization by pressing the Display:

button for longer than 5 s.

"RUN1" to "RUN5" appear in sequence in the lower display during the initialization process. Depending on the actuator, the initialization process can take up to 15 min and it is completed when the following display appears:

The upper value gives the actuator's full turning angle (e.g. 93.5°). The following display appears after button: briefly pressing the

Reference no.: 827A-BA-03-12_gb

ARCA-Regler GmbH D - 47918 Tönisvorst

Page 38 von 52

To leave the Configuration mode, press the button for longer than 5 s. The software status will be disbutton is released, the device will be in manual operation mode. played after about 5 s. When the You can interrupt an initialization that is in progress at any time by pressing the button. Your previous settings will be retained. The parameters will only be returned to the factory settings if you have carried out a "Preset". After successful initialization slipping clutch and leverage ratio switch can be adjusted if necessary (see chapter 4.1.2).

7.2.2

Manual Initialization of Quarter-turn Actuators

With this function the positioner can be initialized without having to move the actuator hard against the end stops. The start and end positions of the travel are set manually When you can move the actuator correctly, leave it in a central position and start the manual initialization. The other initialization steps (optimisation and control parameters) are carried out in the same way as under automatic initialization. 1. Hold the button pressed for longer than 5 s. This will bring you to the configuration mode. Display:

2. Use the Display:

button to set the YFCT parameter to "turn"

3. Switch to the second parameter by pressing the Display:

button briefly.

Ensure that the leverage ratio switch is in the 90° position. button twice to move on to the following display: 4. Press the

The following steps are identical to steps 5) to 8) in the initialization of linear actuators. Following successful initialization, the pivoting range that has been determined is shown on the upper display in degrees After briefly pressing the button the lower line will again show 5.INITM. You are then once more in the Configuration operating mode. button for longer than 5 s. The software status will be displayed To leave the Configuration mode, press the button is released, the device will be in manual operation mode. after about 5 s. When the After successful initialization slipping clutch and leverage ratio switch can be adjusted if necessary (see chapter 4.1.2).

7.3

Copying Initialization Data (Positioner Exchange)

− Electropneumatic positioners can be replaced in a running system without interrupting the process. − By copying and transferring the device and initialization data, it is possible to commission a replacement positioner without needing to initialize it. − An electropneumatic positioner uses the communication interface to transfer data. The following steps are required to exchange a positioner: 1. The device parameters and initialization data (determined at initialization time) of the device needing replacement are read in and saved using SIMATIC PDM or HART Communicator. This step is not required if the device has been parameterised with SIMATIC PDM and the data already stored.

Reference no.: 827A-BA-03-12_gb

ARCA-Regler GmbH D - 47918 Tönisvorst

Page 39 von 52

2. Fix the actuator in its current position (mechanically or pneumatically). 3. Read and note the current position value from the display of the positioner that is being replaced. If the electronics are faulty, find the current position by measurement at the actuator or valve 4. Dismount the positioner. Fit the lever arm of the positioner to the replacement device. Mount the replacement device to the fittings. Put the leverage ratio switch in the same position as on the faulty device. the device data and initialization data from the SIMATIC PDM or the handheld device 5. If the actual value displayed does not accord with the value noted from the faulty positioner, set the correct value with the slip clutch. 6. The positioner is now ready for operation. The accuracy and the dynamic behaviour may not be as good as they would be following a proper initialization. In particular the position of the hard end stops and the associated servicing data may be inaccurate. An initialization must therefore be carried out at the next opportunity. NOTICE Deferred initialization Initialize the replacement positioner as soon as possible. The following properties can be ensured only after initializing: − Optimum adjustment of the positioner as per the mechanical and dynamic properties of the actuator. − Unrestricted accuracy and dynamic behaviour of the positioner − Deviation-free position of the hard end stops − Correctness of the maintenance data

8

Overview of Parameters

8.1

Parameters 1 to 5

Parameters 1 to 5 are the same for all versions of positioner. These parameters are used to adjust the positioner to the actuator. Normally the parameter setup is sufficient to be able to operate the positioner on an actuator. If you want to get to know the positioner in detail, gradually try out the effects of the remaining parameters by systematic testing. Parameter

Function

Parameter values (bold = factory setting)

Unit

1.YFCT

Type of position actuator

2.YAGL

turn (quarter-turn actuator) WAY (linear actuator) LWAY (linear actuator without sine correction) ncSt (quarter-turn actuator with NCS) -ncSt (quarter-turn actuator with NCS, inverse direction of action ncSL (linear actuator with NCS) ncSLL (linear actuator with NCS and lever) Nominal angle of rotation of the message ( - Parameter does not appear if 1.YFCT = “turn”, “LWAY” or “ncS_” has been selected. - Set the leverage ratio switch accordingly)

°

33° 90° 3.YWAY

Range of stroke (optional setting) - The parameter only appears for "WAY" and for "ncSLL". - When used the value must correspond with the set range of stroke on the actuator. Carriers must be scaled to the actuator's stroke value, or if this is not scaled they then must be set to the next largest scaled value.

4.INITA 5.INITM

Initialization (automatic) Initialization (manual)

Reference no.: 827A-BA-03-12_gb

OFF 5 | 10 | 15 | 20 (short lever 33°) 25 | 30 | 35 (short lever 90°) 40 | 50 | 60 | 70 | 90 | 110 | 130 (long lever 90°) NOINI | no / ###.# | Strt NOINI | no / ###.# | Strt

ARCA-Regler GmbH D - 47918 Tönisvorst

mm

Page 40 von 52

8.2

Parameters 6 to 51

These parameters are used to configure the following additional functions of the positioner: − Target value preparation − Actual value preparation − Binary signal processing − Tight closing function − Boundary value detection 6.SCUR 7.SDIR

8.SPRA 9.SPRE 10.TSUP 11.TSDO 12.SFCT

Current range of setpoint 0 ... 20 mA 4 ... 20 mA Setpoint setup Rising Falling Setpoint split range start Setpoint split range end Setpoint ramp OPEN Setpoint ramp CLOSED Setpoint function Linear Equal percentage

0 MA 4 MA riSE FALL 0.0 ... 100.0 0.0 ... 100.0 Auto / 0 ... 400 0 ... 400

Inverse equal percentage

13.SL0 ... 33.SL20 13.SL0 14.SL1 .... 32.SL19 33.SL20 34.DEBA 35.YA 36.YE 37.YNRM

38.YDIR

39.YCLS

40.YCDO 41.YCUP 42.BIN1

Lin 1 - 25 1 - 33 1 - 50 n1 - 25 n1 - 33 n1 - 50 FrEE

1 : 25 1 : 33 1 : 50 25 : 1 33 : 1 50 : 1

Freely adjustable Setpoint turning point (Interpolation points appear only upon selection of 12.SFCT = "FrEE") at 0% 5 % ... 0.0 ... 100.0 95 % 100 % Dead zone of closed-loop controller Auto / 0.1 ... 10.0 Start of the manipulated variable limit 0.0 ... 100.0 End of the manipulated variable limit 0.0 ... 100.0 Manipulated variable scaling Mechanical MPOS On flow FLOW Manipulated variable direction of action for display and position Rising riSE Falling FALL Manipulated variable tight closing None no Top only uP Bottom only do Top and bottom uP do Lower value for tight closing 0.0 ... 0.5 ... 100 Upper value for tight closing 0.0 ... 99.5 ... 100 Function of BE1 Normally open Normally closed (Action on switch closed or High-Level)

43.BIN2

% % s s

None Message only Block configuration Block configuration and manual Move valve to position YE Move valve to position YA Block movement Partial-Stroke-Test Function of BE2 None Message only Move valve to position YE Move valve to position YA Block movement Partial-Stroke-Test

Reference no.: 827A-BA-03-12_gb

% % % %

% %

(Action on switch open or LowLevel)

OFF on bloc1 bloc2 uP doWn StoP PST Normally open

-on

-uP -doWn -StoP -PST Normally closed

(Action on switch closed or High-Level)

(Action on switch open or LowLevel)

OFF on uP doWn StoP PST

ARCA-Regler GmbH D - 47918 Tönisvorst

-on -uP -doWn -StoP -PST

Page 41 von 52

Parameter

Function

Parameter values (bold = factory setting) Normal Inverted

44.AFCT

Alarm function

45.A1 46.A2 47. FCT

without A1 = Min, A2 = Max A1 = Min, A2 = Min A1 = Max, A2 = Max Trigger threshold, alarm 1 Trigger threshold, alarm 2 Function for fault message output

Normal

Inverted

(„+“ means: Logical OR combination)

(High level without fault)

(Low level without fault)

(High level without fault)

49. LIM 50.PRST

51.XDIAG

(Low level without fault)

OFF

0.0 ... 10.0 ... 100 0.0 ... 90.0 ... 100

Fault Fault + not automatic Fault + not automatic + BE Monitoring time for setting of fault message "regulation deviation" Response threshold for fault message "regulation deviation" Preset (factory setting) results in "NOINI"! no Nothing activated Strt Start of factory setting oCAY Display after pushing button for 5 s Activation of extended diagnostics

48. TIM

Unit

% %

Auto / 0 ... 100

s

Auto / 0 ... 100

%

no Strt oCAY

Parameters A up to P appears only if parameter 51.XDIAG is activated with On1, On2 or On3. The contents of the parameters A up to P appears also only if the selected parameter is activated with On.

Off Single-level message Two-level message Three-level message

8.3

OFF On1 On2 On3

Parameters A to P

These parameters are used to set the extended diagnostic functions of the positioner. Note Parameters A to P and their sub-parameters are only displayed when the extended diagnostics has been activated using parameter "XDIAG" with parameter value "On1", "On2" or "On3". A. PST A1.STPOS A2.STTOL A3.STEP A4.STEPD A5.INTRV A6.PSTIN A7.FACT1 A8.FACT2 A9.FACT3 b. DEVI b1.TIM b2.LIMIT b3.FACT1 b4.FACT2 b5.FACT3 C. LEAK C1.LIMIT C2.FACT1 C3.FACT2 C4.FACT3

Partial-Stroke-Test with the following parameters: Starting position Starting tolerance Step height Step direction Test interval Partial-Stroke-Test reference step time Factor 1 Factor 2 Factor 3 General control valve fault with the following parameters: Time constant Limit Factor 1 Factor 2 Factor 3 Pneumatic leakage with the following parameters: Limit Factor 1 Factor 2 Factor 3

Reference no.: 827A-BA-03-12_gb

0.0 ... 100.0 0.1 ... 2.0 ... 10.0 0.1 ... 10.0 ... 100.0 uP / do / uP do OFF / 1 ... 365 NOINI / (C)##.# / Fdini / rEAL 0.1 ... 1.5 ... 100.0 0.1 ... 3.0 ... 100.0 0.1 ... 5.0 ... 100.0

% % %

Auto / 1 ... 400 0.1 ... 1.0 ... 100.0 0.1 ... 5.0 ... 100.0 0.1 ... 10.0 ... 100.0 0.1 ... 15.0 ... 100.0

s %